F a s t l a n e®Swim Unit Installation

3

Deck Mount Accessories Kit

- 1 Top Lid, Sapphire, Acrylic Pool Propulsion Housing

- 2 Protective Hat Channels

- 1 Deck Plate Hanging Bracket

- 1 Deck Plate Cover

- 1 Deck Plate Bottom

- 1 Bonding Lug, 3/16" (4,8mm) Stud Size

- 1 Screw, 316 SS, M/S, Phillips, Truss, 10-32 x 3/8" (9,5mm)

- 2 8 J C Female x 6 J C Male Adapter

- 8 Masonry Screws, 3/16 x 2-1/4" (4,7mm x 57mm), Phillips Flat Head, Blue Coated Steel

- 4 Hose Clip

- 1 Bit, Masonary, 5/32" (4mm)

- 18 Screw, #10 x 3/4" (19mm), SMS, Blunt Tip, Phil Truss Head,

Type B Point, Type A Thread, Passivated 316SS

- 8 Screw, 316L SS, M/S, Phillips Truss 10-32 x 1/2" (12,7mm)

- 16 Screw, #10 x 1" (25mm), SMS, Blunt Tip, Phil Truss Head,

Type B Point, Type A Thread, Passivated 316SS

- 1 Zinc Sacrificial Anode

- 16 Screw, 316 SS, M/S, Type 1 Phillips Truss Head, 10-32 x 1" (25mm)

- 6 Nut, 316 SS, Lock, Hex, with nylon insert, 10-32

he Following two packages will be included ONLY if a Wall Mount Fastlane was purchased:

Parcel 6: Wall Mount Bracket Assembly

Optional Equipment

• Outdoor Power Unit with Weather Guard

• Floor Mirror

• Swim Pace Display

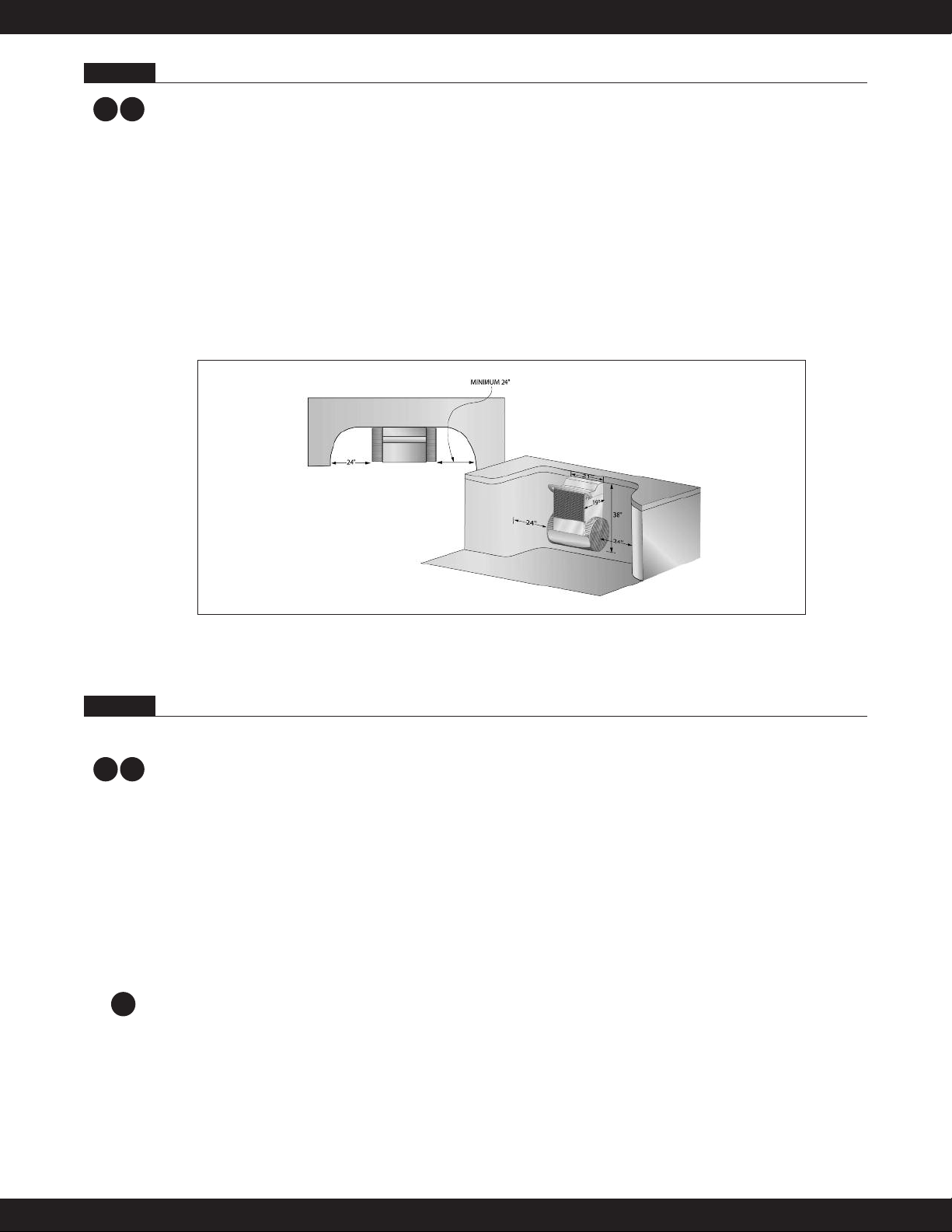

