Emtec BioProTT FlowMCP User manual

BioProTTTM FlowMCP

User Manual

Copyright

All rights reserved, especially with respect to reproduction, distribution and translation. This user manual

or any part thereof must not be reproduced, saved, processed, duplicated or distributed without the writ-

ten consent of em-tec GmbH.

© Copyright em-tec GmbH Finning, 2021

Subject to Technical Changes

Owing to our policy of continuous product improvement, the illustrations and technical data contained in

this document may differ slightly from the current version of the device.

Legal Manufacturer

em-tec GmbH

Lerchenberg 20

86923 Finning

GERMANY

Telefon: +49 8806 9236 0

Fax: +49 8806 9236 50

E-Mail: em-tec-info@psgdover.com

Internet: www.em-tec.de

EN

Table of Contents

1 Intended Purpose and Restrictions...............................................................................8

1.1 Intended Purpose .....................................................................................................8

1.2 Usage Restrictions and Limitations......................................................................8

1.3 Liabilities and Responsibilities.............................................................................8

1.4 Safety Instructions ..................................................................................................9

1.5 Maintenance and Service........................................................................................9

2 General Safety Information, Symbols, Units and Abbreviations..........................10

2.1 Symbols used in this User Manual .....................................................................10

2.2 Symbols on Flow Meter, Sensors and on Packaging.......................................10

3 Description of the Measurement Principle.................................................................11

4 Packaging Contents .........................................................................................................12

5 Installation of the BioProTT™ FlowMeasurement System ....................................14

5.1 Device Description: BioProTT™ FlowMCP (1-4 channels) .............................14

5.2 Device Description: BioProTT™ FlowMCP-a (1 or 2 channels) .....................16

5.3 Installation of the BioProTTTM FlowMCP.............................................................18

5.4 Powering of BioProTT™ FlowMCP ...................................................................... 19

5.5 Connecting the BioProTTTM Clamp-On to the BioProTTTM FlowMCP............. 19

5.6 Mounting and Installation of the BioProTTTM Clamp-On and

the Extension Cables..............................................................................................20

5.7 Line Routing, Shield and Measures to Combat Interference Voltage..........21

5.8 Attaching the BioProTTTM Clamp-On to the Tube ............................................23

5.9 Use of the BioProTTTM Clamp-On.........................................................................24

5.10 Changing the BioProTTTM Clamp-On .................................................................25

5.11 Disassembly and Storage of the BioProTTTM Clamp-On ...............................25

5.12 Cleaning and Disinfection of the BioProTTTM Clamp-On................................25

5.13 Initialization and Start-Up of the BioProTTTM FlowMCP.................................26

6 Web Interface of the BioProTTTM FlowMCP................................................................. 27

6.1 Main Web Page for the BioProTTTM FlowMCP (1-4 channels)......................... 27

6.2 Main Web Page for the BioProTTTM FlowMCP-a.................................................30

6.3 Sensor Information Page for the BioProTTTM FlowMCP .................................33

6.4 Set-Up Page of the BioProTTTM FlowMCP ..........................................................34

6.5 Logging Page of the BioProTTTM FlowMCP .........................................................43

7 Modbus Interface .............................................................................................................44

7.1 Read Input Register (Function Code: 0x04) ......................................................44

7.2 Read Discrete Inputs (Function Code: 0x02) .................................................... 47

7.3 Write Coil (Function Code: 0x05) ......................................................................... 47

7.4 Read Coil (Function Code: 0x01) ..........................................................................48

7.5 Write Register (Function Code: 0x06).................................................................48

BioProTT™ FlowMCP

Page 4 Copyright em-tec GmbHD214-703 BioProTT™FlowMCP – User Manual – V4.0

EN

8 Analog Interface ...............................................................................................................49

