Emtec BioProTT User manual

BioProTTTM Flow Measurement System Version 1.00 page 1 of 75

Operating Instructions

BioProTTTM

Flow Measurement System

© em-tec GmbH

All rights reserved, especially with respect to reproduction, distribution and translation. These

Operating Instructions or any part thereof must not be reproduced, saved, processed, duplicated or

distributed without the written consent of em-tec GmbH.

BioProTTTM Flow Measurement System Version 1.00 page 2 of 75

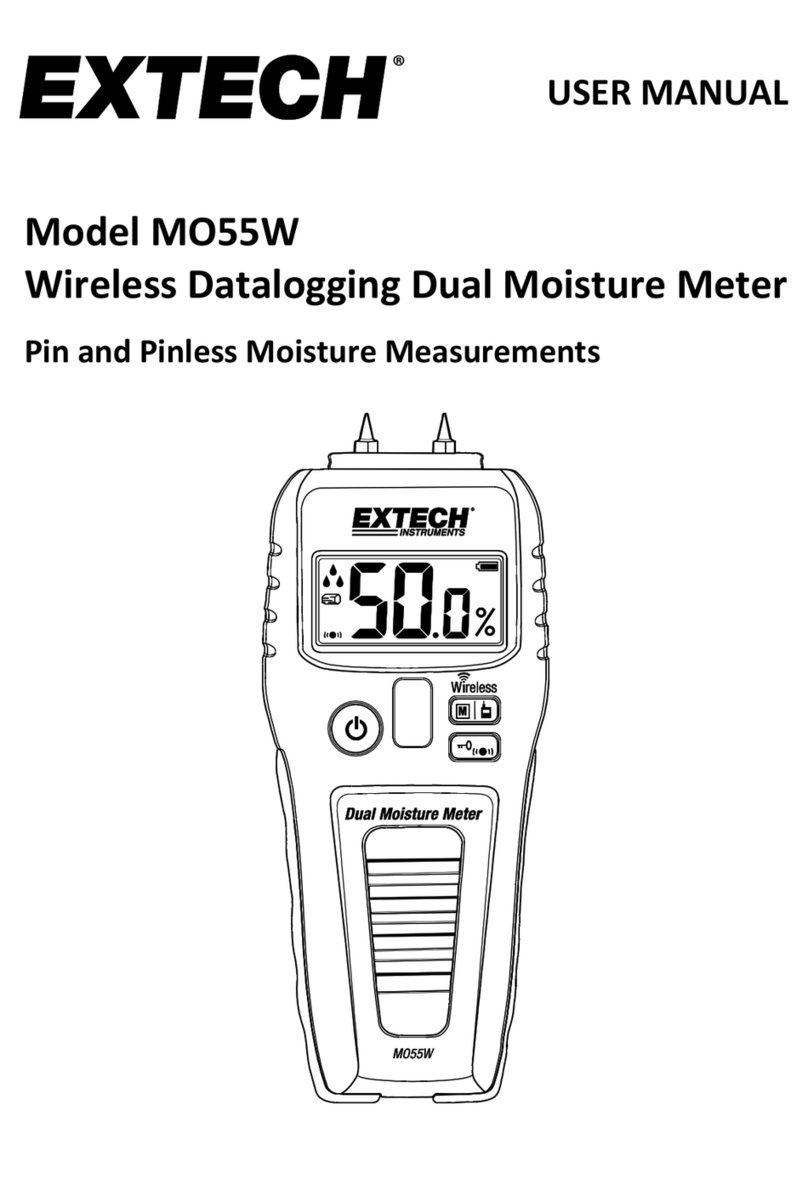

Brief Operating Instructions - Quick Guide BioProTT™Flow Measurement System

Safety instructions

Chapter 2 - Page 6 ff.

Familiarize yourself with the safety instructions!

Setting up and connecting the flow meter

Chapter 6 - Page 15 ff.

Connect the BioProTT™ flow meter to power supply, e.g.

with supplied 24V DC power supply and connect analog or

digital interfaces as needed.

Installing flow sensor

Chapter 7 - Page 29 ff.

Connect Clamp-On Transducer to BioProTT™flow meter

by plugging it into the correct socket.

Please ensure that transducer is proper size for the tubing.

Insert tubing into BioProTT™ Clamp-On Transducer and

close lid. The flow direction is indicated with an arrow.

Prepare Measurement

Chapter 7 - Page 29 ff.

Power the BioProTT™ flow meter on and wait approx. 15s

for initialization.

