Enatel PSX24051 Series User manual

Enatel DC System Manual Page 1 of 31

1U MICRO Compact System

PSX24042x1F-x00 &

PSX24051xF-x00

Installation Manual

V2.1

Manufactured by Enatel Ltd.

321 Tuam Street

PO Box 22-333

Christchurch

New Zealand

Phone +64-3-366-4550

Fax +64-3-366-0884

Email [email protected]

www.enatel.net

Copyright © Enatel Ltd. 2010

Enatel DC System Manual Page 2 of 31

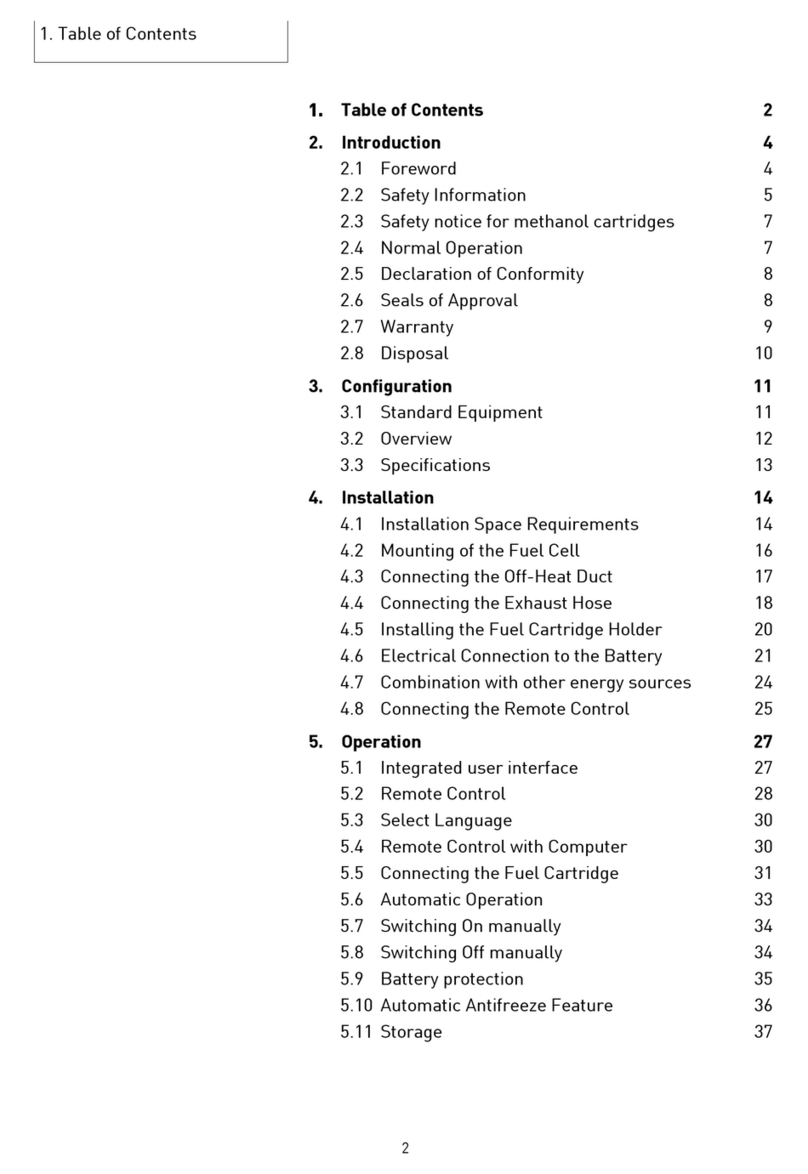

TABLE OF CONTENTS

1.0 Scope..............................................................................................................................4

2.0 System Overview.............................................................................................................5

3.0 Installation .......................................................................................................................6

3.1 Unpacking & Installing in 19” Rack...............................................................................6

3.2 Installing in ETSI Rack.................................................................................................6

3.3 AC Cabling...................................................................................................................7

3.3.1 Upstream Over-current Protection.........................................................................7

3.4 DC Cabling...................................................................................................................9

3.5 Alarm/Ancillary Cabling..............................................................................................10

4.0 Alarm Mapping to Volts-free Relays...............................................................................12

5.0 Circuit Breaker Fail Monitoring.......................................................................................13

6.0 LVD Operation...............................................................................................................14

7.0 DC Earthing...................................................................................................................15

8.0 Commissioning..............................................................................................................16

8.1 System Pre-check:.....................................................................................................16

8.2 Rectifier Start-up........................................................................................................16

8.3 Battery Start-up..........................................................................................................16

8.4 Load Start-up .............................................................................................................16

8.5 DC System Commissioning Check-List......................................................................18

9.0 Maintenance..................................................................................................................22

10.0 Appendix 1 - Rectifier Input Fuse Curves.......................................................................23

11.0 Appendix 2 - System Wiring Diagrams...........................................................................24

Appendix 3 - AC Input Transient Protection..............................................................................28

Appendix 4 - Model Specifications............................................................................................30

11.1 System Part Numbers - 3 Rectifier.............................................................................30

11.2 System Naming Convention.......................................................................................31

Enatel DC System Manual Page 3 of 31

Receiving Instructions

CAUTION:

For your protection, the following information and the product manual should

be read and thoroughly understood before unpacking, installing and using the

equipment.

