Fastlane®Swim Unit Installation

Section 2 CHOOSING A LOCATION FOR YOUR FASTLANE

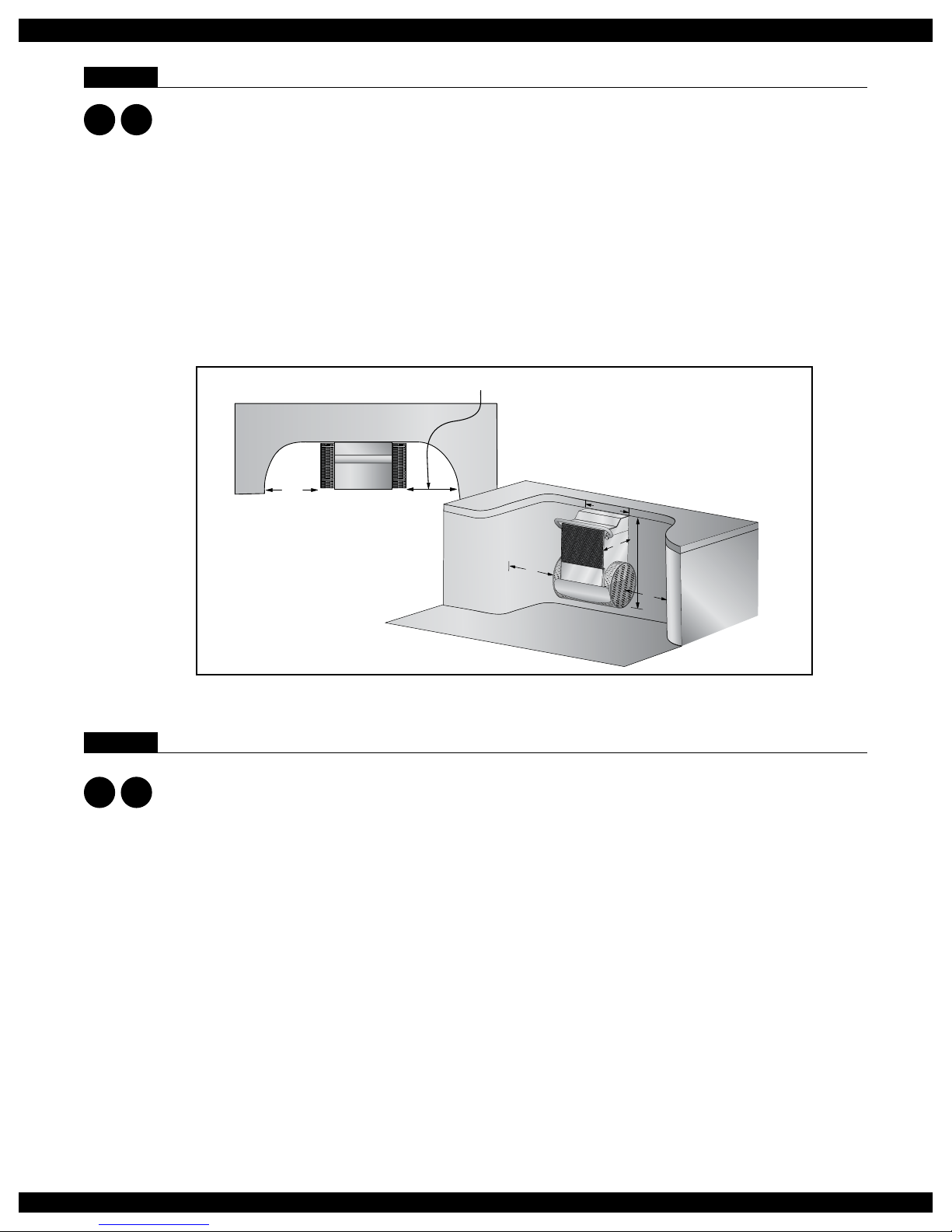

The Fastlane can t in virtually any swimming pool. For optimal water ow, we recommend that you allow

at least 12 feet (3,7m) between the wall on which the Fastlane is installed and the opposing wall in line with

the Swim Unit. The Fastlane has more than 9 square feet (.83m2) of water intake to eliminate any entrap-

ment hazards. The water depth where the Fastlane is installed must be at least 39" (99cm) deep. In addition,

