5

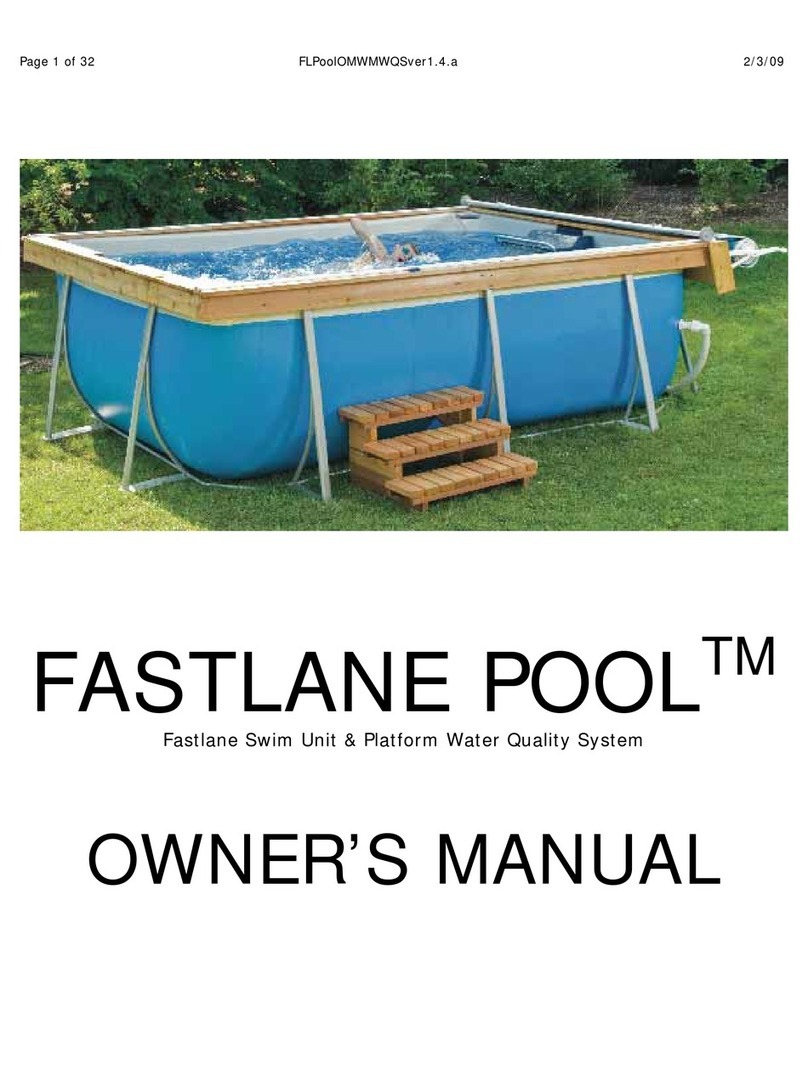

RECEIVING THE FASTLANE POOL

The Fastlane Pool is shipped via UPS and contains at least 16

packages. Additional packages may be sent depending on the

options chosen:

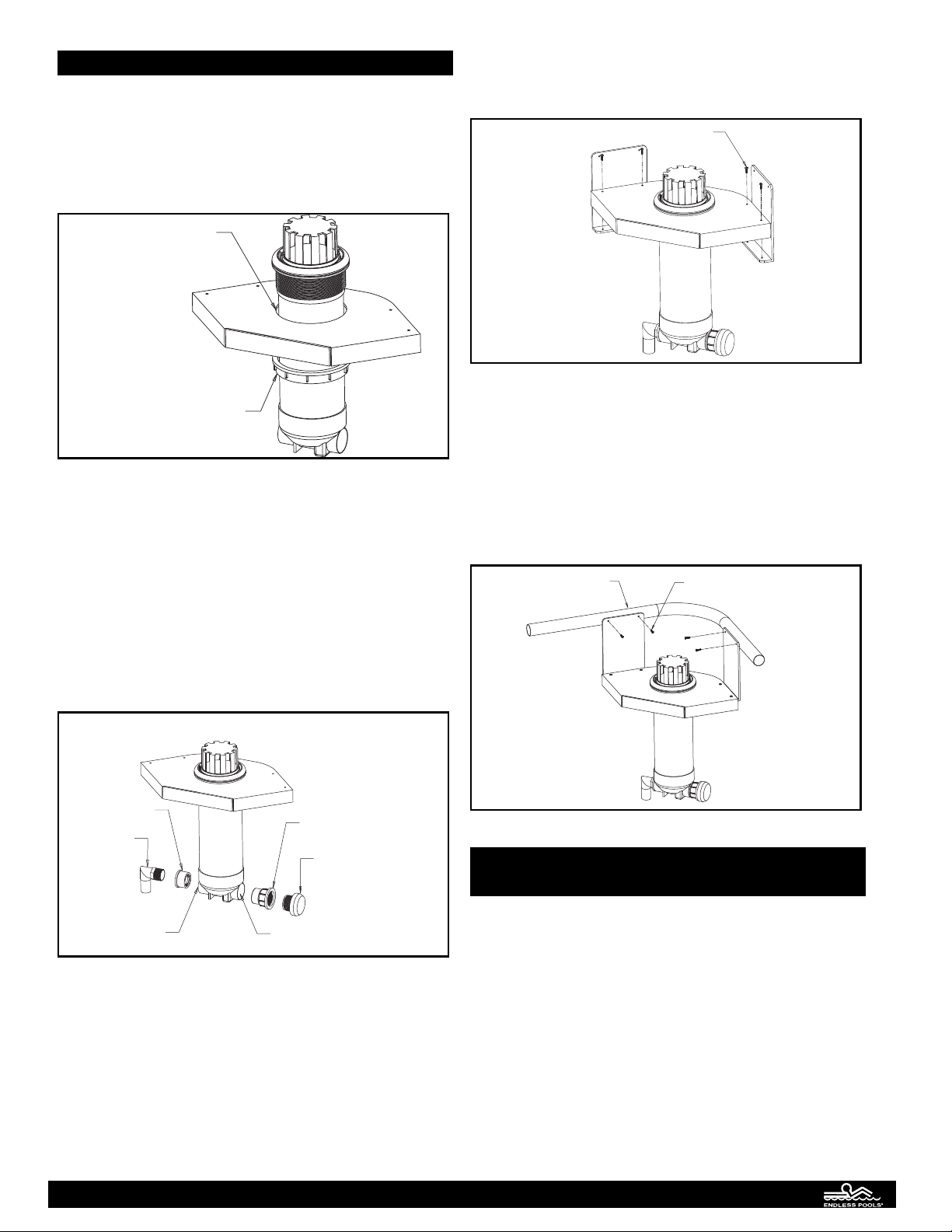

(1) Hydraulic ower Unit

(Box labeled, “Power Unit Kit, 5Hp 60Hz, with Electronics, for

Poolside WQS with 3/12/09 Card 451000” for US Customers

and “Power Unit Kit, 5Hp 50Hz, with Electronics, for Poolside

WQS with 3/12/09 Card 451020” for International Customers)

(1) 5 Gallon Hydraulic Fluid

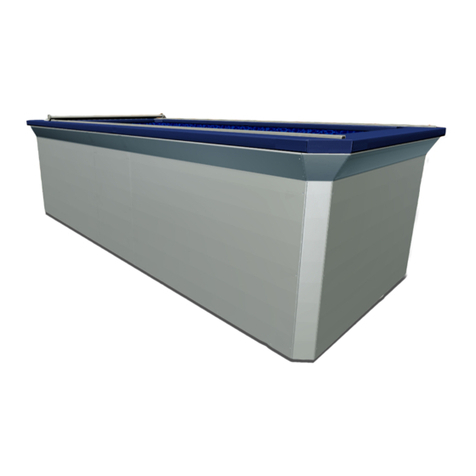

(1) Fastlane ool Swim Unit Housing

(Box labeled, “Fastlane Upper Unit for Rolled Perf Base,

Sapphire 124016”)

(1) Fastlane ool Accessories Kit

(Box labeled Accessory Kit for Fastlane Pool w/ Rolled Perf

Base, Sapphire 124026)

Qty 2 - Hydraulic Hose Protective Channels

Qty 1 - Acrylic Top for Swim Unit

Qty 1 - Acrylic Hanging Bracket

Qty 1 - Lower Standoff

Qty 1 - Owner’s Manual Kit (Padded Envelope)

