END ARMATUREN DG2D AX Series Installation instructions

END-Armaturen GmbH & Co. KG

Oberbecksener Str. 78 · D-32547 Bad Oeynhausen · Telefon (05731) 7900-0 · Telefax (05731) 7900-199 · http://www.end.de

Original Operating Manual

Pressure Actuated Valves

DG2D, DA2D, DL2D, DM2D, DF2D, DFZ,

DG3D, DA3D, DL3D, DM3D, DF3D

.../AX version acc.to European Directve 2014/34/EU (ATEX)

for the use in explosive atmosphere

2 http://www.end.de DG - 10/2019

© by END-Armaturen GmbH & Co. KG

All rights reserved. No part of this publication may be copied or published by means of printing,

photocopying, microfilm or otherwise without prior written consent of

END-Armaturen GmbH & Co.KG. This restriction also applies to the corresponding drawings.

END-Armaturen GmbH & Co. KG has the right to change parts of the valves at any time without

prior or direct notice to the client. The contents of this publication are subject to change without

notice.

This publication has been written with great care. However, END-Armaturen GmbH & Co. KG

cannot be held responsible, either for any errors occurirng in this publication or for their consequences.

The products are specified by the statements in this documentation; no assurance of the properties is given.

END-Armaturen GmbH & Co. KG

Oberbecksener Straße 78

D-32547 Bad Oeynhausen

Telefon: 05731 / 7901 - 0

Telefax: 05731 / 7901 - 999

Internet: http://www.end.de

E-Mail: [email protected]

Edition: 10/2019

Impressum

DG - 10/2019 http://www.end.de 3

Contents

Contents

1 Foreword 5

2 General advice 6

2.1 Validity 6

2.2 Inward monitoring 6

2.3 Complaints 7

2.4 Guarantee 7

2.5 Symbols and their signfication 7

3 Safety advice 8

3.1. Personal protection 8

3.1.1. Safety advice for mounting 8

3.1.3 Safety advice for adjustment and starting 9

3.2 Device safety 10

4 Device description 11

4.1 Device description 11

4.2 Device variants 12

4.3 Name-plate 13

4.4 Explosion proof identification 14

4.5 Description of function 14

4.5.1 Description of function: Pressure actuated valve (2/2-way) 14

4.5.1.1 Normally close with the flow direction 15

4.5.1.2 Normally close against the flow direction 16

4.5.1.3 Normally open, close against the flow direction 16

4.5.1.4 Double acting 16

4.5.2 Description of function: Pressure actuated valve (3/2-way) 17

4.5.2.1 Split function 17

4.5.2.2 Mixing function 17

4.6 Description of options function 18

4.6.1 Pilot valve (Option) 18

4.6.2 Position indicator (Option) 18

4.6.3 Optical position indicator (Option) 18

4.6.4 Stroke stop (Option) 18

4.6.5 Electrical position indicator (Option) 18

4.6.6 Manual override (Option) 18

5 Mounting / Disassembly 19

5.1 Electrical installation 19

5.2 Mounting of a valve with threaded connection 20

5.3 Mounting of a valve with welded connection 20

5.3.1 Protection of the sealings by using Heat Absorbing Paste 20

5.3.2 Protection of the sealings by disassembling the valve top 21

5.3.2.1 Disassembly of the valve top 21

5.3.2.2 Mounting of the valve top 22

5.4 Mounting of the valve (flanged connection) 23

5.5 Connection of the pilot medium 24

5.6. Mounting of a pilot valve (Option) 25

4 http://www.end.de DG - 10/2019

Contents

5.6.1 Pneumatical installation of a pilot valve 25

5.6.2 Electrical installation of a pilot valve 25

5.7 Disassembly 26

5.7.1 Mechanical disassembly 26

6 Starting 27

7 Failure 27

7.1 Failure causes 27

8 Maintenance / Cleaning 28

8.1 Maintenance 28

8.2 Cleaning 28

9 Declaration of conformity 29

10. Annex 30

10.1 Conditions in the potentially explosive area 30

10.2 Equipment groups acc. to EC-directive 2014/34/EU, Annex I 30

DG - 10/2019 http://www.end.de 5

1 Foreword

Dear customer,

Dear assembler / user,

these operation and installation manuals are intented to give you the knowledge which is neces-

sary for you to be able to carry out the mounting and adjustment of an pressure actuated valve

DG2D rapidly and correctly.