We present all equipment to the delivering carrier securely packed and in perfect condition.

Upon acceptance of the package from us, the delivering carrier assumes responsibility for its

safe arrival to you. Once you receive the equipment, it is your responsibility to document any

damage the carrier may have inflicted, and to file your claim promptly and accurately.

Package Inspection

•Examine the shipping crate or carton for any visible damage: punctures, dents and any

other signs of possible internal damage.

•Describe any damage or shortage on the receiving documents and have the carrier sign

their full name.

Equipment Inspection

•Within fifteen days, open crate or carton and inspect the contents for damages. While

unpacking, be careful not to discard any equipment, parts or manuals. If any damage is

detected, call the delivering carrier to determine the appropriate action. They may require

an inspection.

Save all the shipping materials for the inspector to see!

•After the inspection has been made and you have found damage, call us. We will determine

if the equipment should be returned to our plant for repair or if some other method would be

more expeditious. If it is determined that the equipment should be returned to us, ask the

delivering carrier to send the packages back at the delivering carrier’s expense.

•If repair is necessary, we will invoice you for the repair so that you may submit the bill to the

delivering carrier with your claim forms.

•It is your responsibility to file a claim with the delivering carrier. Failure to properly file a

claim for shipping damages may void warranty service for any physical damages later

reported for repair.

Handling

Handle the equipment with care. Do not drop or lean on front panel or connectors. Keep away

from moisture.

Identification Labels

Model numbers are clearly marked on all equipment. Please refer to these numbers in all

correspondence with Enatel.

Enatel DC System Manual Page 4 of 31

1.0 S

COPE

This manual covers essential information for the installation and commissioning of the 1U

MICRO Compact Enatel Compact DC Power System Range (see Appendix for individual model

specifications).

System set-up for the rectifiers, alarms etc., are provided in separate manuals for the SM35/6

supervisory module and RM848 rectifier.

All installation and maintenance must be carried out by suitably qualified personnel.

Note: The 1U MICRO Compact system is available with positive earthing (fixed) or

positive/negative earthing (user selectable - negative earth as default). The installation

manual covers both earthing varieties, the standard system is assumed to be fixed

positive earthing. Where parameters and settings differ between systems, the negative

earthed system parameters will be specified within parenthesis i.e.( ).

Enatel DC System Manual Page 5 of 31

2.0

S

YSTEM

O

VERVIEW

Systems with a model number beginning with PSX24 can hold three rectifier modules and have

a maximum power output of 2.4kW, producing a maximum current output of 44.4A at 54Vdc.

The system is intended to be a complete power system in a box, so no connections need to be

made internally. AC connection is via rear exiting lead with all the DC (Load and Battery)

connections are made at the front of the unit. Alarm connections are accessible from the front.

The system is designed to be extremely simple to install and set up.

The following is a summary of the system:

-Overall size is 483mm wide (19” standard mounting) x 44.5mm high (1U) x 280mm deep

(within ETSI specification)

-Optional ETSI mounting tabs included

-Up to 3* RM848 series rectifiers - may be packaged separately

-SM3x supervisory module (fully integrated in the system)

-Battery Low Voltage Disconnect fitted as standard (80A rating).

-Up to 2*x 30A Battery Circuit Breaker, this may be specified as different values (from 2A to

30A) at time of order.

-Up to 4*x Load Circuit Breaker, this may be specified as different values (from 2A to 30A) at

time of order. If only one Battery Circuit Breaker is fitted, a 5

th

load breaker can be specified

at time of order.

-System weight is approximately 3.6kg without rectifiers, and 5.6kg with three rectifiers fitted.

-Single phase lead supplied for input termination (phase, neutral and earth)

-Front or rear cable access

*values shown are maximum values and depend upon model selected. Please see model

numbers and descriptions in the appendix of this manual.

Note:

This system is supplied with the AC and DC earths connected. The standard system

(+ve earth system) output has the DC Common (earth connection) in the positive side

of the circuit.

The user selectable, positive/negative earth system has the DC Common (earth

connection) in the negative side of the circuit, but can be changed by following the

instructions in the DC earthing section of this manual.

The earth link can be completely removed from the system to isolate earths. Please

see the DC earthing section of the manual.

Enatel DC System Manual Page 6 of 31

3.0 I

NSTALLATION

3.1 Unpacking & Installing in 19” Rack

Upon unpacking, check that the unit is not damaged, and that you have the required number of

rectifiers.

Remove the transport bracket supplied attached to the top of the system.

The unit fits into a standard 19” mounting frame. The mounting screws should be M6, however

M5 may be used with washers. Be sure to mount the unit in the 19” frame squarely if M5

screws are used.

To fit the cover, remove the screws securing the top of the system and place on, allowing the

rear tabs to lock into the slots provided. Secure the cover to the chassis by replacing the

screws. The rack will be able to securely hold the 1U system with just the bottom two screws

fitted. Brace cabinet mounting if necessary.

