Emriver Em2 Installation instructions

Warnings

© 2012 Little River Research & Design; updated July 2018 1

YOU MUST READ AND UNDERSTAND THESE WARNINGS

BEFORE USING THE EMRIVER MODEL

The Emriver model is very heavy when filled with water and sediment. A collapse of the

model’s supports could severely injure or kill a person. Be absolutely sure you understand

how to use the supports.

Use only the supports provided with the Emriver geomodel. Despite weight-bearing claims, no

standard production sawhorse is strong enough to safely support the model. Sawhorses and

folding tables can collapse under dynamic or side loading.

Check all fittings on the aluminum supports before each use to be sure they are secure.

When setting up the box, the supports must be laterally level and aligned. They must also be

aligned with the proper support point underneath the box. Otherwise the box could warp or

collapse when loaded.

Never set the box up on a surface with a slope exceeding 8% (a 7-inch drop in 7 feet).

Never use more than 27 gal (102 L) of water in the model. Using more than the maximum

amount of water and sediment could cause the box or supports to collapse.

Never use more than the provided 150 lb (68 kg) of sediment in the box, and do not place any

heavy objects in the box.

Never allow people to sit or stand on or in the box. Never get underneath the loaded box.

Use only the pump and power supply provided with the Emriver Em2. Be certain to connect

the power supply to a properly grounded outlet. Always use the Ground Fault Circuit

Interrupter (GFCI) provided with the Emriver model (see Figure 18), and be sure to read the

manual that accompanies the GFCI.

When using a 12-volt battery to power the model, always use the Emriver Battery Adapter

from Little River Research & Design. Never bypass the fuses.

When powering the model with a 12-volt battery, be sure you understand the dangers

associated with charging and using lead-acid batteries, and consider using safer spill-proof

batteries.

The box should only be used for its intended purpose as stated herein.

If any part of the box or pumping system is damaged, if you have any doubts about the

electrical or structural safety of the model, or if you do not understand these directions, do not

use this model.

2 © 2012 Little River Research & Design; updated July 2018

[This page was intentionally left blank.]

Introduction

© 2012 Little River Research & Design; updated July 2018 3

Introduction .................................................................................................................................................. 4

Parts and Accessories Checklist .................................................................................................................... 6

Assembly and Operation............................................................................................................................... 7

Setup checklist ............................................................................................................................................21

Disassembly, Transport and Storage .......................................................................................................... 22

Maintenance and Care…………………………………………………………………………………………………………………………..23

Demonstrations and Experiments ..............................................................................................................24

Specifications ..............................................................................................................................................26

All contents copyrighted 2012

Little River Research & Design

All rights reserved

Emriver and the meandering river

logo are registered trademarks

Introduction

4 © 2012 Little River Research & Design; updated July 2018

Introduction

This manual describes the safe use and maintenance of your Emriver Em2 river process simulator. It is

very heavy when filled with modeling media and water, and could be dangerous if not properly

supported, assembled, and operated.

Therefore, it is important that you read, understand, and abide by all the instructions and warnings in

this manual to avoid damage to the model or personal injury. Updates to this manual and other support

for the Emriver model may be found at www.emriver.com.