Please read these instructions carefully and pay particular attention to the advice and warning

notes.

Only instructed and qualyfied mechanician should mount, adjust or maintain the pressure acting

valves.

The pressure acting valves will be deliver in several versions relative to

- pilot pressure and pressure range

- operations

- material

- connection type and connection size.

There are also several options available.

With accessories

- it can switch the pilot media

- it can indicate the position of the piston

- it can happen a manual override

- it can stop the stroke

The field of use of this valve is predominantly

- in food and drink industry

- in chemical installtions

- in ventilation and blower construction

- in heating and air-conditioning technology

- in industrial fittings

- in water treatment etc.

If you have any questions in relation to the pressure acting valves DG2D, we shall be pleased to

answer them.

The telephone number will be found on the inside cover of these operation and installtion manual.

Yours

END-Armaturen GmbH & Co. KG

Foreword

6 http://www.end.de DG - 10/2019

2 General advice

2.1 Validity

These mounting and operating manual is valid for the explosion proofed versions of the pressrue

actuated vales:

DG2Dxxxxxxx/AX..

DA2Dxxxxxxx/AX..

DL2Dxxxxxxx/AX..

DM2Dxxxxxxx/AX..

DF2Dxxxxxxx/AX..

DFZxxxxxxx/AX..

DG3Dxxxxxxx/AX..

DA3Dxxxxxxx/AX..

DL3Dxxxxxxx/AX..

DM3Dxxxxxxx/AX..

DF3Dxxxxxxx/AX..

and their variants:

- with X as a perface to the type

- and a appendage to the type (e.g. /A05)

Advice

The products descript in this documentation in the conditions of our delivery are partly completed

machinery according to annex 2 paragraph g of the directive 2006/42/EC on machinery, which must not

be put into service until the final machinery into which it is to be incorporated has been declared in

conformity with the provisions of the Directive 2006/42/EC on machinery, where appropriate.

Please take notice to the Declaration of incorporation and the assembly instruction.

2.2 Inward monitoring

Please check

- directly after delivery the valve for any transport damages and deficiencies

- with reference to the accompanying delivery note the number of parts.

Do not leave any parts in the package.

General advice

DG - 10/2019 http://www.end.de 7

2.3 Complaints

Claims for replacement or goods which relate to transport damage can only be considered valid if

the parcel service / forwarder has notified without delay.

In case of returns (because of transport damage / repair), please make a damage protocol and

send the parts back to END-Armaturen, if possible in the original packaging,

In case of a return, please mention the following:

• Name and address of the consignee

• Order-/ article-number

• Description of the defect.

2.4 Guarantee

For our pressure actuated valve we give a guarantee period in accordance with the sales contract.

The end of the normal duration of live of the wearing parts represents no defect.

The warrently and guarantee rules of END-Armaturen GmbH & Co. KG are applicable.

2.5 Symbols and their signfication

Paragraphs which are identified with this symbol contain very important advices; this also includes

advices for averting health risks. Oserve these paragraphs without fail!

Paragraphs which are identified with this symbol contain very important advices; this also includes

how to avoid damage to property. Observe these paragraphs without fail!

This symbol indicates paragraphs which contain comments/advice or tips.

This bullet identifies the description of actions which you should carry out.

Symbols and their signification

8 http://www.end.de DG - 10/2019

3 Safety advice

Depending on the technical circumstances and the time under and at which the valve is mounted,

adjusted and commissioned, you must in each case take into account particular safety aspects!

If, for example, the valve works in an operational chemical plant, the potential hazards of commis-

sioning have another dimension from that when this is only being carried out for test purposes an

a „dry“ part of the plant in the assembly room.

Since we do not know the circumstances at the time of the mounting/adjustment/commissioning,

you may find advice on hazards in the following descriptions which are not relevant to you .

