END ARMATUREN NE03 Series User manual

Original Operating Manual

Electric Actuator

NE03

acc. to annex VI of the Directive 2006/42/EC

END-Armaturen GmbH & Co. KG

Oberbecksener Str. 78 · D-32547 Bad Oeynhausen · Telefon (05731) 7900-0 · Telefax (05731) 7900-199 · http://www.end.de

2 http://www.end.de NE03 - 01.2020

© by END-Armaturen GmbH & Co. KG

All rights reserved. END-Armaturen GmbH & Co. KG claims copyright over this documentation.

This documentation may neither be altered, expended, reproduced nor passed to third parties without the

written agreement of the END-Armaturen GmbH & Co. KG. This restriction also applies to the corresponding

drawings.

END-Armaturen GmbH & Co. KG has the right to change parts of the actuator at any time without prior or direct

notice to the client. The contents of this publication are subject to change without notice.

This publication has been written with great care. However END-Armaturen GmbH & Co. KG cannot be held

responsible, either for any errors occurring in this publication or for there consequences.

The products are specified by the statements in this documentation; no assurance of the properties is given.

END-Armaturen GmbH & Co. KG

Oberbecksener Straße 78

D-32547 Bad Oeynhausen

Telephone: +49 -(0)5731 / 7900 - 0

Facsimile: +49 -(0)5731 / 7900 -199

Web: http://www.end.de

Mail: [email protected]

Edition: 14.01.2020

The right is reserved to change designs and devices.

Imprint

NE03 - 01.2020 http://www.end.de 3

Content

Content

1 Foreword................................................................................................................................... 5

2 General advice......................................................................................................................... 6

2.1 Validity ....................................................................................................................................... 6

2.2 Inward monitoring.................................................................................................................... 6

2.3 Complains.................................................................................................................................. 6

2.4 Guarantee.................................................................................................................................. 6

2.5 Symbols and their signification ............................................................................................. 7

3 Safety advice............................................................................................................................ 8

3.1 Personal protection................................................................................................................. 8

3.1.1 Safety advice for mounting .................................................................................................... 8

3.1.2 Safety advice for adjustment and starting........................................................................... 9

3.2 Device safety.......................................................................................................................... 10

4 Device description................................................................................................................ 11

4.1 External parts ......................................................................................................................... 11

4.2 Internal parts .......................................................................................................................... 12

4.3 Device variants....................................................................................................................... 13

4.4 Name-plate ............................................................................................................................. 13

5 Ambient conditions............................................................................................................... 14

6 Assembly instructions.......................................................................................................... 15

6.1 Mechanical mounting ........................................................................................................... 15

6.1.1 Directly mounting................................................................................................................... 16

6.1.2 Mounting via bracket and stem........................................................................................... 17

6.2 Electrical Installation............................................................................................................. 19

6.2.1 Removing of the housing cover........................................................................................... 19

6.2.2 Stripping and connecting the cables / leads..................................................................... 19

7 Adjustment / Starting............................................................................................................ 21

7.1 Adjustment.............................................................................................................................. 22

7.2 Check of the rotating direction of the actuator.................................................................22

7.3 Adjustment of the limit switches......................................................................................... 23

7.4 Adjustment of the optical position indicator ..................................................................... 24

7.5 Verify the adjustment ............................................................................................................ 24

7.6 Mounting of the housing cover............................................................................................ 25

7.7 Starting .................................................................................................................................... 25

8 Emergency operation (manual override)........................................................................... 26

9 Faults........................................................................................................................................ 27

9.1 Fault causes............................................................................................................................ 27

9.2 Disassembly............................................................................................................................ 28

9.2.1 Electrical disassembly .......................................................................................................... 28

9.2.2 Mechanical disassembly...................................................................................................... 28

4 http://www.end.de NE03 - 01.2020

Content

10 Maintenance / Cleaning....................................................................................................... 29

10.1 Maintenance........................................................................................................................... 29

10.2 Cleaning................................................................................................................................... 29