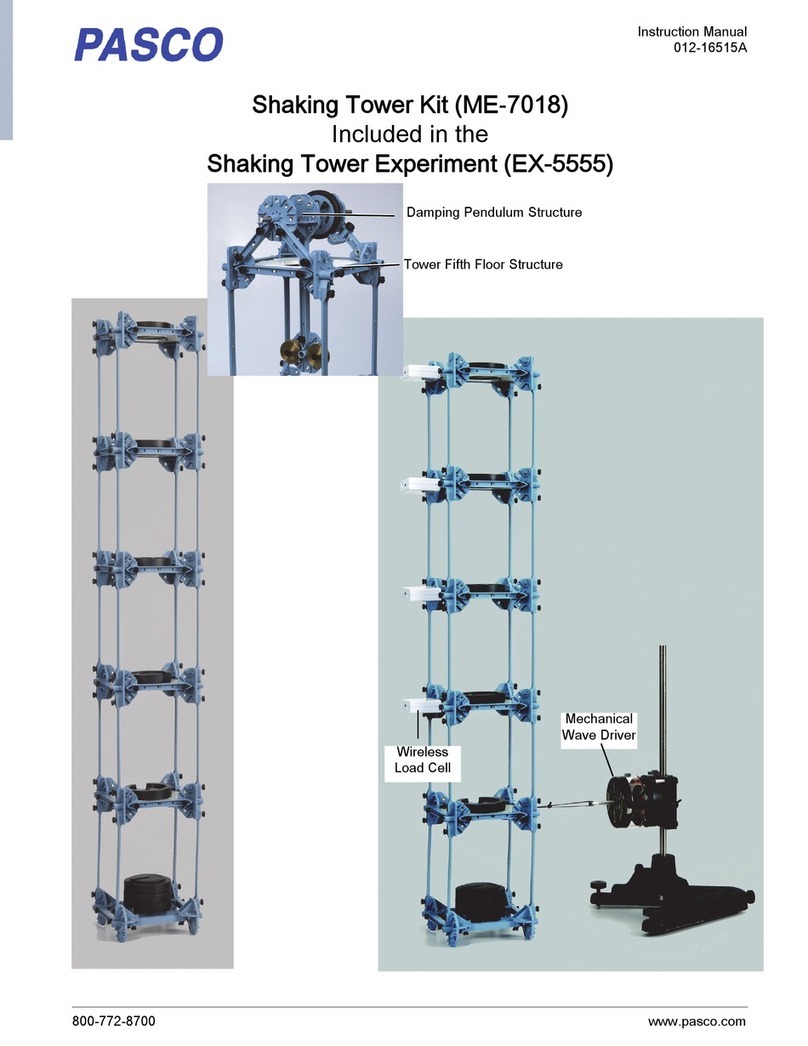

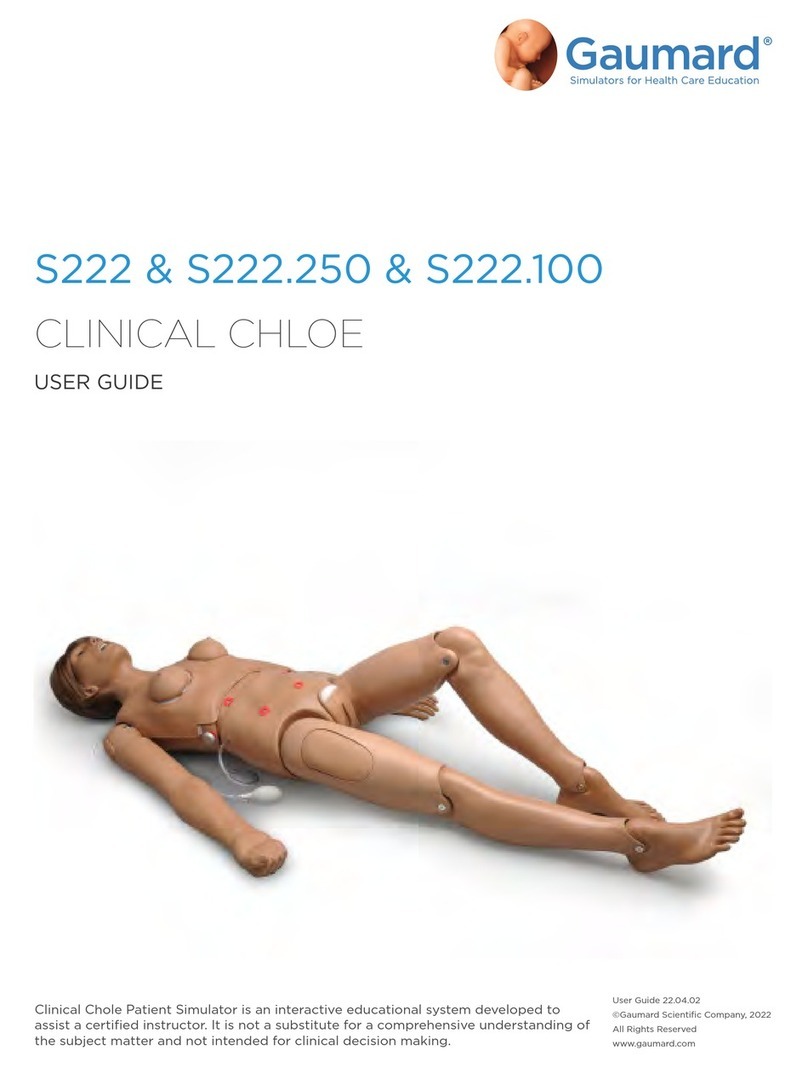

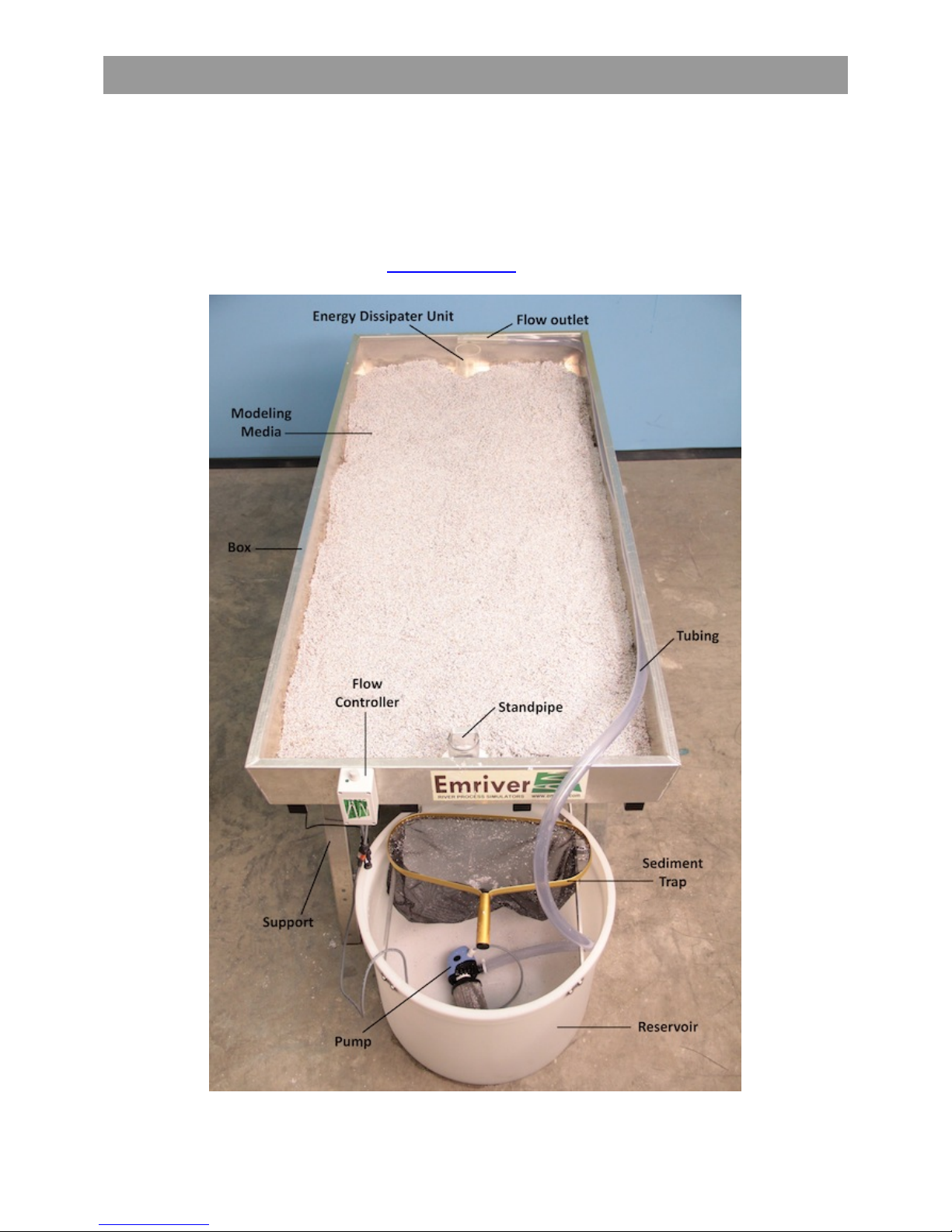

Figure 1. Parts of the Emriver Em2 river process simulator. Power supply is shown in Figure 2.