Qty 1 - Owner’s Manual

Qty 2 - Hydraulic Adapters (8 Female JIC x 6 Male JIC)

Qty 1 - Fastlane Pool Bonding Kit

Qty 38 - 3/4" 10-32 Machine Screws

Qty 10 - 1/2" 10-32 Machine Screws

Qty 4 - Rubber rommets

Qty 6 - 10-32 nuts

(1) Fastlane ool Swim Unit Base

(Box labeled Fastlane Lower Unit for Rolled Perf Base,

Sapphire 124011)

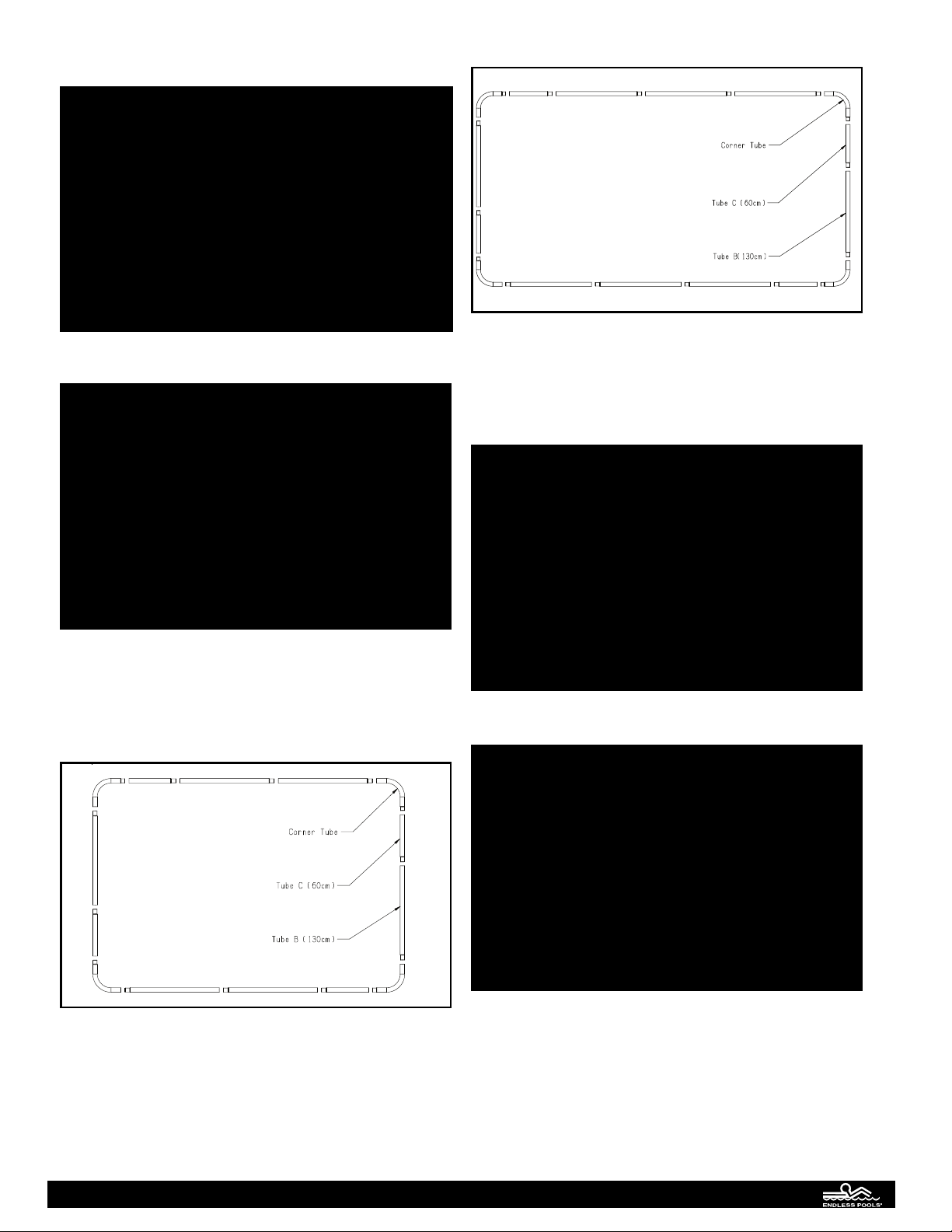

(1) Fastlane ool Liner Box (Only for a 9x13 ool)