Usually a sensor will show a flow value even with no flow

present. Zero this (flow value) offset by pressing the

appropriate button or selecting the appropriate menu option.

Note: ensure that

correct calibration table is selected (for sensors with

more than one table programmed)

tubing is filled with medium,

there is sufficient coupling and

the liquid in the tubing not moving (no flow) before

adjusting the zero offset (flow value ml/min!)

Perform custom calibration if necessary

Perform Measurement

Chapter 7.7 - Page 32 ff.

The BioProTT™ flow measurement system is now ready

for use.

Please note: If troubleshooting is necessary please see chapter TROUBLESHOOTING.

BioProTTTM Flow Measurement System Version 1.00 page 3 of 75

TABLE OF CONTENTS

1INTENDED USE.................................................................................................................................... 6

2GENERAL SAFETY AND IMPORTANT INFORMATION........................................................... 6

2.1 GENERAL SAFETY INFORMATION.................................................................................................... 6

2.2 GENERAL IMPORTANT INFORMATION ............................................................................................. 8

3SYMBOLS, UNITS AND ABBREVIATIONS.................................................................................... 9

3.1 SYMBOLS USED IN THESE OPERATING INSTRUCTIONS..................................................................... 9

3.2 SYMBOLS ON EXTERNAL POWER SUPPLY UNIT............................................................................... 9

3.3 SYMBOLS ON FLOW METER,SENSORS AND ON PACKAGING ......................................................... 10

3.4 UNITS............................................................................................................................................ 12

3.5 DEFINITIONS AND ABBREVIATIONS............................................................................................... 12

4DESCRIPTION OF MEASURING PRINCIPLE............................................................................. 13

5PACKAGING CONTENTS................................................................................................................ 14

6INITIAL SET UP................................................................................................................................. 16

6.1 BASIC CONSIDERATIONS AND POWERING OF FLOW METER AND 4-20 MACIRCUITS.................... 16

6.1.1 Wiring in “Active” Set-Up when Flow Meter is Not Relying on Current Loop Power........... 18

6.1.2 Wiring in “Passive” Set-Up when Powering Flow Meter via Current Loop .......................... 20

6.2 INSTALLATION AND OPERATION OF BIOPROTT™ FLOWTRACK................................................... 21

6.2.1 Front Panel BioProTT™ FlowTrack ...................................................................................... 21

6.2.2 Rear Panel BioProTT™ FlowTrack ........................................................................................ 22

6.2.2.1 Pin Assignment and Cable Colors for Round Connector for Digital Interface.............................. 23

6.2.2.2 Pin Assignment and Cable Colors for Round Connector for Power Analogue Flow and RSS

Interfaces 23

6.2.3 Connecting and powering up the system ................................................................................. 24