Please note the complete system weight is 5.6Kg. Ensure the 19” mounting rails are able to

withstand mounting of the system. The supplied transport bracket can be utilised in cabinets

with 19” mounts at the rear of the cabinet to increase the system mounting rigidity if required.

3.2 Installing in ETSI Rack

Fit ETSI mounting tabs to each side of the compact system chassis. Attach the tabs to the

desired depth with the included M5 Screws. Screws are accessible from the inside of the

system and as such ETSI mounting tabs can only be fitted prior to installing in a rack.

Fig 1, Fitting of ETSI rack mount tabs

Fig 2, Fitting of ETSI rack mount tabs

Note: Fitment of tabs in some positions will require the temporary removable of the DC Battery

connectors and SM3x monitor. These can be replaced once fitment is complete.

Enatel DC System Manual Page 7 of 31

3.3 AC Cabling

The AC cables are clearly labelled at the rear of the system (see Fig 3). The AC cable provided

is 2.5mm

2

cables and suitable terminals should be used.

AC connection internally is via 6.4mm QC tabs. Longer cables can be easily fitted by replacing

the existing cable. Ensure that the AC colour coding is correct for the country of fitment:

Fig 3, AC Cable Detail

Connections should allow for a maximum single phase AC supply of 15A (@ 175VAC) (see next

section).

The AC earth is internally bonded to the system chassis.

DC Common is connected to the AC earth through the placement of the PCB connecting the

backplane to the distribution. Alignment depends on required earthing connection. Please see

the DC earthing section of this manual for more detail.

Note: Please refer Appendix 3 for AC Input Transient Protection.

3.3.1 Upstream Over-current Protection

There are two considerations to take into account when selecting an appropriate fuse/circuit

breaker.

-The upstream protection should protect the downstream cable from overload situations.

-Discrimination should be maintained with the downstream device fuses.

(i) Cable Rating

The maximum current drawn by the DC power system is 15A (5A per rectifier at a minimum

input voltage of 175V

ac

and full output power). The upstream protection device must be able to

supply this load under all conditions without tripping. Therefore, typically at least 20%

headroom is allowed for in the protection device, making its minimum rating 18A.

Note: The current carrying capacity of cables is dependent on the type of cable used. Please

check with your local supplier and local regulations for appropriate sizing.

For convenience, the system is supplied with a 1.0m long, 3-core, 2.5mm

2

flex already

attached. This has a current carrying capacity of 20A.

(ii) Discrimination

Discrimination ensures that the upstream circuit breaker or fuse does not blow if a rectifier input

fails (short circuit). Therefore it is important to ensure the upstream protection discriminates

with the internal fuse of the rectifier. The fuse used in the RM848 is a slow-blow 10A fuse. The

tripping curve for this is shown in Appendix 2 at the rear of this manual.

Enatel DC System Manual Page 8 of 31

A minimum circuit breaker to use for this system is a 20A, D-curve (note, a 20A C-curve breaker

will not discriminate with the rectifier fuse). Therefore, when used with the 2.5mm

2

cable

supplied, a 20A, D-curve breaker should be used.

Alternatively, a 32A C-curve breaker, or greater, can be used. However, AC cable provided

may have to be replaced for a larger cable

1

.

If a fuse is used upstream, then any BS88 or NH g style fuse, of 20A or greater rating will

discriminate.

1

NOTE:

A larger breaker may be used even though in theory it may appear that the 2.5mm

2

wire is not fully prote ted. In fa t

it is prote ted on two a ounts. Firstly it is prote ted by the re tifier input fuse (whi h is only a short distan e away). Se ondly,

the re tifiers are power-limited on their input. Therefore, they an never be overloaded. As a result, the wire an never be

over-loaded by the re tifier – it an only see fault urrent. As a result, depending on lo al authorities, only fault urrent

prote tion may be atered for by the upstream prote tive devi e.

Enatel DC System Manual Page 9 of 31

3.4 DC Cabling

CAUTION:

Use extreme care when fitting batteries & their connections. Remove all jewellery

and rings from oneself prior to commencing the installation. Always use insulated

tools when fitting batteries and take extreme care not to short terminals when

working on them.

All DC Load cables terminate to the connectors at the front of the unit as shown in Figure 5.

These terminals are all 6mm

2

. Load connections are of a ‘push in’ design and cables can be

simply pushed into the connector for termination after stripping to the appropriate length.

Removal requires a small screwdriver to be inserted into the rectangular hole above the

connector whilst pulling on the cable.

Connector designators are available on the pull-out guide. See Figures 4, 5 and 6 for detail.

Fig 4 & 5, DC Connector detail and pullout guide

The battery cabling connects through the SB50 style power-pole connectors. From here it goes

directly to the appropriate circuit breaker, then via a Low Voltage Disconnect relay and current

shunt to the internal live bus. This can be seen in the appropriate wiring diagram as the rear of

this manual.

Note: Systems with only one battery breaker specified can be fitted with an additional load

breaker. Connection to the output from this breaker is made through the remaining SB50

power-pole.