Introduction

© 2012 Little River Research & Design; updated July 2018 5

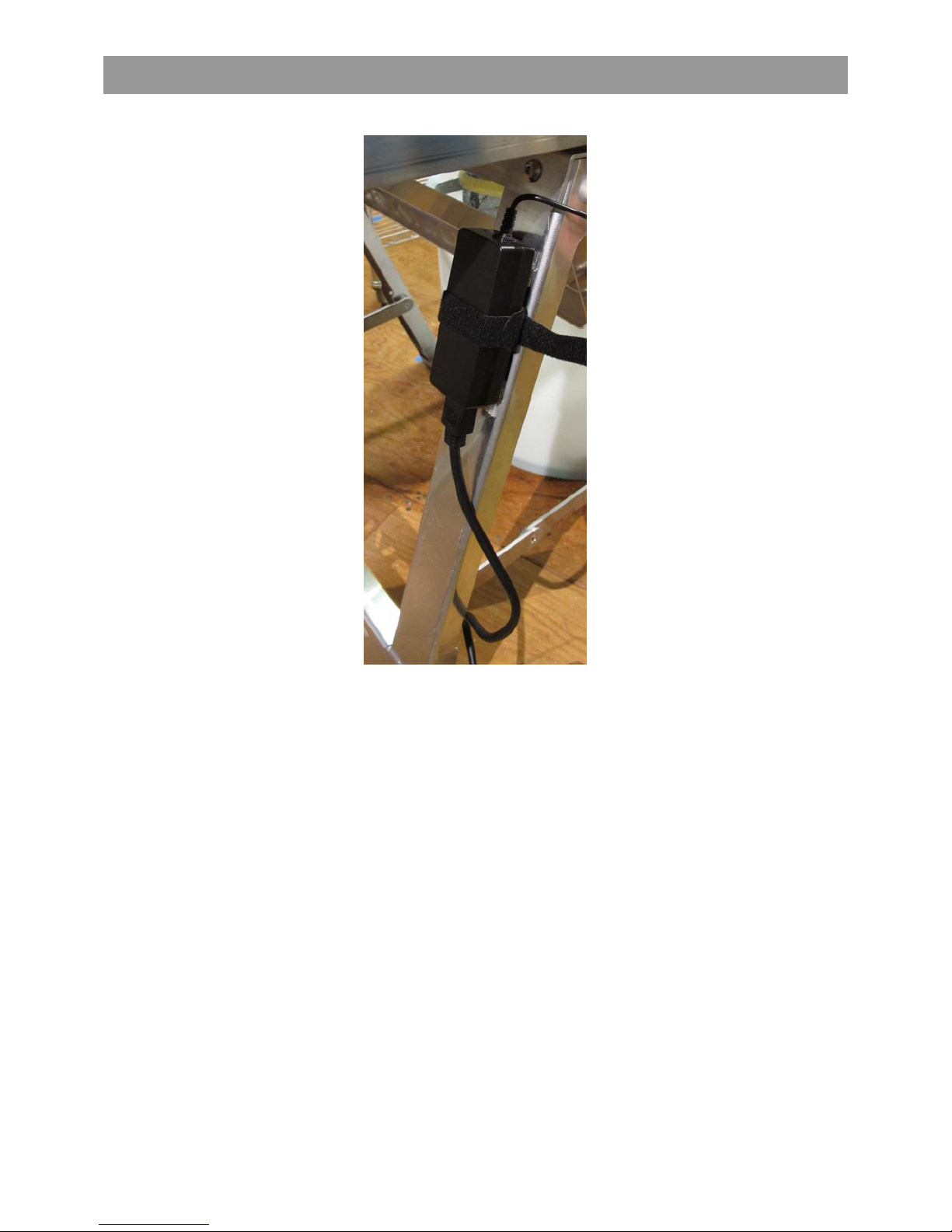

Figure 2. Power supply included with the

Emriver Em2 model, shown attached to the

downstream support.

Parts and Accessories Checklist

6 © 2012 Little River Research & Design; updated July 2018

Emriver parts and accessories checklist:

Parts and Accessories Checklist

Other parts and supplies you may want to have on

hand:

Emriver Em2 Box

Modeling media in 5 buckets

Emriver Use and Care Manual

Emriver Lab Materials

Standpipe

Emriver supports

Reservoir

Sediment trap

Pump and filter

¾-inch-diameter tubing

Electronic Flow Controller

Energy Dissipater Unit (EDU)

Flow outlet

Power supply

GFCI-equipped outlet

Hydraulic shapes

Measuring tape

Solid scoop

Perforated Scoop

Riprap stones

Simulated riparian vegetation

Scrapers for moving media

Blue and green dye

Paper towels and mop

Shim materials

Hand level

Plastic buckets for sediment and water

Garden hose

Scraper/trowel

Notebook

Household bleach

Small towels for drying hands

Sieve

Laser level (for use with Scientific/Academic

Kit)

12-volt battery (for use with Emriver Battery

Adapter)

Battery charger (for use with Emriver Battery

Adapter)

Accessories available for purchase from Little River

Research & Design:

Digital Flow Controller

Emriver Battery Adapter

Structures Kit:

Box culverts

Walled culvert

Double walled culvert

Model houses

Academic Kit:

Emriver level rod and holder

Graduated cylinder (250 mL)

Graduated cylinder (1000 mL)

Graduated beaker (2000 mL)

Stopwatch

Coarse mesh hand sieve

Perforated scooper

Hand size scooper (not perforated)

