ENDA E-100 Series User manual

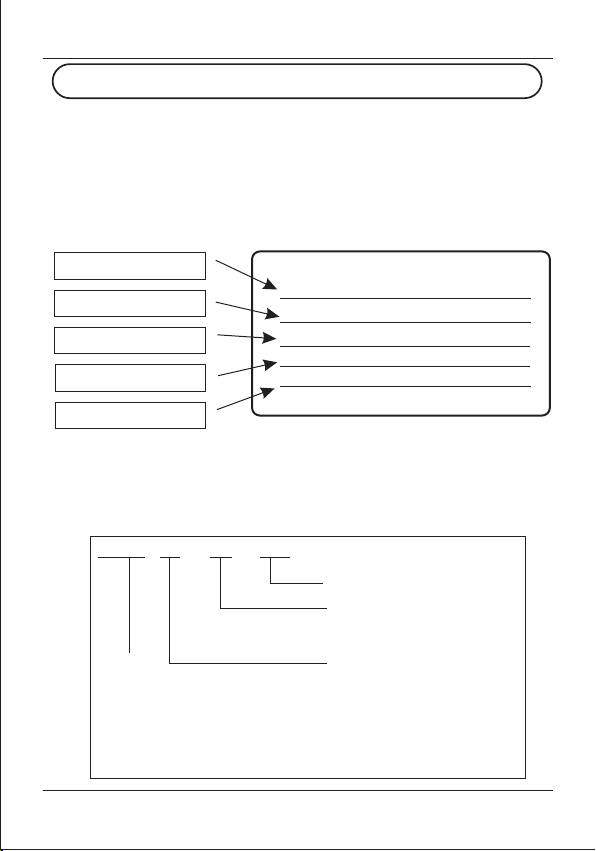

CONTENTS

1. Safety Message

2. Receiving and Checking

3. General Specifications

4. External dimensional diagrams and

Identifying the parts

5. Mounting

6. Wiring

7. Operation

8. Using Intelligent Input Terminals

9. Function List

10. Protective functions

11. Trouble shooting Tips

12. Maintenance and Inspection

13. Option

1-1

2-1

3-1

4-1

5-1

6-1

7-1

8-1

9-1

10-1

11-1

12-1

13-1

Page

ENDA E-100 INSTRUCTION MANUAL

14. RS485 Communication

14-1

1. Safety Messages

For the best results with the E-100 Series inverter,

read this manual and all of the warning labels

attached to the inverter carefully before installing and

operating it, and follow the instructions exactly. Keep this

manual handy for quick reference.

Definitions and Symbols

A safety instruction(message) includes a hazard alert symbol

and a signal word, DANGER or CAUTION. Each signal

word has the following meaning:

This symbol is the "Safety Alert Symbol." It occurs with

either of two signal words : DANGER or CAUTION, as

described below

DANGER : Indicates a potentially hazardous situation

which, if not avoided, can result in serious injury or death.

CAUTION : Indicates a potentially hazardous situation

which, if not avoided, can result in minor to moderate injury,

or serious damage to the product. The situation described in

the CAUTION may, if not avoided, lead to serious results.

Important safety measures are described in CAUTION (as

well as DANGER), so be sure to observe them.

NOTE : Notes indicate an area or subject of special merit,

emphasizing either the product's capabilities or common

errors in operation or maintenance.

1-1

ENDA E-100 INSTRUCTION MANUAL

¡Some drawings in this manual are shown with the protective or

shields removed in order to describe detail with more clarity.

Make sure all covers and shields are replaced before operating

this product.

¡This manual may be modified when necessary because of the

improvement of the product, modification, or changes in

specifications.

¡To order a copy of this manual, or if your copy has been

damaged or lost, contact your ENDA representative.

¡ENDA is not responsible for any modification of the product

made by the user, since that will void the guarantee.

CAUTION

1-2

ENDA E-100 INSTRUCTION MANUAL

Index to Dangers and Cautions in This Manual

Installation-cautions for Mounting Procedures

¡Be sure to install the unit on flame-resistant

material such as a steel plate.

Otherwise, there is the danger of fire.

¡Be sure not to place any flammable materials

near the inverter.

Otherwise, there is the danger of fire.

¡Be sure not to let the foreign object enter vent

openings in the inverter housing, such as wire

clippings, spatter from welding, metal shavings, dust, etc.

