ENDA EI141 Series User manual

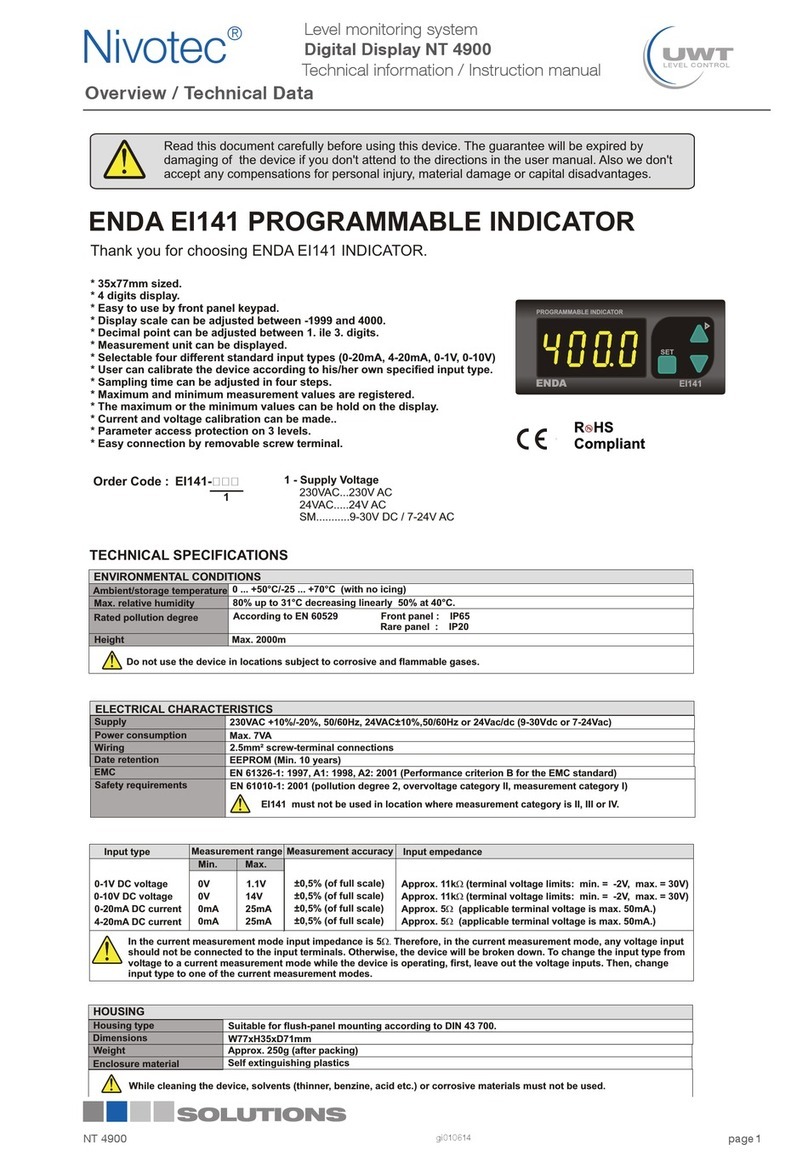

ENDA EI141 PROGRAMMABLE INDICATOR

Thank you for choosing ENDA EI141 Programmable Indicator.

SET

EI141

ENDA

PROGRAMMABLE INDICATOR

EI141-E-09-160217

Order Code : EI141 -

1 - Supply Voltage

230VAC...230V AC

24VAC.....24V AC

12VAC.....12V AC

SM...........9-30V DC /7-24V AC

1/3

SİSEL MÜHENDİSLİK ELEKTRONİK SAN. VE TİC. A.Ş.

Şerifali Mah. Y.Dudullu 34775

ÜMRANİYE/İSTANBUL-TURKEY

Tel : +90 216 499 46 64 Pbx. Fax : +90 216 365 74 01

url : www.enda.com.tr

Barbaros Cad. No:18 ENDA

TM

Please read this document carefully before using this product. The guarantee will be invalidated if the device is damaged by not

following instructions detailed in the manual. The company shall not be responsible for any damage or losses however caused,

which may be experienced as a result of the installation or use of this product.