Assembly and Operation

© 2012 Little River Research & Design; updated July 2018 7

Assembly and Operation

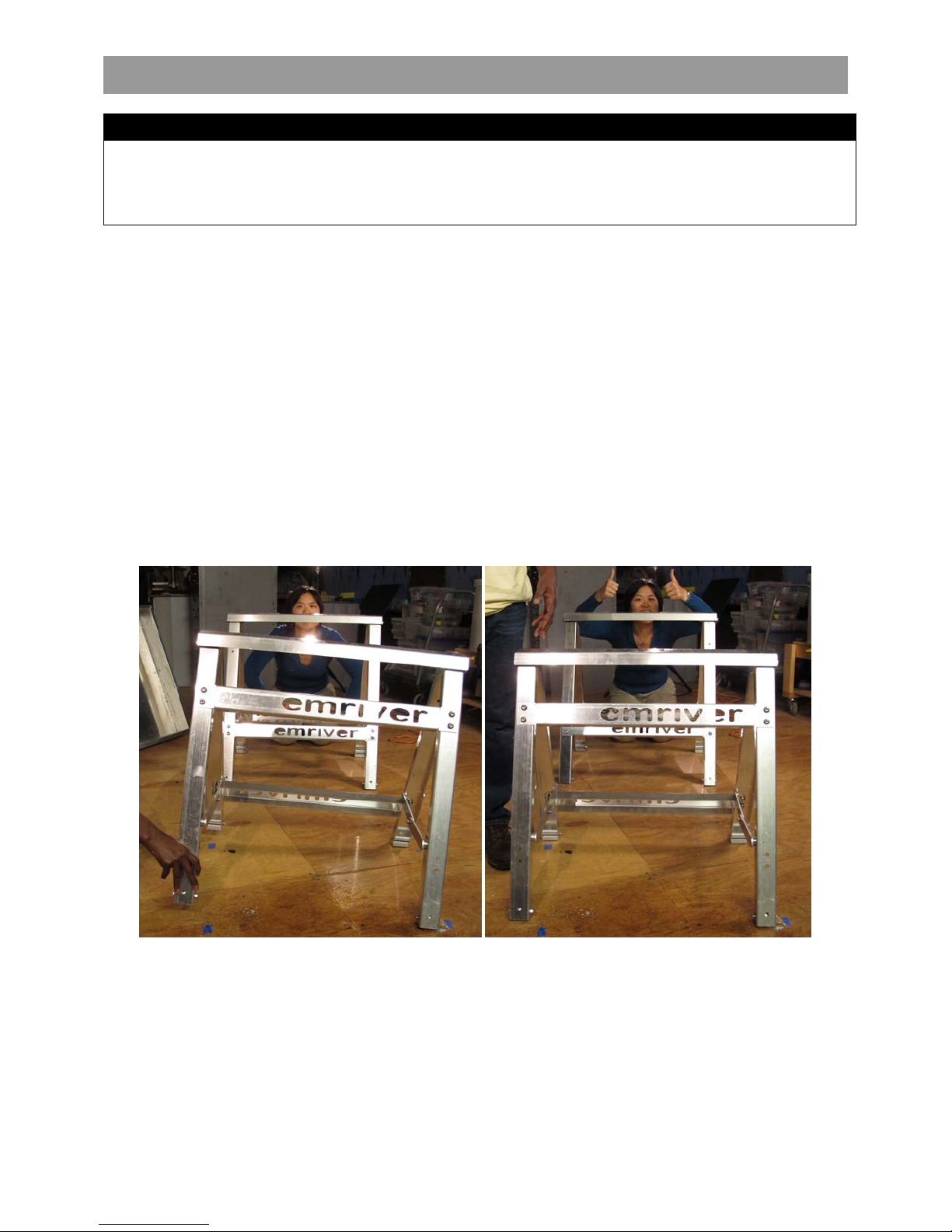

STEP 1 -Set up the supports

To assemble the model, begin by setting up the aluminum supports. The shorter support will

hold the downstream end of the box, so keep in mind how you would like the model oriented

when placing the supports.

If the supports are not properly aligned, the box will twist when fully loaded, which may

damage the box. To check alignment, look across the support crossbars as shown in

Figure 3. The supports must be both level and parallel.

The supports should be set up so that the crossbars are 49 in (1.25 m) apart and aligned as

shown in Figure 3 to prevent damage to the box.

Figure 3. Incorrect (left) and correct (right) support alignment. Crossbars must be both level and

parallel when viewed as shown.

WARNING

When fully charged with water, the model can weigh in excess of 500 lb (227 kg). Dynamic loading during

use, caused by someone leaning on the model, for example, can greatly increase this load. A collapse of

the model’s supports could be dangerous and seriously damage the model. You must be certain the

model is adequately supported and that you have read and understand all warnings.

Assembly and Operation

8 © 2012 Little River Research & Design; updated July 2018

On uneven ground, use shims made from ¾-inch plywood or 2-by-4 scraps under the support

feet as necessary.

Be sure all four feet of each support are properly supported. One horse is modified to provide

clearance for the reservoir (see Figure 9). Place the supports so this opening lies at the

downstream end.

The Emriver supports have a difference in height of about 3 in (76 mm), yielding a box

slope of 6%.

The slope of channels in the box will be determined by the position of the standpipe, so

the exact box slope is not necessarily important.

Note: Labels on the supports display arrows that indicate proper placement and orientation,

with the shorter support at the geomodel’s downstream end. See Figure 4.

Figure 4. Labels on the supports indicate proper orientation, with

the shorter support at the downstream end.

Assembly and Operation

© 2012 Little River Research & Design; updated July 2018 9

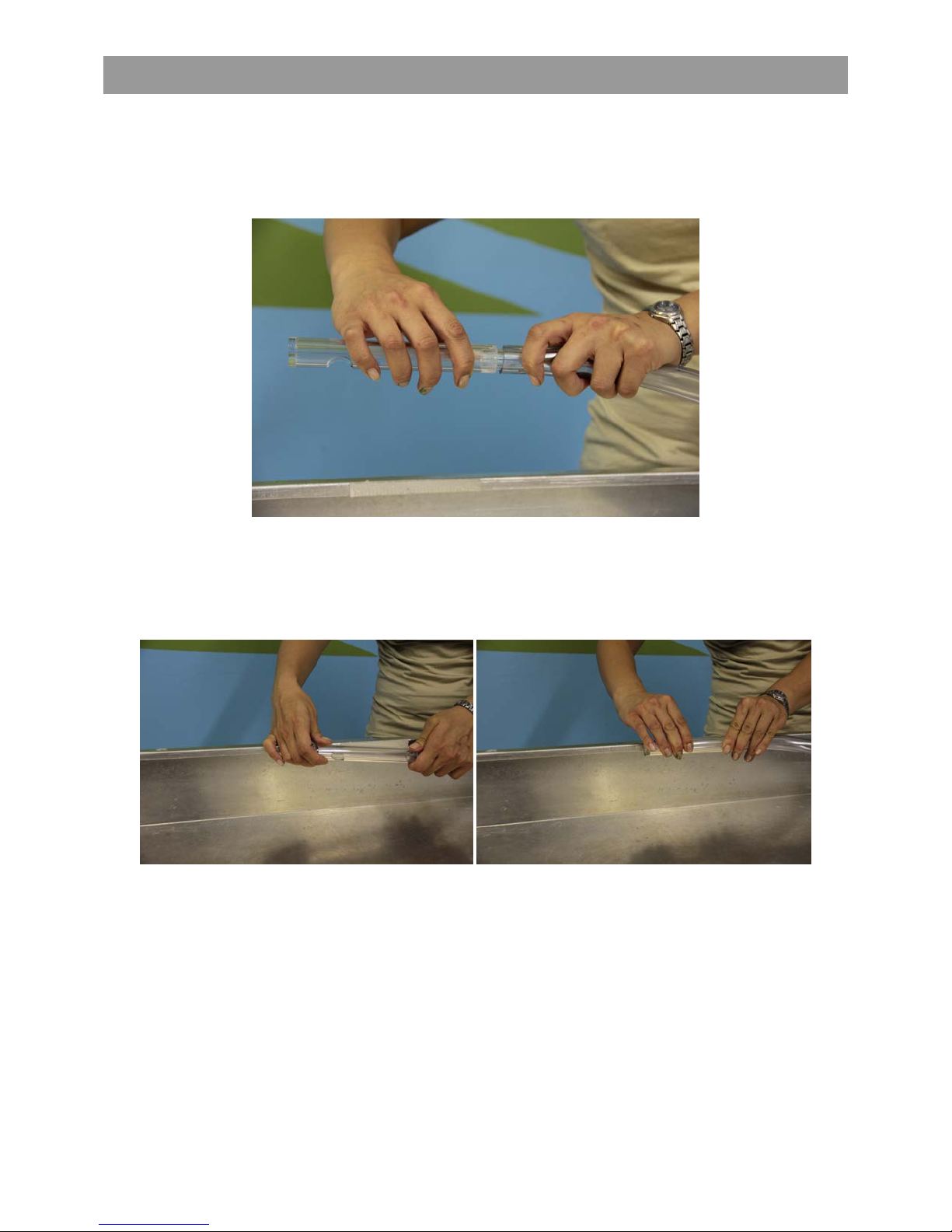

STEP 2 -Install the standpipe in the drain assembly

Install the standpipe by sliding it into the drain assembly from the underside of the box. Insert

the handle first. The seal may be damaged if you insert the standpipe from above. For initial

setup, the standpipe should extend into the box approximately 2 in (50 mm).

The standpipe will move much more freely in the drain assembly seal when wet — you may

want to moisten the standpipe before inserting it.

