HOW TO CONNECT THE MACHINE TO THE POWER SUPPLY

1. Fit the machine plug into the machine"

2. Plug the machine to the power supply.

Note:*Belcre plugging in the machine, ensure that the voltage and

number of cycles indicated, is conformed to your electrical

power supply.

HOW TO USE THE FOOTCONTROL

Sewing speed can be varied by the foot control. The harder you

press on the controller. the faster the mach ine runs.

Note:*By releasing the controller, the machine stops running auto-

matically.

*Before using the machine, practice controlling the speed

with-out threading.

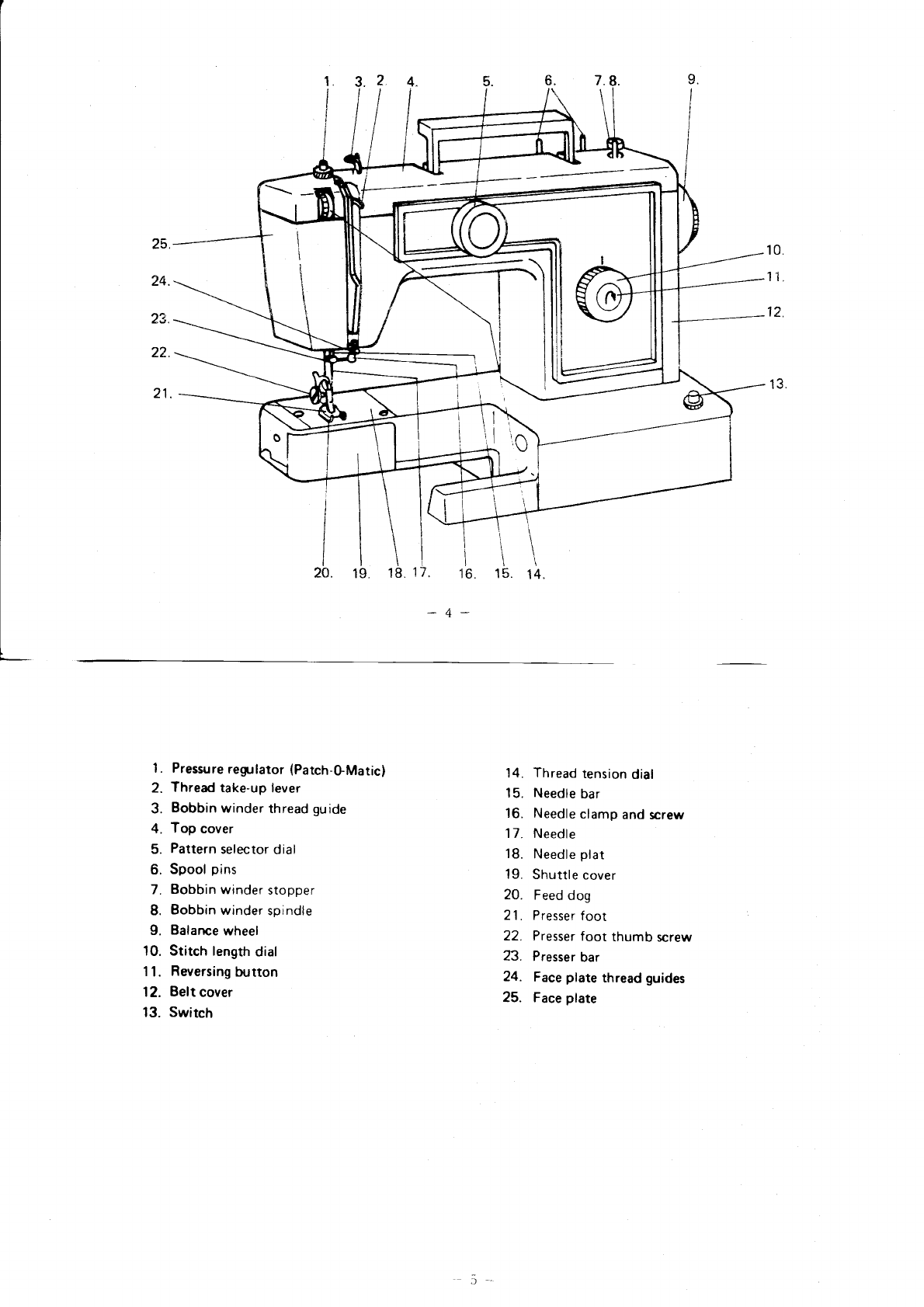

SEWING LAMP

The sewing lamp is located behind the face plate.

Bulb type (Ai : . To remove Unscren

a To replace ... Sc.ew

Bulb type (Bl : o To remove ... Pusn and :\.,,;st counter-clockwise

a To replace ... Push anc I\i, st ciockwrse

Note:*Before replacing a bulb, disconnec: lne mach ne f ron^ the

power supply.

*Bulbs are available from sewing machine retailers, (Use a 15-

Watt bulb) Caution!

Before leaving the machine, changing parts or doing any other work

on it, always disconnect the plug from the wall socket.