- 35x77mm sized.

- 4 digits display.

- Easy to use by front panel keypad.

- Display scale can be adjusted between -1999 and 4000.

- Decimal point can be adjusted between 1. and 3. digits.

- Measurement unit can be displayed.

- Selectable four different standard input types (0-20mA, 4-20mA, 0-1V, 0-10V)

- User can calibrate the device according to specified input type.

- Sampling time can be adjusted in four steps.

- Stores maximum and minimum measurement values.

- The maximum or the minimum values can be hold on the display.

- Current and voltage calibration can be performed.

- Parameter access protection on 3 levels.

- Easy connection by removable screw terminal.

- CE marked according to European Norms.

TECHNICAL SPECIFICATIONS

ENVIRONMENTAL CONDITIONS

Height Max. 2000m

Ambient / Storage Temperature

Max. Relative Humidity

0 ... +50 °C/-25 ... +70°C (With no icing)

Rated Pollution Degree

80% Relative humidity for temperatures up to 31°C, decreasing linearly to 50% at 40°C.

According to EN 60529 Front panel : IP65

Rear panel : IP20

Do not use the device in locations subject to corrosive and flammable gases.

1

Supply

Power Consumption Max. 7VA

2.5mm² screw-terminal connections

Wiring

Date Retention

EMC

Safety Requirements

EN 61326-1: 2013

EEPROM (Min. 10 years)

EN 61010-1: 2010 P ( ollution degree 2, overvoltage category II, measurement category I)

ELECTRICAL CHARACTERISTICS

230V AC +10 -20 or 12/24V AC ±10 , 50/60Hz or optional .% % % 9-30V DC / 7-24V AC ±10% SMPS

EI141 Can not be used if measurement category II, III or IV is required.

While the current measuring mode, input impedance becomes 5Ω . Therefore, in current mode, the device must not be connected any

voltage input. Otherwise, the device is broken. While the device is running in the voltage measurement mode and if required to change

to current measurement mode, then firstly the voltage inputs must be removed and after that, input type must be changed to one of the

current measurement modes.

Input Type

0-1V DC voltage

0-10V DC voltage

0-20mA DC current

4-20mA DC current

Input Empedance

Approx. 11kΩ (terminal voltage limits: min. = -2V, max. = 30V)

Approx. Ω(terminal voltage limits: min. = -2V, max. = 30V) 11k

Approx. Ω 5 (applicable terminal voltage is max. 50mA.)

Approx. Ω(applicable terminal voltage is max. 50mA.) 5

0V

±0,5% (of full scale)

0V ±0,5% (of full scale)

0mA ±0,5% (of full scale)

0mA ±0,5% (of full scale)

1.1V

14V

25mA

25mA

Min. Max.

Measurement Range Measurement Accuracy

HOUSING

Housing Type Suitable for flush-panel mounting according to DIN 43 700.

Dimensions W77xH35xD71mm

Weight Approx. 250g (after packing)

Enclosure Material Self extinguishing plastics

While cleaning the device, solvents (thinner, benzine, acid etc.) or corrosive materials must not be used.

SET

EI141

ENDA

PROGRAMMABLE INDICATOR

INPUT

+

GND

1 2 3 4 5 6 78910 11 12

EI141-230VAC

PROGRAMMABLE INDICATOR

ENDA INDUSTRIAL ELECTRONICS

230V AC +10% - 20%

50/60Hz 7VA

SN: XXXXXXXXX

8 680407 703340

Made In Turkey

INPUT

+

GND

1 2 3 4 5 6 78910 11 12

EI141-24VAC

PROGRAMMABLE INDICATOR

ENDA INDUSTRIAL ELECTRONICS

24V AC ±10%

50/60Hz 7VA

SN: XXXXXXXXX

8 680407 703364

Made In Turkey

INPUT

+

GND

1234567 8 9 10 11 12

EI141-SM

PROGRAMMABLE INDICATOR

ENDA INDUSTRIAL ELECTRONICS

SN: XXXXXXXXX

8 680407 703388

Made In Turkey

9-30V DC / 7-24V AC

±10% 7VA

EI141-E-09-160217

2/3

SİSEL MÜHENDİSLİK ELEKTRONİK SAN. VE TİC. A.Ş.

