Contents

Preface..................................................................................................................1

Contents.................................................................................................................3

Chapter 1 Safety Information and Precautions ...................................................3

1.1 Security Information......................................................................................................... 3

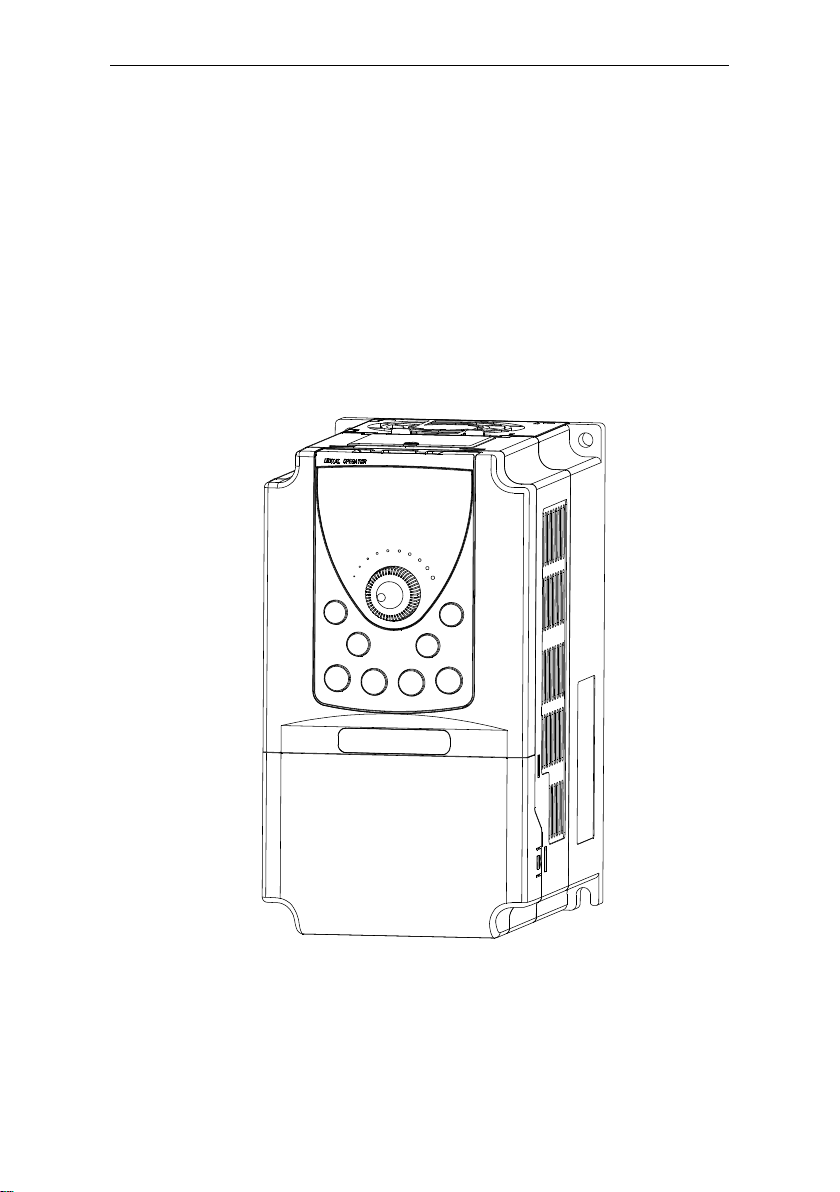

Chapter 2 Product Information.............................................................................6

2.1 Designation Rules............................................................................................................ 6

2.2 Nameplate........................................................................................................................ 6

