F a s t l a n e®S w i m U n i t I n s t a l l a t i o n

5

poly pipe, but rather use a single length for each of the two hydraulic hoses that will run through them. The

goal is to provide an easy route for each of the two 3/8" hydraulic hoses — a route free of obstructions and

unlikely to bind. The hydraulic hoses may run on the surface outside the 1" poly pipe, but care must be

taken not to damage them. It is always best to use the 1" poly pipe provided as it protects the hydraulic

hoses from chafing as well as UV damage. The 1" poly pipe is chosen because of its slipperiness and the

ease with which the 3/8" hydraulic hose slides through it. At the same time, this 1" poly pipe can be easily

kinked which will make it difficult to slide the hydraulic hoses through later.

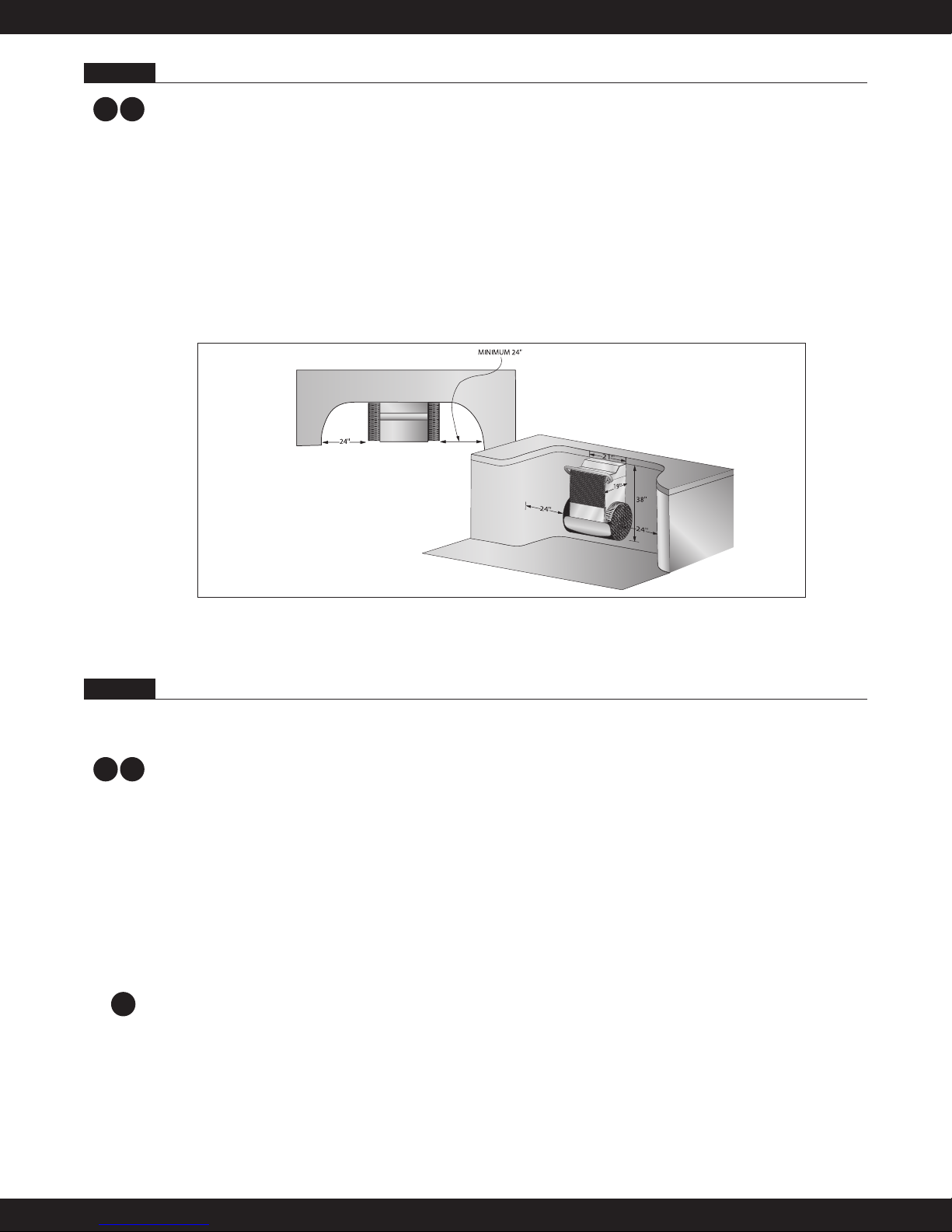

When planning for these two runs of 1" poly pipe, recognize that they penetrate the pool wall 1-1/2" above

the waterline and as a consequence will be flooded if the water level rises to that point. We strongly rec-

ommend that the 1" poly pipe rise to a point above which the water level will never rise to avoid any

potential flooding. This can be done during the 1" poly pipe run or back near the Power Unit. Tighten the

bracket liquid-tite fittings so that the 1" poly pipe is squeezed and water cannot leak around the 1" poly

pipe.

If you are concerned about subsidence and/or kinking, you may prefer to use a heavier 1-1/2" double run of

PVC flex pipe. To accomplish this, simply substitute the two couplings provided with the two (2) liquid-tite

fittings threaded into the PVC bracket, apply Teflon Tape to the couplings, and glue in the 1-1/2" PVC flex

pipe (refer to Photo 4.A.2).

NOTE: The pool builder/installer must decide if they will be using 1" poly pipe or 1-1/2" PVC flex

pipe BEFORE spraying gunite. Once the 1" poly pipe or 1-1/2" PVC flex pipe has been run, cut, and

