EL4.1 –Owner’s Manual – Rev.01 –October 2023V

4.6 Instructions for connecting plastic tubes........................................................................... 28

4.7 Electrical Connection Guide (POWER)............................................................................... 36

4.8 Dry Contact Connection Guide (Optional) (DRY CON.) ....................................................... 38

4.9 Ethernet Port (ETH.) ......................................................................................................... 41

4.10 ISO 22734 Requirements .................................................................................................. 42

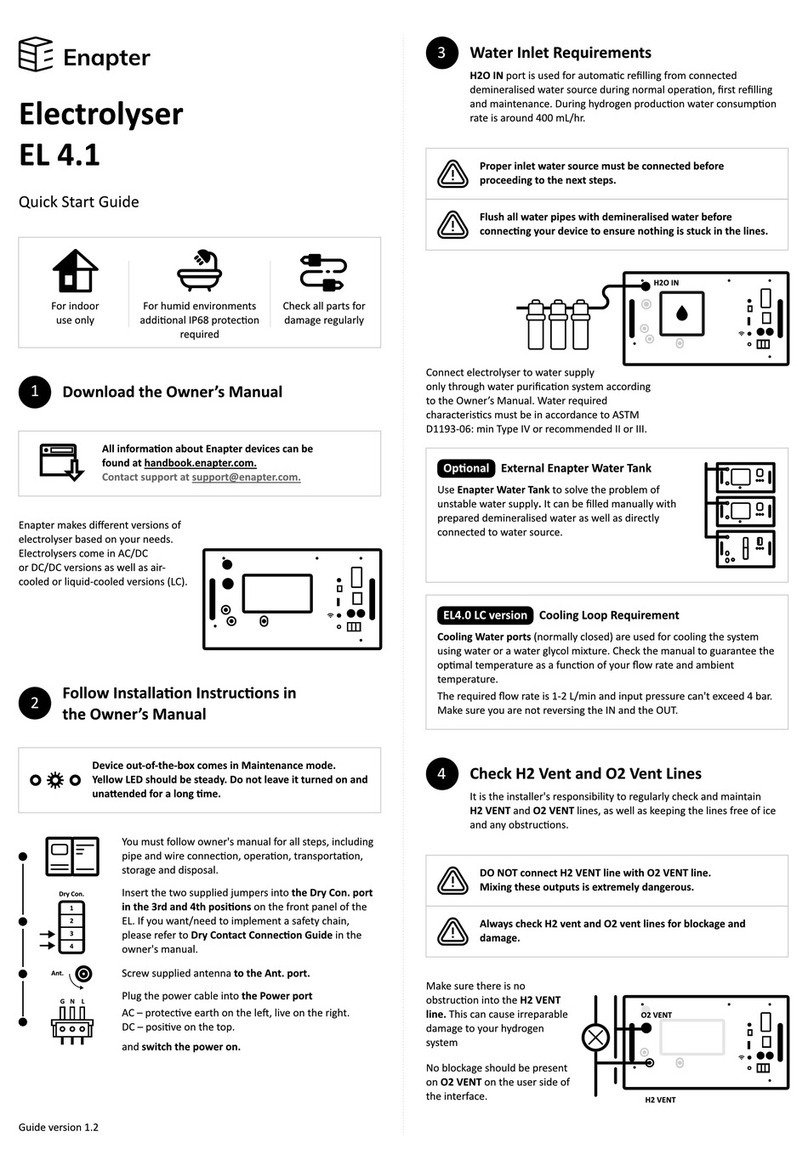

4.11 Initial operation of the electrolyser................................................................................... 42

5. Operation of the Electrolyser ........................................................................................ 46

5.1 Manual Start/Stop............................................................................................................ 46

5.2 Remote Start/Stop............................................................................................................ 46

5.3 Automatic Start/Stop........................................................................................................ 46

5.4 Maintenance Mode.......................................................................................................... 47

5.5 Set Production Rate.......................................................................................................... 47

5.6 Ramp Up .......................................................................................................................... 47

5.7 Ramp Down...................................................................................................................... 48

5.8 Anti-Freezing Routine....................................................................................................... 48

5.9 Preheat Function.............................................................................................................. 48

5.10 Safety Heartbeat .............................................................................................................. 48

5.11 Troubleshooting............................................................................................................... 49

6. Enapter Monitoring Tools ............................................................................................. 51

6.1 Mobile Application ........................................................................................................... 51

7. Maintenance of the Electrolyser.................................................................................... 52

7.1 Updates ........................................................................................................................... 52

7.2 Routine Maintenance....................................................................................................... 52

7.3 5-year Major Maintenance ............................................................................................... 54

7.4 Cleaning........................................................................................................................... 54

7.5 Disposal ........................................................................................................................... 55

7.6 Transport ......................................................................................................................... 55

8. Appendix ...................................................................................................................... 57

Appendix I. Hydrogen Leak Testing.................................................................................................................... 57

Appendix II. Preparing fresh electrolyte ............................................................................................................ 58

Appendix III. Draining the electrolyte ................................................................................................................ 59

Appendix IV. LED States...................................................................................................................................... 61

Appendix V. Error Codes..................................................................................................................................... 61

Appendix VI. Water Specifications ..................................................................................................................... 61