Otherwise, there is the danger of fire.

¡Be sure to install the inverter in a place which can

bear the weight according to the specifications in the text.

Otherwise, it may fall and cause injury to personnel.

¡Be sure to install the unit on a perpendicular wall

which is not subject to vibration.

Otherwise, it may fall and cause injury to personnel.

¡Be sure not to install or operate an inverter which

is damaged or has missing parts.

Otherwise, it may cause injury to personnel.

¡Lift the cabinet by the cooling fin. When moving the

unit, never lift by the plastic case or the terminal covers.

Otherwise, the main unit may be dropped causing damage

to the unit.

¡When mounting units in an enclosure, install a fan or

other cooling device to keep the intake air temperature

below 40¡.

5-1

5-1

5-1

5-1

5-1

5-1

CAUTION

5-1

5-1

1-3

ENDA E-100 INSTRUCTION MANUAL

¡Be sure to maintain the specified clearance

area around the inverter and to provide adequate

ventilation.

Otherwise, the inverter may overheat and cause equipment

damage or fire.

¡Be sure to install the inverter in a well-ventilated

room which does not have direct exposure to

sunlight, a tendency for high temperature, high

humidity of dew condensation, high levels of dust,

corrosive gas, explosive gas, inflammable gas,

grinding-fluid mist, salt damage, etc.

Otherwise, there is the danger of fire.

5-2

5-2

CAUTION

1-4

ENDA E-100 INSTRUCTION MANUAL

DANGER

Wiring-Dangers for Electrical Practices and Wire

Specifications

¡Be sure to connect grounding terminal.

Otherwise, there is a danger of electric shock and/or fire.

¡Wiring work shall be carried out only by qualified

personnel.

Otherwise, there is a danger of electric shock and/or fire.

¡Implement wiring after checking that the power

supply is off. You may incur electric shock and/or fire.

¡Do not connect wiring to an inverter or operate an

inverter that is not mounted according the instructions

given in this manual.

Otherwise, there is a danger of electric shock and/or

injury to personnel.

¡When wiring the emergency stop circuit, check the

wiring thoroughly before operation.

Otherwise, it may cause injury to personnel.

6-2

6-2

6-2

6-2

6-2

1-5

ENDA E-100 INSTRUCTION MANUAL

Wiring-Cautions for Electrical Practices

Be sure that the input voltage matches the inverter

specifications:

¡Single-phase 200 to 230 V 50/60Hz

Otherwise, there is the danger of injury and/or fire.

¡Be sure not to connect an AC power supply to the

output terminals(U.V.W).

Otherwise, there is the danger of injury and/or fire.

¡Do not Run/Stop operation by switching ON/OFF

electromagnetic contactors on the primary or secondary

sides of the inverter.

Otherwise, there is the danger of fire.

¡To connect a braking resistor, follow the procedures

described in this manual.

Otherwise, there is the danger of fire.

¡6-1

6-1

6-1

6-1

CAUTION

1-6

ENDA E-100 INSTRUCTION MANUAL

¡Fasten the screws with the specified fastening

torque. Check for any loosening of screws.

Otherwise, there is the danger of fire.

¡Be sure to install a fuse in the wire for each phase

of the main power supply to the inverter.

Otherwise, there is the danger of fire.

¡Do not perform a withstand voltage test of the

inverter.

Otherwise, it may cause semi-conductor elements

to be damaged.

¡To connect a braking resistor, braking resistor unit

or braking unit, follow the procedures in this manual.

Improper connection may cause a fire.

¡Do not connect or disconnect wires or connectors

while power is applied to the circuit.

Otherwise, it may cause injury to personnel.

6-1

6-1

6-1

6-1

6-1

CAUTION

1-7

ENDA E-100 INSTRUCTION MANUAL

Dangers for Operations and Monitoring

¡Be sure to turn on the input power supply after

closing the main case. While being energized, be

sure not to open the main case.

Otherwise, there is the danger of electric shock and/or fire.

¡Be sure not to operate the switches with wet hands.

Otherwise, there is the danger of electric shock.

¡While the inverter is energized, be sure not to touch

the inverter terminals even when the motor is stopped.

Otherwise, there is the danger of electric shock.

¡If the Retry Mode is selected, the motor may

suddenly restart during the trip reset Do not approach

the machine(be sure to design the machine so that safety for

personnel is secure even if it restarts.)

