P5/8/08 Page 2 of 26

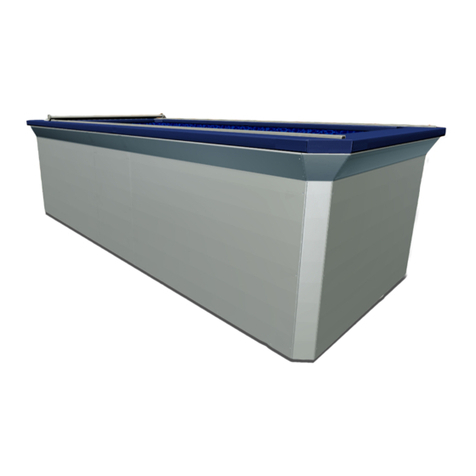

RECEIVING YOUR FASTLANE POOL

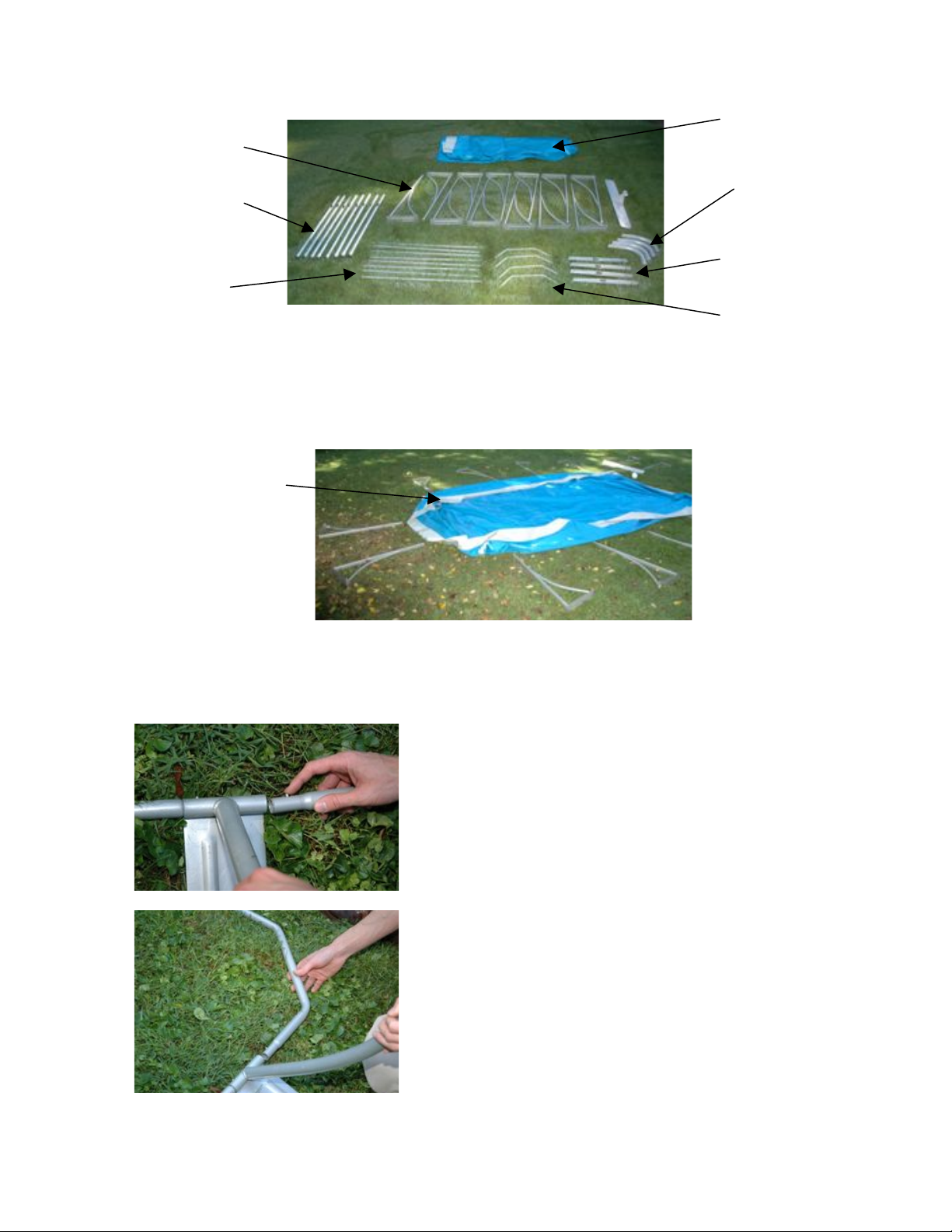

Your Fastlane Pool is shipped by common carrier and contains the following 13 packages:

1. (8) Top 130 cm Straight Tubes, wider (Part B for the pool assembly)

2. Electric Heater (optional), Skimmer, Owner’s Manual and Plumbing & Start-Up Kit

3. (1) 8’ x 16’ Solar Cover

4. (4) Top 60 cm Straight Tubes, wider (Part C for pool assembly) and (8) Straight

