Empisal EES10 User manual

Instruction Manual

Empisal Electronic Sewing EES10

Important

safety

instructions

I

When using an electrical appliance, basic safety should always be followed, including the

following: Read all instructions before using this sewing machine.

DANGER -To

r

educe

therisk of electricshock:

1. An appliance should never be left unattended when plugged in.

2. Always unplug this appliance from the electric outlet immediately after using and

before cleaning.

WARNING -To

r

educe

the risk of burns,

fire,

electric

shock,

or injury to

persons:

1. Read the instruction manual carefully before you use the machine.

2. Keep the instructions in a suitable place close to the machine and hand the

instruction manual over if you give the machine in to a third party.

3. Use the machine only in dry locations.

4. Never leave the machine unsupervised with children or elderly people to avoid any

damage or injury.

5. This appliance can be used by children aged from 8 years and above and persons with

reduced physical, sensory or mental capabilities or lack of experience and knowledge

if they have been given supervision or instruction concerning use of the appliance in a

safe way and understand the hazards involved.

6. Children shall not play with the appliance.

7. Cleaning and user maintenance should not be done by children without supervision.

8. Always switch off the machine if you carry out preparation for work (change the

needle, feed the yarn through the machine, change the footer, etc.).

9. Always unplug the machine if you carry out maintenance (oiling, cleaning).

10. Always unplug the machine if you leave it unattended, to avoid injury by

inadvertently switching on the machine.

11. Don't use the machine if it is in a wet or humid environment.

12.Never pull at the cord, always unplug the machine by gripping the plug.

13. If the LED lamp is damaged or broken, it must be replaced by the manufacturer or its

service agent, in order to avoid a hazard.

14.Never place anything on the foot controller.

15. Never use the machine if the air vents are blocked keep the air vents of the machine

and the foot controller free from dust, fusel and leftovers.

16.The machine must only be used with foot controller type C-8000.

17.The sound pressure level at normal operation is smaller than 75dB (A).

18. Do not dispose of electrical appliances as unsorted municipal waste, use separate

collection facilities.

Important

safety

instructions

II

19. Contact your local government authority for information regarding the collection

systems available.

20. If electrical appliances are disposed of in landfills or dumps, hazardous substances

can leak into the groundwater and get into the food chain, damaging your health and

well-being.

21. When replacing old appliances with new ones, the retailer is legally obligated to take

back your old appliance for disposal at least for free of charge.

22.Children being supervised are not to play with the appliance.

SAVE

THESE INSTRUCTIONS

This sewing machine is intended for household use only.

Contents

PRINCIPAL

PARTS OF THE MACHINE ..........................................................................................................1

ACCESSORIES

......................................................................................................................................................2

CONNECTING

THE MACHINE TO THE POWER SOURCE ......................................................................3

Connecting the machine .....................................................................................................................................3

STARTING SEWING ............................................................................................................................................4

Foot control.........................................................................................................................................................4

CHANGING THE NEEDLE STOP

POSITION

.................................................................................................4

CHANGING THE PRESSER FOOT ...................................................................................................................5

TYPE OF PRESSER FOOT CHART ..................................................................................................................5

REPLACING

THE NEEDLE ...............................................................................................................................6

MATCHING

NEEDLE/ FABRIC/

THREAD

......................................................................................................6

WINDING THE BOBBIN .....................................................................................................................................7

Bobbin winding ..................................................................................................................................................7

INSERTING

THE BOBBIN..................................................................................................................................8

THREADING THE UPPER

THREAD

................................................................................................................9

USING THE NEEDLE

THREADER

.................................................................................................................10

THREAD

TENSION

.............................................................................................................................................11

RAISING UP THE LOWER THREAD .............................................................................................................12

CUTTING THE THREAD ..................................................................................................................................12

TWO-STEP PRESSER FOOT

LIFTER

............................................................................................................13

TO RAISE OR DROP THE FEED DOGS ........................................................................................................13

BUTTONS OF

MACHINE

.............................................................................................................................14-15

Reverse/Auto-stop button (1) ...........................................................................................................................14

Mode selection button (2).................................................................................................................................14

Stitch length adjustment button (3)..................................................................................................................15

Stitch width adjustment button (4)...................................................................................................................15

PATTERN

CHAR

T

...............................................................................................................................................16

USEFUL SKILLS .................................................................................................................................................17

Sewing corners..................................................................................................................................................17

Reverse..............................................................................................................................................................17

Installing the Removable Accessory Storage...................................................................................................17

Free arm............................................................................................................................................................17

Sewing on the heavy fabric..............................................................................................................................18

STRAIGHT

STITCHES

AND NEEDLE

POSITION

......................................................................................19

ZIGZAG

STITCHES

...........................................................................................................................................19

STRETCH

STITCH .............................................................................................................................................20

OVERCASTING

STITCHES

..............................................................................................................................21

BLIND HEM/

LINGERIE

STITCH ..................................................................................................................22

BUTTON SEWING ..............................................................................................................................................23

BUTTONHOLE

STITCHING

.......................................................................................................................24-26

ZIPPER

INSERTION

.....................................................................................................................................27-28

Inserting a centered zipper ...............................................................................................................................27

Inserting a side zipper.......................................................................................................................................28

SATIN STITCH

SEWING

...................................................................................................................................29

SCALLOP

STITCH

..............................................................................................................................................29

SMOCKING

..........................................................................................................................................................30

FAGOTING

...........................................................................................................................................................31