Connector layout for PSX24042x1F-x00 Connector layout for PSX24051x1F-x00

Fig 6, DC Connector detail

Enatel DC System Manual Page 10 of 31

3.5 Alarm/Ancillary Cabling

Alarm and communication cables terminate directly into the connectors of the Supervisory

Module, SM35 or SM36, which terminals are assessable by pulling the monitor forward to

expose connections (see Fig 7 & 8).

Cables can be routed through the front of the system via the cable exit indicated. When routing

the cables, ensure they are kept away from the AC and DC power cables when possible.

Fig 7. For removal, pull monitor forward to release the ball catch.

Fig 8. SM3x cable access

Relays 1- 6 can be used for normally open or normally closed states by jumper selection. The

relay states labelled NO or NC are for their de-energised state. If an alarm is programmed for

the relay to be normally energised (as may be required in the case of a low voltage alarm where

loss of power will put the alarm into its active state), then be sure to connect the remote wiring

appropriately.

For full monitor functionality and operation information, refer to the appropriate monitor manual.

Uncoil the battery temperature sensor and place in the middle of the middle battery string. If the

lead is not long enough, ordinary 2-core copper (approx. 0.75mm

2

) wire can be used as an

extension. The purpose of the battery temperature sensor is to monitor the ambient

temperature of the batteries over long periods of time and adjust the rectifier output (float)

voltage accordingly. As a result, it is not necessary to have the temperature sensor touching

the batteries. If the Battery Temperature Sensor is removed a “battery temp fault” alarm is

generated.

Enatel DC System Manual Page 11 of 31

For remote communications and direct computer connection to the Compact System, refer to

the monitor manual. These connections can be made via the mini-USB port on the front panel

of the monitor (computer connection), and the Ethernet port (SM36 web-based communications

only).

Enatel DC System Manual Page 12 of 31

4.0

A

LARM

M

APPING TO

V

OLTS

-

FREE

R

ELAYS

Relay 1 is pre-configured as the “Monitor Fail” alarm. This alarm activates is the monitor has a

hardware fault or if software becomes corrupted.

All other relays can be mapped to different alarm conditions. The monitor manual details how

these may be changed. On the standard Compact Systems alarms are preconfigured as

follows:

Relay 2: Summary Non-urgent alarm

Relay 3: Summary Urgent alarm

Relay 4: User Configurable

Relay 5: User Configurable

Relay 6: User Configurable

As mentioned, if these mappings are not appropriate, they can be changed in the field to suit

customer requirements.

Enatel DC System Manual Page 13 of 31

5.0 C

IRCUIT

B

REAKER

F

AIL

M

ONITORING

The load circuit breakers are monitored electronically through an internal general purpose input

on the monitor. The digital input will trigger an alarm when it is pulled to the system common

(+ve or –ve depending on configuration) rail. This means that to operate the load must be

connected. In this way, false alarms are avoided when no load is connected and all load circuit

breakers are in the “off” position.

Note:

This also means that a residual voltage will be measured at the load terminal even when

the circuit breaker is turned off. This is high impedance and does not present a hazard

to the user.

The battery circuit breakers however, use voltage sense to detect tripping or whether they are

turned off. This is because when a battery breaker is tripped, there may be very little voltage

difference across the breaker, making electronic fail detection problematic. Hence, if no battery

is connected, the breaker must be “on” to clear the Battery Breaker Fail alarm.

Enatel DC System Manual Page 14 of 31

6.0 LVD

O

PERATION

This system is configured with a single Low Voltage Disconnect contactor in the battery side of

the circuit (see wiring diagram at rear of this manual).

The supervisory monitor unit is powered from both the rectifier side of the LVD contactor and

battery source. Therefore when the low voltage threshold is reached and the LVD disconnects

the battery, the SM3x will loose voltage sense (as voltage sense is measuring rectifier bus

voltage) but still maintains operation for monitoring system. The LVD contactor will not re-

engage until the rectifier power is restored (i.e., until the DC bus voltage is restored).

Enatel DC System Manual Page 15 of 31

7.0 DC

E

ARTHING

The 1U micro system is available with two DC Earthing options. The first is fixed by hardware as

a positive earth system where the positive DC output is tied to AC earth. This cannot be

changed in the field.

With the second option, AC earth can be tied to either the positive or negative output by simply

inverting the -/+ earth PCB. The monitor signals are modified by rotating the second PCB as

shown in figures 9 & 10. The two PCB’s mechanically interlock, preventing incompatible

connections to be made.

+ve Earth

-ve Earth

+ve earth -ve earth

Fig 9 & 10, +ve earth and -ve earth options

For systems that require no connection to earth, the PCB can be cut as indicated in figure 11 to

isolate DC output from AC earth. This modification should be made with both -/+ earth PCB’s in

the +ve earth position (or with the fixed positive earth system)

Fig 11, isolated earth option

Enatel DC System Manual Page 16 of 31

8.0 C

OMMISSIONING

Use the following set of instructions as a guide, unless different procedures are recommended

by local authorities.

8.1 System Pre-check:

1. System installation is completed.

2. Battery and load circuit breakers are turned off, and upstream AC has been turned off (i.e.,

system is completely de-powered).

