1017-947-B1-001, Rev. A1 (08/2021)

Quick Start Guide

3 & 5 Amp Models

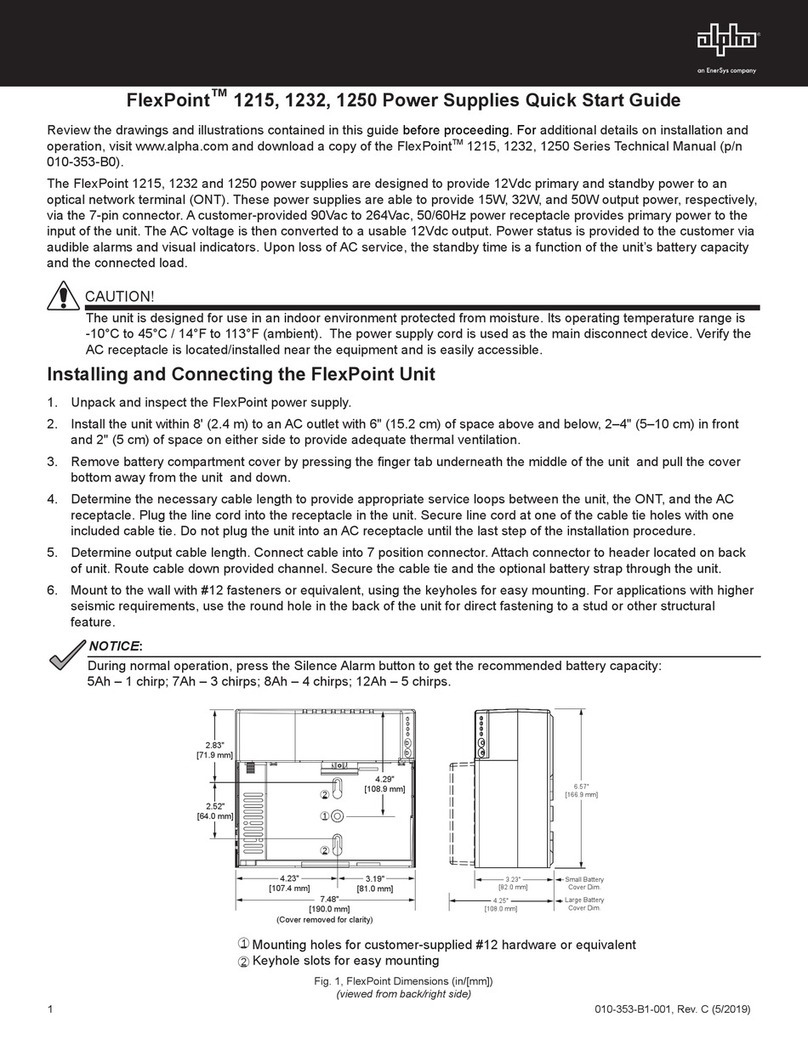

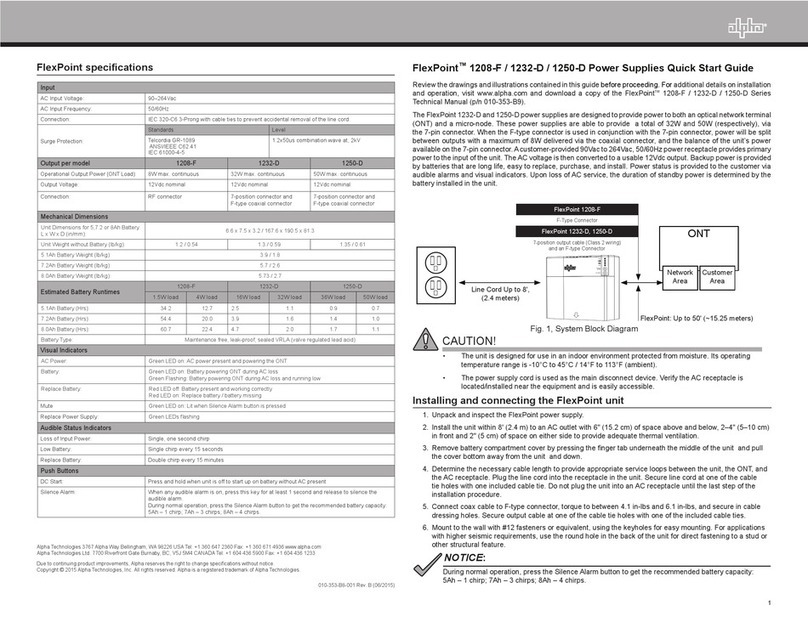

Fig. 1-1, Main Features of the XM3.1-HP Series Power Supply

1.0 Overview

The XM3.1-HP provides Outputs 1 & 2 for powering broadband devices and one auxiliary output for powering ancillary

