Encyclon 651SP-MWTT Manual

6705 14th Avenue • PO Box 1258 •

Kenosha, WI

53143

Phone 800/767-3551 • 262/654-0032 • Fax 262/657-7435 •www.encyclon.com •

sales@encyclon.com

Encyclon Inc.

Cyclonic Filtration Systems

INSTALLATION OPERATION

AND

MAINTENANCE INSTRUCTIONS

FOR

ENCYCLON FILTRATION SYSTEMS

MODEL NO. 651SP-MWTT

SERIAL NO. 20347

INDEX

INDEX 1

PRE-TEXT & WARNINGS 2

DESCRIPTION OF THE FILTER SYSTEM 3 - 4

START-UP PROCEDURE 5

SYSTEM OPERATION 6

TROUBLESHOOTING & MAINTENANCE 7

FILTER CIRCUIT LAYOUT 8

REPAIR PARTS LIST & DRAWING 9 - 10

ELECTRICAL CONTROL – HUBBELL BOOKLET

FILTER PUMP- GUSHER BOOKLET

CLEAN PUMP – WEL-BILT BOOKLET

PRESSURE WASH SECONDARY FILTER

PRE-TEXT & WARNINGS

In order that this ENCYCLON filtration system may give

continuous, satisfactory and safe service it is necessary

that the filter be properly installed, operated and

maintained. Please review this instruction book

thoroughly before installation and operation of the filter.

WARNINGS

Caution is advised when installing this system. The

hoses and piping should never be used for lifting

purposes.

The system should be plugged into a 120V / 1 / 60 Hz

minimum 20 Amp GFCI receptacle.

DO NOT service the system while in operation.

DO NOT place hands in front of pump suction port

while the system is running.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN SERIOUS PERSONAL SHOCK, INJURY

OR DEATH.

Page 2

ENCYCLON SYSTEM DESCRIPTION

The ENCYCLON filtration system continuously cleans

and filters wash water without using filter media to

provide clean water for your application.

The ENCYCLON hydrocyclone is the core of a

continuous filtration system for water applications. The

cyclone removes metallic and non-metallic particles as

small as 5 microns with a specific gravity greater than

1.5. Through continuous filtration and aeration of the

water by the cyclones, bacteria growth is retarded, thus

preventing the water from becoming rancid.

Page 3

Page 4

Here’s How Cyclonic Filtration Works

Dirty liquid enters the cyclone at the inlet orifice (1) of the cyclonic chamber (3).

The shape and tangential location of the orifice develop a downward, spiraling

flow of the liquid. This is called the primary whirl (4) which follows the chamber

walls downward, developing centrifugal force of up to 7500 times that of gravity.

This same force spins out the solid particles

to 5 microns, or .00019” diameter from the

liquid. The solid particles (often referred to as

swarf) strike the wall and slide down to the

discharge orifice (7).

A throttling effect in the lower cyclonic

chamber (6) reverses the descent of the

liquid but not the rotation. This forms the

secondary whirl (5), a rising, spiraling flow of

cleaned liquid that passes up through the

primary whirl to the whirl searcher (2).

The diameter of the whirl searcher is smaller

than the secondary whirl, and the whirl

searcher accepts only the center of the

upward, secondary whirl flow.

The outside portion of the secondary whirl

(containing impurities missed by the primary

whirl) is diverted back to the primary whirl for

further cleansing. This double cleansing

action is significant to the efficiency of the

Encyclon Cyclonic Filtration Systems.

Liquid that passes through the whirl searcher

is then piped out to the clean water storage

tank or can be directly used with 5 micron

filtration with 98% efficiency.

There are no filter media to clog or replace.

Encyclon aerates water to check anaerobic

bacterial growth.