3. Rectifier modules have been placed into their shelf positions, and pulled forward enough to

disconnect them from the system.

4. Check that the protective AC Earth is connected as per local regulations.

Note: This system is available in either positive earthing (-48VDC) or negative earthing

(+48VDC) configurations. Before connecting batteries or rectifiers ensure that the correct

system has been specified and earthing is correct for your application.

5. Turn on AC upstream and check that voltage from phase to neutral are as expected.

8.2 Rectifier Start-up

1. Turn the upstream AC circuits on.

2. Fully insert first rectifier, wait for the rectifier to start and its power on LED to remain green.

3. Check the SM3x powers up, and indicates the system default float voltage on its display. If

the audible alarm activates, press any button to silence it.

4. If a different system float voltage has been specified, set this at this time using the

procedure specified in the SM3x Manual (either from the front panel or connected

computer).

5. Fully insert the rest of the rectifiers ensuring they power up with only their green “power on”

LED illuminated.

6. Check that the load and battery currents on the SM3x are 0 amps (+/- 1 or 2 amps).

7. Check that all SM3x configuration settings are correct (as per customer specification) with

respect to:

- Voltage levels

- Alarm settings

- Alarm mappings to the volts-free relays

(refer to the SM3x manual for information on how to check these via the front panel or

locally connected computer).

8.3 Battery Start-up

Note:

It is important that battery circuit breaker connections should be made when the rectifiers

are turned on and the system is “live”. This is because the system voltage and battery

voltages will be similar, thus minimising any arcing during connection. This also

prevents high current arcing due to the charging of the rectifier output capacitors.

1. Fit only one rectifier initially (to limit any damage if any connections are incorrect).

2. Measure the voltage across each battery string at the terminals of the Compact System.

Ensure that the reading from the DC Common bus to the Battery Live Terminals is -48V (or

+48V as per system specification).

3. Turn on each battery circuit breaker in succession while measuring the battery voltage and

ensure that the voltage increases slightly to the system Float Voltage (typically the voltage

will increase from 2-3V below float to float voltage. At this point the batteries will be drawing

some current to bring them to a full state of charge.

8.4 Load Start-up

1. Ensure downstream load connections have been made and there are no loose/floating

cables.

Enatel DC System Manual Page 17 of 31

2. Turn on load circuit breaker, ensuring that the downstream equipment is being powered up

as expected.

3. Ensure the system float voltage on the SM3x is at the level previously noted.

4. Ensure the load current is at a level expected (could be zero if loads downstream have not

been connected).

Note:

Prior to leaving the system after it has been commissioned, ensure all AC, DC and

battery circuits are off. If it is required that the system is to be left on (to power load

equipment, ensure rectifiers are left in their powered up state, and batteries are in circuit.

This will prevent anyone leaving the batteries only powering the load (in which case the

batteries would go flat).

Enatel DC System Manual Page 18 of 31

8.5 DC System Commissioning Check-List

DC

S

YSTEM

C

OMMISSIONING

C

HECK

-L

IST

Site Name:__________________________ Date:_______________

Tests Without Batteries Connected Measured/

Setting Results

Check Float Voltage Meter:______ __________ V

/

Check Load Current Meter:______ __________ A

/

Alarms:

Voltage thresholds can either be checked using an external power supply, or by

adjusting the SM3x float voltage 0.1V above (or below for the low voltage alarms). It

is recommended to have the batteries disconnected.

1. Adjust the supply/float voltage to 55.7V & observe the “High Float” alarm.

2. Adjust the supply/float voltage to 57.7V & observe the “High Load” alarm.

3. Adjust the supply/float voltage to 52.7V & observe the “Low Float” alarm.

4. Adjust the supply/float voltage to 46.9V & observe the “Low Load” alarm.

High Load Volts (urgent) 57.6V __________ V

/

High Float Volts (non-urgent) 55.6V __________ V

/

Low Float Volts (non-urgent) 52.8V __________ V

/

Low Load Volts (urgent) 47.0V __________ V

/

Depending on the test load available, it may be necessary to adjust the High Load

Current alarm threshold down to suit. For example, with 40A test load, adjust the

High Load Current threshold (use SM3x Config. software, click on the

“Alarms/(Levels)”) to 35A. Then simply apply the 40A load and observe the alarm

change state.

Once the test is complete, be sure to rest the High Load Current to its previous value

(or check with the customer for the correct value they require).

High Load Current (urgent) __________ A

/

Temperature alarm tests are performed by heating up (using a heat gun or other

source) and cooling down (using a aerosol can of freeze, or a tub of ice) the

temperature sensors.

Battery Temperature High (urgent) __________°C

/

Battery Temperature Low (non-urgent) __________°C

/

Room Temperature High (non-urgent) __________°C

/

Enatel DC System Manual Page 19 of 31

Room Temperature Low (non-urgent) __________°C

/

When an AC Monitoring PCB is not fitted at system level (as in most cases), the AC

Fail alarm is generated from the rectifiers. The rectifiers sense if AC is present, and

extend an AC fail alarm to the SM3x. Therefore, to test this alarm, simply turn off the

rectifier AC breakers. To allow the monitor to continue to read alarms there must be

DC present on the output of the system.