8.1 Measurement Using the Analog Interface of the BioProTTTM FlowMCP-a..49

8.2 Zero Flow Adjustment via the Analog Interface ..............................................52

9 Cleaning the BioProTTTM FlowMCP ...............................................................................53

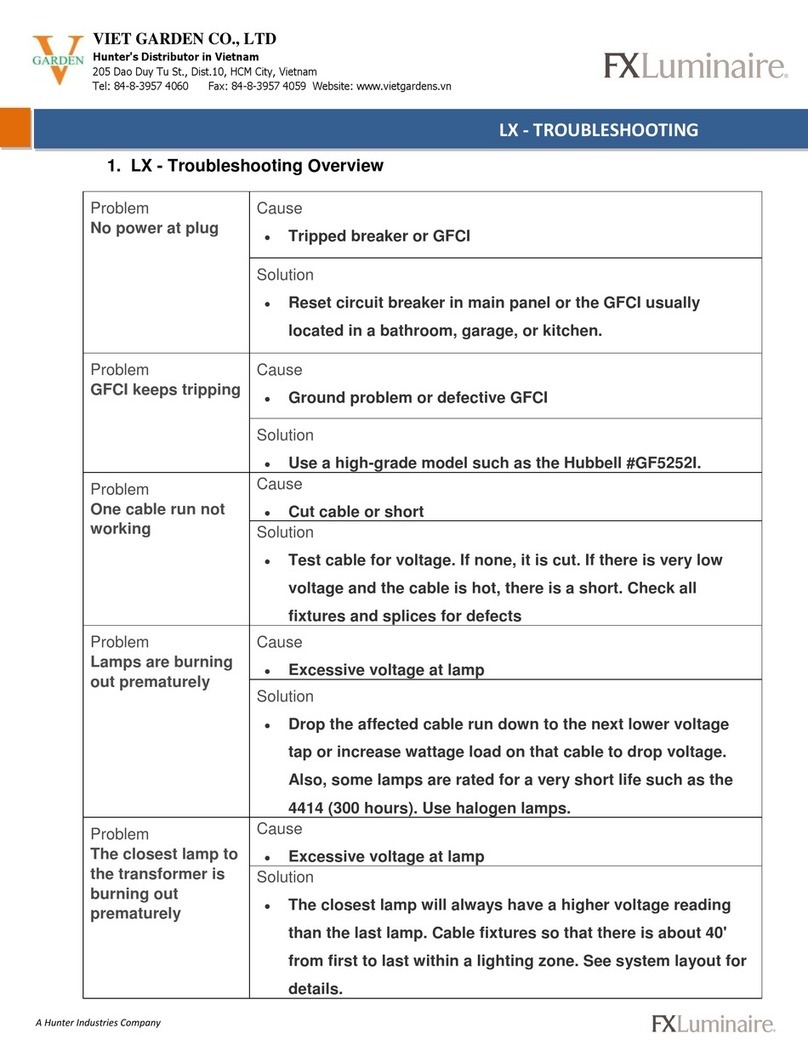

10 Troubleshooting, Support and Service.......................................................................54

10.1 Troubleshooting......................................................................................................54

10.2 Status Information Troubleshooting..................................................................70

11 Electrical Safety and Electromagnetic Compatibility ............................................72

12 Environmental Protection and Disposal..................................................................... 72

13 Manufacturer's Declarations......................................................................................... 73

14 Contact Information for Technical Support ..............................................................73

15 TechnicalSpecicationsoftheBioProTTTM FlowMCP (1-4 channels) ..................74

16 TechnicalSpecicationsoftheBioProTTTM FlowMCP-a..........................................75

BioProTT™ FlowMCP

Copyright em-tec GmbH Page 5D214-703 BioProTT™FlowMCP - User Manual – V4.0

EN

Before you set up or use the BioProTTTM FlowMCP (1-4 channels) or the BioProTTTM FlowMCP-a (1 or 2 channels),

please note:

–This user manual describes the BioProTTTM FlowMCP (1-4 channels) as well as the BioProTTTM FlowMCP-a,

the BioProTTTM FlowMCP version with analog interface (available as one or two channel version).