trenched, the gunite can be sprayed.

If installing the provided 1" poly pipe (standard installation), the Wall Mount Fastlane ships with two

(2) 24' 6" rolls of 1" poly pipe. From the rear side of the pool, feed each 1" poly pipe into the liquid-tite fit-

tings and tighten the cord grip on the 1" poly pipe so that no water will pass between the 1" poly pipe and

the liquid-tite fitting. Unroll the 1" poly pipe to the location where the Power Unit will be located. The 1"

poly pipe is 6" shorter than the standard length of hydraulic hoses provided. As you run the 1" poly pipe, be

certain it does not kink. To ensure you have sufficient lengths of hydraulic hoses to make the necessary

connections to the Power Unit, cut off approximately 3' of each 1" poly pipe. The 1" poly pipe will need to

exit the ground near the Power Unit. If you find the 1" poly pipe is not long enough to reach the Power

Unit, a junction box and additional hydraulic hoses will need to be ordered and installed. In this case, DO

NOT CUT the length of the 1" poly pipe. Refer to Section 5 for additional information.

If installing the 1-1/2" PVC flex pipe, remove the two (2) 1-1/4" liquid-tite fittings from the wall mount

bracket. Thread and adhere with Teflon tape the two (2) 1-1/2" NPT male/slip female PVC fittings into the

wall mount bracket. Unroll the 1-1/2" PVC flex pipe from the wall mount bracket to the Power Unit. The

PVC flex pipe should exit the ground near the Power Unit. Each section of the PVC flex pipe should be no

longer than 21 feet. This will leave enough hydraulic hose to connect to the Power Unit. If you find that 21

feet of the PVC flex pipe is not long enough to reach the Power Unit, a junction box and additional hy-

draulic hoses will need to be ordered and installed. Refer to Section 5 for additional information.