The standpipe has been lubricated with a silicone grease to allow smooth action against the

rubber seal. This lubricant is waterproof, nontoxic, and should last for many uses. As needed,

apply a small amount to restore smooth movement. This silicone grease may be found at most

hardware stores and is typically used for waterproofing electronics and o-rings. An extra tube of

silicone grease has been provided with your model and can be found inside the red carrying

case. Keep the standpipe coated with a thin film of silicone grease to ensure years of trouble-

free operation.

The drain assembly nut should not be over tightened. Some water should leak from around

the drain assembly, down the outside of the standpipe, and into the reservoir. This flow allows

“groundwater” to exit the media and improves river modeling performance.

Figure 5. Insert the standpipe from

the underside of the box to avoid

damage to the seal. The standpipe

will move much easier when the seal

is wet. Never attempt to install the

standpipe from the top of the box.

Assembly and Operation

10 © 2012 Little River Research & Design; updated July 2018

STEP 3 -Install the box

The box MUST be supported at the two reinforced ribs, and nowhere else. See Figure 6.

Figure 6. Support ribs on the underside of the box

(indicated with arrows) are areas where the box

must be supported.

CAUTION

The supports must be properly aligned with the support ribs on the box before any weight is

added to the box. See Figure 8.

Assembly and Operation

© 2012 Little River Research & Design; updated July 2018 11

When the supports are level and aligned, place the box on them.

Note: Gaps of more than 0.25 in (6 mm) between the box’s support ribs and the support

crossbars indicate that the supports are NOT properly aligned.

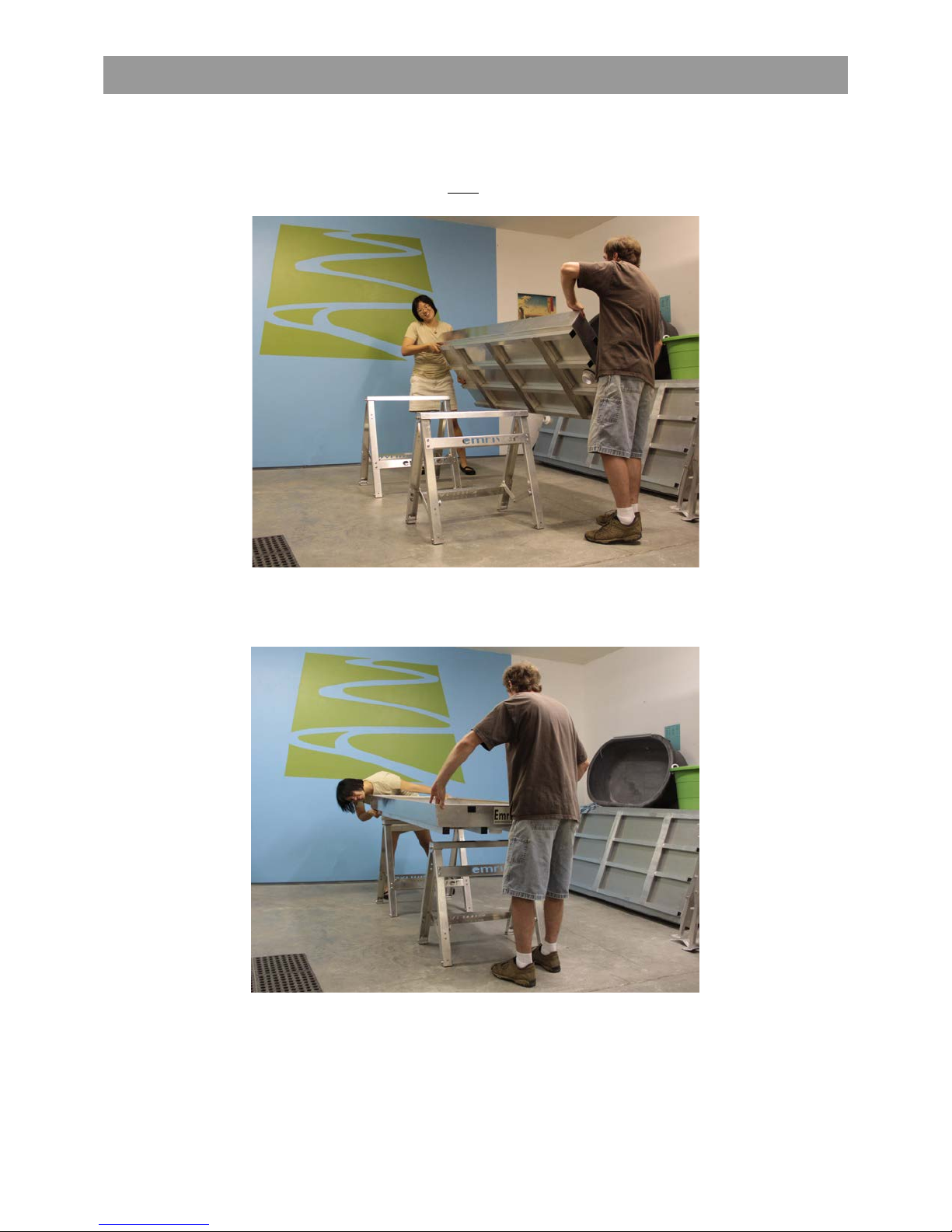

Figure 7. Lift the box onto the supports. It is best to complete this

task with two people.

Figure 8. Check to ensure that the support ribs on the box rest on

the supports properly.

Assembly and Operation

12 © 2012 Little River Research & Design; updated July 2018

STEP 4 -Position the reservoir

Place the reservoir beneath the box at the downstream end. The reservoir should be located as

shown in Figure 9 so that the standpipe will drain into the reservoir. Note that the support at

the downstream end of the box has an opening for the reservoir.

Figure 9. Place the reservoir beneath the support

at the downstream end.

STEP 5 -Position the pump

Attach one end of the tubing onto the arm of the pump. Place the pump, lying on its side, in the

bottom of the reservoir, keeping the wire connectors outside of the reservoir. Check that the

filter is securely attached to the pump. Note that you may have a pump and filter that look

different than those in the photo, but the setup is the same for each.

Figure 10.Place the pump with filter in the bottom of the reservoir, lying on its side. The filter easily screws

onto the pump. The tubing is attached to the arm on the pump.

Assembly and Operation

© 2012 Little River Research & Design; updated July 2018 13

STEP 6 -Fill the reservoir

Using the graduations on the reservoir, fill it with 27 gal (102 L) of water. The reservoir is

graduated in U.S. gal. Position the reservoir before filling it with water. Do not move the

reservoir after it has been filled as this will cause damage to the reservoir. Do not fill the

reservoir with more than 27 gal (102 L) of water.

WARNING

Using more than 27 gal (102 L) of water could damage the box or cause it to collapse. Do not exceed

this volume and do not start the pump until you have filled the reservoir and carefully measured the

total volume of water in the system.