–Throughout this user manual, the term BioProTTTM FlowMCP is used to refer to all versions of the

BioProTTTM FlowMCP, i.e. with or without analog interface, unless clearly indicated otherwise.

–When referring to the BioProTTTM FlowMCP (both with and without analog interface) this usually also

includes the BioProTTTM Clamp-On as both devices need to be used together in order to form the complete

BioProTTTM

–This user manual refers to the features of software version V02.04.11.00 and subsequent ones. The software

version of your device is also displayed on the web interface.

Abbreviation Meaning

BioProTTTM FlowMCP BioProTTTM FlowMCP (1-4 channels); including BioProTTTM FlowMCP 1-a and 2-a.

MCP = Multi-Channel Platform

BioProTTTM FlowMCP -a BioProTTTM FlowMCP with analog interface

BioProTTTM

FlowMeasurement

System

The BioProTTTM FlowMeasurement System consists of the BioProTTTM FlowMCP (1-4

channels)/ BioProTTTM FlowMCP-a (1 or 2 channels), a BioProTTTM Clamp-On, and

the corresponding cables.

Referring to the BioProTT™ FlowMCP

sensor BioProTT™ Clamp-On

Qmin

Qmax

RSS Received Signal Strength which corresponds to the acoustic coupling

EMC ElectroMagnetic Compatibility

N/A Not applicable

PLC Programmable Logic Controller

ID Inner Diameter

OD Outer Diameter

S7 Siemens S7 PLC (Programmable Logic Controller (in German SPS))

Table 1: Abbreviations

BioProTT™ FlowMCP

Page 6 Copyright em-tec GmbHD214-703 BioProTT™FlowMCP – User Manual – V4.0

EN

•Read this user manual carefully before installing and starting up the device!

•The user (= the person who integrates the BioProTTTM FlowMCP into a control cabinet)

is responsible for any risks resulting from an incorrect or incomplete integration of the

BioProTTTM FlowMCP.

•The customer must ensure that the persons involved in the integration of the

BioProTTTM

and process measurement transmitters. In addition, the information in this user manual

must be followed.

• TM FlowMCP was transported or taken from storage,

ensure that the system has enough time to adapt to the ambient temperature in order

to ensure an accurate measurement.

• Due to possible failures of the BioProTTTM FlowMCP or the system it is part of,

BioProTTTM FlowMCP to directly control the closed loop system unless the risk was fully

analyzed and additional risk control measures have been established.

•IftheusedBioProTTTMTM

Clamp-On is used, or if the BioProTTTM Clamp-On is unplugged and reconnected, it must

•The BioProTTTM FlowMCP, the BioProTTTM Clamp-On(s), and sensor lines are part of a

measurements or the accurate function of the system.

•The BioProTTTM FlowMCP consists of components sensitive to electrostatic discharge.

Handle only in EMV-protected areas according to IEC 61326-1.

Although the BioProTT™ FlowMeasurement System represents a state-of-the-art technology, the user may be

put at risk if the device is operated incorrectly. You should therefore read the user manual carefully before

use. Inspect your equipment for completeness and damage after unpacking.

This user manual contains important information on the safe handling of the BioProTT™ FlowMeasurement System

and its accessories and should be kept it in an easily accessible location. Familiarize yourself with, and observe all

warning and safety information.

operating the system the BioProTTTM FlowMCP is part of) of the device to ensure it is used, inspected and

maintained in accordance with the user manual. Subsequent revisions or instructions from the manufacturer

must also be taken into account in this regard.

The manufacturer reserves the right to modify technical data without prior notice. Your local distributor will

supply you with current information and updates to this user manual.

BioProTT™ FlowMCP

Copyright em-tec GmbH Page 7D214-703 BioProTT™FlowMCP - User Manual – V4.0

EN

1 Intended Purpose and Restrictions

1.1 Intended Purpose

The BioProTT™ FlowMeasurement System in general and thus also the BioProTTTM FlowMCP are designed for

transit time method. It is usually used in laboratory, bioprocessing and industrial processes. The device is

intended to be mounted and used in a control cabinets only. The device must be used with compatible em-tec

BioProTTTM Clamp-Ons.