11 Technical data and dimensions.......................................................................................... 30

11.1 Technical data........................................................................................................................ 30

11.2 Dimensions.............................................................................................................................. 31

11.3 Wiring diagram - 24V DC (only for standard actuators without options)......................32

11.4 Wiring diagram - 230V AC (only for standard actuators without options)....................33

12 Index ........................................................................................................................................ 34

NE03 - 01.2020 http://www.end.de 5

1 Foreword

Dear customer,

Dear assembler / user,

These mounting and operating manual are intended to give you the knowledge which is necessary

for you to be able to carry out the mounting and adjustment of an NE actuator rapidly and correctly.

Please read these instructions carefully and pay particular attention to the advice and warning

notes!

The actuators NE are supplied in various versions, depending on

• the actuating time for 90° rotation angle of the output drive shaft

• the operating voltage and

• the max. revolutions of the output drive shaft.

In addition optional extensions are available.

In case of the event of a power failure the output drive shaft of the actuator NE can be adjusted by

the manual override.

The field of use of these actuators are predominantly

• in industrial fittings

• in chemical installations

• in ventilation and blower construction

• in heating and air-conditioning technology

• in machine and plant construction

• in water treatment, etc.

If you have any question in relation to the actuator NE we shall be pleased to answer them.

The telephone number will be found on the inside front cover of these mounting and operation

manual.

Yours

END-Armaturen GmbH & Co. KG

Foreword

6 http://www.end.de NE03 - 01.2020

General advice

2 General advice

2.1 Validity

The mounting and operating manual is valid for the standard versions of the electric actuators

NE.

2.2 Inward monitoring

Please check directly after delivery the actuator for any transport damage and deficiencies with

reference to the accompanying delivery note the number of the parts.

Do not leave any parts in the package.

2.3 Complains

Claims for the replacement of goods which relate to transport damage can only be considered

valid if the parcel service / forwarder has notified without delay.

In case of returns (because of transport damage / repairs), please make a damage protocol and

send the parts back, please only on consultation with the sales department, to the manufacturer, if

possible in the original packaging.

In case of a return, please mention the following:

• Name and address of the consignee

• Ordering- / Article- number

• Description of the defect.

2.4 Guarantee

For our actuators NE we give a guarantee period in accordance with the sales contract.

The end of the normal duration of life of the wearing parts represents no defect.

The warranty and guarantee rules of END-Armaturen GmbH & Co. KG are applicable.

NE03 - 01.2020 http://www.end.de 7

Symbols and their signification

2.5 Symbols and their signification

Paragraphs which are identified with this symbol contain very important advices, this also includes

advices for everything health risks. Observe this paragraphs without fail!

Paragraphs which are identified with this symbol contain important advices, this also includes how

to avoid damage to property. Observe these paragraphs without fail!

This symbols indicates paragraphs which contain comments / advices or tips.

This spanner identifies the description of actions which you should carry out.

8 http://www.end.de NE03 - 01.2020

Safety advice

3 Safety advice

Depending on the technical circumstances and the time under and at which the electric actuator

is mounted, adjusted and commissioned, in each case you have to take into account particular

safety aspects

If, for example, the actuator actuates a slide in an operational chemical plant, the potential hazards

of commissioning have another dimension from that when this is only being carried out for test

purposes on a „dry“ part of the plant in the assembly room.

Since we do not know the circumstances at the time of mounting / adjusting / commissioning

you may find advice on hazards in the following description which are not relevant to you. Please

observe (only) the advice which applies to your situation!

The actuators must not be put into service until the final machinery into which it is to be incorpo-

rated has been declared in conformity with the provisions of the Directive 2006/42/EC on machin-

ery, where appropriate.

3.1 Personal protection

3.1.1 Safety advice for mounting

We wish to point out expressly that the mounting, the electrical installation and the adjustment

of the actuator NE and the accessories must be carried out only by trained specialised personnel

having mechanical and electrical knowledge.

