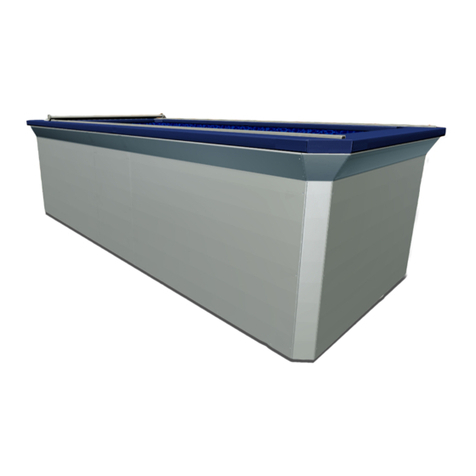

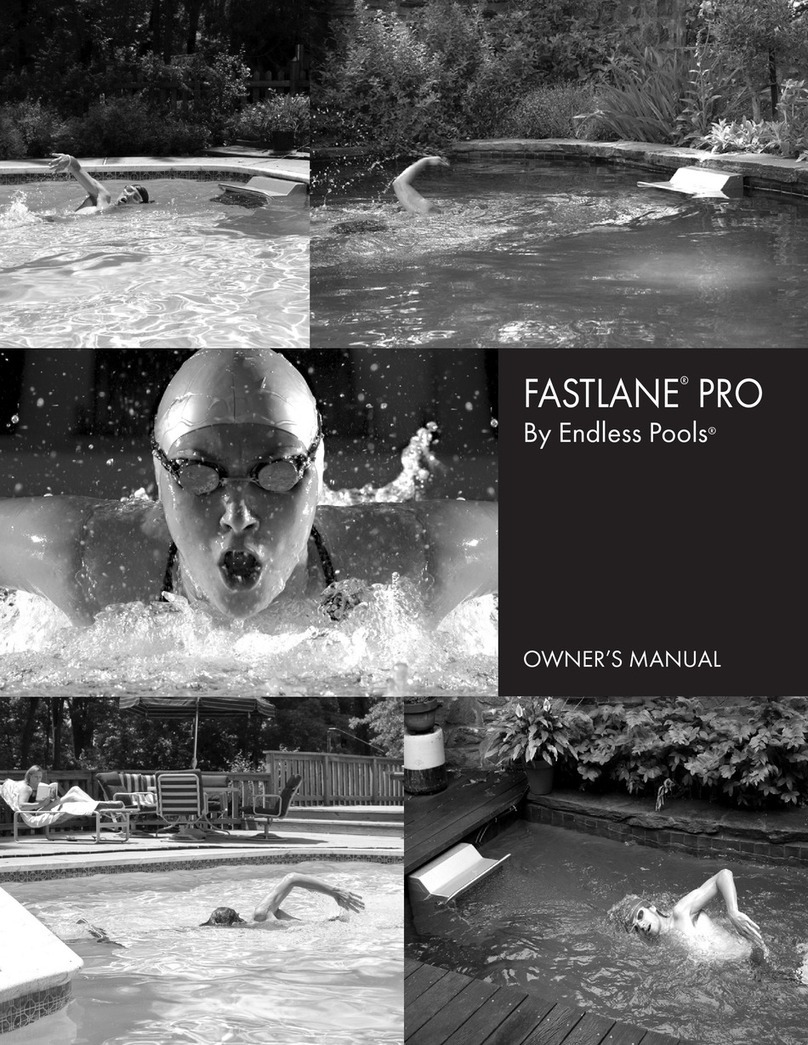

1. Pool Arrival and Inspection

The Standard Endless Pool®arrives in three packages: a skid of

6 pool panels weighing approximately 850 lbs., a 4' x 8' x 4' high

crate weighing about 1,150 lbs and a pair of 6 5/8" wide steel

reinforcing channels. Most shipping companies will lower the

containers to the ground with a hydraulic lift gate on their truck;

the pool can remain in the containers until you are ready to begin

installation. Please contact our shipping department prior to

shipment to answer any questions you may have. Since every

delivery is slightly different, and depends to a large extent on

site conditions, it is important to speak with our shipping depart-

ment well in advance to reduce the chance of surprises. Please

refer to Tech Bulletin #1 for a detailed discussion of shipping

and the choices available.

Upon arrival, the packages, see Figure 1.1, should be inspected

for external damage. Should there be visible damage, you must

complete a damage-claim report provided by the truck driver.

Please call the Endless Pools shipping department immediately

at (800) 732-8660. The pool components are not damaged by

freezing conditions and may be stored outside under a tarp for

an extended period prior to installation. See Figure 1.2.

To begin installation, or to move pool components, begin

unpacking the pool. Using a hacksaw or tin snips, remove the

steel packing straps encircling the pool panel skid. The wooden

top and sides of the crate may be removed with a phillips-head

screwdriver.

2. Main Drain Outlet

Most municipalities recognize our pool wall suction fitting as an

appropriate drain however some municipalities, notably in

Florida, may require a main drain outlet in the floor of your

pool. If you know this is a requirement the main drain needs to

be positioned prior to pouring concrete. Refer to Tech Bulletin

#16A for more information. To obtain a main drain please call

your sales person or our Customer Service Department. If you

are installing an Endless Pool on an existing concrete slab and

your municipality requires a main drain outlet in your pool floor

please call our Customer Service Department for details.

3.Assembly of Pool Panels (Overview)

Bolt the panels together as shown on the video leaving access at

the front of the pool for service. If jets, lights and/or a retractable

security cover are to be installed, outside access to additional

walls will be required. Access requirements are described in the

Technical Bulletins, Technical Specifications and in The

Endless Pool Planning Guide. Packed in the skid of panels is the

Pool Panel Hardware Kit, see Figure 3.1, that contains all of the

pieces necessary to assemble the pool panels and anchor them to

the concrete floor. Also found in the kit is Tech Bulletin #2

describing this simple assembly and a list of all the parts in the

Pool Panel Hardware Kit.

If anchoring down to the concrete is impractical and you have a

flat-bottom pool, you may have selected optional Tension

Straps. If they were ordered with the pool they would be pack-

aged in the pool crate. Instructions for their use are included in

Tech Bulletin #2.

When an Optional Deeper Endless Pool has been selected, the

panel enclosure will be anchored down to the concrete and there

will be a concrete pad with a formed deeper section inside the

panel enclosure. This is shown well in the Installation Video.

Tech Bulletin #2 also includes instructions for this type of instal-

lation and an order form for a Custom Deeper Pool Liner.

4. Panel Assembly Instructions

On a level concrete slab assemble the 6 wall panels. The smooth

wall of each panel should face inward. See Figure 4.1. The front

panel-the panel towards which you will be swimming-has cutouts

for the skimmer, drain, water-return fitting, and 2 hydraulic hoses.

Leave at least 18" of clearance from the front panel surface for the

3

Fig 1.2: Outdoor storage with tarp.

Fig 3.1: Hardware in Panel Kit.

Fig 1.1: Pool crate, panels and channels shown as they will arrive.