WARNING

When full of water, the reservoir weighs over 200 lb (91 kg). It will be damaged or destroyed if moved

when full.

STEP 7 -Position the sediment trap

Place the sediment trap on the aluminum struts in the reservoir. Be sure the sediment trap sits

directly below the standpipe.

Figure 11. Place the sediment trap on the aluminum struts in the

reservoir.

Assembly and Operation

14 © 2012 Little River Research & Design; updated July 2018

STEP 8 -Attach and position the tubing and flow outlet

Connect flow outlet to the tubing as shown below in Figure 12.

Figure 12. Insert the flow outlet into the tubing.

After the tubing is attached, align and attach the mushroom fasteners on the back of the flow

outlet to the fasteners on the inside of the box at the upstream end, as shown in Figure 13. The

outlet should snap into place.

Figure 13. Align the mushroom fasteners on the flow outlet with those on the inside of the box at the

upstream end. Snap the fasteners together to secure the outlet to the box.

Place the tubing along the inside edge of the box, starting from the attached flow outlet. The

tubing should run out of the box and into the reservoir, where it is connected to the pump (see

Figure 1). Starting from the upstream end, roll the tubing under the lip of the box until you are

near the standpipe. This will keep the tubing from interfering with demonstrations and media

behavior. See Figure 14.

Assembly and Operation

© 2012 Little River Research & Design; updated July 2018 15

Figure 14. Tuck the tubing beneath the lip on the inside of the box.

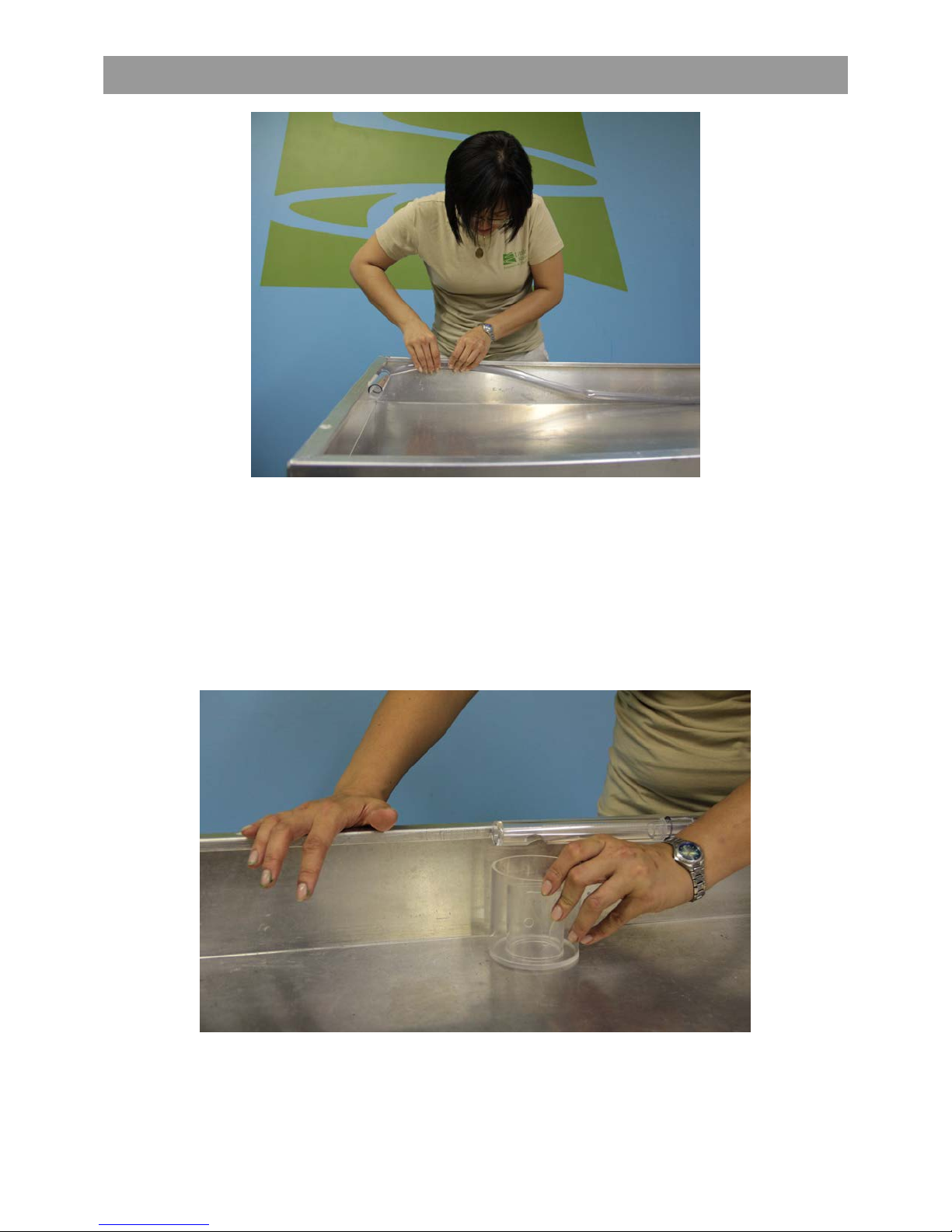

STEP 9 -Position the Energy Dissipater Unit

Place the Energy Dissipater Unit (EDU) beneath the flow outlet. The flow outlet opening should

line up with the innermost cylinder of the EDU. The EDU’s Y-shaped opening should face

downstream. See Figure 24 for a photo of the EDU while in use.

Figure 15. Place the EDU beneath the flow outlet.