(Box labeled, “Fastlane Pool Liner Box, 9 x 13 157070”)

Qty 1 - Pool Liner

Qty 2 - Vertical Struts

Qty 4 - Top Corner Tubes

Qty 4 - Bottom Corner Tubes

(1) Fastlane ool Liner Box (Only for a 9x17 ool)

(Box labeled, “Fastlane Pool Liner Box, 9 x 17 157072”)

Qty 1 - Pool Liner

Qty 4 - Vertical Struts

Qty 4 - Top Corner Tubes

Qty 4 - Lower Corner Tubes

Qty 2 - 130cm Top Straight Tubes

Qty 2 - Straight Bottom Tubes

(1) Fastlane ool Strut Box

(Box labeled, “Fastlane Pool Strut Box 157067”)

Qty 8 - Vertical Struts

(2) Fastlane ool Tube Box

(Box labeled, “Fastlane Pool Tube Box 157068”)

Qty 3 - 130cm Top Straight Tubes

Qty 2 - 60cm Top Straight Tubes

Qty 3 - Straight Bottom Tubes

(1) Fastlane ool Equipment Hutch

(Box labeled, “Hutch Box for Fastlane Pool Equipment

157064”)

Qty 1 - Equipment Hutch

Qty 1 - Equipment Mounting Board

Qty 1 - Pump Mounting Clamp

(1) Fastlane ool Water Quality System

(Box labeled: Fastlane Pool, Skimmer Plumbing and start-up

Box with Teleweir Skimmer and Skimmer Housing [4302250])

Qty 1 - Skim-Filter

Qty 1 - Circulating Pump

Qty1 - Plumbing Parts bag

Qty 2 - Thru-wall Fittings

Qty 2 - MPT x Slip 90º Street Elbows

Qty 2 - Slip x Slip Unions

Qty 2 - Slip x Slip Ball Valves

Qty 2 - Pump Unions with O-Rings

Qty 1 - Male Slip x Female Slip 90º Street Elbow

Qty 2 - MPT x Insert 90º Elbow

Qty 2 - Plastic Hose Clamps

Qty 2 - Threaded Plug with O-Ring

Qty 1 - Eyeball Fitting

Qty 1 - 4oz PVC Cleaner

Qty 1 - 4oz PVC Cement

Qty 1 - Teflon Tape

Qty 1 - Liquid Tite Electrical Fitting

Qty 1 - 1-1/2" Slip x 1-1/2” Slip x 3/4” FPT Tee

Qty 1 - 3/4" Hose Spigot

Qty 1 - 2" Male Slip x 1-1/2"FPT Bushing Reducer

Qty 1 - Suction Fitting Assembly

Qty 1 - Skimmer Straight Nut

Qty1 - Fastlane Pool Start Up Bag

Qty 1 - Container of Test Strips

Qty 1 - Water Clarifier

Qty 1 - pH Increaser

Qty 1 - pH Decreaser

Qty 1 - Bag of Shock

Qty1 - Fastlane Pool Skim Filter Housing Assembly

Qty 1 - Skim Filter Housing

Qty 5 - 1/2" 10-32 Stainless Steel Machine Screws

Qty 5 - 1" Self Tapping Stainless Steel Screws

Qty 1 - 11/64" Drill Bit

Qty 1 - 3' Length of Suction Hose

(1) 50’ Roll of Flexible VC

(1) Fastlane ool Ladder

(1) Solar cover

(only shipped if a Retractable Security Cover Kit was not

ordered)

(1) Optional Heater Controller

(Box labeled, “Fastlane Pool Heater Kit, 60Hz 157073” for

US Customers and, “International Fastlane Pool Heater Kit,

50Hz 157069” for International Customers)

Qty 1 - Heater Controller

Qty 1 - Keypad for Heater Controller

Qty 2 - Heater Tail Piece

Qty 2 - Heater Tail Piece T askets

Qty 1 - Slip x Slip 90º Elbow

Qty 1 - Male Slip x Female Slip 90º Street Elbow

Qty 2 - 2-1/4" PVC Nipple

Qty 1 - 4-1/4" PVC Nipple

Qty 1 - Heater Controller Mounting Clamp

Qty 4 - 3/4" 10-32 Machine Screw

Qty 2 - 10-32 KEP Nut