1.2 Usage Restrictions and Limitations

The BioProTTTM FlowMCP was developed and is sold for the above-mentioned intended purpose and use

only. The BioProTTTM FlowMCP and the BioProTTTM Clamp-Ons are not intended to be used for the following

purposes/under the following circumstances:

•as medical device

•

• for measurements in explosive areas

• for home or consumer use

• for outdoor use

• for legal metrology

• when the housing is damaged

Due to the single-channel structure of each individual channel, the BioProTTTM FlowMCP is not a fail-safe

system. If applied in safety-critical systems, the user has to consider a partial or complete system failure and

is responsible for the introduction of additional risk measures in their system.

For more information concerning compatible BioProTTTM Clamp-Ons, please contact em-tec GmbH.

1.3 Liabilities and Responsibilities

The user is responsible to use, check and maintain the BioProTTTM FlowMCP and the

BioProTTTM Clamp-On in accordance with the user manual. em-tec GmbH is neither liable nor responsible for

any consequences arising from the use of the BioProTTTM FlowMCP and/or the BioProTTTM Clamp-On that does

BioProTT™ FlowMCP

Page 8 Copyright em-tec GmbHD214-703 BioProTT™FlowMCP – User Manual – V4.0

EN

1.4 Safety Instructions

If the BioProTTTM FlowMCP is integrated into an industrial system, the user and operator have to observe the

following:

• The measured values supplied by the BioProTTTM

and/or analog interface.

•

if necessary, take actions independent of the BioProTTTM FlowMCP to minimize the risk.

• In case of an error, the device will provide error/warning information. More information regarding the

suggested action to solve the respective error/warning can be found in chapter 10 "Troubleshooting".

1.5 Maintenance and Service

In general, em-tec GmbH recommends the device to be checked in regard to measuring accuracy and safety

relevant aspects every two years.

The service for the BioProTTTM FlowMCP and the BioProTTTM Clamp-On may be carried out by

em-tec GmbH only. If these instructions are not followed, em-tec GmbH shall accept no liability for the device

and the warranty will be void.

If you experience any trouble with the measurement despite following the instructions in this document, or if

your BioProTTTM FlowMCP is damaged in any way, please contact our service department. Make a note of the

serial number of the BioProTTTM FlowMCP and the sensor before you contact our staff.

If you need to return the BioProTTTM FlowMCP and/or the BioProTTTM Clamp-On for servicing, please follow

these steps:

•Contact our service department at:

em-tec GmbH

Service Department

Am Graben 6-8

86923 Finning

Germany

em-tec-service@psgdover.com

• Our service department will send you a RMA form.

• Fill out the form and include it in the shipment.

BioProTT™ FlowMCP

Copyright em-tec GmbH Page 9D214-703 BioProTT™FlowMCP - User Manual – V4.0

EN

2 General Safety Information, Symbols, Units and Abbreviations

2.1 Symbols used in this User Manual

Symbol Meaning

Warning! This safety symbol precedes critical information that must be strictly

observed in order to prevent injuries and fatal hazards. This warning symbol is the

most important safety symbol.

Caution! Important information regarding correct handling.

Must be strictly observed!

If this information is not observed, faults or damage to the product or its surroundings

may occur.

Table 2: Symbols in this User Manual

2.2 Symbols on Flow Meter, Sensors and on Packaging

Symbol Meaning

Read this user manual carefully before use. Keep it in an easily accessible location

for future reference. Replacement copies of this user manual are available from the

manufacturer.

Manufacturer

em-tec GmbH · Lerchenberg 20 · 86923 Finning · Germany

Serial number

Order number

The manufacturer declares the conformitiy of the device with the applicable European

Regulations and Directives.

Do not dispose of this device together with domestic waste!

The device as a whole as well as any parts must be disposed of in accordance with

WEEE Directive and national legislation.