Otherwise, it may cause injury to personnel and/or fire.

¡If the power supply is cut off for a short period of

time, the inverter may restart operation after the power

supply recovers if the command to operate is active.

If a restart may pose danger to personnel, so be sure to use

a lock out circuit so that it will not restart after power recovery.

Otherwise, it may cause injury to personnel.

¡The Stop Key is effective only when the stop function

is enabled. Be sure to prepare emergency stop key

separately.

Otherwise, it may cause injury to personnel.

DANGER

7-1

7-1

7-1

7-1

7-1

7-1

1-8

ENDA E-100 INSTRUCTION MANUAL

¡After the operation command is given, if the

alarm reset is conducted, it will restart suddenly.

Be sure to set the alarm reset after verifying the

operation command is off.

Otherwise, it may cause injury to personnel.

¡Be sure not to touch the inside of the energized

inverter or to put any conductive object into it.

Otherwise, there is a danger of electric shock and/of fire.

DANGER

7-1

7-1

1-9

ENDA E-100 INSTRUCTION MANUAL

Cautions for Operations and Monitoring

¡The heat sink fins will have a high temperature.

Be careful not to touch them.

Otherwise, there is the danger of getting burned.

¡Install a holding brake separately if necessary.

Otherwise, there is the danger of accident.

¡Check the direction of the motor, any abnormal

motor vibrations or noise.

Otherwise, there is the danger of equipment damage.

¡The operation of the inverter can be easily changed

from low speed to high speed. Be sure check the

capability and limitation of the motor and machine

before operating the inverter.

¡If you operate a motor at a frequency higher than

the inverter standard default setting (60Hz), be sure

to check the motor and machine specifications with

the respective manufacturer. Only operate the motor at

elevated frequencies after getting their approval.

Otherwise, there is the danger of equipment damage.

¡All the constants of the inverter have been preset

at the factory.

Otherwise, there is the danger of equipment damage.

CAUTION

7-2

7-2

7-2

7-2

7-2

7-2

1-10

ENDA E-100 INSTRUCTION MANUAL

Dangers and cautions for Troubleshooting

Inspection and Maintenance

¡Wait at least five(5) minutes after turning off the

input power supply before performing maintenance

or an inspection.

Otherwise, there is the danger of electric shock.

¡Make sure that only qualified personnel will

perform maintenance, inspection, and part replacement.

(Before starting to work, remove any metallic objects from

your person(wrist watch, bracelet, etc.) Be sure to use tools with

insulated handles.

Otherwise, there is a danger of electric shock and/or injury to

personnel.

¡Never touch high-voltage terminals in the inverter.

Otherwise, there is a danger of electric shock.

¡The logic PCB employs CMOS ICS.

Do not touch the CMOS elements.

They are easily damaged by static electricity.

¡Do not connect or disconnect wires, connectors, or

cooling fan while power is applied to the circuit.

Otherwise, it may cause injury to personnel.

¡Never modify the product.

Otherwise, there is a danger of electric shock and/or injury to

personnel.

DANGER

DANGER

Dangers for using

12-1

12-1

12-1

12-1

12-1

1-11

ENDA E-100 INSTRUCTION MANUAL

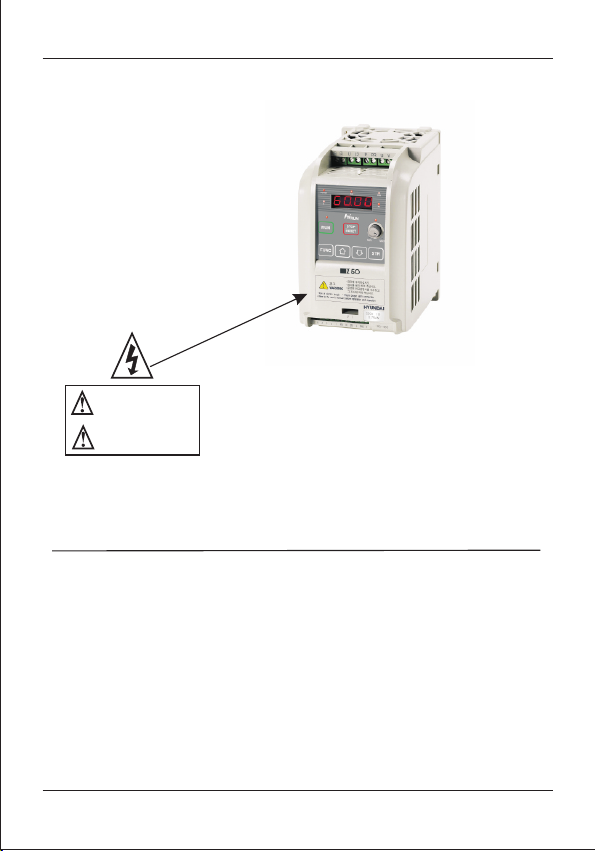

WARNING DISPLAY

WARNING

DANGER

A warning label is displayed on the main cover of the inverter,

as shown in the figure.