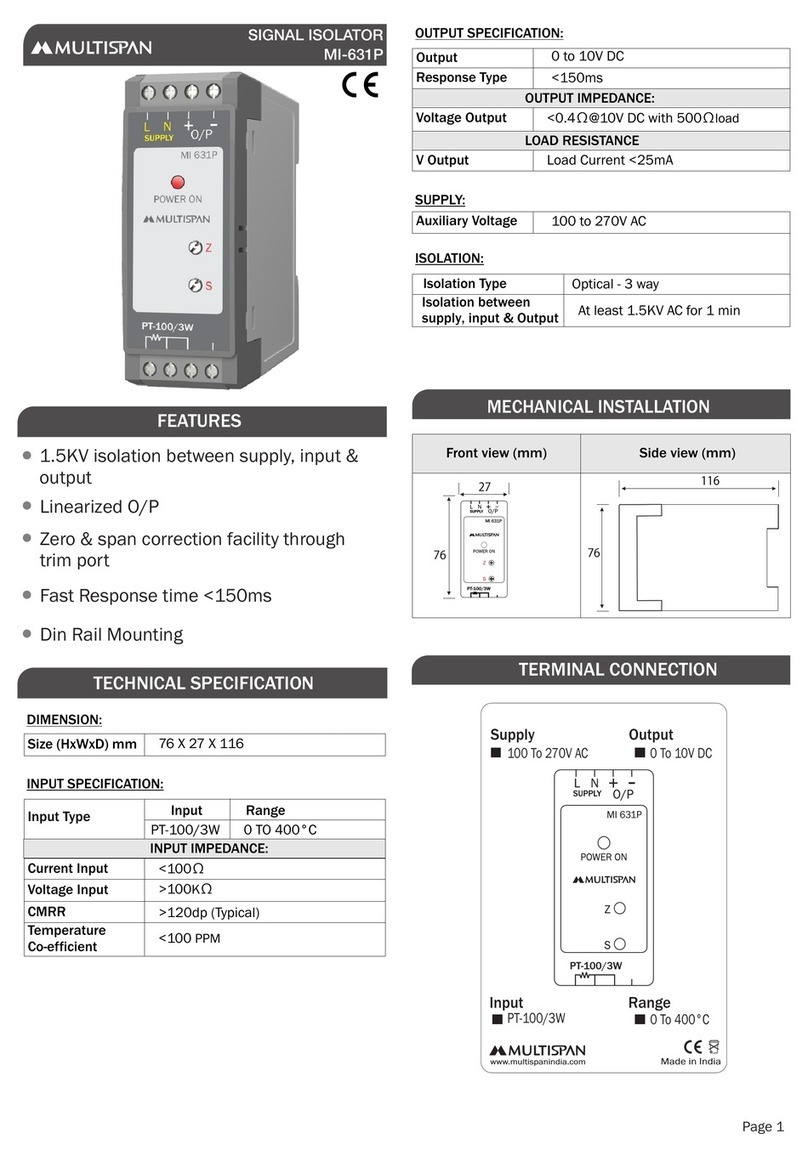

6.3 INSTALLATION AND OPERATION OF BIOPROTT™ FLOWTRACK DINRAIL NOTE:PRELIMINARY

INFORMATION!............................................................................................................................................ 25

6.4 INSTALLATION AND OPERATION OF BIOPROTT™ FLOWTRACK PLUS .......................................... 26

6.4.1 Front Panel BioProTT™ FlowTrack plus ............................................................................... 27

6.4.2 Menu Structure of BioProTT™ FlowTrack plus ..................................................................... 28

6.4.3 Rear Panel BioProTT™ FlowTrack plus ................................................................................ 29

6.4.4 Connecting and Powering up .................................................................................................. 29

6.5 MOUNTING.................................................................................................................................... 30

7PERFORMING MEASUREMENTS ON TUBING SYSTEMS USING BIOPROTTTM CLAMP-

ON TRANSDUCERS.................................................................................................................................... 31

7.1 INSTALLATION OF THE BIOPROTTTM CLAMP-ON TRANSDUCER ................................................. 31

7.2 CLAMPING ONTO TUBE................................................................................................................. 31

7.3 MEASUREMENT ACCURACY AND TUBE ARRANGEMENT............................................................... 32

7.4 RECEIVED SIGNAL STRENGTH (RSS /ACOUSTIC COUPLING)........................................................ 33

7.5 USE OF ACOUSTIC COUPLANT....................................................................................................... 33

7.6 ZERO ADJUSTMENT....................................................................................................................... 35

7.7 PERFORMING FLOW MEASUREMENTS ........................................................................................... 35

7.7.1 Measurement Using the Analog Interface of BioProTT™ FlowTrack, BioProTT™ FlowTrack

plus and BioProTT™ FlowTrack DINrail ............................................................................................. 35

7.7.1.1 Received Signal Strength (RSS / Acoustic Coupling)................................................................... 35

7.7.1.2 Flow Value.................................................................................................................................... 36

7.7.2 Measurement Using the Digital Interface (RS232) of the Different BioProTT™ Flow Meters

38

7.7.3 Measurements Using BioProTT™ FlowTrack plus................................................................. 41

7.7.3.1 Flow Value and Coupling ............................................................................................................. 41

BioProTTTM Flow Measurement System Version 1.00 page 4 of 75

7.7.3.2 Selection of Calibration Table....................................................................................................... 41

7.7.3.3 Selection of Calibration Factor...................................................................................................... 42

7.7.3.4 Adjustment of Brightness.............................................................................................................. 43

7.7.3.5 Totalizing...................................................................................................................................... 43

7.7.3.6 Status and Error Information......................................................................................................... 45

7.7.4 Custom Calibration Procedure................................................................................................ 45

8STATUS INFORMATION, TROUBLESHOOTING, SUPPORT AND SERVICE...................... 47

8.1 AVAILABLE STATUS CODES/INFORMATION FOR FLOW METER..................................................... 47

8.2 AVAILABLE ERROR CODES/INFORMATION FOR FLOW METER ...................................................... 48

8.3 TROUBLESHOOTING ...................................................................................................................... 50

8.4 CHECKING CURRENT LOOPS OF FLOW METER.............................................................................. 52