Please observe (only) the advice which applies to your situation!

3.1. Personal protection

3.1.1. Safety advice for mounting

We wish to point out expressly that the mounting, the electrical installation and the adjustment

of the valves and the accessories must be carried out only by trained specialist personnel having

mechanical and electrical knowledge!

Switch off all the devices / machines / plant affected by mounting or repair.

If appropriate, isolate the devices / machines / plant from the mains.

Check (for example in chemical plants) whether the switching off of devices / machines / plant

will cause potential danger.

If appropriate, in the event of a fault in the valve (in a plant which is in operation) inform the

shift forman / safety engineer or the works manager without delay about the fault, in order, for

example, to avoid an outflow / overflow of chemicals or the discharge of gases in good time by

means of suitable measures!

Before mounting or repair, remove the pressure from pneumatic / hydraulic devices / machines

/ plant.

Emty the conduit from medium.

If necessary, set up warning signs in order to prevent the inadvertent starting up of the devices /

machines / plant.

Observe the respective relevant professional safety and accident prevention regulations when

carrying out the mounting / repair work.

Check the correct functioning of the safety equipment (for example the emergency push off but-

tons/ safety valves, etc)!

Safety Advice

DG - 10/2019 http://www.end.de 9

Safety Advice

3.1.3 Safety advice for adjustment and starting

As a result of the starting (pneumatic or by hand) of a pressure actuated valve the flow of gases,

steam, liquids, etc. may be enabled or interrupted!

Satisfy yourself that, as the result of the starting or the test adjustments of the valve, no potential

hazards will be produced for the personnel or the environment!

If necessary, set up warning signs in order to prevent the inadvertent starting up or shutting down

of the devices / machines / plant.

By ending mounting check the correct function and the tightness of the valve.

Check the right position and correct function of mounted pilot valves and limit switches

Through suitable measures, prevent actuating links being trapped by moving actuating ele-

ments!

Check the right function of all saftey devices (for example emergency off push buttons / safety

valves, etc. )!

Carry out the starting and the adjustments only in accordance with the instructions discribed in

this documentation!

When adjustments are being carried out on an opened and switch on (operational) limit switches

or pilot valves, there is the risk that live parts(230V AC~) can be touched!

Therefore the adjustment must be carried out only by the electrican or a person having adequate

training, who is aware of the potential hazard.

10 http://www.end.de DG - 10/2019

Safety Advice

3.2 Device safety

The pressure actuated valve

- is a quality product which is produced in accordance with the recognized industrial

regulations.

- left the manufacturer`s work in a perfect safety condition!

In order to maintain this condition, as installer / user you must carry out your task in accoedance

with the discritions in these instructions, technially correctly and with the greatest possible pre-

cision!

We assume, as trained specialist you are having mechanical and electrical knowledge !

The valves must be used only for a purpose corresponding to its construction!

The valves must be used within the values specified in the technical data.

Satisfy yourself that, as the result of the mounting, the starting or as a result of the test adjusments

on the valves, no potential hazards will be produced for devices / machines / plant!

Open the valve only to such an extant as described in this documentation!

Do not loose the locking ring of the pilot cylinder or don`t try to disassemble the pilot cylinder.

Do not mount the valve, start the valve or carry out any adjusments on it if the valve, the supply

lines or the part of the plant on which it is flange- mounted is damaged !

By ending mounting check the correct function and the tightness of the valve and check the cor-

rect function of the pilot valve and limit switches.