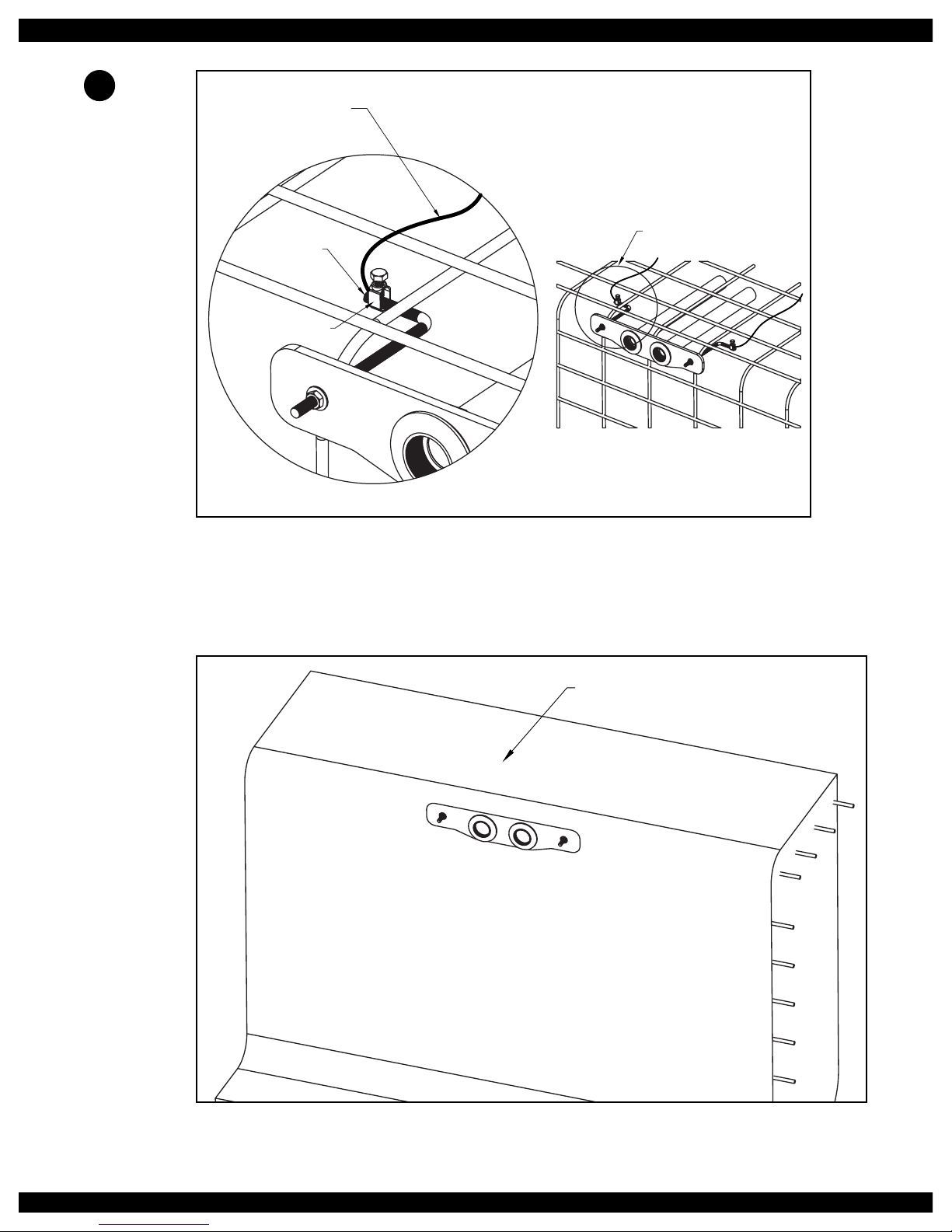

the Fastlane must be installed no closer than 24" (61cm) from any adjacent wall as shown in Figure 2.1,

Minimum Clearance Guidelines.

When choosing a location for your Fastlane, you should also consider the route for the hydraulic hoses

to run back to the Power Unit. The Power Unit needs to sit on a solid, level surface, preferably not on

wet ground, and requires a 30-amp, 220-volt GFCI electric service. For UK and international electrical

requirements, please refer to Section 11. The optional Outdoor Power Unit with Weather Guard may be

located outside, but should not be subject to driving rain. Typically, the Power Unit is located with the other

pool equipment and, if possible, long hydraulic runs should be avoided because of pressure loss. If you

wish to have a run greater than 25' (7,6m), you must transition from 3/8" (9,5mm) hydraulic hoses to 1/2"

(12,7mm) run hoses with the addition of a junction box as reviewed in Section 5.