PATCHWORK STITCHING

..............................................................................................................................31

TWIN NEEDLE ....................................................................................................................................................32

WARNING FUNCTIONS ....................................................................................................................................33

Warning beeping sound ....................................................................................................................................33

Return bobbin winder spindle to left ...............................................................................................................33

The sewing machine is in trouble ....................................................................................................................33

MAINTENANCE ..................................................................................................................................................34

Cleaning the sewing machine surface..............................................................................................................34

Cleaning the hook.............................................................................................................................................34

TROUBLE

SHOOTING

GUIDE ..................................................................................................................35-36

III

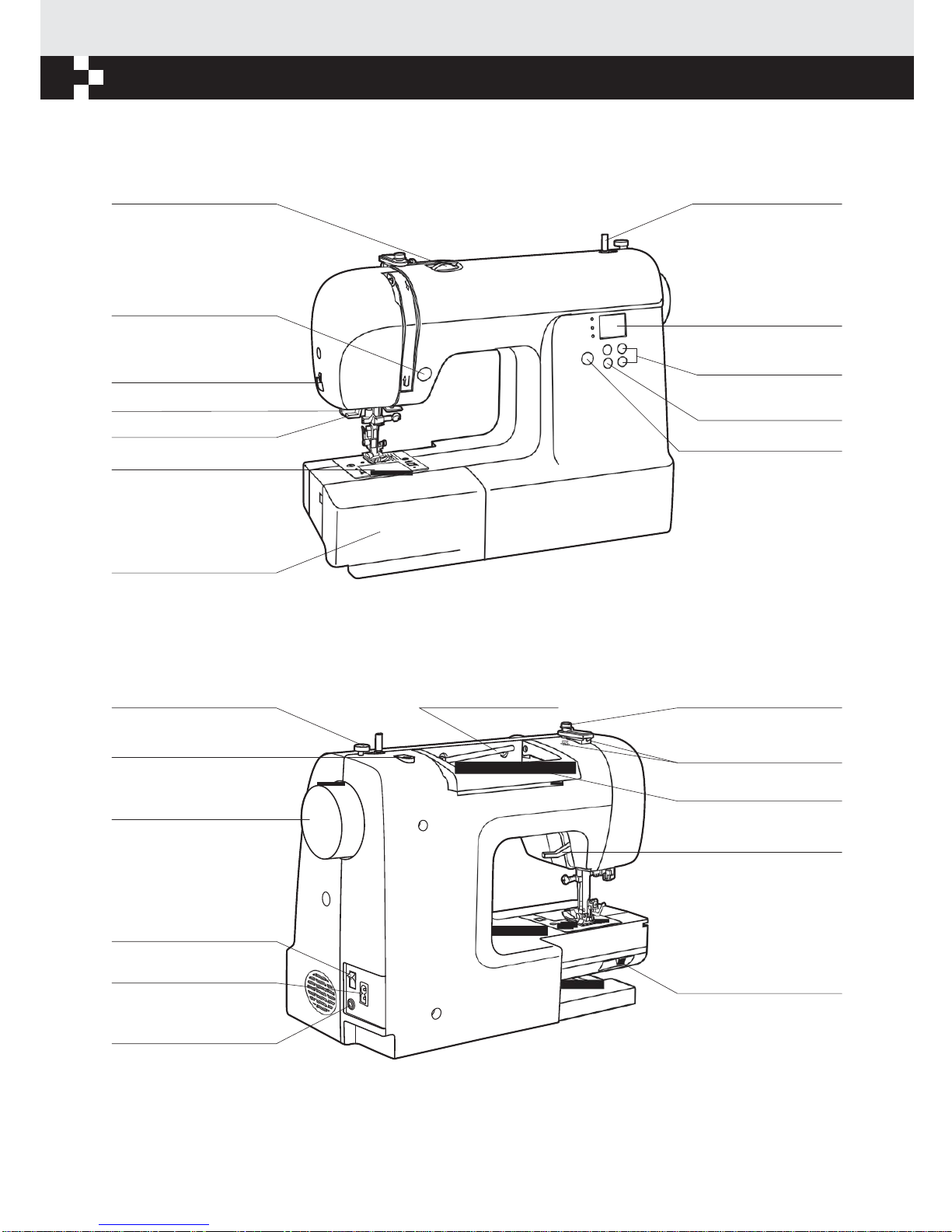

1

Principal

parts of the

machine

Tension dial

Bobbin winder

spindle

Reverse/ Auto-stop button

Thread cutter

Buttonhole lever

Auto needle threader

Bobbin cover plate

Sewing table and

accessory box

Digital display

screen

Stitch width

adjustment buttons

Stitch length

adjustment buttons

Mode

selection

button

Bobbin winder stopper

Hole for second spool pin

Horizontal spool pin Bobbin thread guide

Upper thread guide

Hand wheel

Main power switch

Power cord

Handle

Presser foot lifter

Drop feed lever

Foot controller connector

Table of contents

Other Empisal Sewing Machine manuals

Empisal

Empisal Dress Maker 120A User manual

Empisal

Empisal em-250 User manual

Empisal

Empisal EEM350 User manual

Empisal

Empisal Designer 800 User manual

Empisal

Empisal EEMC220 User manual

Empisal

Empisal Expression 889 User manual

Empisal

Empisal EES50 User manual

Empisal

Empisal Dress Maker 270D User manual

Empisal

Empisal ESM2900 User manual

Empisal

Empisal creations User manual