8.4.1 Method 1 –Using Power from Flow Meter and Measuring with Ampermeter ....................... 52

8.4.2 Method 2 –Providing Power Externally in Current Loop and Measuring with Ampermeter. 54

8.4.3 Method 3 –Checking Functionality with a Voltmeter............................................................. 55

8.5 RECOMMENDED PERIODIC CHECKS............................................................................................... 56

8.6 SUPPORT AND SERVICE ................................................................................................................. 57

8.6.1 Contact Information for Technical Support............................................................................. 57

8.6.2 Returns / RMA ......................................................................................................................... 58

9CLEANING, LOW LEVEL DISINFECTION AND MAINTENANCE......................................... 59

9.1 CLEANING OF THE BIOPROTTFLOW METER.............................................................................. 59

9.2 CLEANING AND DISINFECTION OF THE CLAMP-ON TRANSDUCER................................................. 60

10 APPROVAL INFORMATION........................................................................................................... 61

10.1CE MARK...................................................................................................................................... 61

10.2 ELECTRICAL SAFETY AND ELECTROMAGNETIC COMPATIBILITY................................................... 61

11 TECHNICAL DESCRIPTION........................................................................................................... 62

11.1 TECHNICAL DATA BIOPROTT™ FLOWTRACK /BIOPROTT™ FLOWTRACK PLUS ....................... 62

11.2 TECHNICAL DATA BIOPROTT™ CLAMP-ON TRANSDUCER.......................................................... 63

12 ENVIRONMENTAL PROTECTION AND DISPOSAL................................................................. 66

13 MANUFACTURER'S DECLARATIONS......................................................................................... 67

13.1 INFORMATION ON ACOUSTIC OUTPUT DATA................................................................................. 67

13.2 DECLARATION OF CONFORMITY ................................................................................................... 69

14 ORDERING INFORMATION FOR THE BIOPROTTTM FLOW MEASUREMENT SYSTEM

AND ACCESSORIES................................................................................................................................... 70

15 RETURN INFORMATION AND DECLARATION OF CONTAMINATION............................. 72

16 APPENDIX........................................................................................................................................... 74

16.1 CALIBRATION PROTOCOL FOR BIOPROTT™ CLAMP-ON TRANSDUCERS...................................... 74

BioProTTTM Flow Measurement System Version 1.00 page 5 of 75

Read these Operating Instructions carefully before starting up the

device!

Although the BioProTTTM flow measurement system represents state-of-the-art

technology, the user may be put at risk if the device is operated incorrectly. You should

therefore carefully read the Operating Instructions before use.

These instructions contain important information on the safe handling of the BioProTTTM

flow measurement system and accessories. Read these Operating Instructions carefully

before using the device and accessories, and keep them in an easily accessible location.

Familiarize yourself with and observe all warning and safety information.

It is the responsibility of the operator of the device to ensure it is used, inspected and

maintained in accordance with the Operating Instructions. Subsequent revisions or

instructions from the manufacturer must also be taken into account in this regard.

The manufacturer reserves the right to modify technical data without prior notice. Your

local distributor will supply you with current information and updates to these Operating

Instructions.

Please note:

When BioProTTTM is used in this manual, it usually refers to the complete flow

measurement system consisting of flow meter and Clamp-On Transducer.

There are 3 versions of the flow meter:

oBioProTT™ FlowTrack: flow meter without display in standard industry

housing.

oBioProTT™ FlowTrack DINrail: flow meter without display for DIN rail

mounting.

Please note: this flow meter is not available yet

oBioProTT™ FlowTrack plus: flow meter with display and enhanced

functionality in standard industry housing

The differences of the flow meters (including SW features) will be pointed out in

the appropriate chapters.

This manual covers the following software versions of the BioProTTTM flow meter:

oFT_GFX_EV2200

The software version can be retrieved using the display or the digital

interface.

BioProTTTM Flow Measurement System Version 1.00 page 6 of 75

1Intended Use

If this device is not used as intended, the user may be exposed to

risks that were not taken into account during development.

The BioProTTTM flow measurement system is designed for non-invasive measurement

of volumetric flow of liquids. The measurement is based on the ultrasonic transit time

method. Usually used in laboratory, bioprocess and industrial processes.

2General Safety and Important Information

2.1 General Safety Information

Warning! The general safety information below must be observed

without fail to ensure safe handling of the device

Type of danger

Safety information

Risk of explosion

The BioProTTTM flow measurement system is not designed for use

in an explosive atmosphere or with explosive mediums. Take care

when using oxidants or flammable gases.