Şerifali Mah. Y.Dudullu 34775

ÜMRANİYE/İSTANBUL-TURKEY

Tel : +90 216 499 46 64 Pbx. Fax : +90 216 365 74 01

url : www.enda.com.tr

Barbaros Cad. No:18 ENDA

TM

TERMS

1) Measurement value, measurement unit, the minimum or the maximum measured values are

displayed in the run mode.

Parameter name, parameter value or a user defined unit is displayed in the programming mode.

3) De

Used for making the minimum and the maximum measured values equal in the run mode.

crement or parameter selection key in the programming mode.

2) Increment or parameter selection key in the programming mode.

Used for displaying measurement unit or the max. measured value in the run mode.

4) Used for selecting run and programming modes, displaying

measurement unit or making the minimum and the maximum measured values equal.

adjusting parameters,

4 digits 7 segment yellow LED display

( 2 ),( 3 ),( 4 ),( 5 ) Keypad

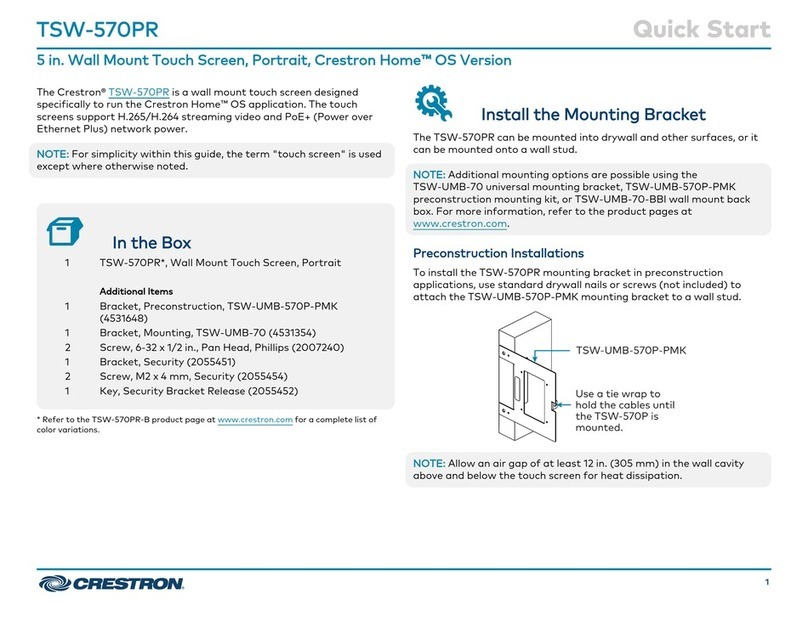

( 1 ) Digital display

12.5mm

Micro switch

Character height

Panel cut-out

71,5mm

29,5mm

Note :

1) Panel thickness should be maximum 7 mm.

2) There must be at least 60mm free space

behind the device, otherwise it would be difficult to

remove it from the panel.

DIMENSIONS

Flush mounting

clamp

Panel

Depth

2

71mm 5mm

Flush mounting

clamp

1

Rubber

packing

SETSET

EI141

ENDA

PROGRAMMABLE INDICATOR

35mm

77mm

For removing mounting clamps ;

- Push flush mounting clamps in

direction 1 as shown in the figure below.

Then pull out the clamps in direction 2 .