Bottom Tubes, thinner (Part F for pool assembly)

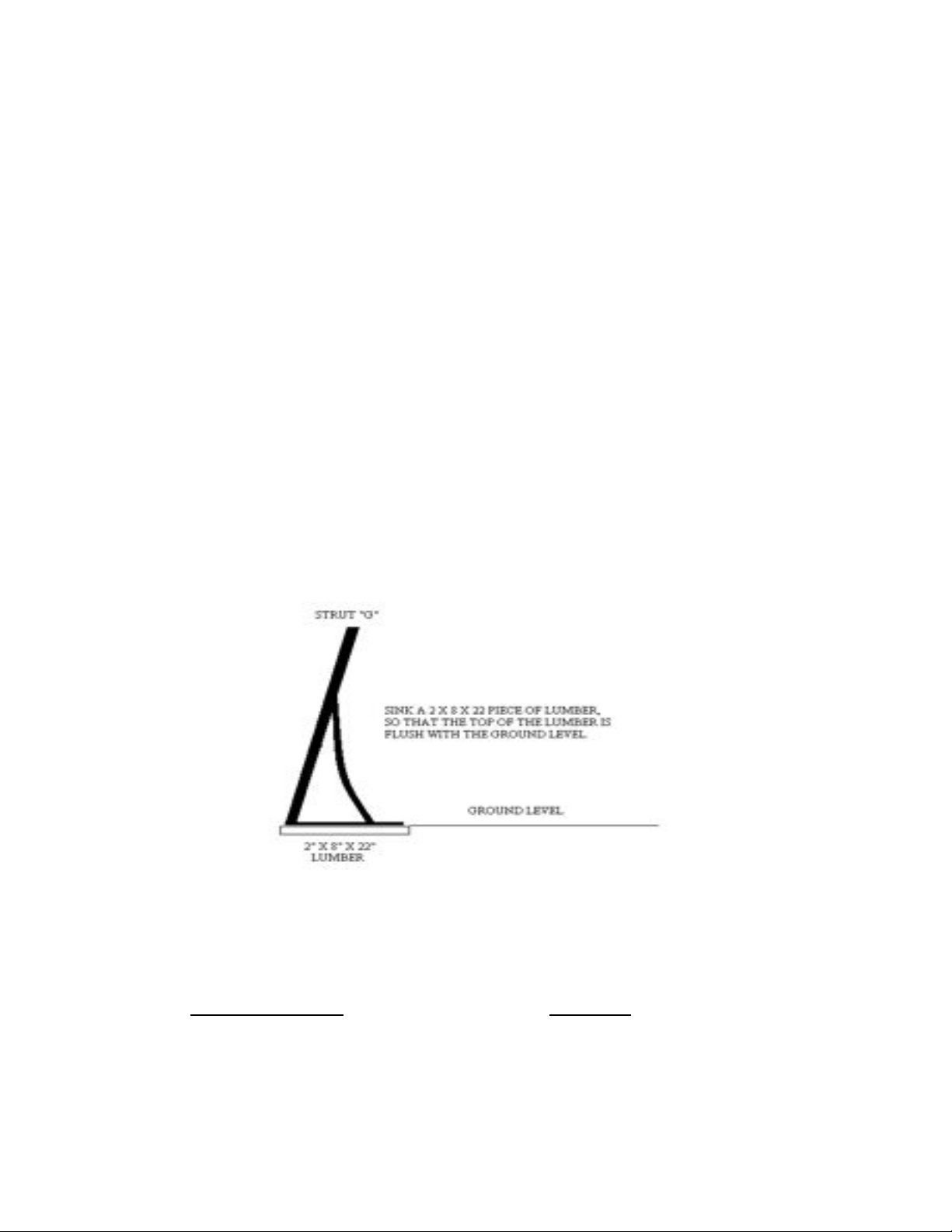

5. (6) Vertical Struts (Part G for pool assembly) and (4) Top Corner Tubes, wider (Part

D of pool assembly)

6. (6) Vertical Struts (Part G for pool assembly) and (4) Bottom Corner Tubes, thinner

(Part E of pool assembly)