Risk to electrical

safety, or of

increased

electromagnetic

emissions or

lower resistance

of device to

interference

Use of accessories, power supply units, cables (lines) and sensors

other than those specified in these Operating Instructions is not

permitted.

Any external power supply that is not supplied with the system shall

have an output voltage of 24 V DC (±10%), must be current limited

to max. 6.25 A and continuously short circuit proof.

The device must not be used in residential areas.

Please ensure that all national requirements with respect to EMC

and electrical safety regulations are met when connecting a power

supply that was NOT originally shipped.

See chapter ELECTRICAL SAFETY AND ELECTROMAGNETIC

COMPATIBILITY; see chapter INITIAL SET UP

BioProTTTM Flow Measurement System Version 1.00 page 7 of 75

Type of danger

Safety information

Risk to safety due

to defective

device, applied

parts or

accessories

A defective device, sensors/parts or accessories must not be used

and must be replaced immediately. This applies in particular if the

cable insulation is damaged or if parts have broken off or are bent.

Electric shock

The power supply unit may not be immersed into liquids. However,

in the event of the ingress of liquid, pull out the power plug

immediately. Stop using the device and send it to our back for

inspection; see chapter RETURNS / RMA.

Malfunctions,

inaccurate

measured value

due to high-

frequency devices

The BioProTTTM flow measurement system may be influenced by

radio frequency (RF) devices. This includes mobile RF

communication equipment. Use of a RF device in the vicinity of the

BioProTTTM flow measurement system may also cause its

accessories to malfunction which may, among other things, lead to

measured values being provided inaccurately or incorrectly.

Overheating of

the device &

power supply

Prevent the device and power supply from being covered and direct

heat or sun radiation.

Faulty repairs

Repairs to the device shall only be carried out by authorized service

personnel. Unauthorized repairs will void manufacturer’s warranty.

Faulty electrical

installation

Comply with the installation requirements; refer to the chapter

ELECTRICAL SAFETY AND ELECTROMAGNETIC

COMPATIBILITY.

Measuring

inaccuracy,

Risk to electrical

safety

The measuring accuracy and safety-relevant aspects should be

checked at least every 2 years. Please refer to chapter

RECOMMENDED PERIODIC CHECKS for details

Risk of

infection/environ-

mental

contamination

due to improper

disposal

The device and accessories must be disposed of in accordance with

the national specifications for waste electrical and electronic

devices.

In case microbial contamination may be present on the device after

being used, we recommend you dispose of these separately in

accordance with the applicable regulations.

In case microbial contaminated, device or accessories shall be

cleaned and disinfected before they are sent to the manufacturer.

Do not return a device/sensor if you are not absolutely certain that

all traces of hazardous substances have been removed, e.g.

substances which have penetrated crevices or diffused through

plastic. Refer to chapter RETURN INFORMATION AND

DECLARATION OF CONTAMINATION for additional

information.

For more application-specific warnings, refer to the corresponding chapters.

The manufacturer only considers itself to be responsible for the safety, reliability and

usability of the device if:

The device is used in accordance with the instructions for use.

BioProTTTM Flow Measurement System Version 1.00 page 8 of 75

Installation, connection to the electricity supply and process control system,

additions, readjustments, changes or repairs and maintenance are only carried out

by qualified persons who have been authorized and trained. These qualified persons

must have read and understood this manual and must follow them accordingly.

The flow measurement system must be operated by persons authorized and trained

by the plant operator. Compliance with the instructions in this manual is

compulsory.

The manufacturer provides no warranty and assumes no liability in the event of non-

compliance with the above.

2.2 General Important Information

The following symbols are used in these Operating Instructions to highlight specific

information.

Caution! Important information regarding correct handling. To be

carried out and strictly observed!

If this following information is not observed, faults or damage to the

product or its surroundings may occur.

Type of damage

Important information

Electrical

malfunction or

irreparable

damage

The BioProTTTM flow measurement system is intended to be used

with its own power supply (shipped with the system) or e.g. within

electrical control cabinets with their own power supply.

The DC power supply line shall be shorter than 30 m and shall not

leave the building.

Damage due to

ultrasonic sound

At all device settings of the BioProTTTM flow measurement system

the Clamp-On Transducer generates ultrasonic sound only at a low

acoustic output level.

The ultrasonic sounds generated are harmless to persons, protein

solutions (e.g. blood, blood cells) and the environment according to

current knowledge, providing the system is used properly.