(n (s

I

i

-6

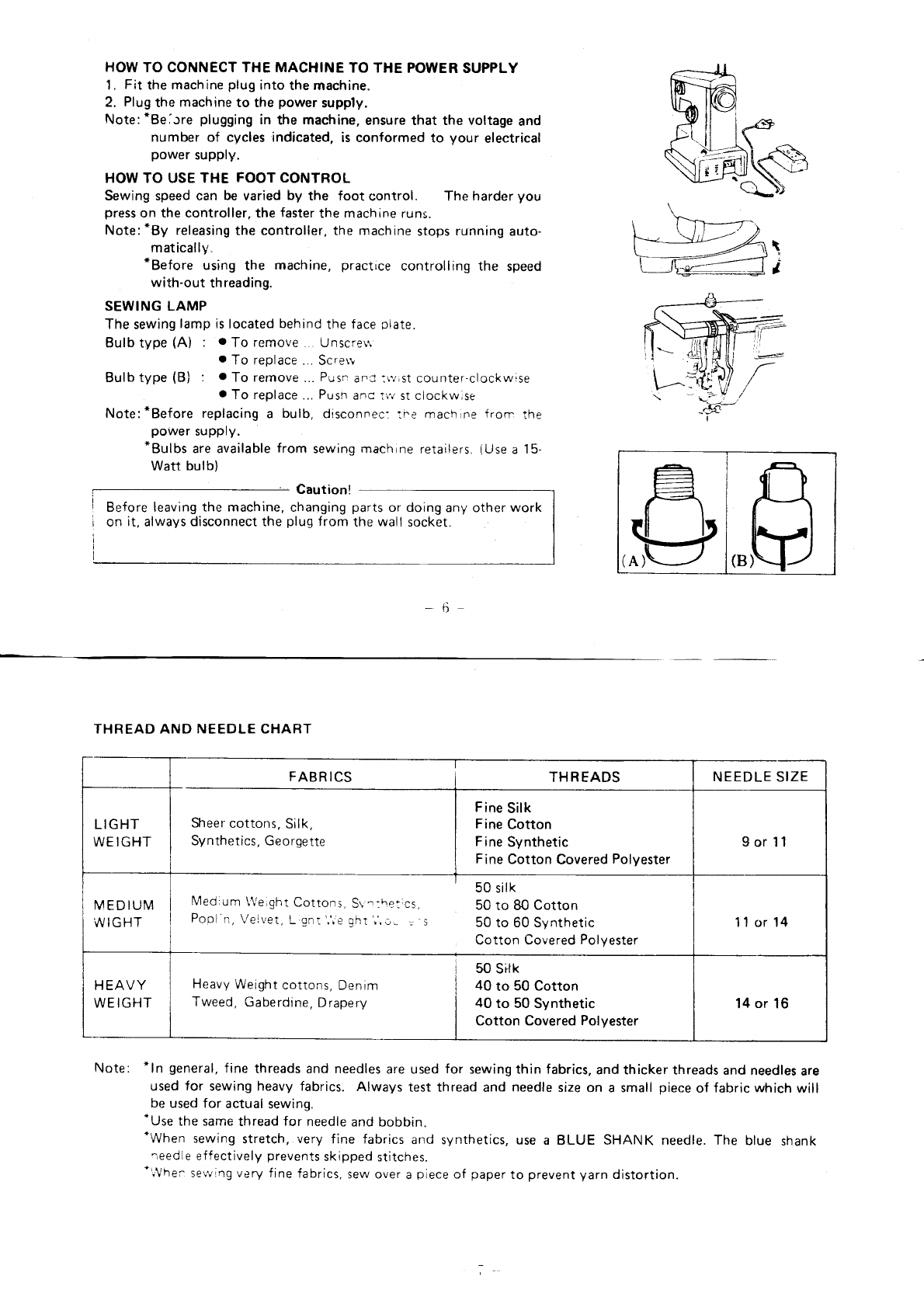

FABR ICS THREADS

Sheer cottons, Silk,

Synthetics, Georgette

NEEDLE SIZE

LIGHT

WEIGHT 9or 11

MEDIUM

WIGHT Med;um \te ght Cottons, Sr'":hetrcs.

Poo :, \/eivet. L gr: ,', e gnt ,', v- s

50 silk

50 to 80 Cotton

50 to 60 Synthetic

Cotton Covered Polyester 'l l clr 14

HEAVY

WEIGHT Heavy Weight cottons, Denim

Tweed, Gaberdine, Drapery

50 sitk

40 to 50 Cotton

40 to 50 Synthetic

Cotton Covered Polyester 14 or 16

THREAD AND NEEDLE CHART

*ln general, fine threads and needles are used for sewing thin fabrics, and thicker threads and needles are

used for sewing heavy fabrics. Always test thread and needle size on a small piece of fabric which will

be used for actual sewing.

*Use the same thread for needle and bobbin.

*When sewing stretch, very fine fabrics and synthetics, use a BLUE SHANK needle. The blue shank

aeedle effectively prevents skipped stitches.

'iVrrer^ seyving very fine fabrics, sew over a piece of paper to prevent yarn distortion.

Note

Fine Silk

Fine Cotton

Fine Synthetic

Fine Cotton Covered Polyester