devices in the enclosure. The output voltage for Output 1 and 2 are dependent on the model of the power supply and

the location of the Vout Selection Tap. The output voltage of Auxiliary Output 1 is dependent on the model. See page

5 for model numbers and their corresponding output voltages. The XM3.1-HP is composed of the following embedded

modules:

Transformer Module — provides a critical load with current-limited regulated AC power that is free of spikes, surges,

sags and noise.

Power Processing Module (PPM) — contains circuits for the Inverter, Sensing, Relays and Input/Output power.

Power Control Module (PCM) — controls the core power supply functions such as Line Mode (AC Input), Inverter,

Battery Charger, Data Storage and AC Output.

Element Monitoring Module (EMM) — is the interface between the Power Control Module and the Cable Modem Module

(CMM). The EMM provides the necessary data storage and performs advanced functions such as logging power supply

events, utility events, and battery health analysis. Additionally, the EMM provides the interface for the local web page and

logic for the ancillary equipment such as tamper switches. NOTE: Should the EMM be removed, the Smart Display will

be disabled.

Cable Modem Module (CMM) — interfaces with the EMM to provide the necessary communication over the DOCSIS®

and Ethernet networks. The CMM enables the local Ethernet port for local web server access. The CMM may be removed

from the power supply along with the EMM. NOTE: Smart Display functionality will cease until the EMM is installed.

1 Line Cord IEC Input 9 Alarm LED 17 Ethernet (ETH) Connector 25 SFP Port

2 Aux Output, 110Vac/220Vac, RMS 10 Self-Test Button 18 LNK: CPE Link Status

3 Output 1 [Voltage set by VSelection] 11 Local/Remote Indicator (LRI) Connector 19 Alarm / Ready

4 Output 2 [Voltage set by VSelection] 12 Precision Temperature Sensor (PTS) Connector 20 RF Connector for CMM

5 V Selection Tap Terminal Block 13 Cable Modem Power (PWR) Indicator 21 Rx/Tx Power Indicator

6 Smart Display 14 Tamper (TPR) Switch Connector 22 Battery Input 12V

7 Soft Keys 15 Environmental Control Connector 23 External Ground Connection

8 Output LED 16 Upstream/Downstream Indicator for CMM 24 Folding Handle

This power supply has been approved by regulatory authorities which require its use with Alpha®enclosures.

Refer to Section 8.

ATTENTION:

Introduction

This guide describes the XM3.1-HP power supply (3 and 5 Amp models) and provides procedures with regard to the

for 3 & 5 Amp Models (Alpha p/n 017-947-B0-001) available at www.alpha.com.

Technical Manual and other support documentation on the website to become familiar with the features and functions of

the equipment in this system before proceeding. Failure to install and/or use this equipment as instructed in the system

personnel should service the system.

1 Line Cord IEC Input 10 Self-Test Button 19 Alarm / Ready

2 Aux Output, 110VAC/220VAC, RMS 11 Local/Remote Indicator (LRI) Connector 20 RF Connector for CMM

3 Output 1 [Voltage set by VSelection] 12 Precision Temperature Sensor (PTS) Connector 21 Rx/Tx Power Indicator

4 Output 2 [Voltage set by VSelection] 13 Cable Modem Power (PWR) Indicator 22 Battery Input 12V

5 VSelection Tap Terminal Block 14 Tamper (TPR) Switch Connector 23 External Ground Connection

6 Smart Display 15 Environmental Control Connector 24 Folding Handle

7 Soft Keys 16 Upstream/Downstream Indicator for CMM 25 SFP Port

8 Output LED 17 Ethernet (ETH) Connector

9 Alarm LED 18 LNK: CPE Link Status

3

4

5

2

1

24 23

LEFT SIDEFRONT

3

4

5

2

16

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

CMM

EMM

PPM

25

PCM