Follow these instructions when handling the inverter.

1-12

¡Risk of electric shock.

¡Ensure proper earth connection.

¡Refer to the user's manual before installation

and operation.

ENDA E-100 INSTRUCTION MANUAL

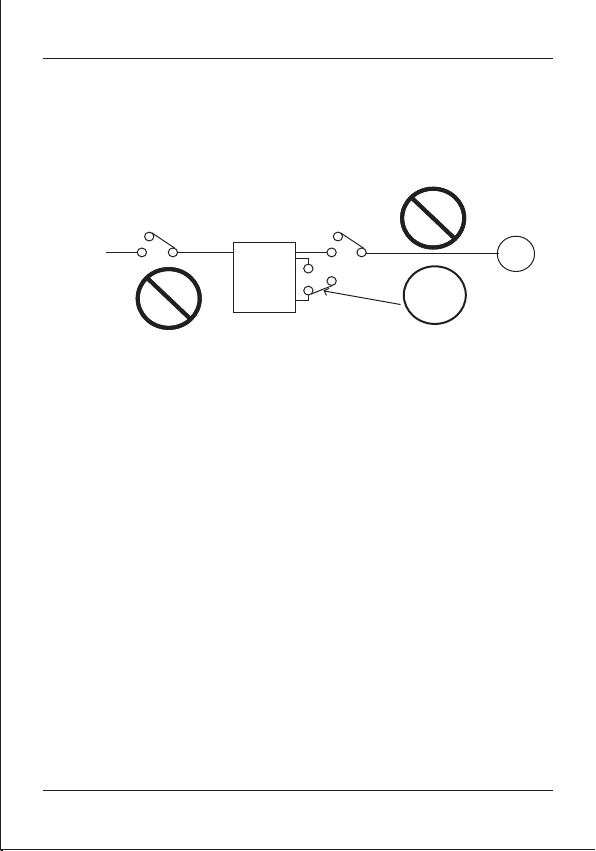

Note1) Do not Run/Stop operation by switching on/off electromagnetic

contactors (Mc0, Mc1) on the primary or secondary sides of the

inverter.

Operate the inverter by Run/Stop commanding [FW/RV].

L

Power

supply

Mc0

L1, L2

Mc1

FW(RV)

ON,OFFON,OFF

ON,OFFON,OFF

ON,OFF

Inverter

Motor

Note 2) Motor Terminal Surge Voltage Suppression Filter

In a system using an inverter with the voltage control PWM system, a

voltage surge caused by the cable constants such as the cable length

(especially when the distance between the motor and inverter is 10m or

more) and cabling method may occur at the motor terminals.

Note 3) Input power disconnection

This inverter is not able to protect input power disconnection.

Be careful to connect the wires.

1-13

ENDA E-100 INSTRUCTION MANUAL

Note 4) In the cases below involving a general-purpose inverter, a large

peak current flows on the power supply side, sometimes destroying the

converter module.

¡The unbalance factor of the power supply is 3% or higher.

¡The power supply capacity is at least 10 times greater than the inverter

capacity(and the power supply capacity, 500kVA or more).

¡Abrupt power supply changes are expected.

some examples) Several inverters are interconnected with a short bus.

An installed leading capacitor opens and closes.

Note 5) RC Value of the thermal Relay is 1.1 times greater than the

motor rated current. Also, RC Value is adjustable to the wiring

distance, but contacts us in this case.

Note 6) Do not connect and disconnect the power supply more than

1/5(minute / number)

There is the danger of inverter damage.

Note 7) When the EEPROM error E 08 occurs, be sure to confirm the

setting values again.