Caution, fragile!

Handle with care!

Protect against moisture! Store in a dry place.

Temperature limit during storage

Moisture limit during storage (non-condensing)

Air pressure limit

Storage Conditions

BioProTT™ FlowMCP

Page 10 Copyright em-tec GmbHD214-703 BioProTT™FlowMCP – User Manual – V4.0

EN

Symbol Meaning

Transport Conditions

Table 3: Symbols on Flow Meter, Sensors and Packaging

3 Description of the Measurement Principle

The function of the BioProTTTM FlowMCP and the BioProTTTM Clamp-On is based on an acoustic measurement

system incorporates two piezo ceramics that act as both ultrasonic transmitter and receiver. The measurement

TM Clamp-On,operatesby alternately transmitting

and receiving an ultrasonic pulse between the two ceramics and measuring the transit time difference that

it takes for the pulse to travel between them.

This method determines the transit time difference of ultrasonic signals through a measuring

For a higher accuracy, our BioProTTTM Clamp-Ons incorporate two pairs of sound transducers, i.e. four piezo

Figure 1: Sensor Structure

When sending ultrasonic signals through the measuring section, the transit time difference depends on the

•

downstream signal needs less time.

•

Consequently, the transit time difference is measured for every pulse. The difference between upstream and

by accurately measuring the difference between upstream and downstream transit time Tup and Tdown, it is

BioProTT™ FlowMCP

Copyright em-tec GmbH Page 11D214-703 BioProTT™FlowMCP - User Manual – V4.0

EN

4 Packaging Contents

The BioProTT™ FlowMCP is shipped with the following components:

BioProTTTM FlowMCP (1-4 channels)

ordered variant).

One(1)powersupplyconnector(ID13023); connected

to the device.

Extension cables (ID 13065) for the BioProTTTM

The cables are 1.1 m long and intended to be used in

a process control cabinet.

BioProTT™ FlowMCP

Page 12 Copyright em-tec GmbHD214-703 BioProTT™FlowMCP – User Manual – V4.0

EN

BioProTTTM FlowMCP-a (1 or 2 channels)

channels (depending on the ordered variant)

One(1)powersupplyconnector (ID13023); connected

to the device.

Extension cables (ID 13065) for the

BioProTTTM

channel. The cables are 1.1 m long and intended to

be used in a process control cabinet.

One (1) analog connector (ID 13399); connected to

the device

BioProTT™ FlowMCP

Copyright em-tec GmbH Page 13D214-703 BioProTT™FlowMCP - User Manual – V4.0

EN

5 Installation of the BioProTT™ FlowMeasurement System

The BioProTTTM FlowMeasurement System consists of the BioProTTTM FlowMCP (1-4 channels)/

BioProTTTM FlowMCP-a (1 or 2 channels), a BioProTTTM Clamp-On, and the corresponding cables.

• Compliance with the prescribed operating parameters and safety information must be

ensured prior to the use of the device. The user is responsible for the integration of the

device into their system, including the observation of safety aspects and electromagnetic

compatibility.

•The following instructions must be strictly observed.

5.1 Device Description: BioProTT™ FlowMCP (1-4 channels)

The image below shows the interfaces available for the BioProTT™ FlowMCP (1-4 channels):

Figure 2: Device Description BioProTTTM FlowMCP (1-4 channels)

No Components Description

1 power supply 4-pin connecting socket for terminal block with PIN assignment as shown below

2 Sensor Connector

#1-#4 D-Sub connection socket to connect the sensor to the extension cable

3 Ethernet connection connector for Ethernet / LAN cable (Modbus TCP)

4 USB connection USB for em-tec service purposes only

BioProTT™ FlowMCP

Page 14 Copyright em-tec GmbHD214-703 BioProTT™FlowMCP – User Manual – V4.0

EN

5 LEDs LEDs for device status signalization

Power

Lights: when power is connected

Off: when no power is connected;

if power supply fails or if the power supply is too low, refer to

chapter 10 "Troubleshooting".