For more detailed information, see chapter INFORMATION ON

ACOUSTIC OUTPUT DATA.

BioProTTTM Flow Measurement System Version 1.00 page 9 of 75

3Symbols, Units and Abbreviations

All symbols and abbreviations used are explained in this chapter.

3.1 Symbols used in these Operating Instructions

The following symbols are used in these Operating Instructions to highlight specific

information.

Symbol

Meaning

Warning!

This safety symbol precedes critical information that must be strictly

observed in order to prevent injuries and fatal hazards. This warning

symbol is the most important safety symbol.

Caution!

Important information regarding correct handling. Must be performed

and strictly observed!

If this information is not observed, faults or damage to the product or

its surroundings may occur.

3.2 Symbols on External Power Supply Unit

Symbol

Meaning

Alternating current:

Alternating current must be fed to the supplied external power supply

unit. The values for the supply voltage must correspond to those of the

power supply unit: 100-240 VAC / 50-60 Hz.

Friwo Gerätebau GmbH (manufacturer)

Protection Class II (protective insulation)

As a safety guarantee, this power supply unit has additional insulation

to prevent dangerous touch voltage in the event of a fault. A PE

conductor must not be connected to this device.

IP40

Protected against access by wire

Do not dispose of this device as domestic waste!

Devices that have been placed on the market on or since 13.08.2005

must be disposed of as waste devices according to Directive

2002/96/EEC (WEEE) and national legislation.

CE marking: The external power supply unit satisfies the requirements

of Low Voltage Directive 2006/92 EC and EMC Directive 2004/108

EC.

UL test mark for recognized components for Canada and the USA by

Underwriter Laboratories Inc.

BioProTTTM Flow Measurement System Version 1.00 page 10 of 75

Symbol

Meaning

Direct current

(24 V DC from external power supply unit)

Caution

Further warnings and precautions exist.

(Refer to these instructions for use)

3.3 Symbols on Flow Meter, Sensors and on Packaging

Symbol

Meaning

Caution

Further warnings and precautions exist.

(Refer to these instructions for use)

IP65

Protected against dust and high pressure water jets / wash down from all

directions (BioProTT™FlowTrack, BioProTTFlowTrack plus,

BioProTT™ Clamp-On Transducer).

Please note: Unused connector sockets should be covered e.g. with the

provided flexible grip caps to avoid accumulation of dirt or any

potential short circuits.

IP20

Protected against access by finger (BioProTT™FlowTrack DINrail)

Direct current

(24 V DC from external power supply unit)

Do not dispose of this device as domestic waste!

Waste devices must be disposed of in accordance with Directive

2002/96/EEC and national legislation.

Manufacturer:

em-tec GmbH

Lerchenberg 20

86923 Finning

Germany

Serial number

Order number

CE marking: The device satisfies the requirements of EMC Directive

2004/108 EC

BioProTTTM Flow Measurement System Version 1.00 page 11 of 75

Symbol

Meaning

FCC-Mark that the United States Federal Communication Commission

authorized the device

Caution, fragile!

Handle with care!

Protect against moisture! Store in a dry place.

Temperature limit during storage

non-

condensing

Moisture limit during storage (non-condensing)

Air pressure limit

Storage

Transport

BioProTTTM Flow Measurement System Version 1.00 page 12 of 75

3.4 Units

Unit

Meaning

"

Tube size in inches, 1 inch ≈25.4 mm

ID" x WT"

Tube dimensions in inches:

Internal diameter ID x wall thickness WT

Outer diameter = internal diameter ID + 2 x wall thickness WT

3.5 Definitions and Abbreviations

Definitions,

Abbreviation

Meaning

CT / BCT

Clamp-On Transducer respectively BioProTTClamp-On Transducer

flow meter

BioProTT™ FlowTrack, BioProTTFlowTrack plus,

BioProTTFlowTrack DINrail

flow sensor

BioProTTClamp-On Transducer

PCS

Process Control System

ID

Inner diameter

OD

Outer diameter

TT

Transit-Time

RSS

Received Signal Strength which corresponds to the acoustic coupling

WT

Wall thickness

BioProTTTM Flow Measurement System Version 1.00 page 13 of 75

4Description of Measuring Principle

The physical measurement principles applied in the BioProTTTM flow measurement system

are described in this chapter.

The BioProTTTM flow measurement system uses the ultrasonic transit-time method (TT =

transit-time) which delivers precise flow values in tube systems and pipes.