As this causes the rectifier output to cease, a Rectifier Fail alarm is also generated.

To generate the Urgent Rectifier Fail, turn off the required number to make this occur

(usually set to 2, but check via the SM3x Config software for the setting (under the

“Rectifier Control” section fo the “Control” tab)).

AC Fail (urgent) Urgent

/

Rectifier Fail (non-urgent) Non-urgent

/

Urgent Rectifier Fail (urgent) No. Modules:____

/

To check Load MCB fail, connect a load, but with no load turned on. Then switch the

breaker to it’s off position, and turn on some load (any amount will do). This will

cause the alarm to occur as the load side to the circuit will be taken to system

common voltage. Turn off the load, and then return the breaker to its on position.

Load MCB Fail (urgent)

/

A Rectifier Off Normal alarm is generated with the rectifier enters a state that may

degrade its performance (e.g., a single fan fail), or a state that is outside of normal

operating conditions (e.g., high temperature, or current limit).

You can observe an Off Normal alarm when the system is placed in current limit, or

you may wish to stop a fan to generate the alarm. The best way to stop a fan is to

use a small cable tie (non-metallic), and push it approximately 1cm through the

rectifier grille.

Rectifier Off Normal (e.g., fan failed) (non-urgent)

/

Tests with Batteries

•Turn off Battery Breaker/s

•Connect battery/batteries

•Check the correct Battery Capacity (Ahrs) has been entered (SM3x Config.,

“Charge” tab, top right of screen). This is the total capacity, so for example

100Ahr strings in parallel, this should be 200.

•Go to SM3x Config., “Control” tab. Set the Battery Charge Current Limit to

“Enabled” (middle right of screen). Also check Battery Current Limit (BCL) is

set to desired level (usually 0.1C

10

, (10%)). This means that for a single

100Ahr battery, the BCL will be 10A, or if two 100Ahr batteries are connected

in parallel, the BCL will be 20A.

•Go to SM3x Config., “Battery Monitoring” tab. “Tick” Logging Enabled.

Set:

- Status Log Sampling Interval to 7 days (provides a “snapshot” of the battery

state every 7 days)

- Discharge Log Sampling Interval to 1 minute

- Discharge Log Continuation Time to 5 minutes (this is the length of time

Enatel DC System Manual Page 20 of 31

logging continues for after AC power is returned)

•Connect load (but turn off).

•Check V

f

is set to 54.0V.

•Turn on Battery Breaker/s

Check Battery current is positive if charging

/

For systems fitted with Battery Monitoring

(BCM) cards:

Go to SM3x Config., “Battery Monitoring” tab

and “tick” start scanning.

Check that the all the battery cell voltages are

approximately the same, at about 2.25V (or

13.5V for 12V monoblocs).

If any are out by a large amount, then check

the BCM sense wiring is correct.

/

Set load to required level (e.g., 30A),

Initiate Battery Discharge Test (from SM3x

Config., “Charge” tab, click “Battery Test

Enabled”)

Check operates

/

Check Battery Current is negative

(discharging)

/

Check Battery Current Meter:______ __________ A

/

After several minutes, or until the battery

voltage has dropped below approx. 47V,

“un-tick” (stop) Battery Test (from SM3x

Config., “Charge” tab). During this time the

Battery Condition Monitor if fitted) will be

logging every minute.

Battery Current Limit (BCL)

Check that the battery recharge current is

limited to the Battery Current Limit level

(usually 0.1C

10

, (10%))

Note: as the BCL is based on fine voltage

control of the system bus, the BCL make take

one or two minutes to “settle”, i.e., you may

observe a brief excursion of the battery

recharge current beyond the BCL setting.

BCL functions

_______%

Yes/No

Check Manual Equalise (if configured)

/

A Battery MCB Fail alarm is generated from the voltage measured across the battery

MCB.

Therefore, to check a Battery MCB Fail alarm, simply open one of the battery MCB’s.

If batteries are connected to the system at this time, the alarm may take a few

moments to activate. Once test is complete, turn breaker back on.

Battery MCB Fail (urgent)