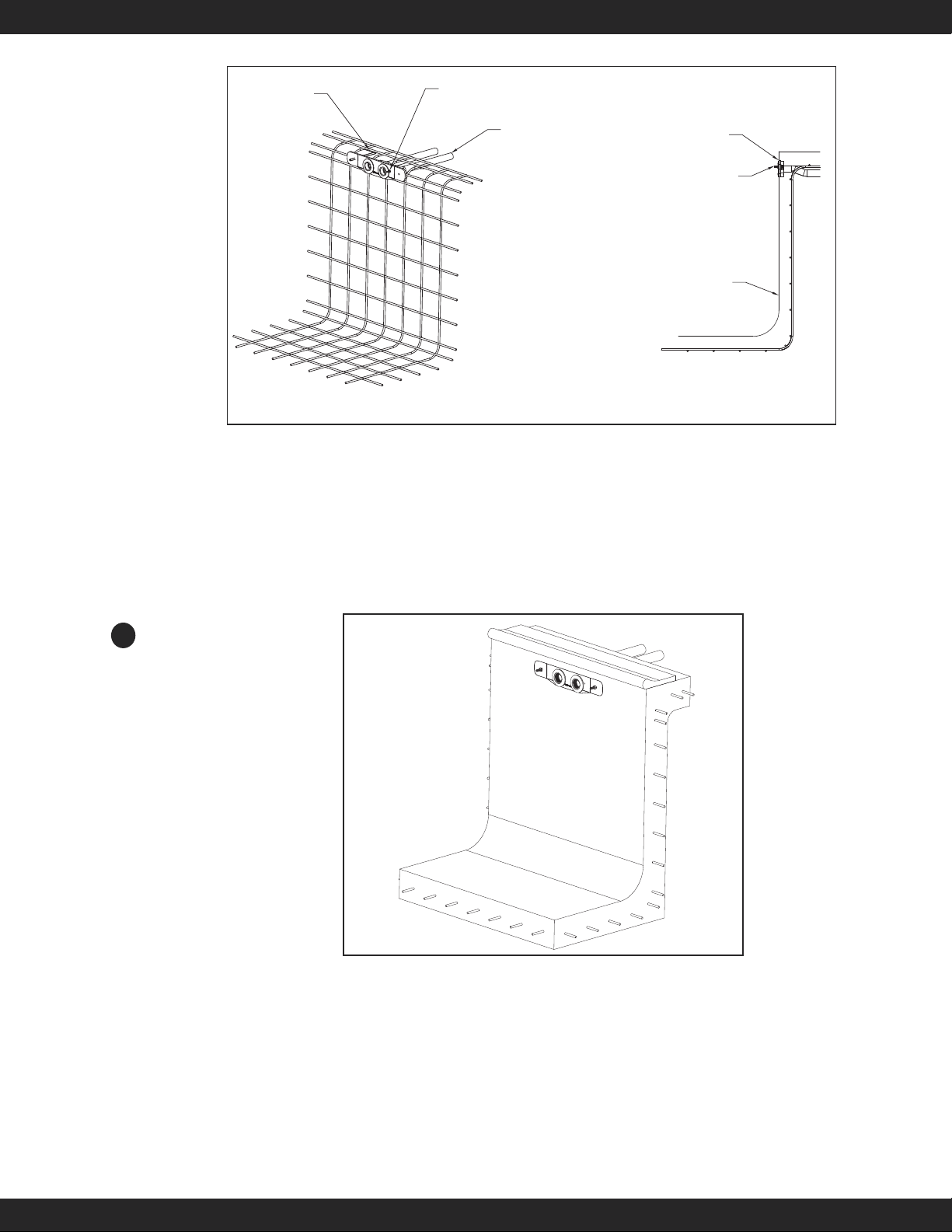

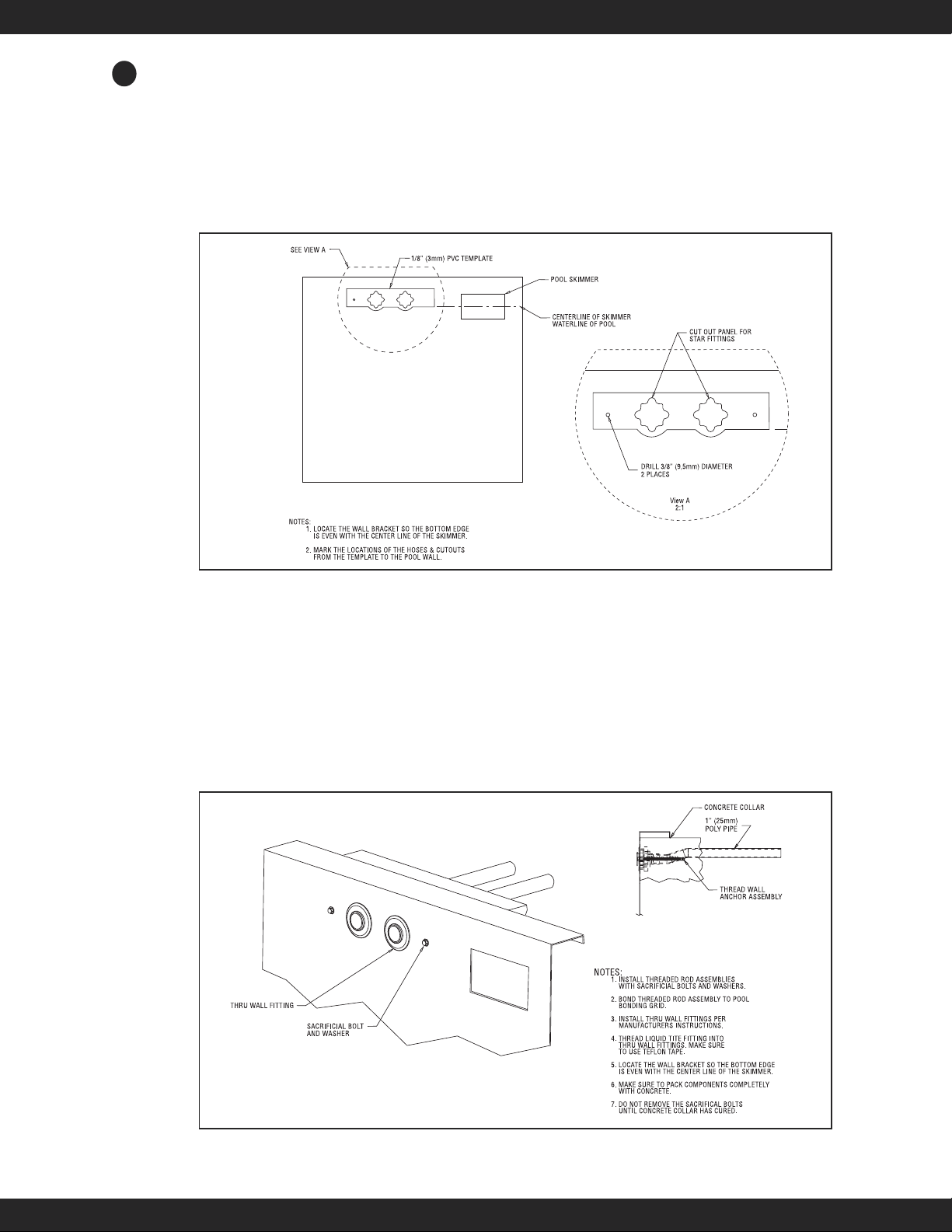

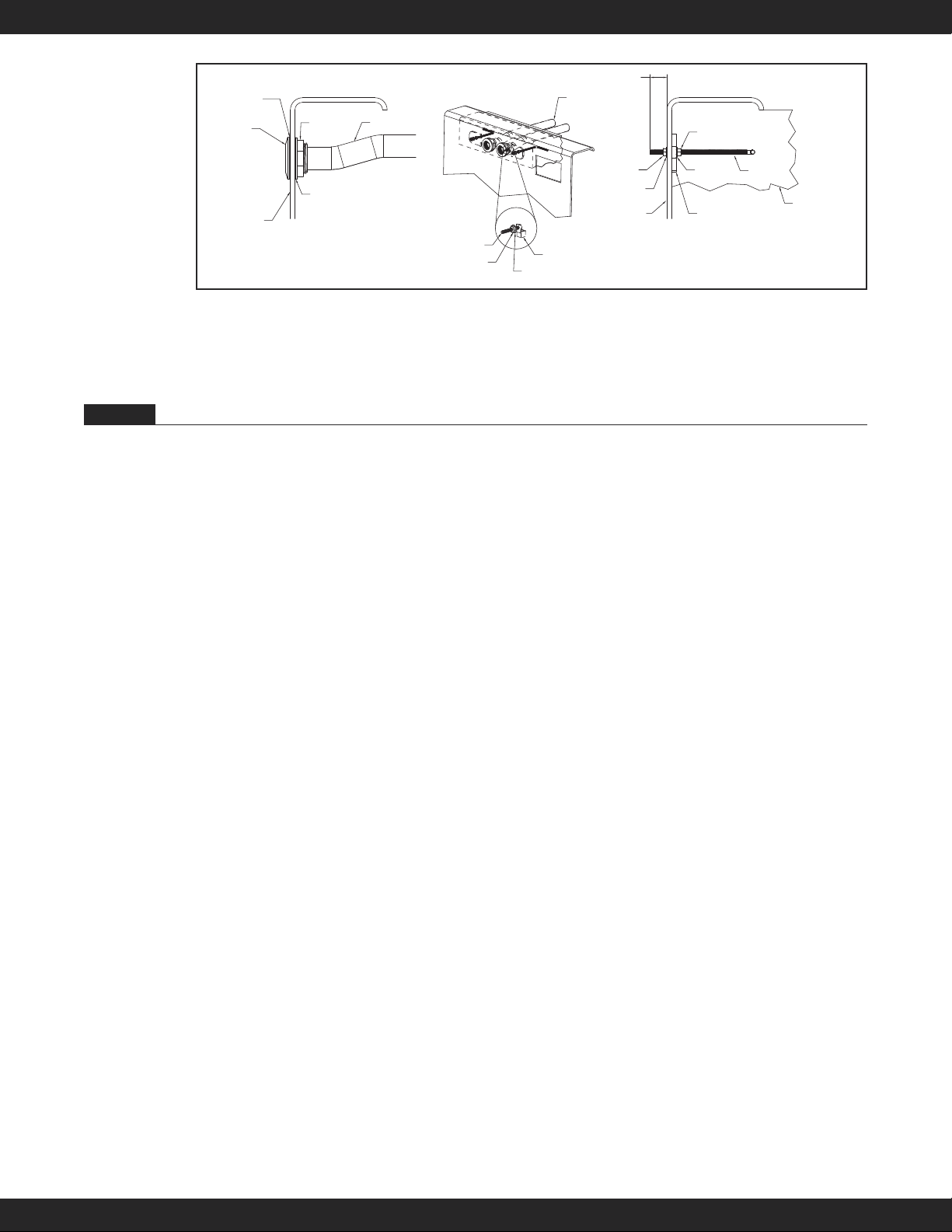

Section 4 WALL MOU T BRACKET

NO E: Please read instructions fully before beginning bracket installation.

4.A. Gunite/Concrete Pool

f the pool being constructed is gunite or concrete, please follow the instructions below.