Switch off all the devices / machines / plant affected by mounting or repair.

If appropriate, isolate the devices / machines / plant from the mains.

Check (for example in chemical plants) whether switching off the devices / machines / plant will

cause potential danger.

If appropriate, in the event of a fault in the actuator (in a plant which is in operation), inform the

shift foreman / safety engineer or the works manager without delay about the fault, in order, for

example, to avoid an outflow / overflow of chemicals or the discharge of gases in good time by

means of suitable measures.

Before mounting or repair, remove the pressure from the pneumatic / hydraulic devices /

machines / plant.

If necessary, set up warning signs in order to prevent the inadvertant starting up of the devices /

machines / plant.

Observe the respective relevant professional safety and accident prevention regulations when

carrying out the mounting / repair work.

Check the correct functioning of the safety equipment (for example the emergency push off but-

tons / safety valves, etc).

Before electrical installation of the actuator, check the voltage-free state of all lines to be con-

nected.

NE03 - 01.2020 http://www.end.de 9

Safety advice

3.1.2 Safety advice for adjustment and starting

As a result of the starting (electrically or by hand) of the actuator, the position of a slide / valve /

flap or the like on which it is flange-mounted - referred to below as the actuating element - will be

changed!

As a result, the flow of gases, steam, liquid, etc. may be enabled or interrupted.

Satisfy yourself that, as a result of the starting or the test adjustments on the actuator, no potential

hazards will be produced for personnel or the environment!

If necessary set up warning signs in order to prevent the inadvertent starting up or shutting down

of the devices / machines / plant!

After completing the adjustment, check the correct function and, if appropriate, compliance with

the intended angular position of the actuator and the function of the switches of the adjusted to

the angular positions!

Check the function of the end position switches.

Check whether the actuating element is actually 100 per cent closed when the controller signals

the corresponding end stop.

Through suitable measures, prevent that limbs being trapped by moving actuating elements!

Check the correct function of the safety devices (for example emergency push off buttons / safety

valves, etc.

Carry out the starting or the adjustment only in accordance with the instructions described in this

documentation!

In case of adjustments on an actuator which is open and switched on (ready to use), there is a

risk that live parts can be touched.

The adjustments must therefore be carried out only by an electrician or a person having adequate

training, who is aware of the potential hazard.

10 http://www.end.de NE03 - 01.2020

Safety advice

3.2 Device safety

The electric actuator NE

• is a quality product which is produced in accordance with the recognized industrial

regulations

• and which has left the manufactures work in a perfect safety condition.

In order to maintain this condition, as installer / user you must carry out your task in accordance

with the descriptions of these instructions, technically correctly and with the greatest possible

precision.

We assume that you have, as a trained specialist, sound mechanical and electrical knowledge!

The actuator must be used only for the purpose corresponding to its construction.

The actuator must be used only within the values specified in the technical data.

Satisfy yourself that, as a result of the mounting, the starting or as the result of the test adjust-

ments on the actuator, no potential hazards will be produced for devices / machines / plant!

Open the actuator only to such an extent as described in this documentation!

Do not mount the actuator, start the actuator or carry out any adjustments on it, if the actuator, the

supply lines or the part of the plant on which the it is flange-mounted is damaged!

Before mounting the actuator, check the free running of the actuating element.

Before the electrical installation of the actuator, check that all the lines to connected are voltage-

free.

After completing the mounting or the adjustments, check the correct function and, if appropriate,

compliance with the intended angular position of the actuator and also the function of the switches

adjusted to the angular positions.

If the actuator is used in the open air, check, on an approximately six monthly cycle, that the

device is dry on the inside.

After fitting the housing cover, tighten the cross-point screws for fixing the housing cover with a

torque screwdriver.

On this regard, observe the torque specified in chapter 8.3.

Do not use any abrasive, caustic or flammable cleaning aids for cleaning the housing, or any high-

pressure cleaning devices.