Device Lights: when no device failure is present

Blinking: when a device failure is present*

Sensor

Lights: when all sensors are connected

Blinking: when a sensor is not connected or when a sensor failure

connected to a sensor (e.g. only one sensor connected to BioProTTTM

MCP 2)

Activity Lights or blinking:

present

Off:

Link Lights: when Ethernet connection is present

Off: no Ethernet connection is present

*for more details, refer to chapter 10 "Troubleshooting"

Table 4-1: Components BioProTTTM FlowMCP (1-4 channels)

The PIN assignment on the power connection is as follows:

PIN Number Meaning

1 +24 V DC, max. 2A

2 Ground

3n/a

4n/a

Table 4-2: Pin assignment terminal block

1 2 3 4

Figure 3: Terminal block

BioProTT™ FlowMCP

Copyright em-tec GmbH Page 15D214-703 BioProTT™FlowMCP - User Manual – V4.0

EN

5.2 Device Description: BioProTT™ FlowMCP-a (1 or 2 channels)

The image below shows the interfaces available for the BioProTT™ FlowMCP-a (1 or 2 channels):

Figure 4: Device Description BioProTTTM FlowMCP-a

No Components Description

1 Power Supply 4-pin connecting socket for terminal block with PIN assignment as shown below

2 Sensor Connector

#1-#2 D-Sub connection socket to connect the sensor to the extension cable

3 Ethernet connection connector for Ethernet / LAN cable (Modbus TCP)

4 USB connection USB for em-tec service purposes only

5 LEDs LEDs for device status signalization

Power

Lights: when power is connected

Off: when no power is connected;

if power supply fails or if the power supply is too low,

refer to chapter 10 "Troubleshooting".

Device Lights: when no device failure is present

Blinking: when a device failure is present*

Sensor

Lights: when all sensors are connected

Blinking: when a sensor is not connected or a sensor

failure is present*

connected to a sensor (e.g. only one sensor connected

to BioProTTTM MCP 2-a)

Activity Lights or blinking: Ethernet or Modbus TCP communi-

Off:

Link Lights: when Ethernet connection is present

Off: no Ethernet connection is present

BioProTT™ FlowMCP

Page 16 Copyright em-tec GmbHD214-703 BioProTT™FlowMCP – User Manual – V4.0

EN

6 Terminal Block

(analog signal) Connector Pin Description

1 RSS Channel 1 Current Loop +

2 RSS Channel 1 Current Loop GND

3 Flow Channel 1 Current Loop +

4 Flow Channel 1 Current Loop GND

5 RSS Channel 2 Current Loop + *

6 RSS Channel 2 Current Loop GND *

7 Flow Channel 2 Current Loop + *

8 Flow Channel 2 Current Loop GND *

9 Remote Zero Channel 1 +

10 Remote Zero Channel 1 GND

11 Remote Zero Channel 2 *

12 Remote Zero Channel 2 GND *

13 n/c

14 n/c

15 n/c

16 n/c

*Only available for BioProTTTM FlowMCP 2-a

Table 5-1: Components of BioProTTTM FlowMCP-a

The PIN assignment on the power connection is as follows:

PIN Number Meaning

1 +24 V DC, max. 2A

2 Ground

3n/a

4n/a

Table 5-2: Pin assignment terminal block

1 2 3 4

Figure 5: Terminal Block

BioProTT™ FlowMCP

Copyright em-tec GmbH Page 17D214-703 BioProTT™FlowMCP - User Manual – V4.0

EN

5.3 Installation of the BioProTTTM FlowMCP

The BioProTTTM FlowMCP supports DINrail mounting for the use in cabinets of process controls (IP20)

and can thus be mounted only on a standard mounting channel (DIN-rail to EN 50022, TH 35/7,5

or TH 35/15). The mounting and the removal is the same for the BioProTTTM FlowMCP (1-4 channels) as it is for

the BioProTTTM FlowMCP-a (1 or 2 channels).