2.3 AT580 Models and Technical Data .................................................................................. 6

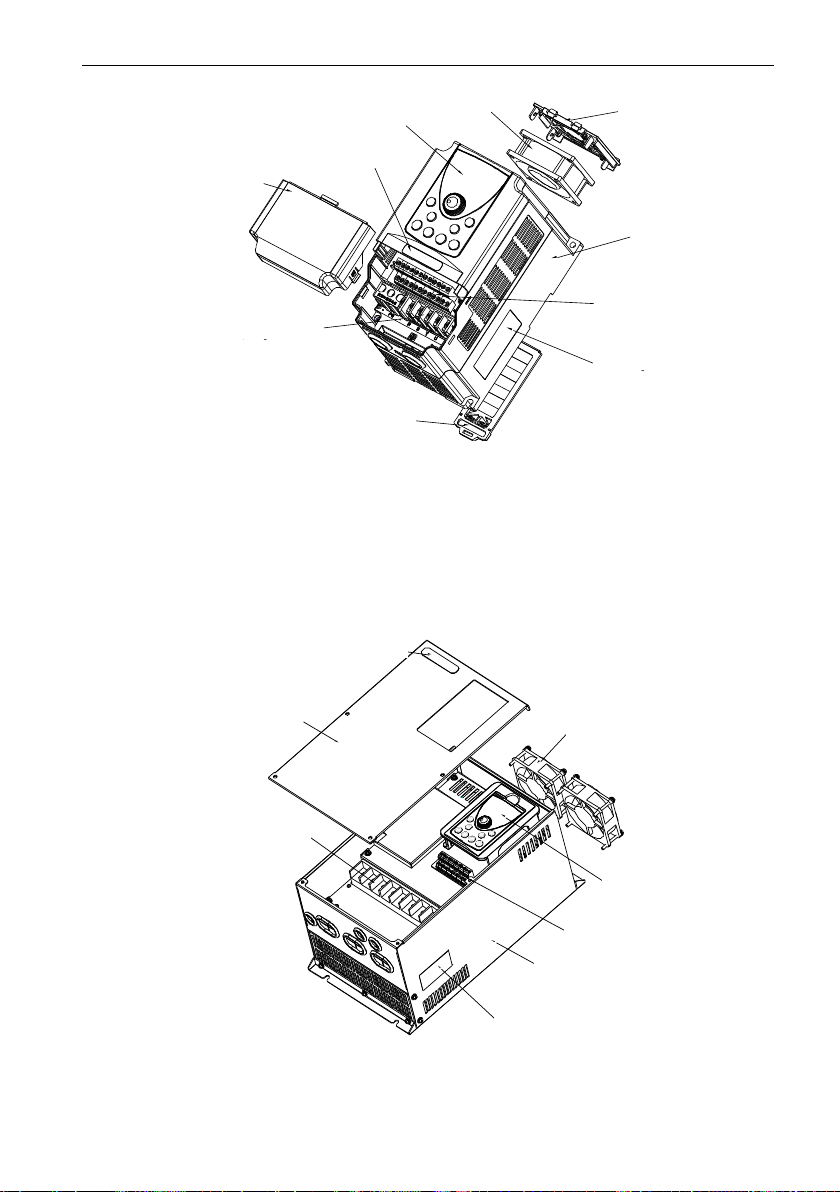

2.4 Product Description of Each Part .................................................................................... 8

2.5 Technical Specifications................................................................................................... 9

2.6 Appearance and Installation Size of the Keyboard ....................................................... 13

2.7 Appearance and Hole Size of the Keyboard Tray ......................................................... 13

2.8 Appearance and Installation Size of the Double Row Keyboard................................... 14

2.9 Appearance and Hole Size of the Double Row Keyboard Tray .................................... 14

Chapter 3 Mechanical Installation......................................................................15

3.1 Installation Environment ................................................................................................ 15

3.2 The Disassembly of The Cover Plate............................................................................ 16

Chapter 4 Electrical Installation .........................................................................17

4.1 Electrical Installation...................................................................................................... 17

4.2 Description of Peripheral Electrical Devices.................................................................. 18

4.3 Peripheral Electrical Components Selection Guidance................................................. 18

4.4 Selection of Braking Unit and Braking Resistor ............................................................ 19

4.5 Wiring Method................................................................................................................ 21

Chapter 5 Operating and Display .......................................................................28

