Endress+Hauser OUSAF12 User manual

Other Endress+Hauser Security Sensor manuals

Endress+Hauser

Endress+Hauser Prosonic FDU83 Installation instructions

Endress+Hauser

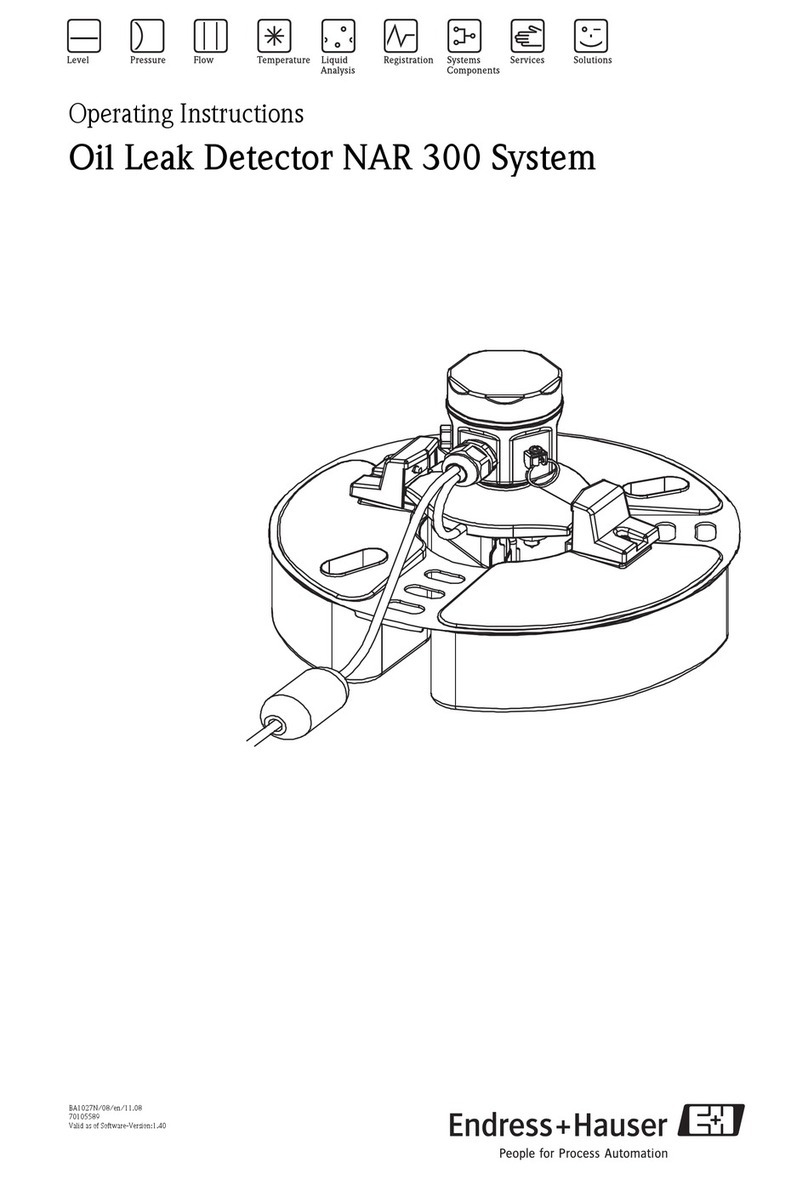

Endress+Hauser NAR 300 User manual

Endress+Hauser

Endress+Hauser Nivotester FTL325P-H3A3 Technical specifications

Endress+Hauser

Endress+Hauser Micropilot FMR56 Technical specifications

Endress+Hauser

Endress+Hauser Nivotester FTL325N-**** Series User manual

Endress+Hauser

Endress+Hauser USR30 Manual

Endress+Hauser

Endress+Hauser Liquiphant S FTL70 User manual

Endress+Hauser

Endress+Hauser nivotester FTL 325 P User manual

Endress+Hauser

Endress+Hauser SOP300 Technical specifications

Endress+Hauser

Endress+Hauser Nivotester FTL325N-**** Series User manual

Endress+Hauser

Endress+Hauser NAR300-13 Series User manual

Endress+Hauser

Endress+Hauser NAR 300 User manual

Endress+Hauser

Endress+Hauser Nivotester FTL325N 1 1 Series User manual

Endress+Hauser

Endress+Hauser nivotester FTL 325 P User manual

Endress+Hauser

Endress+Hauser Turbimax CUS51D User manual

Endress+Hauser

Endress+Hauser Nivotester FTL325N-**** Series Technical specifications