INPUT

+

GND

1 2 3 4 5 6 7 8 9 10 11 12

EI141-230VAC

PROGRAMMABLE INDICATOR

ENDA INDUSTRIAL ELECTRONICS

230V AC +10% - 20%

50/60Hz 7VA

SN: XXXXXXXXX

8 68040 7 70334 0

Made In Turkey

Flush mounting

clamp

1

22

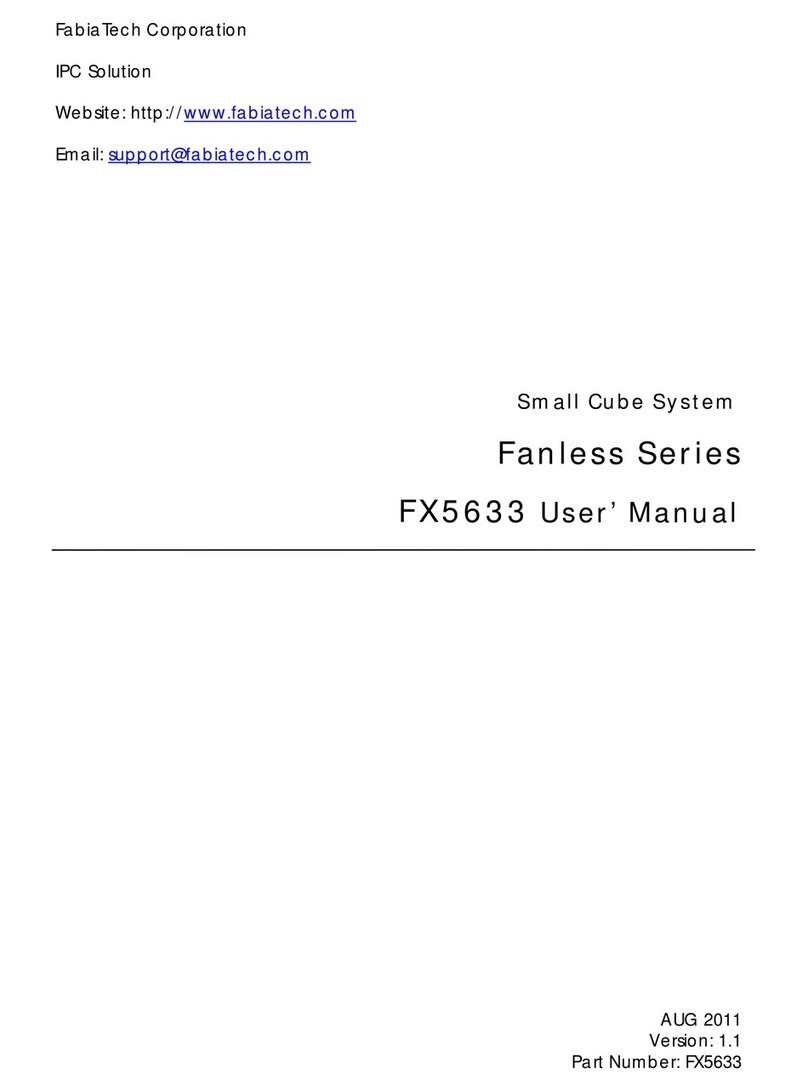

CONNECTION DIAGRAM

ENDA EI141 is intended for installation in control panels. Make sure that the device is used only for intended purpose.

grounded on the instrument side. During an installation, all of the cables that are connected to the device must be free of electrical power. The

device must be protected against inadmissible humidity, vibrations, severe soiling. Make sure that the operation temperature is not exceeded.

All input and output lines that are not connected to the supply network must be laid out as shielded and twisted cables. These cables should not

be close to the power cables or components. The installation and electrical connections must be carried out by a qualified staff and must be

according to the relevant locally applicable regulations.

The shielding must be

2

1

184-253V AC

50/60Hz 7VA

230V AC

Supply

Switch

Cable size: 1,5mm²

Fuse

F 100 mA

250V AC

Neutral

Line

SUPPLY :

NOTE :

Fuse should

be connected

1) Mains supply cords shall meet the requirements of IEC 60227 or IEC 60245.

2) In accordance with the safety regulations, the power supply switch shall bring the identification of the relevant instrument and it should

be easily accessible by the operator.