DG - 10/2019 http://www.end.de 11

Device Descriptions

4 Device description

4.1 Device description

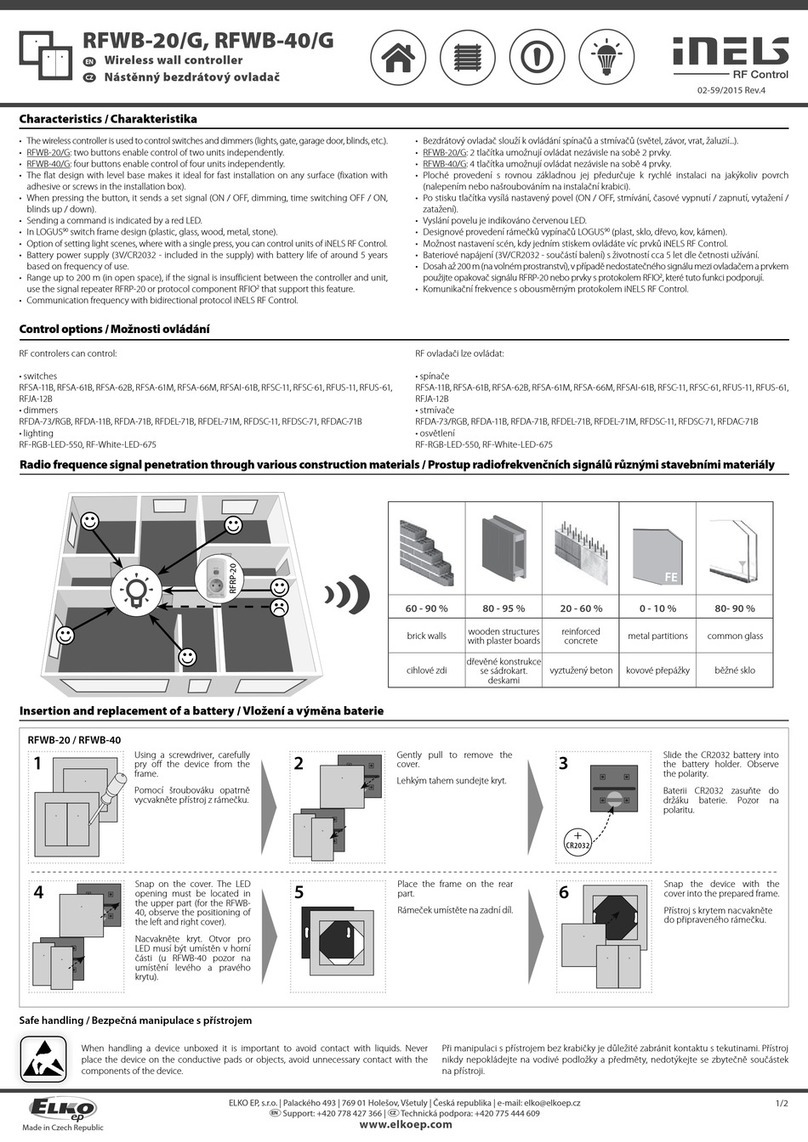

1 Valve body

2 Pilot cylinder

3 Screw joint

4 Cap

5 Connection

6 Pilot port

7 Flow direction indicator

8 Name plate

9 Warning note

10 Connection for grounding

Fig. 4.1 - Device descriptions - front / rear

6

2

3

1

5

7

8

9

4

5

10

Armaturen

PE

12 http://www.end.de DG - 10/2019

4.2 Device variants

The pressure actuated valves DG2D will be delivered in various variants.

The following table explains the composition of the article number to you. These article numbers

will be seen on the name plate:

For example: DG2D3112025/AX/OS

Pressure actuated valve, stainless steel / PTFE, normally close with the

flow direction, brass cylinder Ø80mm, G 1", optical position indicator

Device Variants

3. Digit

Ways

2. Digit

Connection

1. Digit

Product

D= Pressure actuated

valve

G= B.S.P. thread

DIN ISO 228 T1

A= Welded connection

DIN 3293

L= Welded connection

ISO 4200

M = Welded connection

DIN 11850-R2

F = flanges acc. to DIN

2531 / 2533 / 2545

2= 2/2-ways

3= 3/2-ways

6. Digit

Seals material

seat / stem

1= brass

2= bronze

3= stainless steel

4= Carbon steel

5= GG (grey cast iron)

6= GGG (ductile iron)

7= Light alloy

8= Plastic

4. Digit

Operation

D= direct acting

5. Digit

Body material

1= PTFE / PTFE

2= PTFE / NBR

3= PTFE / FKM

4= PTFE / EPDM

5= NBR / PTFE

6= NBR / NBR

7= FKM / FKM

8= FKM / PTFE

brass cylinder

0= Ø 32 mm

1= Ø 50 mm

2= Ø 80 mm

3= Ø 125 mm

(aluminium alloy)