/

This manual suits for next models

9

Table of contents

Other Enatel Power Supply manuals

Popular Power Supply manuals by other brands

WAGO

WAGO 2787-2154 product manual

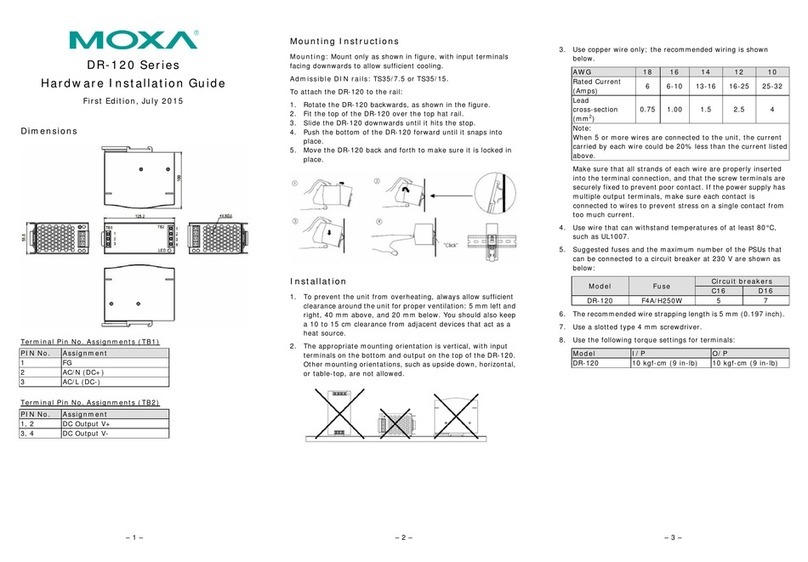

Moxa Technologies

Moxa Technologies DR-120 Series Hardware installation guide

heinzinger

heinzinger EVO Series user manual

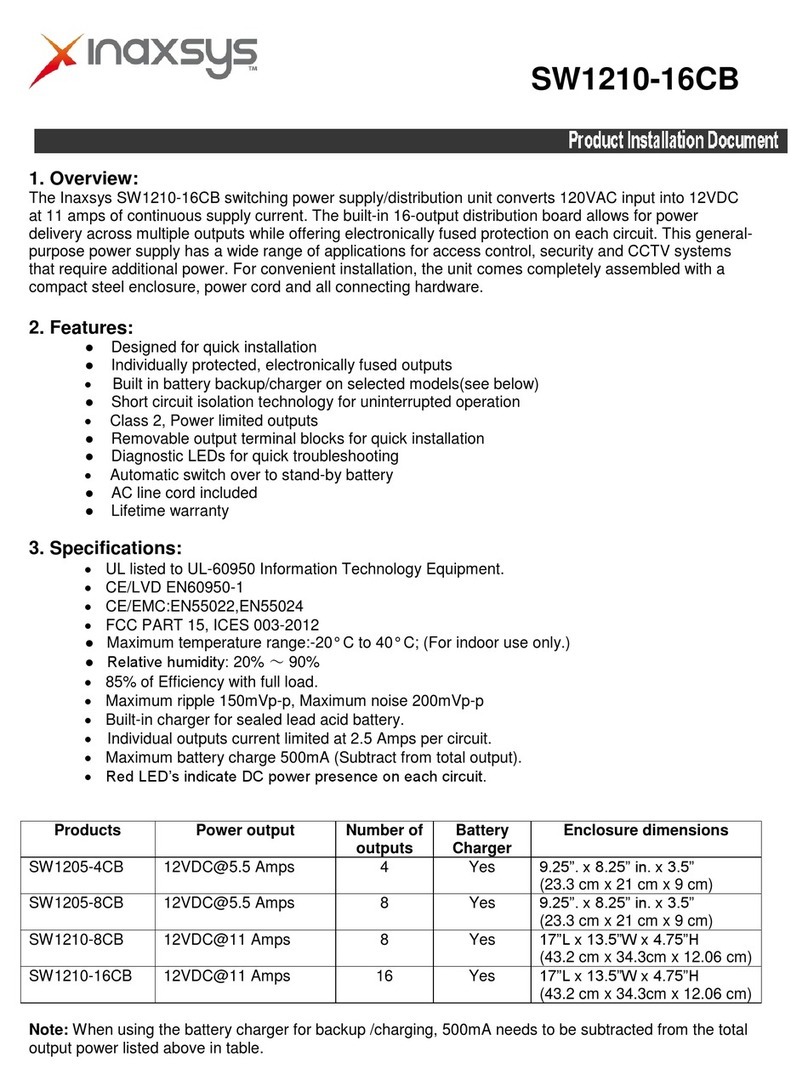

Inaxsys

Inaxsys SW1210-16CB Product installation document

Elenco Electronics