5.3.1 Mounting

• Engage the module from the top in the top-hat rail and swivel it down

so that the module slides into position.

• There is only one correct mounting position for the device. The sensor

connections are on the device bottom.

• Please ensure that the BioProTTTM

setting up any connections.

• Other modules may be rowed up to the left and right of the device.

• There must be at least 5 cm clearance for heat dissipation above and

• The standard mounting channel must be connected to the equipotential bonding

strip of the switch cabinet. The connection wire must feature a cross-section of

at least 10 mm². Figure 6: Assembly, mounted

position

5.3.2 Removal

• To successfully remove the BioProTTTM FlowMCP, one needs a screwdriver with

a 3-3.5 mm blade.

• First disconnect the power supply, the sensor, and the signal lines.

• Then disconnect and remove the sensor extension cables and the Ethernet

connection and/or analog connection.

•

Figure 7: Disassembly

BioProTT™ FlowMCP

Page 18 Copyright em-tec GmbHD214-703 BioProTT™FlowMCP – User Manual – V4.0

EN

5.4 Powering of BioProTT™ FlowMCP

The terminal block requires a screwdriver with a 3.5 mm blade. The wires used in conjunction

with the terminal block should not exceed 1.5 mm2.

The BioProTT™ FlowMCP works with a 24V DC power, which has to be supplied

from an external power supply (please see table 4-1 and 4-2 in chapter 5.1 and

table 5-1 and 5-2 in chapter 5.2 for pin assignment.

Figure 8: DC power supply to

the device on terminal block

• The BioProTT™ FlowMCP needs to be connected to a limited energy circuit (24V DC with

max. 2 A).

• The current needs to be limited by an overcurrent protection device of 2 A (slow). The

overcurrent protection device shall be a fuse or a non-adjustable non-self-resetting

electromechanical device (see F1 in Figure 8).

5.5 Connecting the BioProTTTM Clamp-On to the BioProTTTM FlowMCP

To connect the BioProTTTM Clamp-On to the BioProTTTM FlowMCP, carefully attach the 15-pin high density

D-Sub socket to the sensor connection at the bottom of the BioProTTTM FlowMCP. Once this is done, the

sensor can be connected to the extension cable before it is attached to the tube.

• The connector of the BioProTTTM Clamp-On must be dry when plugged in.

• While installing the BioProTTTM Clamp-On, be sure not to impair the function of the tubing

system.

• Ensure that the tube size which is used corresponds with the size of the

BioProTTTM Clamp-On.

BioProTT™ FlowMCP

Copyright em-tec GmbH Page 19D214-703 BioProTT™FlowMCP - User Manual – V4.0

EN

5.6 Mounting and Installation of the BioProTTTM Clamp-On and the Extension Cables

The BioProTT™ FlowMCP includes sensor extension cables (ID13065)

for the use inside the control cabinet with a length of max. 1.1 m.

The female plug of the sensor extension cable can be mounted on the cabinet

wall with a thickness of up to 6.5 mm/ 0.26 inch (for panel cut-out refer to

Figure 11).

It is important, that the device connection to the control cabinet wall is tight.

The male plug (D-Sub) of the sensor extension cable is inserted in the sensor

port of the BioProTT™ FlowMCP and needs to be secured by the screws. The

cut-out panel with its dimensions and distances is indicated in Figure 11.

The red marks on the socket and the plug indicate the correct orientation for

inserting the plug.

• It is recommended that only one extension cable is used when connecting a

BioProTTTM Clamp-On.

• The total length of cable between sensor and flow meter must not exceed 4 m.

Figure 9: Panel cut out

in cabinet; numbers refer to mm

Figure 10: Cable Length and Connection

BioProTT™ FlowMCP

Page 20 Copyright em-tec GmbHD214-703 BioProTT™FlowMCP – User Manual – V4.0

This manual suits for next models

1

Table of contents

Other Emtec Measuring Instrument manuals