4= Ø 100 mm

stainless steel cylinder

5= Ø 50 mm

6= Ø 80 mm

7= Ø 125 mm

(aluminium alloy)

8= Ø 100 mm

9= Ø 32 mm

threaded flanged and welded

connection connection

006 = G

⅛

008 = G

¼

010 = G ⅜

015 = G

½DN 15

020 = G

¾DN 20

025 = G 1 DN 25

032 = G 1¼DN 32

040 = G

1½DN 40

050 = G 2 DN 50

065 = G

2½DN 65

080 = G

3 DN 80

100 = G 4 DN 100

125 = others sizes DN 125

150 = on request DN 150

AX = version acc. to ATEX (obligatory)

ES = electric / mechanic position indicator

FL = flanged connection PN 16

HB = stroke stop

HN = manual override

HY = hygienic version

HO = stroke stop and optical position indicator

7. Digit

Operation

8. Digit

Piston- Ø

9. - 11. Digit

Connection

for 2/2-way-version:

1= Normally close

with the flow

direction

2= Normally close

against the flow

direction

3= Normally open

against flow

direction

4= Double acting

for 3/2-way-version:

1= split function

2= mixing function

15. - 20. Digit

Options

NI = inductive proximity limit switch

OF = free of oil and grease

OG = without valve body

OS = optical position indicator

NS = contactless position indicator (Reed-Kontakt)

V= for vacuum

VD = for vaccum and pressure

DG - 10/2019 http://www.end.de 13

Name-plate

4.3 Name-plate

The pressure acting valves DG2D will be provided with a name- plate, which permitts a definite

identification of the valves and shows the most important technical data to you. The name-plate

should not be displaced or changed

Abb. 4.2 - name-plate

Art.Nr. Article number of the valve (see also chapter 4. „device variants“)

Serie Order- or production-number

Betriebsdruck (PS) Max. admisable working pressure of the valve [bar]

Steuerdruck Recommend pilot pressure of the valve[bar]

Temperatur (TS) Temperature range of the valve

Größe (DN) Connecting size of the valve

Prüfdruck (PT) Testing pressure of the valve

Fluidgruppe Allowed fluid group of the valve

Herstellung Date of manufacturing

II 2G Ex h IIC T4 Gb : explosion proofed identification

II 2D Ex h IIIC T135° Db

END-Armaturen GmbH & Co. KG

D-32547 Bad Oeynhausen

+49 (0)5731 - 7900-0 www.end.de

Art.Nr.: DG2D3122050/AX

Serie: 220885

Betriebsdruck (PS): 8 bar

Steuerdruck: 6 bar

Temperatur (TS): -10°C ... +100°C

Größe (DN): 50 / G2"

Prüfdruck (PT): 12 bar

Fluidgruppe: 1

Herstellung: 14.02.2002

0062

II2G Ex h IIC T4 Gb

II2D Ex h IIIC T135° Db

14 http://www.end.de DG - 10/2019

Device Variants

4.5 Description of function

4.5.1 Description of function: Pressure actuated valve (2/2-way)

A slanting seat in the valve body will be closed with or against the flow direction by a valve disk.

The valve disk is connected with the piston by a stem. It`s dynamical sealing and guidance hap-

pens by a screw joint between valve body and pilot cylinder. The slanting valve design renders a

highly flow rate by low dirtyness.

Pressure actuated valves would be actuated wit a piston by a neutral pilot media (air, water, oil).

It works in a pressure range from 0 bar up to the max. nominal pressure which you can see in the

pressure table. The flow direction is fixed and signed on the valve.

4.4 Explosion proof identification

The pressure actuated valves are having an explosion proof identification, which shows the details

of the protection class to you:

Explosion proof identification of the pressure actuated valve:

Group II

Category 2G/2D (for zone 1 and zone 21)

Explosion proof classification: h - constructional safety

Temperature class (max. temperature of the surface):

T4 : Tmax. = 135°C

T5 : Tmax. = 100°C

T6 : Tmax. = 85°C

4.5 Corresponding use

Pressure actuated valves are work equipment with constructional safety designed for applicati-

ons in atmospheres according to category 2G (zone 1 + zone 2) / 2D (zone 21 + zone 22).