1-14

ENDA E-100 INSTRUCTION MANUAL

Inverter Specifications Label

Before installing and wiring, check the following

(1) Check the unit for physical damage that may have occurred

during shipping

(2) Verify that the package contains one inverter and one manual

after packing the E-100 inverter.

(3) Verify that the specifications on the labels match your purchase

order

Model Number convention

The model number for a specific inverter contains useful information

about its operating characteristics. Refer to the model number legend

below:

015 S

E-100

Series name

Input voltage:

S: single phase 200V class

2. Receiving and checking

If any part of E-100 is missing or damaged, call for service immediately

2-1

-

022 : 2.2kW (3HP)

007 : 0.75kW(1HP)

015 : 1.5kW (2HP)

Maximum applicable motor capacity

Inverter model number

Motor capacity for this model

Power Input Rating: frequency,

voltage, phase

Output Rating: Frequency,

voltage, phase current

Manufacturing codes:

Lot number, date, etc.

Customer Service Center : 080-029-5555 A/S Center : 052-230-8445/6

EN DA

Model : E-100-015S

Power : 1.5kW/2HP Temp : -10 40¡ ¡

Input : 50Hz/60Hz, 200~230V, 1Ph

MFG NO :

Output : 0.5¡400Hz, 200~230V, 3Ph 7.0A

www.enda.com.tr

F

Configuration type

F: operator pannel equipped

ENDA E-100 INSTRUCTION MANUAL

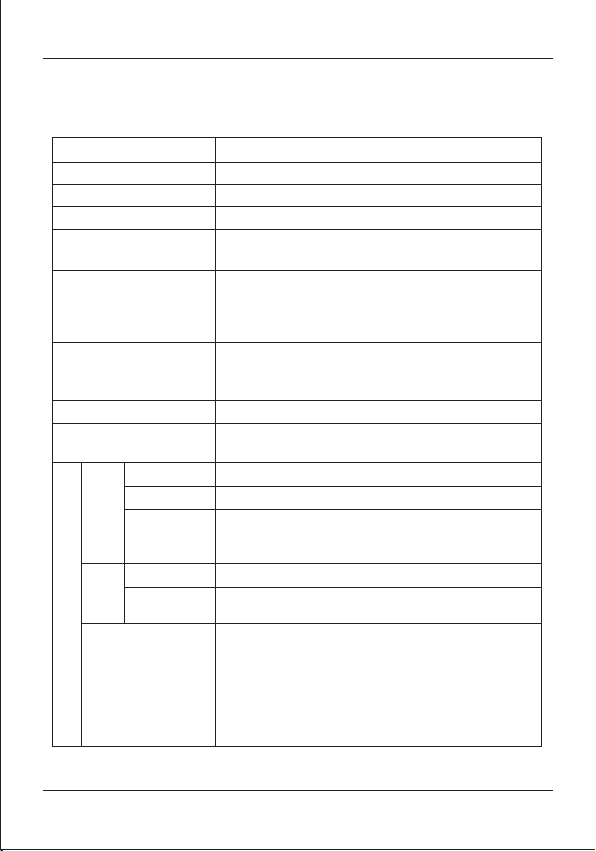

3. E-100 Inverter Standard Specifications.

Model-specific tables

The standard specifications of E-100 inverter is as follows;

Item Sing-phase 200V Class

Model E-100 series

Applicable motor size *2

kW

HP

Rated capacity(200V)kVA

Rated input voltage

Rated output voltage *3

Rated output current(A)

Starting torque

(with sensorless vector

control )

Dynamic braking

approx. % torque,

(short time stop)

*5

with resistor,

from 50/60Hz

without

resistor

DC braking

Weight (kg)

E-100

-007S

E-100

-015S E-100

-022S

0.75 1.5 2.2

1 2 3

1.9 3.0 4.2

Single-phase 200 to 230V ¡10%, 50/60 Hz ¡5%

3-phase 200 to 230V (corresponding to input voltage)

5.0 7.0 10.0

200% or more

approximately 100%

approximately 150%

Variable operating frequency, time and braking force

1.1 1.2 1.2

3-1

ENDA E-100 INSTRUCTION MANUAL

General Specifications

The following table applies to all E-100 inverters.