START-UP PROCEDURE

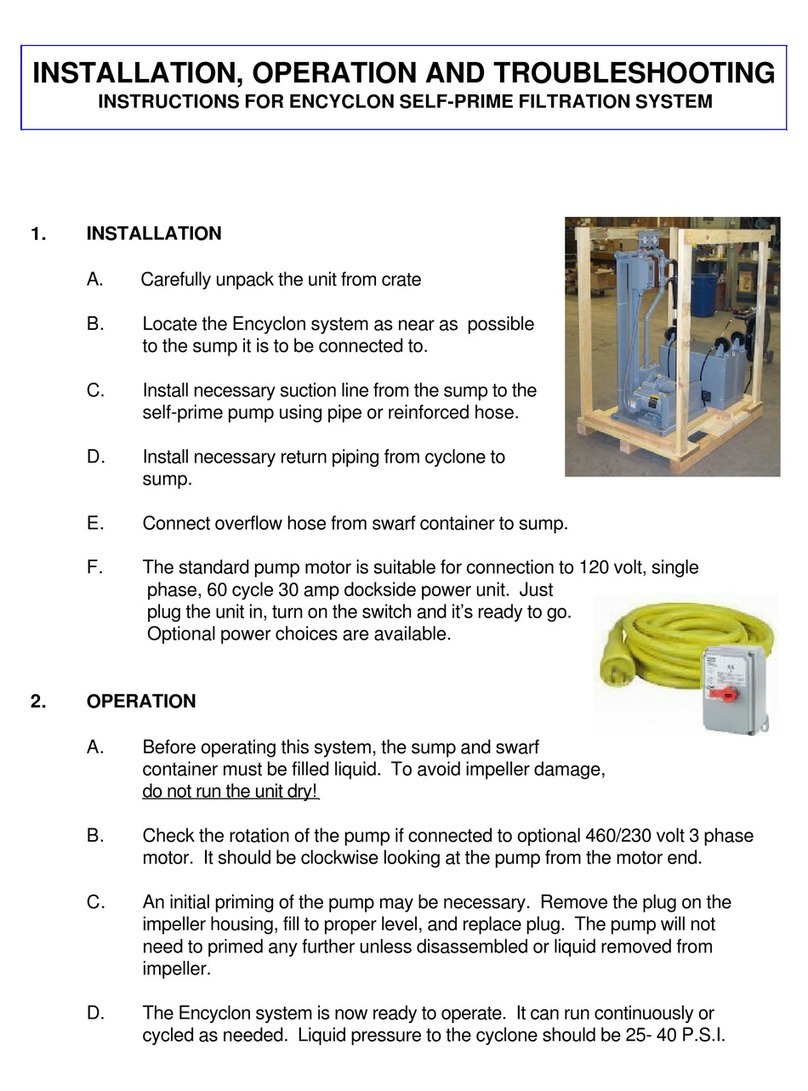

1. Locate the ENCYCLON system as close as possible to the below grade

sump.

2. Fill the “Clean Tank” (Front) first, then the “Dirty Tank” (Rear) and then the

“Swarf Container” with clean water up to the overflow fittings.

3. Prime both pumps by removing the plugs on the impeller housings. Open

1-1/2” Ball Valve leading to the Cyclone Pump. Open 1” Ball Valve

leading to the Clean Pump. DO NOT open 1” Ball valves attached to the

drain of each tank as these are only used for drainage of the tanks.

4. Attach the supplied 1” hose to the 1” fitting on top of the “Dirty Tank” and

the other end to the below grade “Sump Pump” supplied by others.

5. The Dirty Tank 2” overflow hose, and the 1-1/2” overflow hose from the

Swarf Container should be directed towards the wash pad or below grade

sump.

6. Make sure the “ON / OFF” rotary control for both pumps is in the “OFF”

position. Plug shore cord into a minimum 120 Volt / 1 / 60 Hz, 20 Amp

outlet.

7. Turn Cyclone Pump “ON”, Turn Clean Pump “ON” using the rotary switch.

The Clean Pump has a separate ON/OFF rocker switch which is in the

“ON” position from the factory. The Clean Pump will not function without

the Cyclone pump running.

8. Connect pressure washer to hose bib and open valve.

Page 5

SYSTEM OPERATION

1. Both tanks and the swarf container should be filled up to the overflow

fittings.