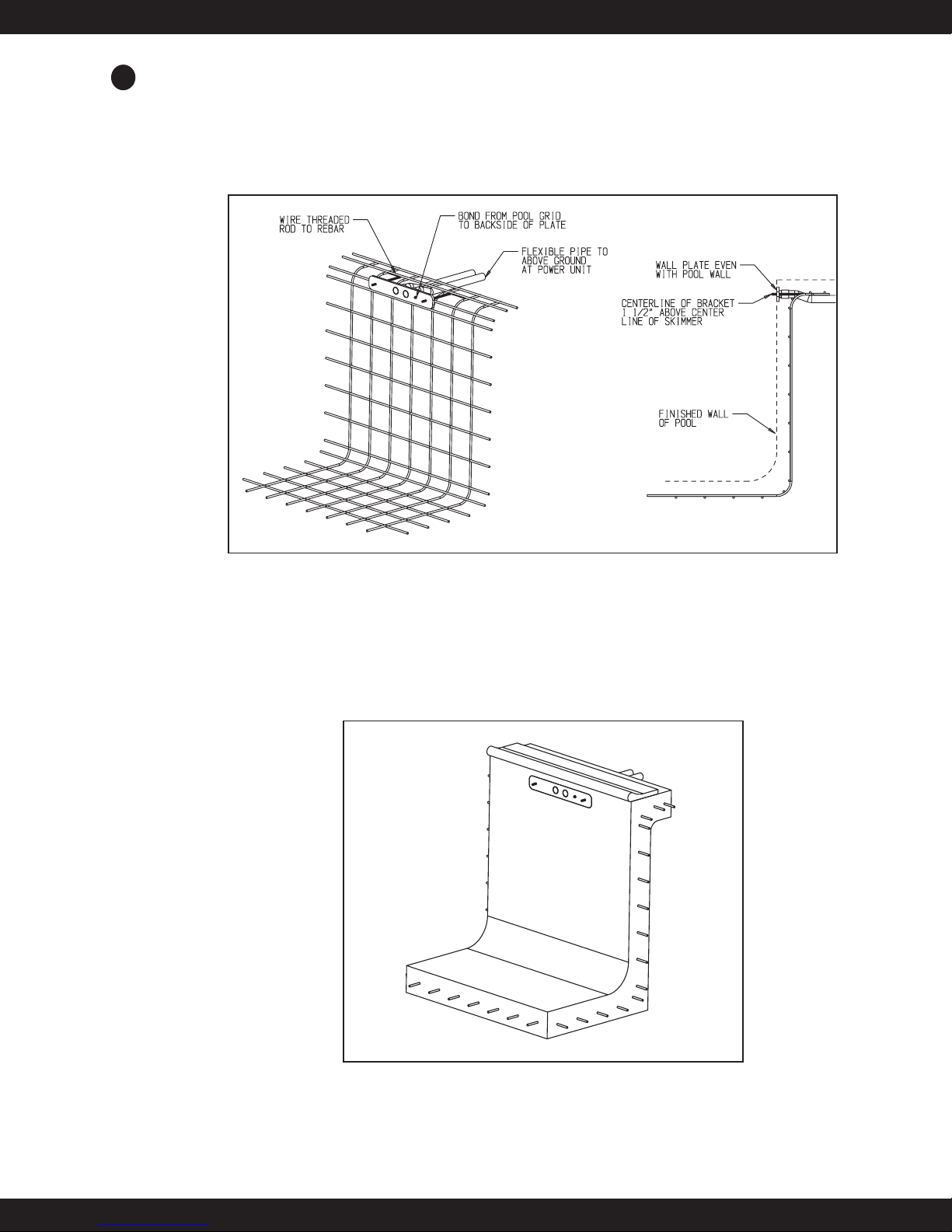

3/8" Stainless Steel Mounting

Rod. Firmly secure these

rods to the rebar grid.

These 1-1/2" couplings may

be used if you choose to use

1-1/2" PVC flex pipe rather

than the 1" poly pipe as your

conduit to the Power Unit

and junction box.

Example of 1-1/2"

PVC Flex Pipe

Bracket Plate

Bonding

Lug Set

Hang and secure Fastlane

on these SS threaded rods.

Wall Mount Fastlane Bracket.

Install this side flush with the

finished pool surface.

Attach SS bonding wire from

inside the Fastlane housing to

the bonding lug.

Cover PVC end with duct tape

to prevent gunite from clogging

the PVC.

Photo 4.A.2

W