NE03 - 01.2020 http://www.end.de 11

Device description

4 Device description

4.1 External parts

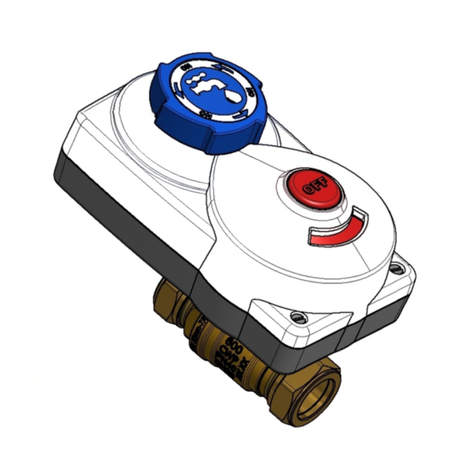

Fig. 4.1 - External parts NE03

1Optical position indicator

2 Body cap

3Cap screw

4Cable entry M20x1,5

5 Ground, external

6Body

7Manual override

8Clutch lever for manual override

9Mounting pad with hole cycle

acc. to ISO 5211 F03, F04 and F05

10 Main shaft SW11

11 Allen key for manual override

3

4

5

2

1

7

6

8

9

10

11

12 http://www.end.de NE03 - 01.2020

Device description

4.2 Internal parts

Fig. 4.2 - Internal parts NE03

1Optical position indicator

2 LED for optical position indicator

3Limit switch

4Connecting terminal

5 Ground, internal

6Shaft for optical position indicator

7Heater

8Control board

9Motor

10 Switch cam

11 Gear box

1

2

3

4

5

additional limit switch OPEN

limit switch OPEN

additional limit switch CLOSE

limit switch CLOSE

8

7

6

9

11

10

Detail limit switch

Detail connecting terminal

8

7

6

5

4

3

2

1

NE03 - 01.2020 http://www.end.de 13

4.3 Device variants

Ordering example: e.g. NE034100

= Electric actuator, type NE03, 230V 50/60Hz, with 2 additional limit switches

Device description

1.+ 2. Digit

Product

3.+ 4. Digit

Actuator type

5. Digit

Voltage

6. Digit

Options

7.+ 8. Digit

NE = Electric actuator 03 = NE03 (30Nm) 2= 24V DC

4= 230V AC

1 = 2 additional

limit switches

(Standard)

00 = reserved for

mounting on

valves

4.4 Name-plate

The actuators will be provided with a name-plate, which permits a definite identification of the

actuator and shows the most important technical data to you. The name-plate should not been

displaced or changed

Fig. 4.3 - Name-plate

Type type of actuator. The type designation NA or SA (Watergates) is the same as

NE (END-Armaturen)

Motor: nominal power supply [A]

O.P.: mounted additional options

Torque: nominal torque [Nm]

Supply: nominal voltage [V]

S.No.: serial number of the actuator

Type SA03 Torque 30Nm

Motor 0,8A Supply 230V1Ph

O.P. S.N. HE10000

watergates

knife-gate-valves - Stoffschieber

14 http://www.end.de NE03 - 01.2020

5 Ambient conditions

The actuators NE are designed for rough operating conditions.

However, some special conditions are to be observed for its mounting and subsequent operation.

Take care that

• the actuator will be mounted in accordance with the mounting advice listed below.

• the actuator is used in accordance with the characteristic values specified on the

name-plate or in the separate data sheet.

• mounting of the outdoors only after request.

• the actuators must be protected from environmental influences (e.g. UV radiation, frost,

humidity).

The non-observance of the mounting advice or use outside the specified characteristic values can

have a negative influence on the functional reliability of the actuator.

The use of the actuator under the influence of radioactive radiation may take place only after

discussions with the manufacturer

Ambient conditions

NE03 - 01.2020 http://www.end.de 15

6 Assembly instructions

The mounting of the actuator NE is restricted to

• the mechanical mounting of the actuator on the part of the devices / machines / plant

which contains the actuating element, and

•

the connection of the actuator to the motor drive and control lines.

The actuator may be mounted in any desired position.