Item General Specifications

Frequencysetting

resolution

Protective housing*1 Enclosedtype(IP20)

Space vector PWM control

Digital command : ¡0.01% of the maximum frequency

Analog command : ¡0.1% of the maximum frequency

Digital : 0.01Hz(100Hz and less), 0.1Hz

(100Hz or more)

Analog: Max. Setting frequency/ 500(DC 5V input),

max. setting frequency/ 1000(DC 10V, 4¡20mA)

0.01 to 400Hz

Control method *6

Output frequency range *4

Frequencyaccuracy

Overload current rating

Acceleration/deceleration

time

Operator panel

Operator panel

Potentiometer

External signal

External signal

Intelligent input

terminal

Volt./ Freq. Characteristic

Freq-

setting

FWD/

REV

Run

Input signal

Any base freguencysetting possible between0Hz

and 400Hz.

V/F control (constant torque, reducedtorque).

150%, 60 seconds

0.1 to 3000sec.,(linear accel. / decel. s-curve,

u-curve), second accel. / decel. setting available

Up and Down keys / Value settings

Analog setting via potentiometer.

1W, 1§ to 2 variable resistor

DC 0¡5V, DC 0¡10V(Input Impedonce 700§)

4¡20mA(Input Impedonce 25§)

§

Run/Stop(Forward/Reverserun changeby command)

Forward run/stop, Reverse run/stop set by terminal

assignment (NC/NO)

FW(forward run command), RV(reverse run

command), CF1¡CF4(multistage speed setting),

JG(jog command), 2CH(2-stage accel./decel.

command), FRS(free run stop command),

EXT(external trip), USP (unattended startup),

SFT(soft lock),AT(analogcurrent input select

signal), RS(reset), SET(2nd setting selection)

3-2

ENDA E-100 INSTRUCTION MANUAL

Ambient temperature

Vibration

Ambient humidity

Storage temperature

Location

Options

Other functions

Protective function

Output signal

Operating

Environment

Remote operator unit, cable for operator, braking

unit, braking resistor, AC reactor, DC reactor,

noise filter.

Altitude 1,000m or less, indoors(no corrosive gasses

or dust)

2

5.9m/s (0.5G), 10 to 55Hz(conforms to the test

method specified in JIS C0911)

90% RH or less (no condensing)

-20 ¡60 (short-term temperatureduring

transport)

¡ ¡

-10 to 40¡

Over-current, over-voltage, under-voltage, overload,

extreme high/low temperature, internal

communication error, external trip, EEPROM error,

USP error, instantaneouspower failure, output

short-circuit detection.

AVR function, curvedaccel./decel.profile,upperand

lowerlimiters,16-stage speedprofile, fine adjustment

of start frequency, carrier frequencychange (0.5 to

16Khz),frequencyjump, gainandbiassetting, process

jogging,electronicthermal leveladjustment,retry

function, trip history monitor, 2nd setting selection,

auto tuning, V/f characteristic selection, automatic

torque boost,frequencycoversion display, USP

function

Item General Specifications

3-3

Intelligent output

terminal

Frequency monitor

RUN(run status signal), FA1 (frequencyarrival

signal), FA2 (setting Frequencyarrival signal),

OL(overloadadvance notice signal), OD(PID error

deviation signal),AL(alarm signal)

Analogmeter (DC0¡10Vfull scale, Max. 1mA)

Analogoutputfrequency, Analogoutputcurrentand

Analogoutputvoltage signalsselectable.

ENDA E-100 INSTRUCTION MANUAL

Footnotes for the preceding tables :

1. The protection method conforms to JEM 1030.

2. The applicable motor refers to ENDA standard 3-phase motor

(4-pole). To use other motors, care must be taken to prevent the rated

motor current(50/60Hz) from exceeding the rated output current of the

inverter.

3. The output voltage decreases as the main supply voltage decreases

(except for use of the AVR function). In any case, the output voltage

cannot exceed the input power supply voltage.

4. To operate the motor beyond 50/60Hz, consult the motor mamanufacturer

about the maximum allowable rotation speed.

5. The braking torque via capacitive feedback is the average decelection

torque at the shortest deceleration (stopping from 50/60Hz as indicated).

It is not continuous regenerative braking torque. And, the average

deceleration torque varies with motor loss. This value decreases when

operating beyond 50 Hz. If a large regenerative torque is required, the

optional regenerative braking resistor should be used.

6. Control method setting A31 to 2 (sensorless vector control) Selected,

set carrier frequency setting b11 more than 2.1kHz.

3-4

ENDA E-100 INSTRUCTION MANUAL

This manual suits for next models

3

Table of contents