The max. temperature of the media, depending ot the switching frequency per minute, should not

exceed the following values:

85°C(n≤5/min)/40°C(n≥60/min) at temperature class T6

100°C(n≤5/min)/65°C(n≥60/min) at temperature class T5

135°C(n≤5/min)/100°C(n≥60/min) at temperature class T4. (n: Open- Close- cycle)

The ambient temperature should not exceed 60°C.

By using the pressure actuated valves, observe that the flow rate of potentially explosive media

inside the pressure actuated valve will be less than:

v≤2m/sforpotentiallyexplosiveliquidsand

v≤20m/sforpotentiallyexplosivegaseousfluids.

II 2G Ex h IIC T4 Gb

II 2D Ex h IIIC T135°C Db

II 2G Ex h IIC T5 Gb

II 2D Ex h IIIC T100°C Db

II 2G Ex h IIC T6 Gb

II 2D Ex h IIIC T85°C Db

DG - 10/2019 http://www.end.de 15

Description of Function

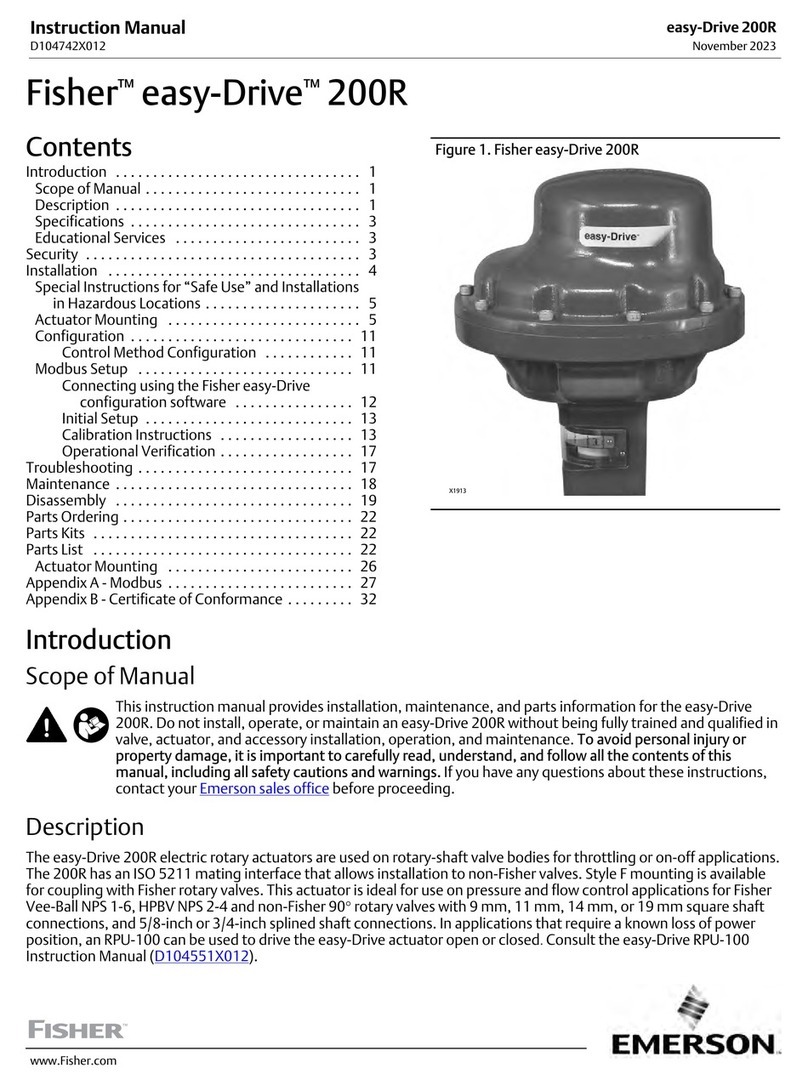

Fig. 4.4 - description of function - normally closed with the flow direction

© END-Automation GmbH & Co. KG

4.5.1.1 Normally close with the flow direction

The in neutral position closed valve obtains this function by a spring, which acts in close direction.

