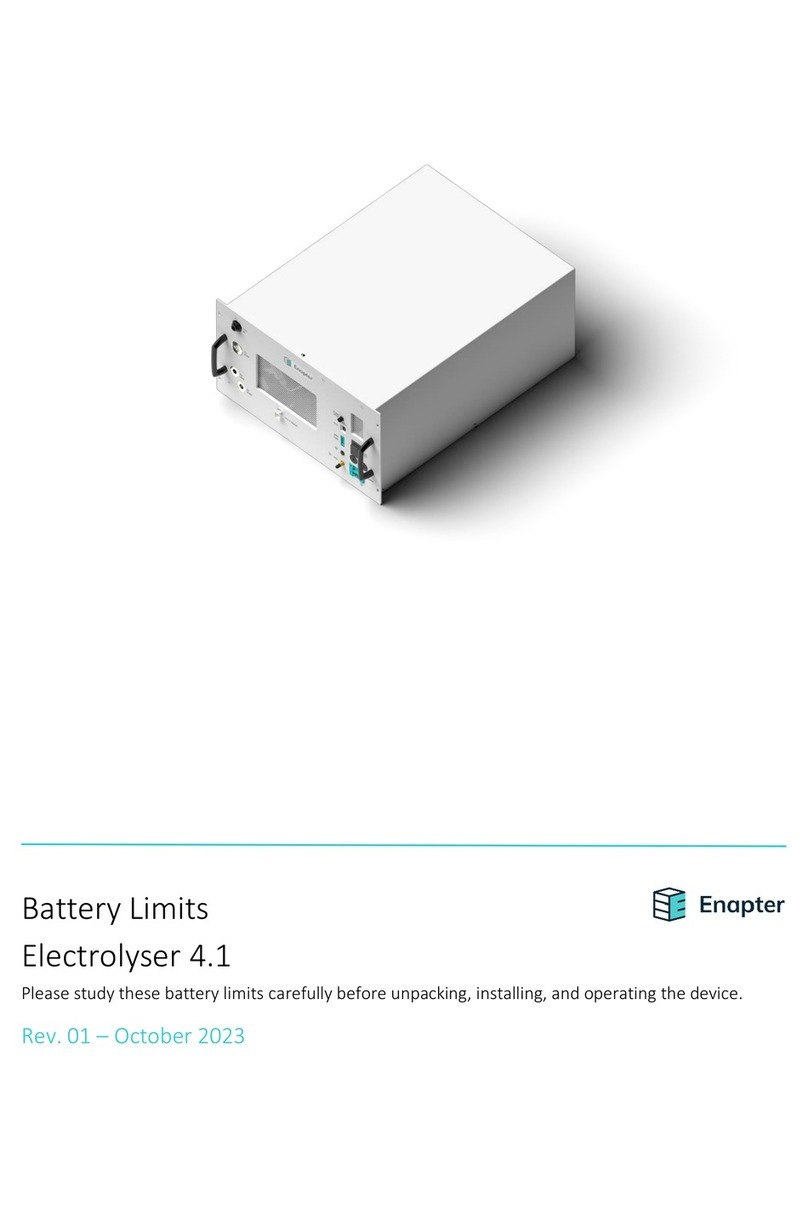

EL –Battery Limits –Rev.01 –September 2022V

TABLE OF CONTENTS

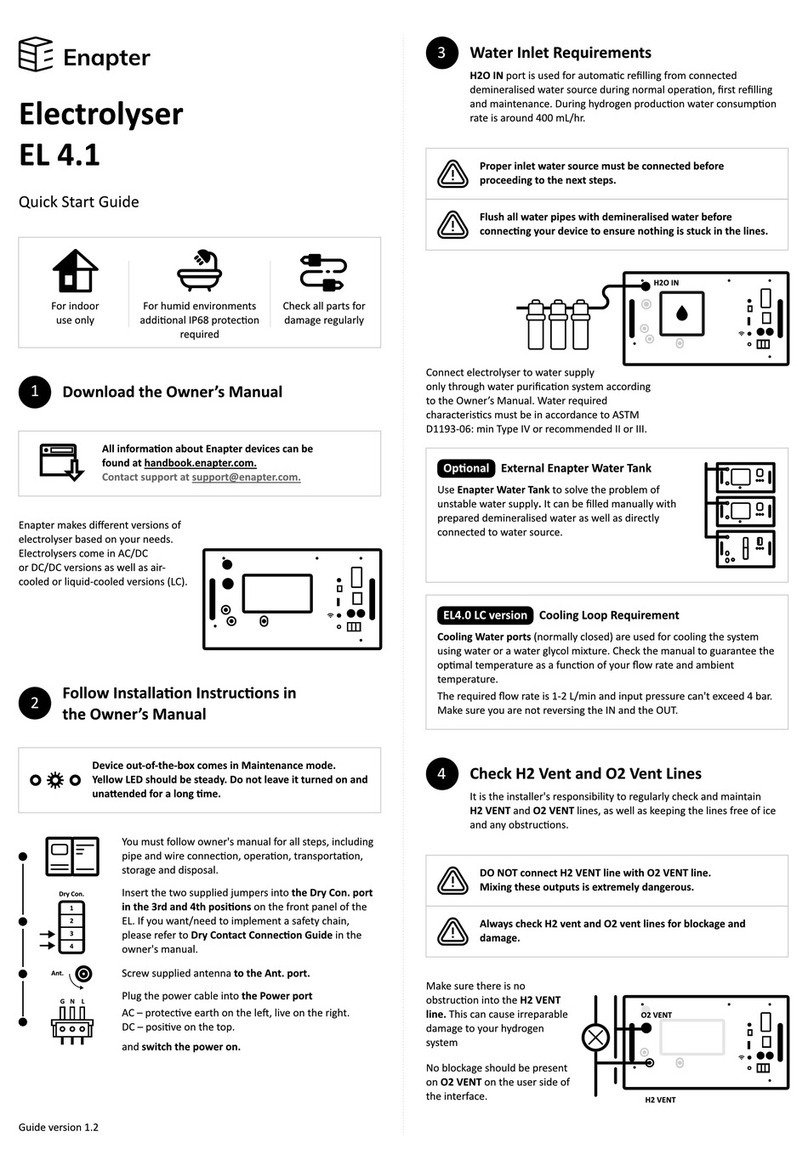

1.Device Interfaces ................................................................................................................ 7