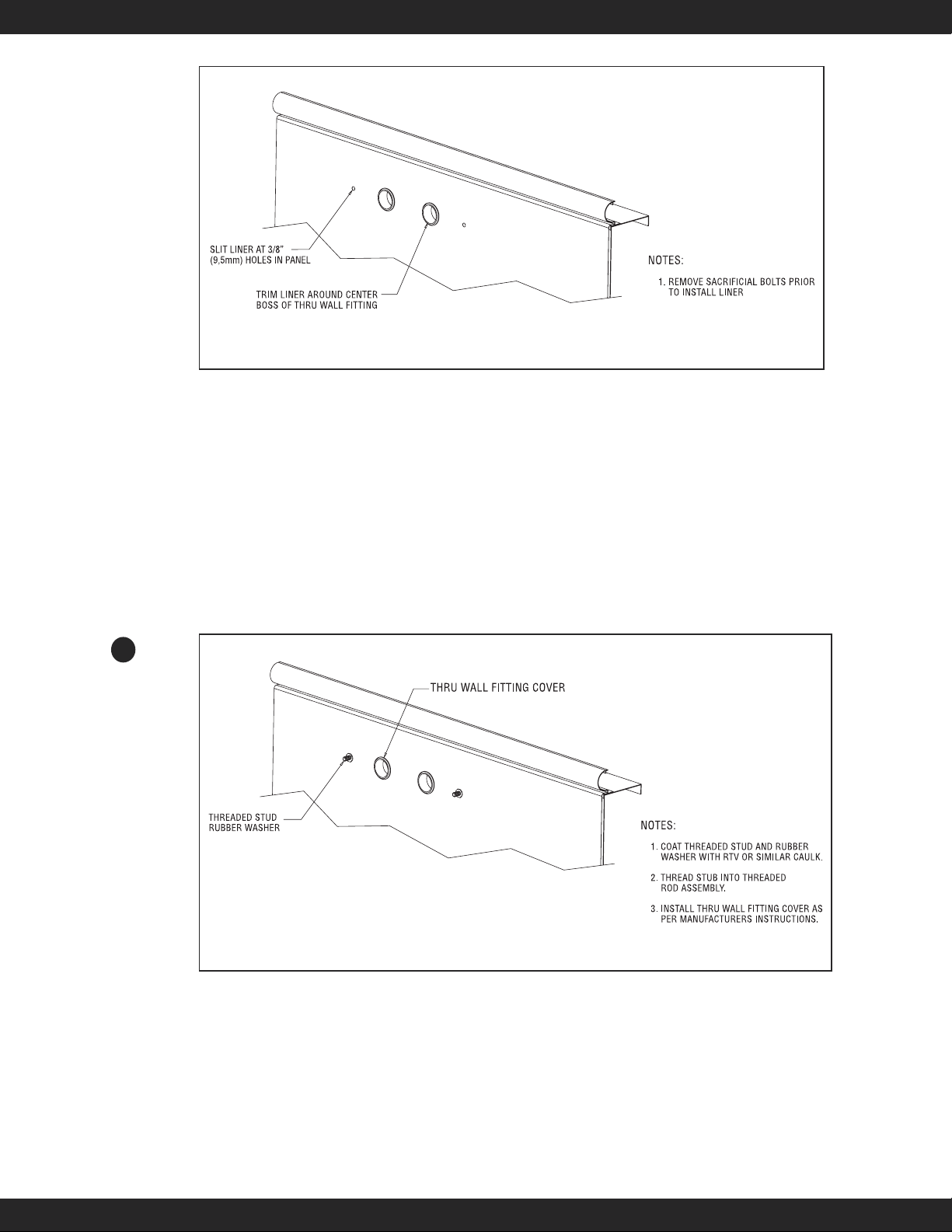

Parcel 6 includes the Wall Mount Fastlane bracket for concrete or gunite pools. (refer to Photo 4.A.1)

- 1 Gunite/Fiberglass Wall Bracket PVC Plate

- 1 Screw, 316L SS, M/S, Phillips Truss 10-32 x 1-1/2" (38mm)

- 1 Bonding Lug, 3/16" (4,8mm) Stud Size

- 1 Washer, Flat, #10 x 7/16OD x .062 Thick, 316 SS

- 1 Nut, Jam, 10-32, 316SS

- 1 Nut, 316 SS, Lock, Hex, w/ Nylon nsert, 10-32

- 2 Threaded Rod, 3/8-16, 316 SS, 10.25 in long (26cm)