5.1 Operation and Display Interface.................................................................................... 28

5.2 Function Indicator Description....................................................................................... 29

5.3 Keyboard Button Description Table............................................................................... 29

5.4 Viewing and Modifying Function Codes ........................................................................ 29

5.5 Selecting Menu Mode.................................................................................................... 30

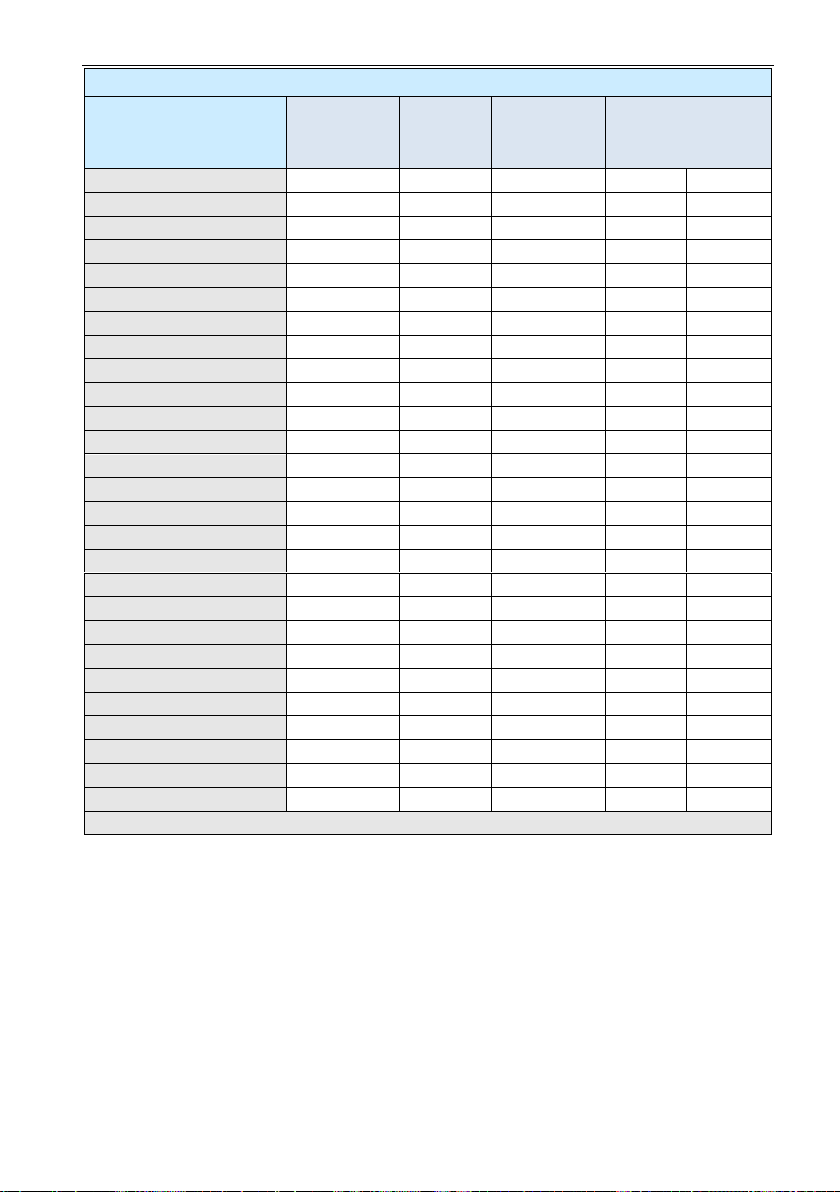

Chapter6 Function Parameter List .....................................................................31

Chapter7 Description of Function Codes ..........................................................65

Group F0 :Basic Parameters ............................................................................................... 65

Group F1: Motor parameters ............................................................................................... 70

Group F2:Input Terminal...................................................................................................... 72

Group F3: Output Terminals ................................................................................................ 79

Group F4: Auxiliary Functions.............................................................................................. 83

Group F5: Vector Control Parameters................................................................................. 91