In the following description, we assume that you have carefully read the previous chapters and

that you will observe the safety advice and the warning notes in chapter 3 „safety advice“ during

the mounting / disassembly work.

If you have not yet read chapter 3 „safety advice“ please do so now and then return to this point!

The mounting and the electrical installation may be carried out only by trained specialist person-

nel with sound mechanical and electrical knowledge.

The mechanical mounting is identical in all variants.

The electrical installation is different, depending on the type of drive an equipment.

Therefore, for the electrical installation, observe the wiring diagrams at the end of these mounting

and operating manual

The explanation of the designation will be found under

4.3 “Device variants”.

6.1 Mechanical mounting

Two mounting variants are available:

• directly mounting, or

• mounting with bracket and stem (accessory)

Before mounting you have to fix a qualified mounting variant for your application.

Directly mounting will be able, if the dimensions of the shafts and the ISO - flanges of the actuator

and the slide/valve/flap are the same. Differences of the dimension for the stem of the slide/valve/

flap will be able to be equalized by available bushings (option) in some cases.

A mounting with bracket and stem will be necessary, if the differences of the dimensions between

the shaft of the actuator and the stem of the slide/valve/flap are not able to be equalized by a bush-

ing or the ISO-flanges did not match.

This mounting variant will also be used by high/low medium temperatures or voluminous isolated

pipes.

By mounting with bracket and stem observe also the mounting device of the supplier of these parts.

Do not drill any holes into the body of the actuator- the damage of the actuator or a insufficient

fastening of the actuator will be the result.

Assembly

16 http://www.end.de NE03 - 01.2020

6.1.1 Directly mounting

Before starting the assembly of actuator and slide/valve/flap, observe that the actuator and the

slide/valve/flap are in the same end position, e.g. both in OPEN or in CLOSE position. Furthermore

the operating direction on actuator and slide/valve/flap must be the same.

Put the bottom side of the actuator to the slide/valve/flap that the stem will enter into the octagonal

boring of the shaft of the actuator. If necessary use a appropriate bushing (options), to equalize

differences of the dimension between the stem and the shaft.

Align the actuator to the slide/valve/flap.

Put the actuator onto the stem of the slide/valve/flap until the surface of the actuator cling to the

ISO - flange of the slide/valve/flap. If this operation will be ponderous the shaft of the actuator will

be driven onto the stem of the slide/valve/flap by slightly strokes without any tools.

Fasten the actuator with fit bolts. Observe the maximum depth of the threaded holes of the actua-

tor. Would there be two sizes of hole circles to fasten the actuator, you have always to use the

greater one.

Tighten the screws. Therefore observe the maximum torque of the choused screws.

Assembly

Fig. 6.1 - Assembly, directly mounting

o.k.

o.k.

Position

NE03 - 01.2020 http://www.end.de 17

6.1.2 Mounting via bracket and stem

Before starting the assembly of actuator and slide/valve/flap, observe that the actuator and the

slide/valve/flap are in the same end position, e.g. both in OPEN or in CLOSE position. Furthermore

the operating direction on actuator and slide/valve/flap must be the same.

Put the stem onto the stem of the slide/valve/flap. Therefore observe the position of possibly posi-

tion indicators.

Put the bracket onto the slide/valve/flap and align them .

Fasten the bracket with fit bolts. Observe the maximum depth of the threaded holes of the actuator.

Would there be two sizes of hole circles to fasten the actuator, you have always to use the greater

one. Tighten the screws. Therefore observe the maximum torque of the choused screws.

Put the bottom side of the actuator to the slide/valve/flap that the stem will enter into the octagonal

boring of the shaft of the actuator.

Assembly

Fig. 6.2 - Assembly, mounting via bracket and stem

o.k.

Position indicator?

18 http://www.end.de NE03 - 01.2020

Assembly

Align the actuator to the slide/valve/flap response to the console.