MINIMUM 24” (61cm)

24"

(61cm)

24

"

(61cm)

24

"

(61cm)

39

"

(99cm)

21

"

(53,3cm)

19"

(48,2cm)

Fig. 2.1 Minimum Clearance Guide

Section 3 RECEIVING YOUR FASTLANE

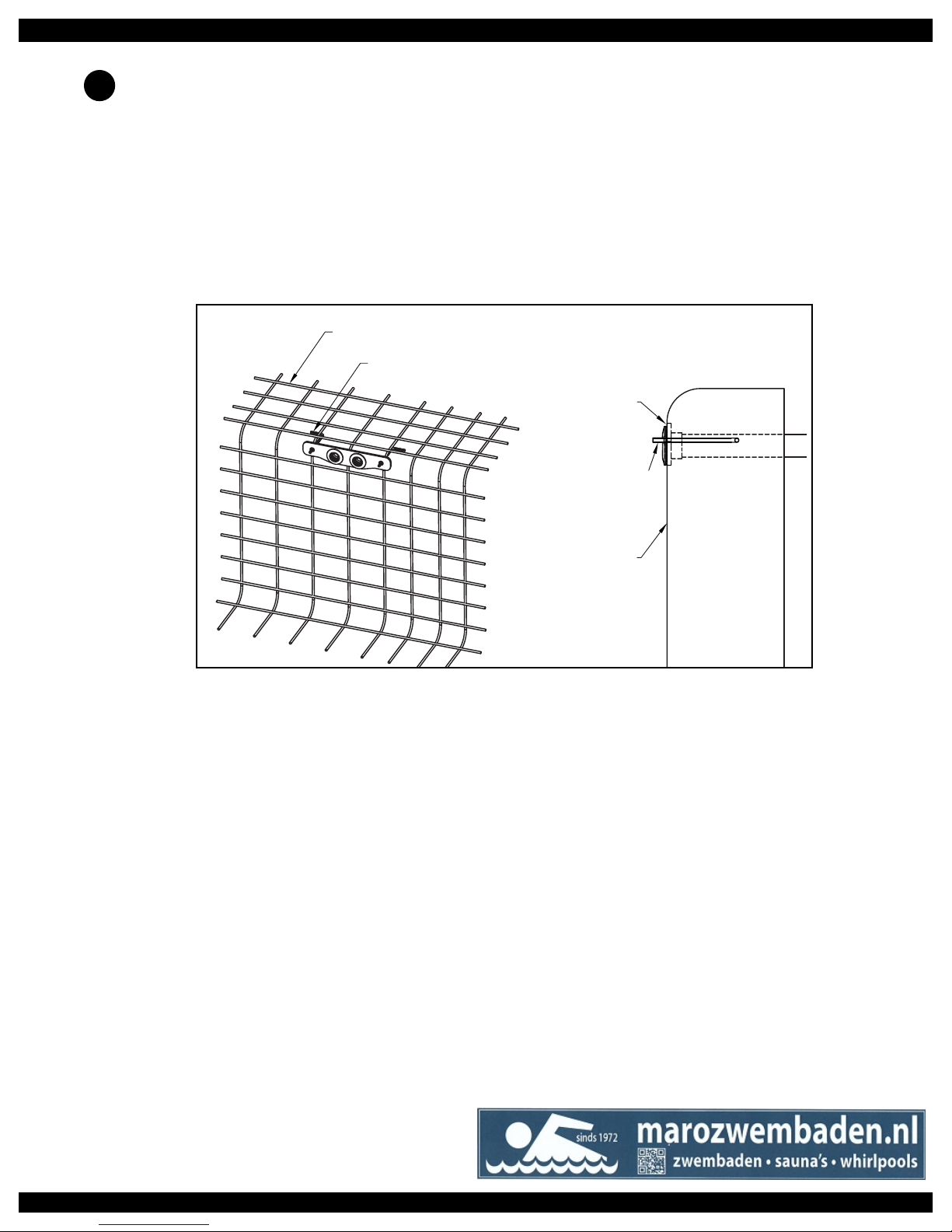

The Endless Pools Fastlane is comprised of a minimum of six (6) parcels. Additional parcels may be

shipped as appropriate. All items will be shipped via UPS Ground.

Items shipped UPS

Parcel 1: Fastlane Propulsion Housing Kit

Parcel 2: Fastlane Propulsion Base Kit

Parcel 3: Hydraulic Power Unit (wireless remote controls and antenna kit located inside controller)

Parcel 4: Hydraulic Fluid (5 Gallon container)

Wall Mount Fastlane

Parcel 5: Wall Mount Fastlane Mounting Kit (wall mount bracket and hardware for wall mount kit)

Parcel 6: Accessory Kit for Fastlane (hat sections, propulsion housing lid, hardware kit

for Fastlane assembly)

Deck Mount Fastlane

Parcel 5: Accessory Kit for Fastlane (hat sections, propulsion housing lid, hardware kit

for Fastlane assembly)

Bracket Kit for Deck Mount Fastlane (hanging bracket, deck plate, hardware for bracket kit)

Optional Equipment

Weather Guard Floor Mirror

Swim Pace Display Wi-Fi Kit (included in the accessory kit if purchased)

W

W

D

D

5