10

Installation, start-up and servicing

General installation

Only allow qualified personnel to work on the installation. Connect joints or flanges correctly to the inlet

and outlet joint. Handle the filter with great care. The tube is very fragile. Remember that any

ferromagnetic tools and components are attracted to the magnet and may damage it.

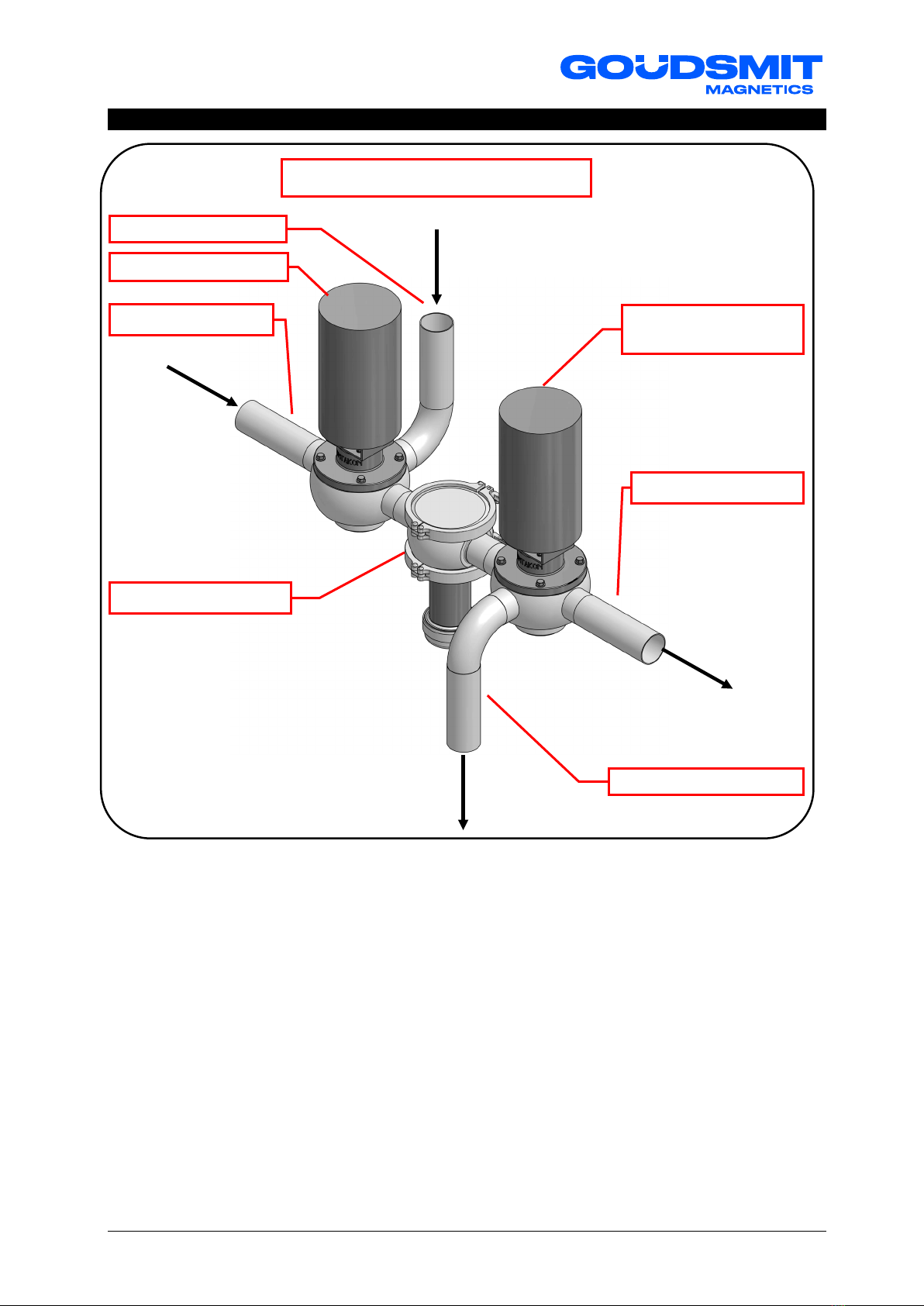

Installation Pneumatic bar CIP filters

DIN11864-1:2008 Aseptic screwed pipe connection, standard type

DIN11864-2:2008 Aseptic flanged pipe connection, standard type

DIN11864-3:2008 Aseptic clamp pipe connection, standard type

For other options consult EHEDG Position Paper “Pipeline and Process connections”

General start-up

Ensure that:

•The device has no damages or malfunctions and all connections, whether mechanical or

pneumatic, are made properly.