Put the actuator onto the stem of the slide/valve/flap until the surface of the actuator cling to the

ISO - flange of the bracket. If this operation will be ponderous the shaft of the actuator will be

driven onto the stem of the slide/valve/flap by slightly strokes without any tools.

Fasten the actuator with fit bolts. Observe the maximum depth of the threaded holes of the actua-

tor. Would there be two sizes of hole circles to fasten the actuator, you have always to use the

greater one.

Tighten the screws. Therefore observe the maximum torque of the chosen screws.

If necessary install a applicable protection device to prevent accidental touching into the bracket.

Fig. 6.3 - Assembly, mounting via bracket and stem

o.k.

Position

NE03 - 01.2020 http://www.end.de 19

Assembly

6.2 Electrical Installation

Please be sure that the voltage of the power supply must be in accordance with the specification

of the name-plate

Protect the electric actuator appropriate to the current consumption.

Connect the actuator each with its own switching device.

6.2.1 Removing of the housing cover

Loosen the four socket screws with an Allen key and pull the housing cover hard to remove it!

For assistance, you can insert a screwdriver a few millimetres between housing cover and hous-

ing and lever the cover open..

Do not damage the cover and/or the sealing rubber in the process. In this case, the degree of

protection IP 67 would no longer be ensured!

6.2.2 Stripping and connecting the cables / leads

Take care that all leads which have to be stripped and connected during the installation work

have all their poles isolated from the power supply.

When stripping leads which are live, there is a risk of a life-threatening shock.

Remove the sheaths of the motor drive cable and the control cable and the insulation from the

leads in accordance with figure 6.3.

In the case of leads with stranded conductors, provide the ends in each case with a wire end

sleeve.

Lead the cable for the motor and the cable for the limit switches through the cable fittings.

Feed the stripped ends of the leads into the terminals as far as the stop and then tighten them. The

assignment of the connections can be seen from the wiring diagrams at the end of these mounting

and operation manual.

At actuators witch are provided with options additional operating manuals enclosed if possible.

Please take notice of this manual, the references and the appropriate wiring diagram.

Fig. 6.4 -Electrical installation - stripping of the cables / leads

6

20 http://www.end.de NE03 - 01.2020

Don’t miss to connect the two ground earth (Internal one marked by sticker, outer is between the

mechanical bolt stops (see figure 6.5) ).

Ensure that no bare wires protrude from the terminals and thus produce the risk of a shock or of

a short circuit.

Tighten the cable fittings so firmly that the strain relief becomes effective and the cable lead

through corresponds to the predefined degree of protection (IP67).

Bend the leads in the actuator such that they are not trapped when the housing cover is fitted.

Lay the cables to their starting positions (as appropriate, in conduits or cable ducts).

Observe that no moisture come into the actuator along the cable. Install the cable by a bow into

the actuator by example, so that moisture can drip of.

Ensure that the cables are not crushed or sheared and that they are not under pressure or tension.

Do not lay the control cable parallel to other cables which lead to high-power loads. Powerful

electromagnetic fields could induce currents in the control lines which may possibly lead to

malfunctions.

Finally, carry out the adjustments to the actuator, for this please observe the chapter

7. „Adjustment / Starting“

Close the actuator again.

Ensure that the circumferential rubber sealing ring in the housing is not damaged and correctly

seated in the groove.

Fit the housing cover and screw it tight using the 4 screws. For this, observe the chapter

7.6 „Fitting the housing cover“.

Fig. 6.5 -Electrical installation - connection of the earth conductor

Assembly

8

7

6

5

4

3

2

1

This manual suits for next models

1

Table of contents

Other END ARMATUREN Controllers manuals

Popular Controllers manuals by other brands

Johnson Controls

Johnson Controls PCA3613 installation instructions

Omron

Omron CP1L brochure

KELCO

KELCO F29 MK3 Installation & programming manual

Continental Access

Continental Access Accelaterm CICP2800 Quick setup guide

Seltron

Seltron SGC26 manual

Hornbach

Hornbach Activalve S468 Installation maintenance and operating instructions