www.encorehartco.com | Phone: (224) 723-5524

. . . Innovating Legendary Products

2

The Han-D-Ringer (RAM1001)

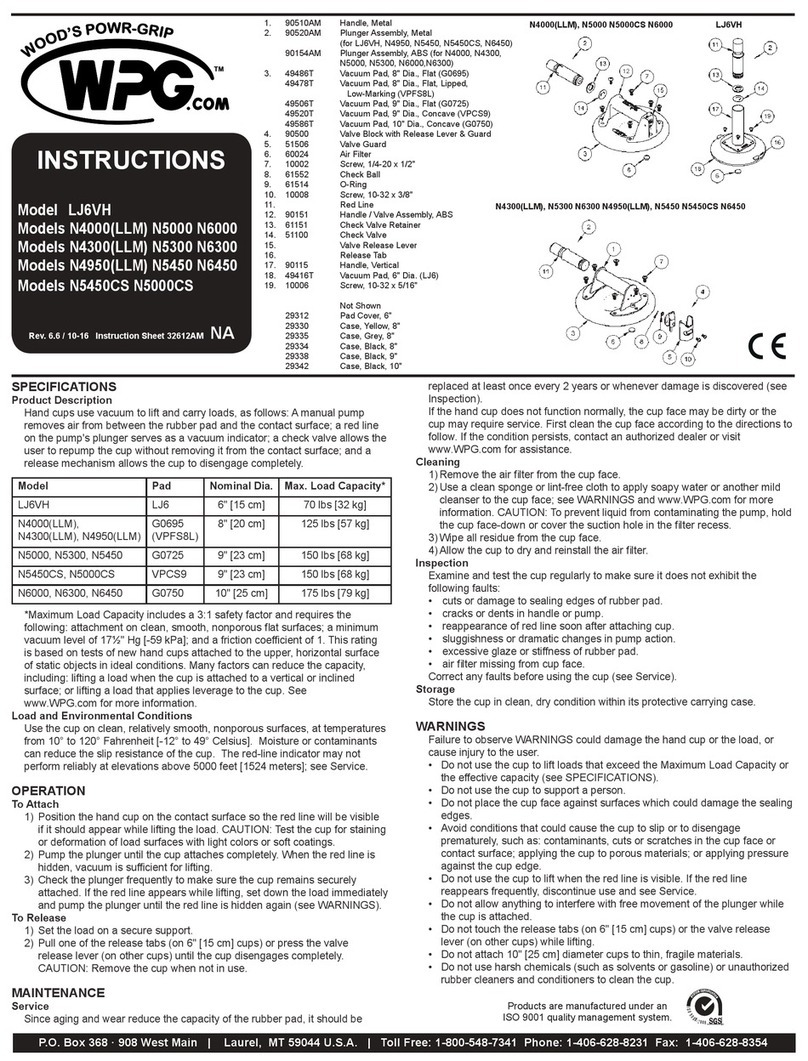

Han-D-Ringer PARTS

1 B14001 Pin 1

2 B14002 Spring 2

3 B14003 LowerJaw 1

5 B14005 Pin 2

6 B14006 Pin 2

8 B14008 Roller 2

10 B14010 Screw 1

11 B14011 Pusher 1

12 B14012 Magazine 1

13 B14013 Housing(Right) 1

14 B14014 Pin 1

15 B14015 PusherSpring 1

16 B14016 Roller,PusherSpring 1

19 B14019 Pin 1

20 B14020 Housing(Left) 1

21 B14021 Screw 4

22 B14022 Pin 1

23 B14023 V-spring 1

24 B14024 UpperJaw 1

26 B14026 Screw 2

27 B14027 Screw 1

28 B14028 Guide 1

29 B14S029 Guide(Optional) 1

35 B14035 Screw 1

201 B14201 DeltaLaminationAssy. 1

202 B14202 JawLinkAssy.(Right) 1

203 B14203 JawLinkAssy.(Left) 1

204 B14204 HandleAssy. 1

205 B14205 SpringAssy. 1

Item # Part # Description Qty Item # Part # Description Qty

SPECIFICATIONS

WEIGHT: 0.8lbs(0.4kg)

DIMENSIONS (HxWxL): 7x2x7”(178x50x178mm)

MATERIALS: Steel and molded composite

plastic

USED WITH: 9/16” D-rings, collated on a strip

MAGAZINE CAPACITY: 50rings

PRIMARY POWER: Manually powered

2018-0125

TROUBLESHOOTING

JAMMING PROBLEMS

The most common reason is insucient pusher spring

tension. This occurs when the tool is used with an

insucient ring quantity. This tool is not designed to

empty its magazine during operation. Reload when the

pusher makes contact with the tunnel in the housing.

If a jam occurs, pull pusher back to the locked position

and pull rings out of jaw mechanism area. Point nose

of tool down, and while holding onto rings, cycle tool

slowly. User may need to shake pliers to assist the ring

in falling out. This should force jammed ring out of jaw

mechanism.

RING DOES NOT CLOSE COMPLETELY

1. Check for foreign debris in the jaw area. This is

especially true in the area between the housing and

the rollers.

2. Thejawsmaybewornfromextendeduse.Replacing

thejaw(s)isrecommended.

3. Whenthetoolisusedincorrosiveapplications,a

water-dispersing lubricating oil should be applied

on a regular basis to the jaw pins and rollers.

Unlubricated and/or corroded jaw pins may cause

the tool to function poorly.

FEEDING PROBLEMS

1. If rings do not feed smoothly down the magazine,

check pusher spring for tension. If the magazine is

covered with dirt from eld use, clean the magazine

and apply a light coating of water-dispersing

lubricating oil. If magazine is worn or damaged,

replace it.

2. Whenringsfeedproperlyonthemagazinebutdo

not feed into the jaws without spitting out of the

magazine side of the tool, or if the rings sit in the jaw

grooves on an angle, check jaws to insure freedom of

movement.

3. Ifjawsdonotopencompletelyallowingthenext

ring to enter jaws, check the jaw open V-spring

(Item#23)forwear.Itmayneedreplacement.

4. NeveruselooseringsintheHan-D-Ringer.

. . . Innovating Legendary Products