Note :

Holding screw

0.4-0.5Nm

Equipment is protected throughout

by DOUBLE INSULATION.

S.Cod.

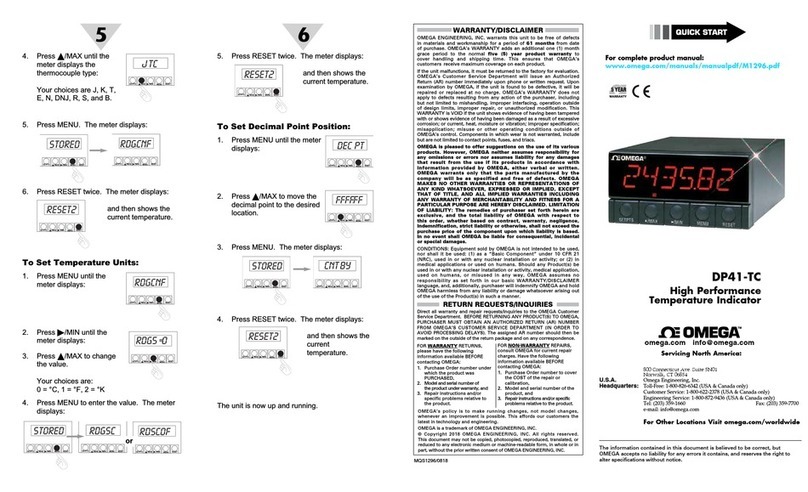

d.C.sc.

Uo.sc.

D.Ca.s.

S.Cod.

a.CAL.

1.CA.

10.CA.

If key is pressed and held for 5

seconds programming mode is entered

U.opt. d.Cal. SECU.

d.pnt.

Cal.t.

l.sCl.

H.sCl.

l.inp.

H.inp.

CAL.t.=U.ınP.

Yes

No

d.Cnf.

i.typ.

ratE

Hold

dsp.C.

Unit

If first and then keys are

pressed together , measurement

unit appears. See Unit parameter

for programming.

If first and then keys are

pressed together, the maximum and the

minimum measurement values become

equal to the measured value at that time

and the message res. appears on

display.

Pressing this key the minimum

measured value up to that time

appears.

Pressing this key the maximum

measured value up to that time

appears

The minimum measured

value

The maximum

measured value

Measurement unit 870 1453

Bar.

&

Programming Mode

3/3

Running Mode

Measurement

value

1000

Res.

EI141-E-09-160217

SET

SET

SET

SET SET

SET

SET

CAL.t. = Calibration type.

Selectable as S.inP. or .

If S.inp. is selected, input type is one the

four standard input types. If U.inP is

selected, input types can be modified.

See NOTE 1 for modification.

U.inP

i.typ. = Input type.

Input type can be selected as 0-20mA,

4-20mA, 0-1V or 0-10V.

See NOTE 1 for programming.

rAte = Sampling rate.

Measurement is performed at each 200ms.

However,

for FASt rate, each measurement is displayed.

for SLo.1 rate, the average of 4 successive

measurements is displayed.

for SLo.2 rate, the average of 8 successive

measurements is displayed.

for SLo.3 rate, the average of 16 successive

measurements is displayed.

See NOTE 1 for programming.

Hold = Display holding parameter.

Selecting NonE , this parameter becomes

inactive.

Selecting Lo. , always the minimum

measured value is displayed.

Selecting Hi. , always the maximum

measured value is displayed.

dSP.C. = Display configuration.

Selectable as PrcS. or Pr.Un. . If PrcS. is

selected, process value appears. If Pr.Un.

is selected, process value and then

measurement unit are displayed 4 and 2

seconds successively.

See NOTE 1 for programming.

Unit = Measurement unit.

A constant, a message etc. to be displayed

can be entered. If a decimal point is desired,

it should be included before entering the

character.

For including decimal point first, then,

keys are pressed and held together. And

then, by using key decimal point can be

adjusted.

d.Pnt. = Decimal point.