2. Make sure the below grade sump is filled up to the height of the return

from the wash pad. Connect the Sump Pump to the supplied 1” hose, and

then connect the other end to the 1” fitting on top of the dirty tank.

3. Connect the power washer hose to the hose bib on the trailer and open

the valve.

4. The ENCYCLON filter system is now ready to operate. During the wash

operation, the ENCYCLON system should be run continuously and can be

run after the wash operation is shut down if further filtration is desired or

required.

5. Turn “ON /OFF” control to “ON” position for the Cyclone Pump. Inlet

pressure to the cyclone should be 25 – 40 P.S.I. and the outlet pressure

should be less than 10 P.S.I.

6. When mud appears on the surface of the swarf container, it must be

emptied to prevent swarf from re-entering the below grade sump.

7. Keep water levels in all tanks up throughout the washing operation.

8. Cyclone Pump can run continuous as it is set up for closed loop operation,

and the Clean Pump can run continuous as a pressure switch is used.

9. Make sure the Sump Pump does not send more liquid to the Dirty Tank

than 20 GPM. This can be controlled with a ball valve on the Sump Pump.

The Dirty Tank has an overflow to return excess water back to the sump.

10. The system will have a running water level of approximately 120 gallons in

the Clean Tank and a running level in the Dirty Tank of approximately 110

gallons. The 2” overflow line should be directed back to the sump.

11. If the pressure washer is pulsing purge the secondary filter by opening the

red valve for a few seconds to clear it.

NOTE: Cyclone pump must be ON before the clean pump can be turned

ON. Finally the pressure washer can be turned ON.

Page 6

TROUBLESHOOTING & MAINTENANCE

Normally the ENCYCLON system needs no maintenance. However, there are

some things to watch for. Most problems can be detected by monitoring the

pressure gauges mounted on the cyclone manifold assembly.

1. Low “Cyclone In” pressure below 25 P.S.I. gauge

A. Disassemble and check for obstruction in suction line from

the dirty tank to the pump.

B. Disassemble and check for obstructions in pump casing and

impeller.

C. Disassemble and check for obstructions in pressure line.

2. High “Cyclone Out” pressure above 10 P.S.I. gauge

A. Check for obstruction in the piping from the cyclone to the

clean tank.

B. Check for clogged cyclone assembly.

3. Clogging of nozzles

A. Stop pump motor and unscrew the cap nut that secures the

ceramic nozzle.

B. The cleaning of the nozzle and the conical part of the cyclone

is done with a wire of about 1/8 inch in diameter rounded off at

the end, so that there is no damage done to the inside cone

surface.

C. Reassemble nozzle after cleaning by reversing above step.

4. Clean pump surging

A. Purge the secondary filter by opening the red valve while the

clean pump is running for a few seconds to clear the filter.

Page 7

Page 8

RECOMMENDED REPAIR PARTS

When ordering repair parts the following should be given to

assure delivery of proper parts for your filter system.

1. Model No.:

2. Serial No.:

3. Part No.:

4. Quantity:

5. Description:

6. Send Order To: Encyclon, Inc.

6705 14th Avenue

Kenosha, WI 5314

800-767-3551

262-657-7435 – Fax

Part No. Qty. Description Page

650-023 1 Pressure Gauge 0-30 N/A

650-024 1 Pressure Gauge 0-60 N/A

274-125 1 90 degree Hose 10

200-002 4 Hose Clamp 10

601-001 1 Inlet Nozzle 10

957-003 1 2-1/2” O’ Ring 10

602-001 1 Cone Shaped Casing 10

957-002 1 1” O’ Ring 10

603-001 1 Cap Nut 10

604-001 1 Ceramic Nozzle 10

605-001 1 Spray Protector 10

282-125 1 Straight Hose 10

800-117 1 Filter Pump / Gusher 2 H.P. N/A

RH30425 1 Pump Mechanical Seal N/A

61051-EPDM 1 Pump Housing Gasket N/A

800-123 1 Clean Pump – “WEL-BILT” N/A

Page 9

Table of contents

Other Encyclon Water Filtration System manuals