Elenco Electronics STPS-1 operating instructions

Valcom

Valcom VP-12124 user guide

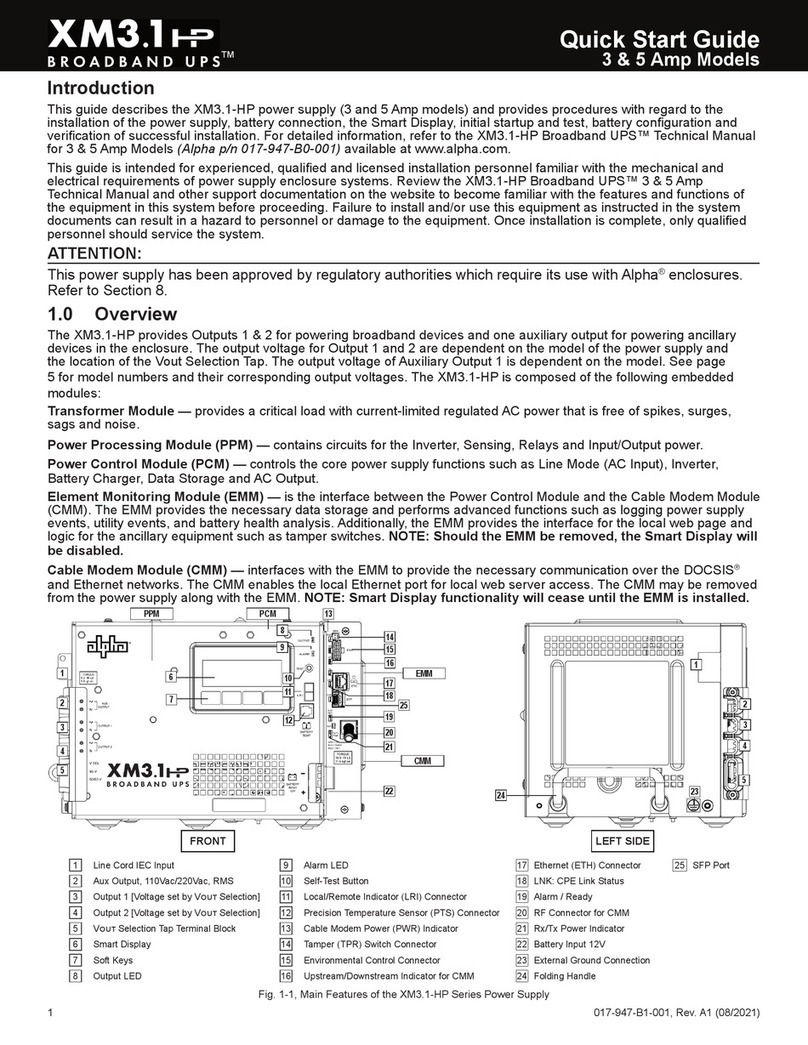

Alpha

Alpha BROADBAND UPS XM3.1-HP quick start guide

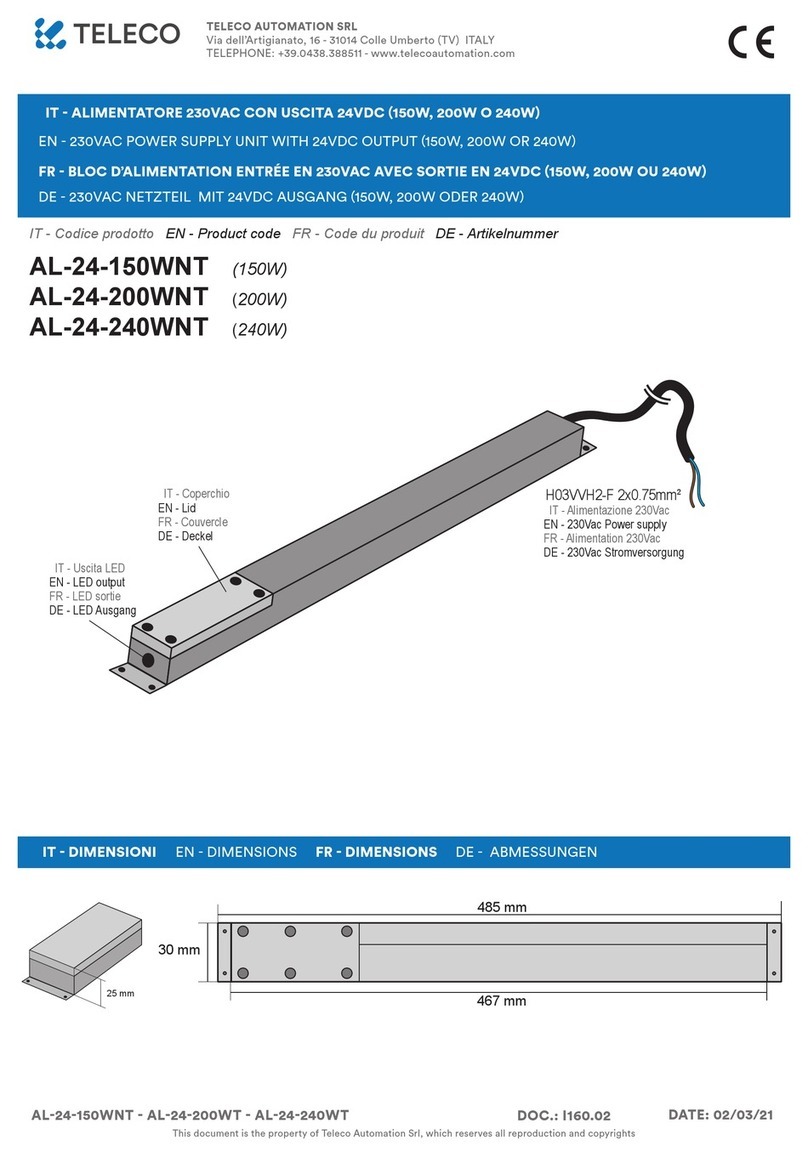

TELECO AUTOMATION

TELECO AUTOMATION AL-24-150WNT instructions

Chloride

Chloride LT041XAT operating manual

EFOY

EFOY EFOY Pro 600 manual

Intepro systems

Intepro systems PSI 9040-170 3U operating guide

Thermaltake

Thermaltake Toughpower XT TPX-575M user manual