By feeding with compressed air the pilot pressure moves the piston against the spring and lift up

the valve disk from the seat. Therefore the valves open.

Because the valve closes with the flow direction, the nominal pressure supports the closing pro-

cess and seals the valve disk against the seat additionally. If the media flows through the valve with

a high speed the valve could close to fast and this could causes pressure shocks in the pipes.

The electrical control signal will be changed into the pressure media control by an optional avai-

lable solenoid valve. The figure 4.3 shows a directly mounted solenoid valve type MGAG3D.

Fig. 4.3 - description of function (Options: optical position indicator, solenoid vavle)

valve closed valve opend by

compressed air

valve closing by

spring force

© END-Armaturen GmbH & Co. KG

16 http://www.end.de DG - 10/2019

Description of Function

4.5.1.3 Normally open, close against the flow direction

The in neutral position opened valve obtains this function by springs mounted under the piston. The

valve closes against the flow direction only by the pilot pressure.

Fig. 4.6 - description of function - normally open, close against flow direction; double acting

Fig. 4.5 - description of function - Normally close against the flow direction

4.5.1.2 Normally close against the flow direction

The in neutral position closed valve obtains this function by a spring, which acts in close direction.

By feeding with compressed air the pilot pressure moves the piston against the spring and lift up

the valve disk from the seat. Therefore the valves open.

The valve closes against the flow direction only by the spring force. Therefore the valve closes

slowly and prevents pressure shocks in the pipes.

4.5.1.4 Double acting

The valve closes against the flow direction only by the pilot pressure. Also the valves opens with

the flow direction only by the pilot pressure.

© END-Automation GmbH & Co. KG

© END-Automation GmbH & Co. KG

DG - 10/2019 http://www.end.de 17

Description of Function

Fig. 4.8 - Description of function: mixing function

© END-Armaturen GmbH & Co. KG

A P1

P2

A P1

P2

Mischfunktion

A

P1P2

4.5.2.2 Mixing function

At this function the valve valve will be pressurized by two ports (P1/P2). In case of the position of

the piston flows from one of the two inlet ports to the outlet port. (P1►A / P2►A)

4.5.2 Description of function: Pressure actuated valve (3/2-way)

A straight seat in the valve body will be closed with or against the flow direction by a valve disk.

The valve disk is connected with the piston by a stem. It`s dynamical sealing and guidance hap-

pens by a screw joint between valve body and pilot cylinder. The 3/2-way pressure actuated valve

renders two functions: 1. split function

2. mixing function

Pressure actuated valves would be actuated wit a piston by a neutral pilot media (air, water, oil).

It works in a pressure range from 0 bar up to the max. nominal pressure which you can see in the

pressure table. The flow direction is fixed and signed on the valve.

4.5.2.1 Split function

At this function the valve will be pressurized by the inlet port P. In case of the position of the piston

the medium flows from the inlet port to one of the outlet ports. (P►A / P►B)

Fig. 4.7 - Description of function: split function

P B

A

P B

A

Aufteilfunktion

B A

P

split-function

mixing-function

18 http://www.end.de DG - 10/2019

4.6 Description of options function

4.6.1 Pilot valve (Option)

The 3/2- ways pilot valve which is necessary to control the pressure actuated valve will be mounted

directly on the pilot cylinder or in an external control box. For double acting valves it is necessary to

install a 4/2-or 5/2-ways pilot valve. The valve position will be selected by feeding compressed air.

The actuating time will be controlled by throttle valves.

The declaration of conformity and the mounting and operating manual of the pilot valve will be

separatly add to the delivery of a pressure actuated valve.

4.6.2 Position indicator (Option)

The signal of the position of the pressure actuated valve can be indicate in different ways: by an

optical position indicator or by an electrical position indicator.

4.6.3 Optical position indicator (Option)

On the stem there is a red pin mounted, which indicates the position of the valve on top of the pilot

cylinder. The hole for the red pin in the pilot cylinder is covered by a clear plastic cap. You can see

the pin in the position „open“.