2.Interfaces specifications...................................................................................................... 9

2.1 H2O IN................................................................................................................................ 9

2.2 O2 VENT............................................................................................................................. 9

2.3 COOLING WATER IN / OUT................................................................................................ 10

2.4 H2 OUT ............................................................................................................................ 10

2.5 H2 VENT........................................................................................................................... 11

2.6 FILL / DRAIN ..................................................................................................................... 11

2.7 START / STOP ................................................................................................................... 12

2.8 POWER............................................................................................................................. 12

2.9 ETHERNET ........................................................................................................................ 12

2.10 DRY CON .......................................................................................................................... 12

2.11 WiFi BUTTON ................................................................................................................... 13

2.12 ANTENNA......................................................................................................................... 13

2.13 ON/OFF BUTTON / BREAKER............................................................................................. 13

2.14 FUSES............................................................................................................................... 13

2.15 HANDLE BAR .................................................................................................................... 13

2.16 FRONT MESH.................................................................................................................... 13

2.17 LED .................................................................................................................................. 13

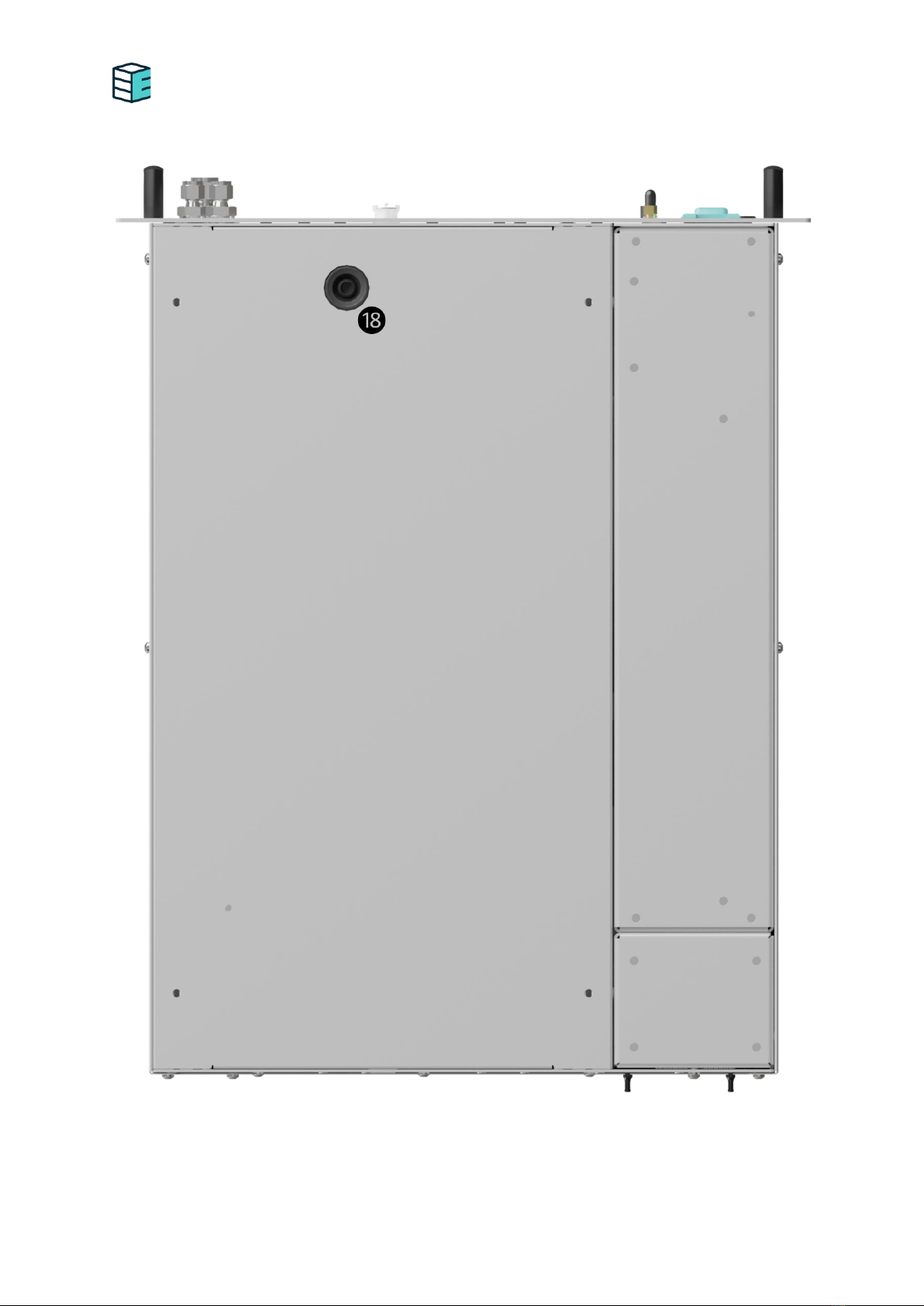

2.18 LEAKAGE DRAIN HOLE ...................................................................................................... 13