- 6 Nut, Jam, 3/8-16, 316SS

- 6 Washer, 316 SS, Flat, 3/8" x 7/8" (9,5mm x 22mm)

- 2 Washer, 316 SS, Lock, Medium Split, 3/8" (9,5mm)

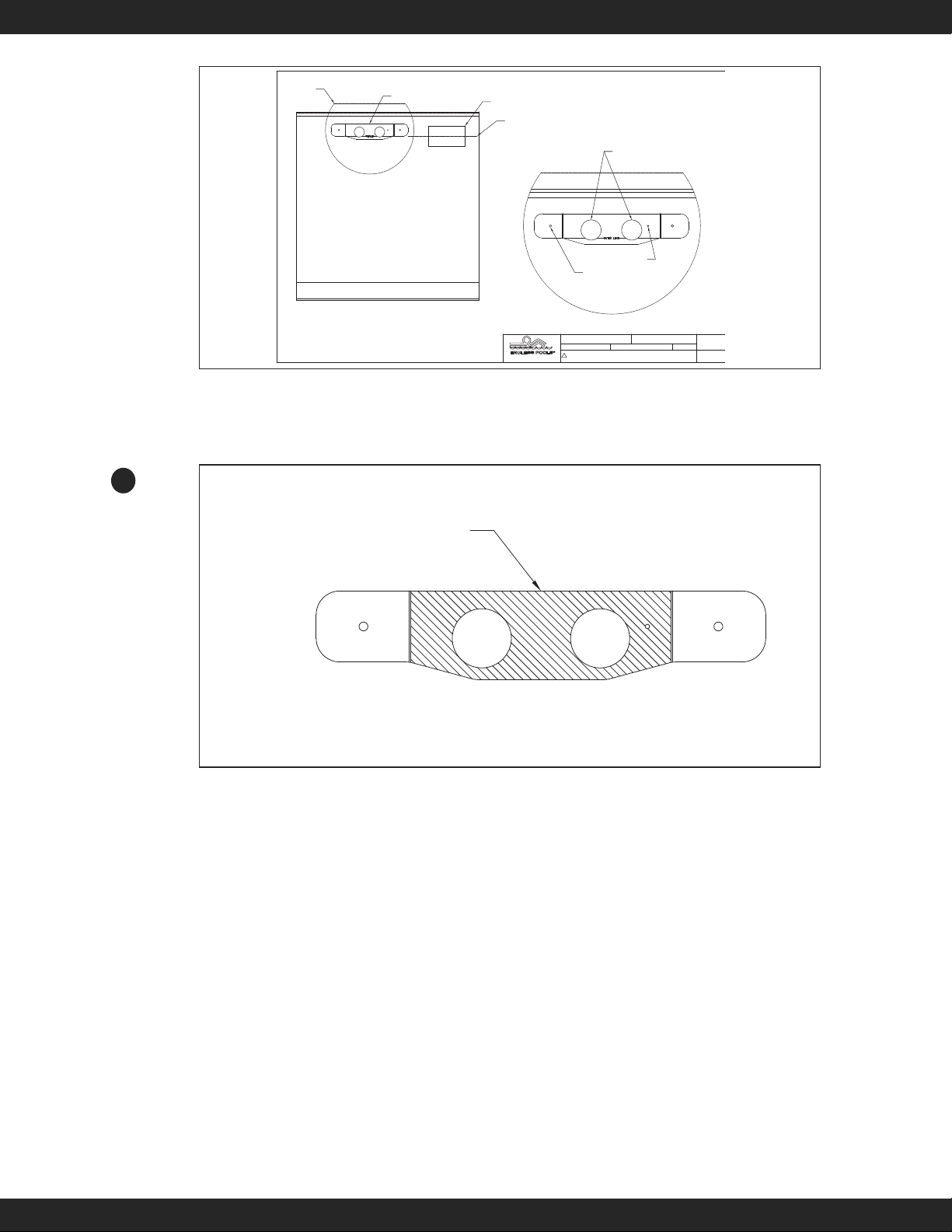

- 2 Thruwall Fitting, PVC, Schedule 40, Round Cutout, 1-1/2" (38mm) FSlip

- 2 Bushing, PVC, Reducer, 1-1/2" (38mm) MPT x 1" (25,4mm) FPT

- 2 Cord Grip Liquid Tite Fitting, PVC, 1" (25,4mm) NPT, fitting only

D

WD

W

W