Assembly and Operation

16 © 2012 Little River Research & Design; updated July 2018

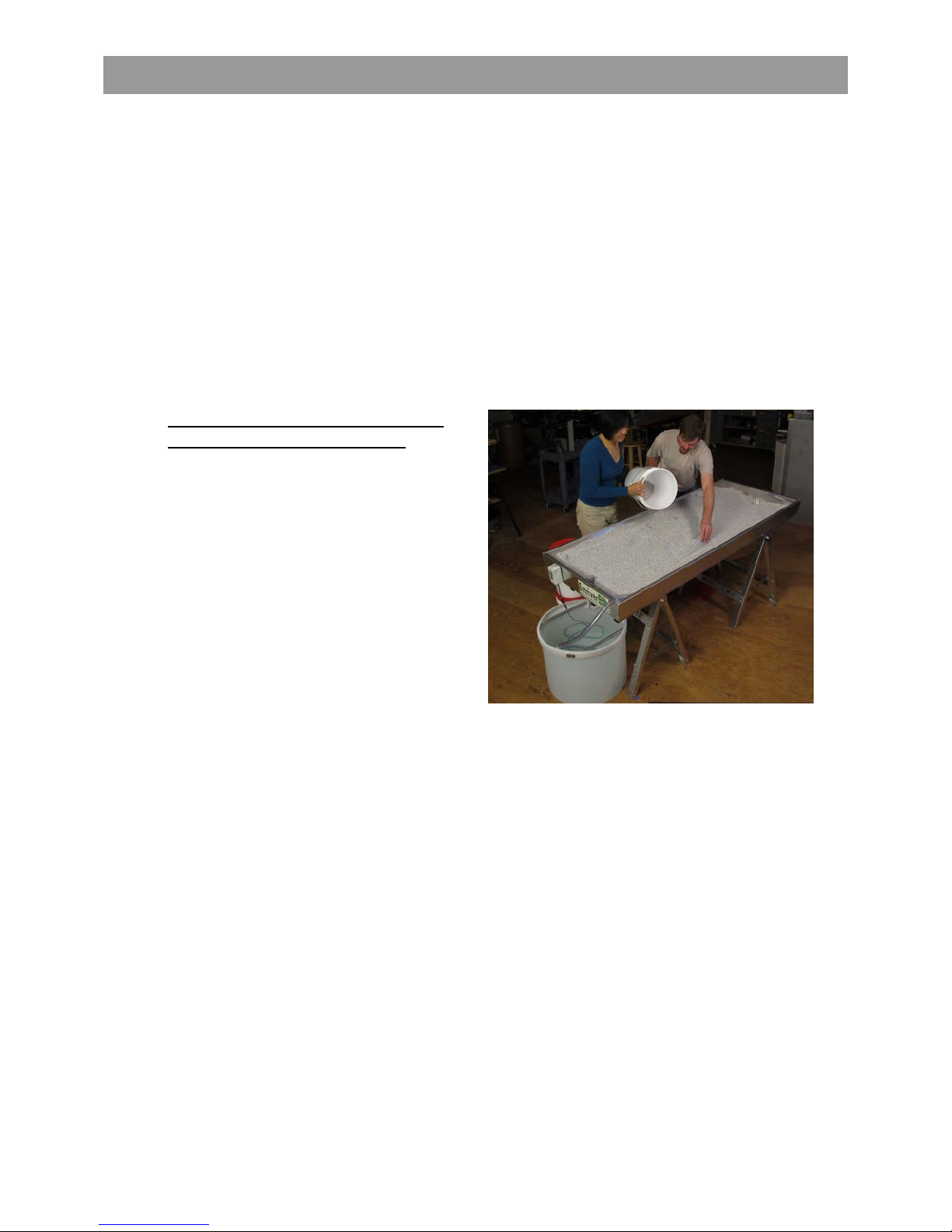

STEP 10 -Fill the box with modeling media (sediment)

Pour the media into the box one bucket at a time. Spread the media using the scraper included

with your geomodel to distribute it evenly throughout the box. See Figure 16.

Handling the media:

•During experiments and demonstrations, sediment leaving the box will accumulate in

the sediment trap. The rate at which the sediment trap fills is highly variable,

depending on activity in the box.

•When the sediment trap becomes full, use the perforated scoop included with the

Emriver model to return sediment to the box.

Allowing sediment to accumulate in the

reservoir will NOT harm the pump. The

filter is sized to allow the pump to function

normally even when completely buried in

sediment. However, fine debris such as

dirt, lint and pollen can accumulate in the

media over time and clog this filter. Just

give it a rinse now and then.

Figure 16. Pour the media into the box

Assembly and Operation

© 2012 Little River Research & Design; updated July 2018 17

STEP 11 -Power the pump

Attach the brick power supply to the leg of the shorter support using the mushroom fasteners

on the support and the brick power supply. Wrap the Velcro® strap around the support leg and

the brick power supply to fasten securely. See Figure 17.

Figure 17. Attach the brick power supply to the leg of the downstream

support.

Connect the power cord to the Ground Fault Circuit

Interrupter (GFCI) (US users only). If you are using an

extension cord, connect the extension cord to the

GFCI. Do not plug the model's power cord directly

into a wall outlet. Always use the GFCI.

If the red indicator light on the GFCI is on, it is ready

for use and the model should be powered. If the red

indicator light is off, press the red “Reset” button.

Figure 18. Always connect the power

cord to the GFCI. Never plug the

model's power supply directly into a

wall outlet.

Assembly and Operation

18 © 2012 Little River Research & Design; updated July 2018

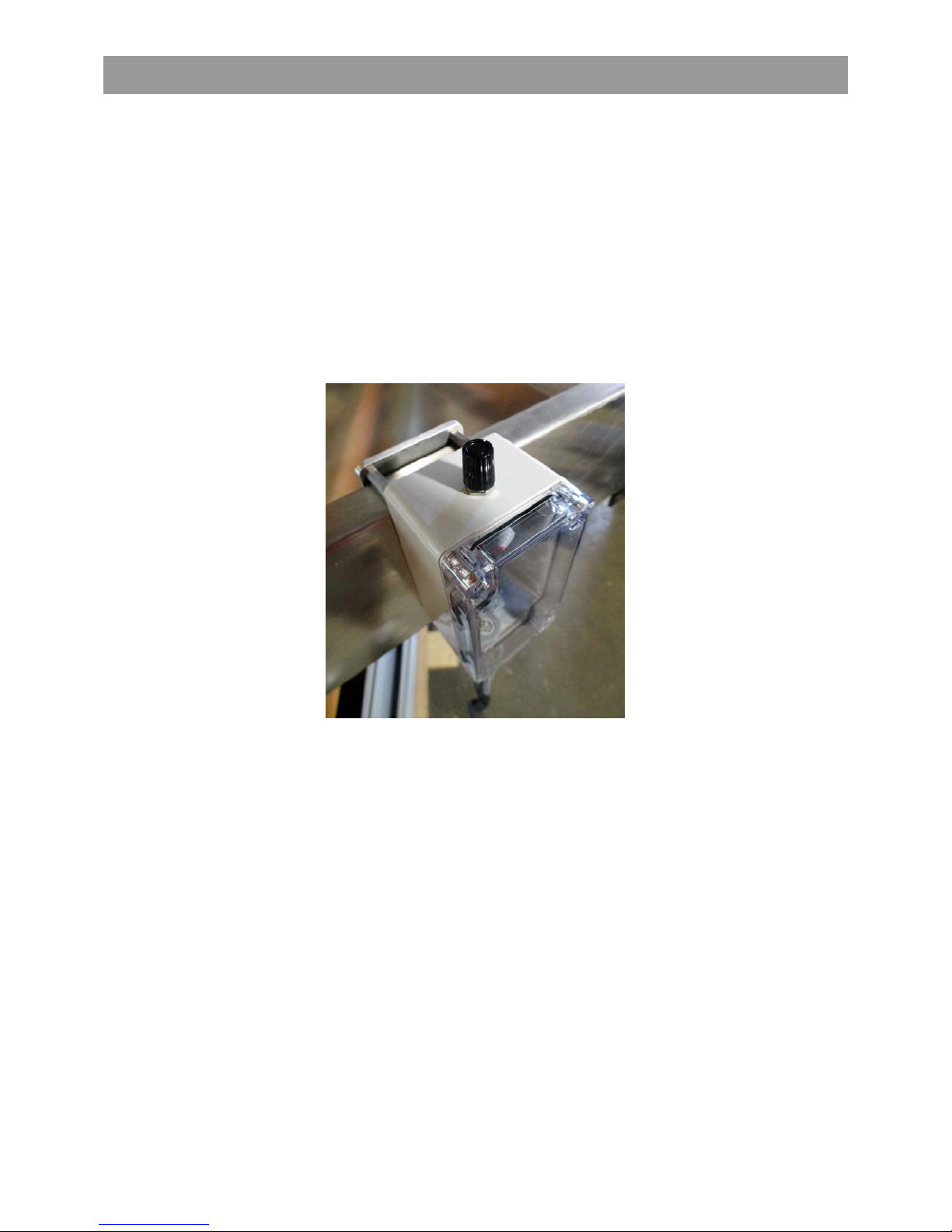

STEP 12 -Attach the Electronic Flow Controller (Model K28, or older Crayfish)