Decimal point can be adjusted between

1. and 3. digits.

See NOTE 1 for programming.

L.SCL. = Lower limit for the scale.

It can be adjusted between -1999 and

(H.SCL. -100).

See NOTE 1 for programming.

H.SCL. = Upper limit for scale.

It can be adjusted between (L.SCL. +100)

and 4000.

See NOTE 1 for programming.

SET

At this state, the reference voltage or

current that corresponds to L.SCL. Parameter

is applied to the input.

To initialize calibration, first then

keys are pressed together and held until ‘CAL'

message appears. See NOTE 2.

SET

At this state, the reference voltage or

current that corresponds to H.SCL.

parameter is applied to the input.

To initialize calibration, first then

keys are pressed together and held until

‘CAL' message appears. See NOTE 2.

SET

SET

SET

s.Cod. = Access code for calibration menu.

This parameter should be 222.

See NOTE 1 for programming.

A.CAL. = Current calibration.

At this state, 20 mA current is applied to the

input of the device.

10.CA. = 10V

At this state, 10V is applied to the input of

the device.

input calibration.

1.CA. = 1V input calibration.

At this state, 1V is applied to the input of

the device.

For initializing calibration, first then

keys are pressed together and held until ‘CAL'

message appears. See NOTE 3.

To initialize calibration, first then

keys are pressed together and held until ‘CAL'

message appears. See NOTE 3.

To initialize calibration, first then

keys are pressed together and held until ‘CAL'

message appears. See NOTE 3.

s.Cod. = Access code for safety menu.

This parameter should be 333.

See NOTE 1 for programming.

d.C.Sc. = ConF. menu protection level

parameter.

nonE = No menu is seen.

P. no = Menu is seen but can not be programmed.

P.yES. = Menu is seen and programming is possible.

See NOTE 1 for programming.

Uo.Sc. = U.oPt. menu protection level

parameter.

nonE = No menu is seen.

P. no = Menu is seen but can not be programmed.

P.yES. = Menu is seen and programming is possible.

See NOTE 1 for programming.

d.Ca.S. = d.CAL. menu protection level

parameter.

nonE = No menu is seen.

P. no = Menu is seen but can not be programmed.

P.yES. = Menu is seen and programming is possible.

See NOTE 1 for programming.

CAL. CAL.

C.End C.End

s.Err.

S.Err.

C.Err.

C.Err.

The message on the left flashes approximately 5

seconds and calibration is completed.

The message on the left flashes approximately 5

seconds and calibration is completed.

If calibration is success, the C.End

message appears for 1 second.

If calibration is unsuccess, the S.Err

message appears for 1 second and

passed to the next step.

.

If the difference between the reference voltages or currents applied for the calibration of H.inP. and L.inP. is lower than one

half of the full scale, this error message appears on the display.

For example: Assume that the selected input type is 0-1V. In this case, if the difference between the reference voltages

applied for calibration of H.inP. and L.inP. is lower than 0.5V, this error message appears.

If the reference voltage or current applied to the input for calibration is too high or too low, this error message appears.

ERROR MESSAGES

CAL okey?CAL okey?

Yes Yes

No No

NOTE 2 NOTE 3

SET

For adjusting a selected parameter first press and hold key. Then, by using keys adjustment

can be made.

Parameter adjustment method

NOTE 1

If increment key is pressed and held 0.6 seconds, the value of the selected parameter changes rapidly. If

waited enough, the value increases 100 at each step. After 1 second following the release of the key, initial

condition is returned. The same procedure is valid for the decrement key.

Entering from programming mode to run mode:

If no key is pressed within 20 seconds during programming mode, data is stored automatically and the run mode is entered.

Alternatively the same function occurs by pressing key and holding for 5 seconds after pressing key and

entering main menu.

SET

If calibration is success, the C.End

message appears for 1 second.

If calibration is unsuccess, the .Err

message appears for 1 second and

passed to the next step.

C.

This manual suits for next models

6

Table of contents

Other ENDA Touch Panel manuals