MegaPress™ Pipe Preparation Tool

Description

The RIDGID®MegaPress®and MegaPressG®

(registered trademarks of Viega GmbH & Co.)

Pipe Preparation (Prep) Tool is used to pre-

pare the end of schedule 5 to 40 black steel

pipe for use with Viega MegaPress fittings.

The pipe preparation tool is powered by a

user supplied 1/2" drill (1,200 to 4,000 rpm

operating range), cleans the outside of the

pipe and deburrs the pipe end outside diame-

ter. The pipe preparation tool can be used

with stationary or rotating pipe. Two pipe

preparation tools are available: one for the

1/2" to 1" pipe size range and one for the 11/4" to

2" pipe size range.

The RIDGID MegaPress Pipe Prep Tools are

not approved for use with galvanized or epoxy

coated pipe. Please see the fitting manufac-

tures instructions for proper preparation tech-

niques for these types of pipe.

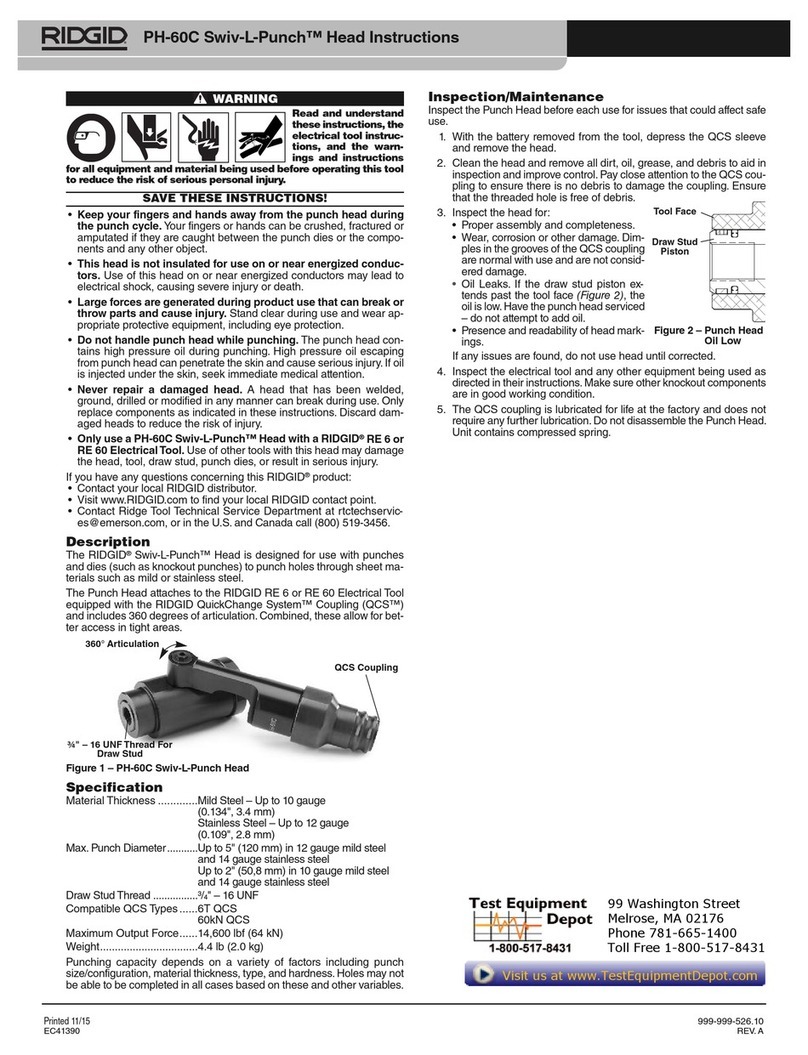

Figure 1 – MegaPress Pipe PreparationTool

Abrasive Strip Information

Contact the fitting manufacturer for

specific information on their system, includ-

ing compatible pipe, installation instructions,

minimum distance between fittings, seal ma-

terial, inspection, testing, etc. Incorrect instal-

lation can cause system leaks and exten-

sive property damage.

Specific Safety Section

WARNING

This section contains important safety in-

formation that is specific to this tool.

Read these precautions carefully before

using the MegaPress®Pipe End Prepara-

tion Tools to reduce the risk of serious

personal injury.

SAVE THESE INSTRUCTIONS!

•Use personal protective equipment. Al-

ways wear eye protection.Protective equip-

ment such as dust mask, respirator, non-

skid safety shoes, hard hat, or hearing pro-

tection used for appropriate conditions will

help reduce the risk of personal injury.

•Keep hands away from rotating pipe

and parts. To prevent entanglement,

crushing or striking injuries, allow equip-

ment to come to a complete stop before

touching the pipe or equipment.

•Only use RIDGID®Press Tools, attach-

ments and preparation tools when spec-

ified by the fitting manufacturer for use

with their system. Use of incorrect equip-

ment for a system can cause system leaks,

damage the equipment, void warranties or

cause severe personal injury.

•Read and understand these instruc-

tions and the warnings and instruc-

tions for all equipment and products

being used with this tool before operat-

ing. Failure to follow all warnings and in-

structions may result in property damage

and/or serious personal injury.

•Avoid breathing of dust created from

pipe cleaning and deburring. Some dust

created may contain chemicals known to

cause cancer, birth defects or other serious

personal injury.Consider the pipe material

and coatings when determining appropri-

ate respiratory protection, including things

such as lead based paint.

Your risk from these exposures varies,

depending on how often you do this type

of work and the concentration of dust.

To reduce your exposure to these chem-

icals, work in a well ventilated area, and

use respiratory protection selected based

on appropriate regulations and standards,

such as ANSI Z88.2 and OSHA.

1

NOTICE

Catalog No. Description

38008 Abrasive Strips, 1/2: to 1" (Pack of 10)

38003 Abrasive Strips, 11/4" to 2" (Pack of 10)