7. (1) Ready-to-Assemble Pool Ladder

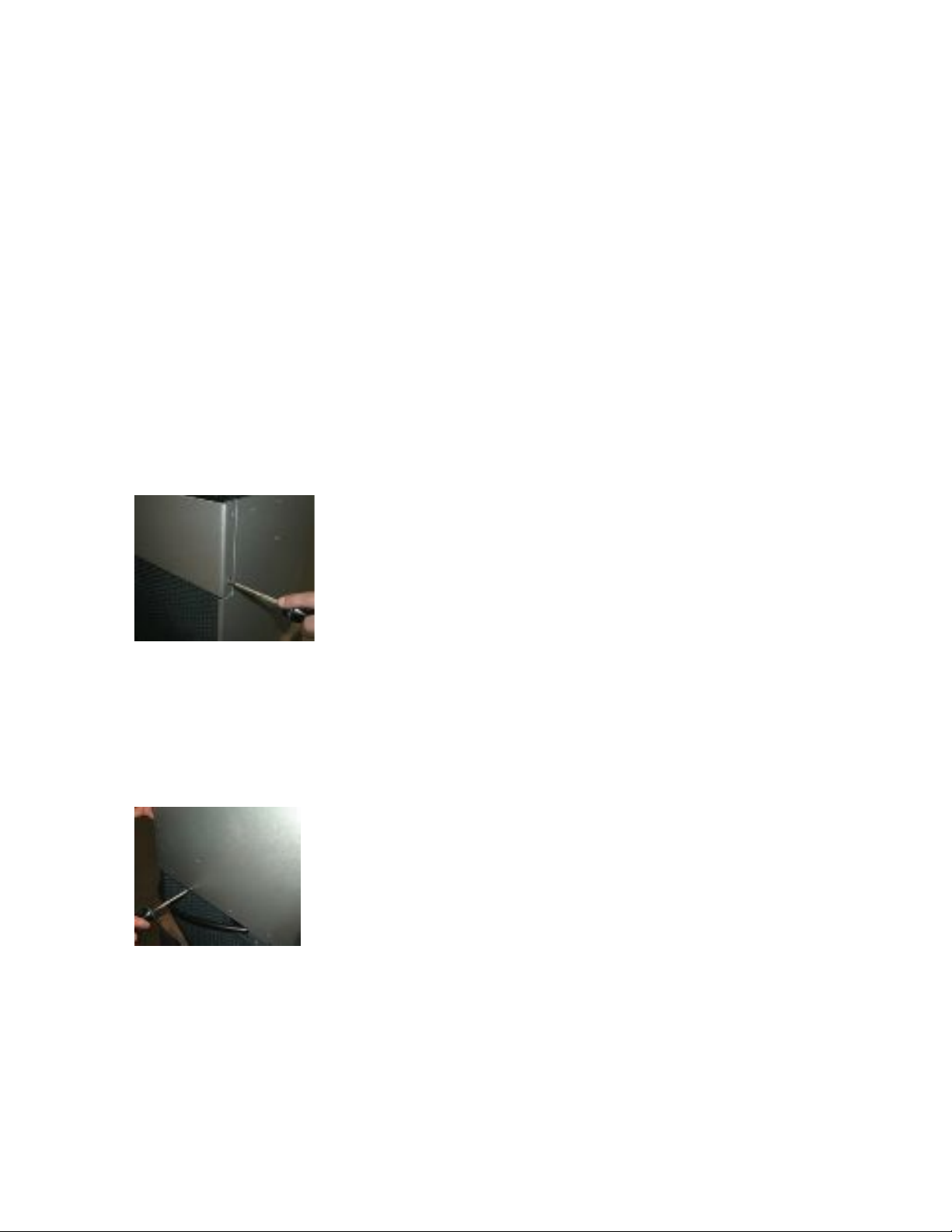

8. (1) Reinforced Fabric-Wall Pool Liner (Part A for pool assembly), (1) vinyl bag with

pins and patches, Pump 2-Speed 110-volt Processed, Filter Cartridge Housing and

Pump Base with Inserts

9. (1) Flex Tube 50’ x 1.5” sched 40

10.(1) 5 Gallon Bucket of Hydraulic Fluid

11.(1) Fastlane Swim Unit Housing

12.(1) Fastlane Swim Unit Base with attached 25’ of Hydraulic Hoses

13.(1) Fastlane Hydraulic Power Unit (5 hp standard, 6 hp optional)

14. (1) Accessory Kit, which includes:

a. (1) Hanging Bracket

b. (1) Top Bumper Piece

c. (1) Extension Bumper

d. (1) Top (of the housing)

e. (4) Liner Grommets

f. (2) Hat Sections

g. (1) Owner’s Manual Kit, which includes:

!(1) Fastlane Pool Owner’s Manual

!(34) 10-32, 3/4” Screws, 316L Stainless Steel, M/S, Phillips Truss

!(6) 10-32, 1/2” Screws, 316L Stainless Steel, M/S, Phillips Truss

!(6) 10-32 Lock Nuts, Stainless Steel

!(2) Adapters, 8 JIC Female x 6 JIC Male, 8-6TRTXN-S

POOL POSITIONING

To ensure maximum enjoyment and efficiency, consider the following steps when selecting

the desired location of your Fastlane Pool.

"Select a location that receives maximum sunlight for increased heat and extended

use.

"Select a location with as little wind exposure as possible to minimize heat loss.

"Be aware of the amount of trees and shrubbery around your pool to limit the amount

of debris.

"Select a location with accessibility to water and electric sources.

"Consider privacy when selecting a location.