The ultrasonic converters (piezoceramics) in the flow sensors transmit high-frequency

acoustic signals in and against the flow direction. The time difference between these

signals is proportional to the volumetric flow.

The basic principle is explained below.

Transmitter/

Receiver

Receiver/

Transmitter A

B

Tube

Flow

a

Figure 1: Principle of ultrasonic flow measurement (simplified using only two ceramics)

One piezoceramic (A) is excited by a set of high-frequency vibrations and transmits

ultrasonic waves to a second opposing piezoceramic (B) that acts as a receiver. The

piezoceramics are arranged at a specific angle α in relation to the flowing medium. The

transit time is influenced by the medium. The flow velocity of the medium can be

calculated using the measured transit time differences. The flow in litres per minute is

established using the known cross-section of the tube being scanned by ultrasonic

transmission.

Four ultrasound converters in a crosswise arrangement transmit high-frequency sound

signals alternately in and against the direction of the flow. The transit time for each

impulse is measured; the transit-time difference between the upstream and downstream

movement of the impulses is proportional to the volumetric flow.

BioProTTTM Flow Measurement System Version 1.00 page 14 of 75

5Packaging Contents

The BioProTTTM flow measurement system is shipped including the following

components:

Flow meter in either of the following variants:

oBioProTT™ FlowTrack (without display), or

oBioProTT™ FlowTrack plus (with display)

oBioProTT™ FlowTrack DINrail (without display for DIN rail mounting)

Please note: Flexible grip caps are provided for all sockets and should not be

removed until a socket is actually used to avoid any dirt accumulation or any

potential short circuits.

Power supply with country specific adaptor. Currently the following adaptors are

available: EURO, UK, USA/JAPAN, IEC - others on request.

Two (2) pre-configured 2 m long cables with plug on one end and terminal blocks on

other end.

One (1) pre-configured cable, 2 m long, for digital output with plug on one end and

standard female D-sub connector.

BioProTTTM Flow Measurement System Version 1.00 page 15 of 75

A male D-Sub to USB adapter for connection to standard USB ports.

Please download current driver from link specified on actual adapter labeling.

Terminal block adapter - BioProTT™ FlowTrack DINrail only

Extension cable for flow sensor in process control cabinet - BioProTT™ FlowTrack

DINrail only

Please note: a picture is not yet available

BioProTTTM Clamp-On Transducer.

The BioProTTTM Clamp-On Transducer is shipped pre calibrated and ready to be

connected to either of the flow meters.

Printed Manual.

BioProTTTM Flow Measurement System Version 1.00 page 16 of 75

6Initial Set Up

6.1 Basic Considerations and Powering of Flow Meter and 4-20 mA

Circuits

Generally, devices in 4-20 mA environments can be classified based on the current source

of the 4-20 mA loop as “active”or “passive”. Passive (or 2-wire) devices rely on loop

power, whereas active (or 4-wire) devices are providing power i.e. there is a separate

power supply for the device and the loop.

The BioProTT™ flow measurement system supports both modes of operation. However,

the flow meter always needs power to operate!

In a 2 wire environment with the DC power supply located e.g. at the process control the

flow meter and the current loop are powered via PCS.

Alternatively the flow meter (always requiring a power supply!) can also provide power to

the current loop.

4-20mA

1

Sensor

31 3 1 3 1 3

Power Flow RSS

sockets with pin numbers

4

2

BioProTT flow meter RSS +

socket -

Digital

Electronics 4

2

Flow +

socket -

PCS

-

+

+ -

+ 24V

4-20mA -

+

+ -

Socket sample

with pin assignment

RS 232

Power supply for flow meter

Flow and RSS current loops

incl. power supply

Figure 2: BioProTT flow meter schematics with focus on power supply

The figure above shows some of the electrical design which is important to properly wire

the system. The pin assignment corresponds to the pins as outlined the in following

chapters.

BioProTTTM Flow Measurement System Version 1.00 page 17 of 75

As discussed the flow meter needs power to operate, which can be provided:

With the power supply unit supplied with the flow meter (via power socket)

With another (different) external DC power supply

othis power source can be either the power source of the 4-20 mA loop

oor separate 24 V DC power supply

Please note:

When power is supplied via the power socket the on/off switch is used to power on the

flow meter otherwise the on/off switch does not have an effect

Ensure that there are no conflicting power sources/voltages applied to

Pin 1 and Pin 3 of either of the Power, Flow or RSS socket, as this they are internally

bridged between the sockets.

Below pin assignments and cable colors for round connectors for Power, Flow and RSS

sockets are shown (identical for all flow meter variants).

