INDEX

1!INTRODUCTION – GENERAL INFORMATION................................................................................................ 4!

1.1!PURPOSE OF THE MANUAL......................................................................................................................... 4!

1.2!THE MANUFACTURER.................................................................................................................................. 5!

1.3!THE IDENTIFICATION OF THE MACHINE .................................................................................................... 5!

1.4!RECOMMENDATIONS TO THE BUYER........................................................................................................ 5!

2!THE DESCRIPTION OF THE SELF-CLEANING FILTER................................................................................. 6!

2.1!THE PURPOSE............................................................................................................................................... 6!

2.2!FUNCTIONAL DESCRIPTION........................................................................................................................ 6!

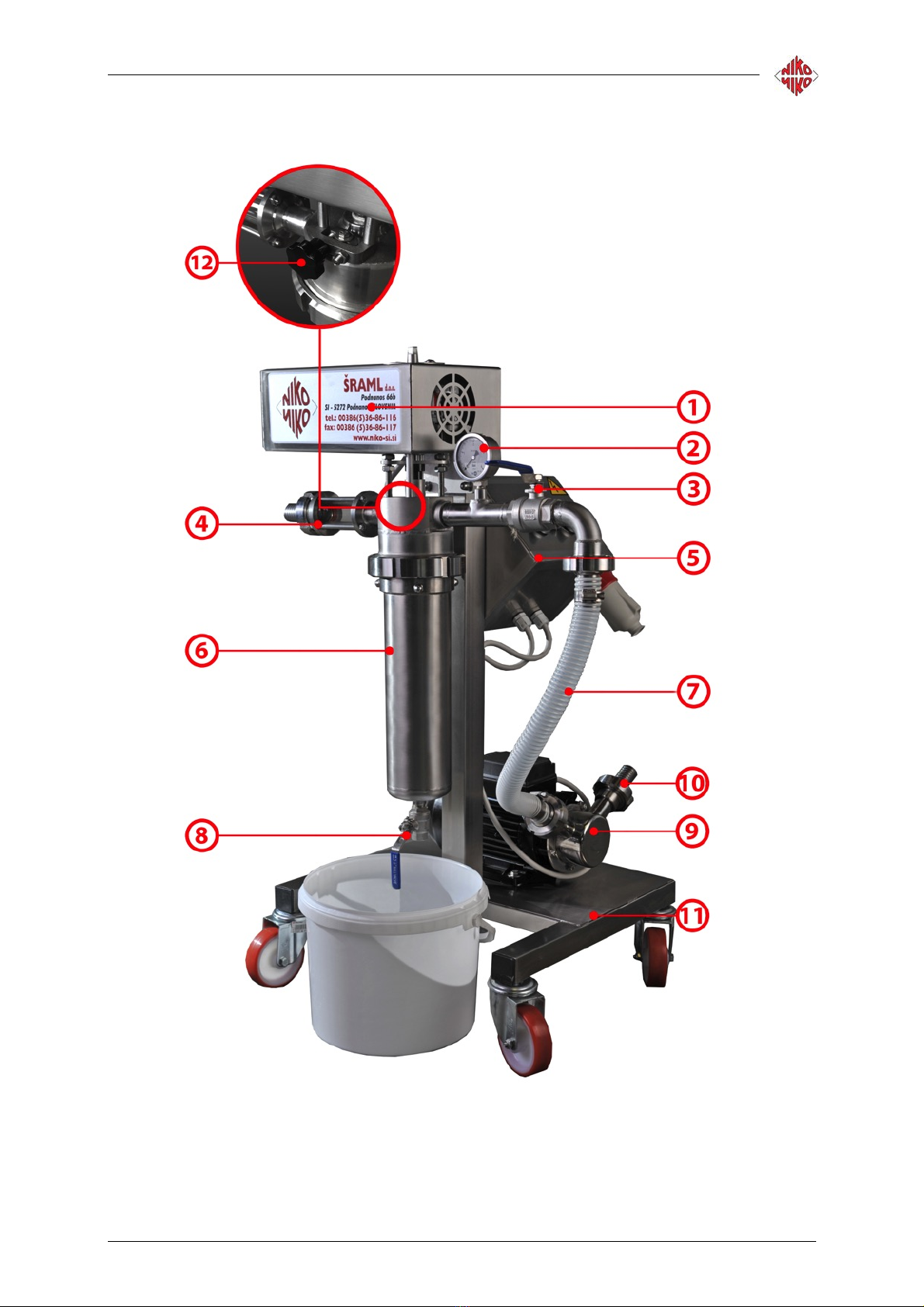

2.3!MAIN COMPONENTS OF THE SELF-CLEANING FILTER............................................................................ 6!

2.4!TECHNICAL DATA......................................................................................................................................... 8!

2.5!WORK AREA .................................................................................................................................................. 8!

3!SAFETY ............................................................................................................................................................. 9!

3.1!SAFETY ELEMENTS...................................................................................................................................... 9!

3.2!SAFETY MECHANISMS................................................................................................................................. 9!

3.3!SAFETY REGULATIONS ............................................................................................................................... 9!

3.4!SAFETY AT WORK PLACE ......................................................................................................................... 10!

3.5!SAFETY BEFORE AND DURING THE FUNCTIONING ............................................................................... 10!

3.6!SAFETY DURING CLEANING AND MAINTENANCE –THE PROCEDURE OF ISOLATION OF THE SELF-

CLEANING FILTER ................................................................................................................................................ 11!

3.7!PERSONAL SAFETY EQUIPMENT ............................................................................................................. 11!

4!TRANSPORT, MOUNTING AND INSTALLATION ......................................................................................... 12!

4.1!LIFTING ........................................................................................................................................................ 12!

4.2!PLACING THE SELF-CLEANING FILTER................................................................................................... 12!

4.3!ELECTRICAL INSTALLATION .................................................................................................................... 12!

5!COMMANDS.................................................................................................................................................... 13!

5.1!OVERVIEW OF COMMAND ELEMENTS –COMMAND BOX...................................................................... 13!

5.1.1!DESCRIPTION AND FUNCTIONS OF THE COMMAND ELEMENTS ....................................................... 13!

6!STARTING AND STOPPING THE SELF-CLEANING FILTER....................................................................... 14!

6.1!STARTING THE SELF-CLEANING FILTER................................................................................................. 14!

6.2!STOPPING THE SELF-CLEANING FILTER ................................................................................................ 14!

7!USE OF THE SELF-CLEANING FILTER ........................................................................................................ 15!

7.1!JUICE FILTRATION...................................................................................................................................... 15!

7.1.1!OPENING THE VENTING VALVE.............................................................................................................. 16!

7.1.2!SETTING OR CHANGING THE FILTER CARTRIDGE .............................................................................. 17!

7.1.3!ADJUSTING THE SELF-CLEANING SYSTEM (SCRAPER) ..................................................................... 19!

7.2!CLEANING.................................................................................................................................................... 20!

7.2.1!CLEANING THE INTERIOR OF THE SELF-CLEANING FILTER............................................................... 20!

7.2.2!CLEANING THE EXTERIOR OF THE SELF-CLEANING FILTER.............................................................. 20!