If you purchased the Digital Flow Controller (Model K500, or older Alix), see the separate

instruction sheet. Attach the flow controller to the downstream end of the box using the hook

(note that some older controllers have a Velcro connection). See Figure 19.

Figure 19. Attach the controller to the downstream end of the box.

Connect the pump to the controller using the gray, blue, and orange connectors (note there is

one red tab that is not a connector). Then, connect the controller to the power supply using the

black and red connectors. See Figure 20. Note that older models of the pump and controller

have different connectors. The older models will not work with the new models as shown here.

Simply match up the colors on the connectors.

Figure 20. The pump, at left, connects to the flow controller,

middle. The flow controller, right, connects to the power supply.

The color-coded connectors on each component will match up.

Assembly and Operation

© 2012 Little River Research & Design; updated July 2018 19

A square, green indicator light in the circuit board displays when the power is on. Change flow rate

using the knob on the controller. Pressing the knob resets the flow to zero. See Figure 21.

Troubleshooting: If the controller does not produce flow, and there are no lights on the circuit board,

check the power supply to ensure that the cord is fully connected and that there is a light on the power

brick.

If the power light is on, but there is no flow, check to see that the flow indicator LED is lit on the circuit

board (round green light). If it is lit, check the connection between the controller and the pump. Also

check for any obstructions or clogged filters. Expel all air from pump and hose. If the flow indicator LED

is not lit, adjust the knob clockwise until the LED is lit and there is flow.

Figure 21. Turn on the pump and

control flow with the knob.

Note:The knob does not turn the pump off completely; it merely stops flow. The pump is on as long as

the power is connected. To completely turn off the pump, the power must be disconnected.

Note:If the pump is reluctant to prime when started, reorient or shake it a bit (while underwater) to

remove air trapped in its intake. If necessary, clean any debris from the filter by unscrewing it from the

pump and flushing it with water.

Assembly and Operation

20 © 2012 Little River Research & Design; updated July 2018

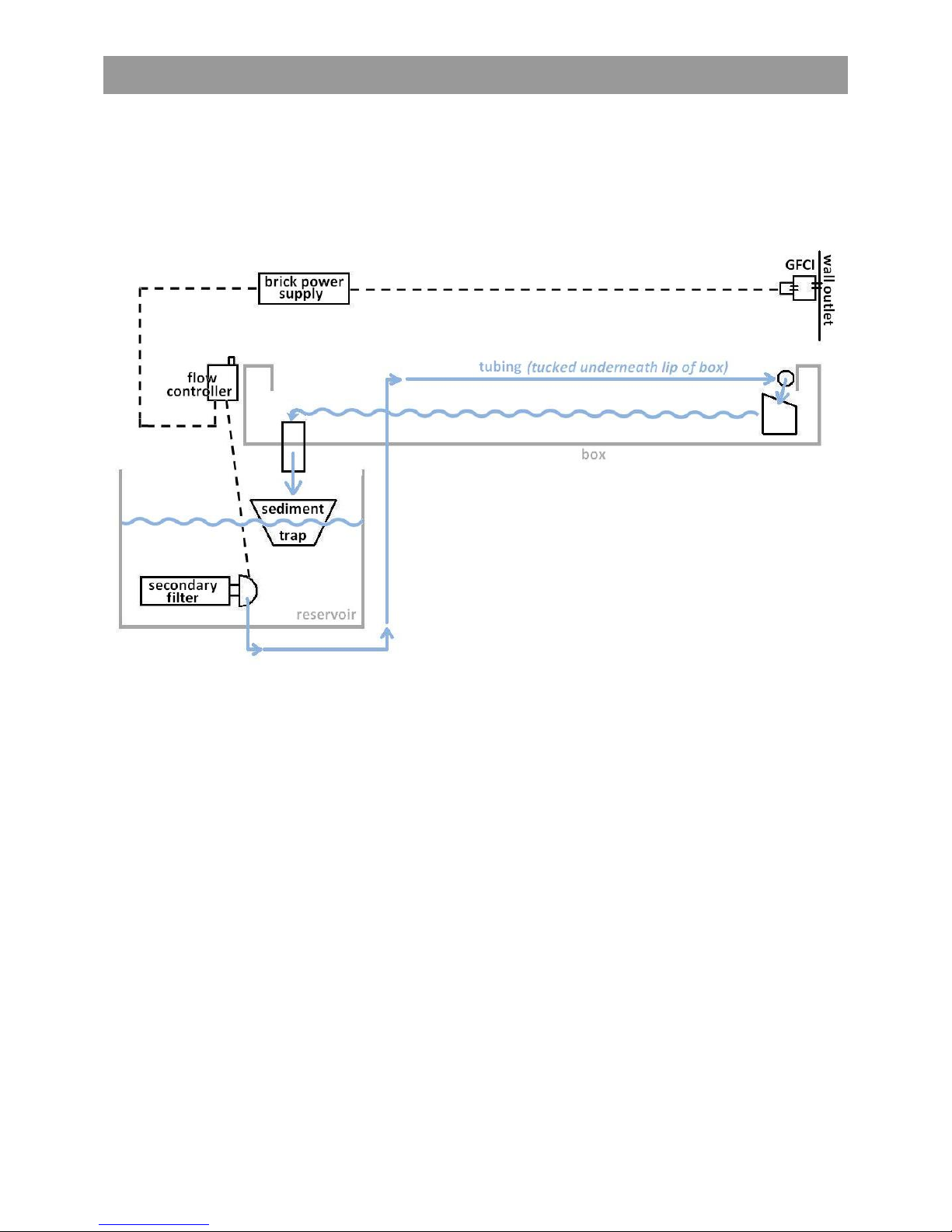

Flow Pathways

After the Emriver Em2 model has been assembled according to the instructions in this manual, it is

ready for use. Figure 22 is a conceptual chart that shows flow pathways of water and electricity through

a properly assembled Emriver Em2 model during use.

Figure 22. Flow pathways for water (solid line) and electricity (dotted line).

Table of contents