Figure 3: BioProTTflow meter rear view with one analogue plug connected -example w/ Flow socket

Figure 4: BioProTTview of power and analogue Flow and RSS socket

Pin No

Signal Power

Signal Flow/RSS

Wire color

(in supplied cabling)

1

24 V (24C_in)

24 V (24C_in)

Brown

2

Not assigned

Current Loop +

White

3

Ground in (GND_in)

Ground in (GND_in)

Blue

BioProTTTM Flow Measurement System Version 1.00 page 18 of 75

4

Not assigned

Current Loop -

Black

Details can be found in the following chapters.

6.1.1 Wiring in “Active” Set-Up when Flow Meter is Not Relying on

Current Loop Power

As discussed above, in an “active set-up” the device is not relying on current loop power,

instead the power supply used to power the device is also used to power the current loop.

This and the “active” wiring are shown in more detail below.

DC power can be supplied with the power supply unit shipped with the system. If this

power supply unit is not used, DC power can be supplied either through PIN 1/3 of the

Power, Flow or RSS socket using a compatible connector, e.g. from BINDER (part number

99 0079 100 04 - CIRCULAR, CONNECTOR, PLUG, 4POS).

This is e.g. useful, when connecting it to a process control and centrally powering the

devices on or off. In case power is provided via the Flow or RSS socket, the on/off button

is no longer “active”, i.e. the flow meter will start up as soon as power is available.

If power is supplied via the power socket please observe the on/off button.

The “active” set-up means that the power supply used to power the flow meter is also used

to power the current loop. To do so, a wire bridge is applied from Pin 1 to Pin 2 of the

Flow respective RSS cable.

BioProTTTM Flow Measurement System Version 1.00 page 19 of 75

For details see the circuit diagram below and observe the wiring instructions.

Figure 5: BioProTT flow meter rear view with one analogue plug connected -example w/ flow socket

Pin No

Flow / RSS

Wire color

(in supplied cabling)

Connected with

1

24 V (24C_in)

Brown

+ 24 V DC supply

2

Current Loop +

White

Connect Pin 1

with Pin 2

3

Ground in (GND_in)

Blue

Ground (GND) /

Return of PCS

4

Current Loop -

Black

Send (+) of PCS

Figure 6: Schematics - looking at pins of rear of flow meter of either Flow or RSS socket

Please note: the basic wiring diagram is identical to the “active” set-up, just the

power source is different.

3

4

2

1

PIN 1: +24 V

PIN 3: Ground (GND)

PIN 4: Current Loop (-)

PIN 2: Current Loop (+)

Return (-) Send(+)

of PCS

- +

+ -

BioProTTTM Flow Measurement System Version 1.00 page 20 of 75

6.1.2 Wiring in “Passive” Set-Up when Powering Flow Meter via

Current Loop

In a passive set-up, the current loop provides its own power as per definition. The power

from the current loop is then also used to operate the flow meter.

Since the flow meter always needs power to operate, you need to apply a logical “jumper”

to use the power from the current loop and provide it to the flow meter. This is explained

in detail below.

Figure 7: BioProTT flow meter rear view with one analogue plug connected -example w/ RSS socket

Pin No

Flow / RSS

Wire color

(in supplied cabling)

Connected with

1

24 V (24C_in)

Brown

Connect Pin 1 with Pin 2

Note: due to the wire bridge,

the flow meter is now powered

also!

2

Current Loop +

White

[see above]

3

Ground in

(GND_in)

Blue

Ground (GND) / Return of

PCS

4

Current Loop -

Black

Send (+) of PCS

Figure 8: Schematics - looking at pins of rear of flow meter of either Flow or RSS socket

Please note: only supply power to the flow meter via one of the sockets to avoid any

potential electrical problems. Either Flow or RSS socket pins can be used, when

power is supplied from the loop.

3

4

2

1

PIN 1: +24 V

PIN 3: Ground (GND)

PIN 4: Current Loop (-)

PIN 2: Current Loop (+)

Return (-) Send (+)

of PCS

Table of contents

Other Emtec Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Trolex

Trolex XD One user manual

PCB Piezotronics

PCB Piezotronics X3501A2060KG Installation and operating manual

AXIOMA METERING UAB

AXIOMA METERING UAB QALCOSONIC E4 Technical operation guide

Extech Instruments

Extech Instruments MO55W user manual

Bushnell

Bushnell PRIME LP520KB manual

JB

JB DV-22N operating manual