4.6.4 Stroke stop (Option)

You are able to limited the stroke in the valve by a stroke stop. Therefore you can regulate the flow

rate of the valve.

4.6.5 Electrical position indicator (Option)

The electrical positon indicator indicates the position of the valve over a long distance or sends a

electrical signal to a controll box. For this there are several position indicators available: electric-

mechanic position indicator, contactless position indicator (Reed- contact) or inductive proximity

limit switch.

By the different variants one or both valve positions can be indicated.

4.6.6 Manual override (Option)

By the option „Manual override“ the pressure actuated valve can be opened or closed by a hand

wheel. By turning the hand wheel the stem of the valve lift up the valve disk from the seat or senk

down the valve disk. See also chapter 9. „Emergency operation with manual override“.

Description of Function

DG - 10/2019 http://www.end.de 19

5 Mounting / Disassembly

The mounting of the pressure actuated valve ristricts to

- the mechanical mounting into the prescribed pipes

- the connection of the hose for the pilot medium with the pilot port

- the electrical mounting of accessories, e.g.. pilot valve or limit switch.

The installation of the pressure actuated valve is as you desired.

In the following description we assume, that you have read the former chapters attentive. We also

assume that you will observe the safety advices and warnings from chapter 3. „Safety advice“

during the mounting / disassembly.

If you have not read chapter

3 „Safety advices“

until now, read these important advices now and turn back to this page!

The mounting and the electrical installation must be carried out only by trained specialest per-

sonnel having mechanical and electrical knowledge!

The following figures are showing the pressure actuated valves without any options! Perhaps the

valve mounting by you is equiped with option!

Your device variant you can see at the name-plate on the pilot cylinder of the valve. For their

meaning see also chapter

4.2 „Name-plate“.

The mechanical installation are the same by all variants. It differs only by the type of connection.

Observe the flow direction, specified on the valve body.

Before mounting the valve clean up the pipes. Pollution will be reduce the safety and the lifetime of

the valve. If necessary mount a Y- strainer in front of the valve.

Avoif strains of the valve body by non align pipes.

5.1 Electrical installation

On principle you have to earth the pilot cylinder at the assigned connection for grounding.

The electrical installation depends on the used options. Therefore you have to observe the instal-

lation and operating manuals of the attached options.

Mounting / Disassembly

20 http://www.end.de DG - 10/2019

5.2 Mounting of a valve with threaded connection

Before lay on sealing compounds,check the hardly screwing by the pipes into the valve body.

Lay on the correct sealing compounds on the pipes end. By using PTFE-ribbon or hemp sealings

observe the screw direction. Don´t use sealing compounds which are not prescribed for your

employment.

Screw the pipes into the connection ends of the valves. Don´t use the pilot cylinder as a lever.

Strike up the pipes with pressure after that time the manufacturer of the sealing compounds pre-

tends for harden it.

Check the tightness af all connections.

5.3 Mounting of a valve with welded connection

By welding the valve body with the pipes observe appropriate demands and guide lines.

The safety demands by welding are depending on the place and the position of the point of weld.

Welding the parts at a serviceable device/machine/plant the potential of danger is as higher as

welding the parts in a welding room.

If appropriate, inform the shift foreman / safety engineer or the works manager and the fire

brigade of your factory

By welding observe your own national guide lines about safety and prevention of accidents.

By welding the valve between the pipes you have to take measures first, to prevent the damage

of the sealings.

5.3.1 Protection of the sealings by using Heat Absorbing Paste

To protect the seals of the of a pressure actuated valve you have to apply a amount of heat absor-

bing paste (e.g. TECHNOLIT heat absorbing paste, BLOC-IT heat absorbing paste, METAFLUX

THERMEX) to the area to be protected.

By using the heat absorbing paste you have to observe the instructions of the manufacturer.

By making multiple welding seam, the valve will have to be cool down after every working opera-

tion.

Mounting / Disassembly

This manual suits for next models

23

Table of contents

Other END ARMATUREN Controllers manuals