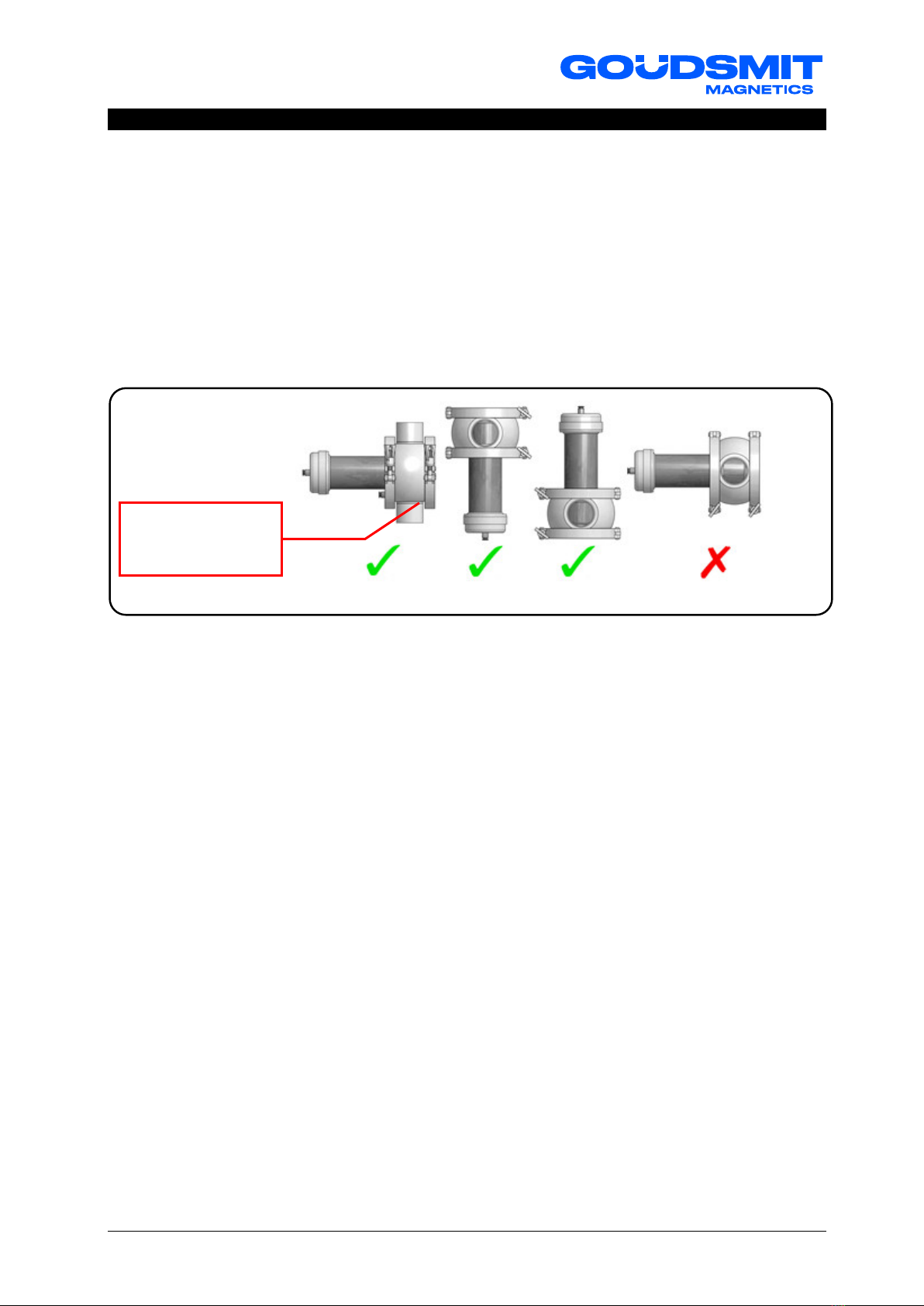

•The filter correctly is installed and at the proper work height. Never install with both the two

connection flanges and the magnet bar in a horizontal position.

Start-up pneumatic bar filters

Test the pneumatic bar operation with a paperclip. It should react if the magnet is operated.

Servicing

If the magnet bar tube is damaged or dented, check that it still operates correctly.

Spare parts include the pneumatic magnet bar and the seals. The seals must be replaced every year.

Goudsmit Magnetic Systems can offer a yearly inspection with a replacement of seals and magnetic

inspection report and certificate.

Storage and dismantling

When recycling the device at the end of its technical life, dispose of correctly and according to local

regulations.

set-up for

CIP applications