Endura DVR5300 Series Instruction sheet

IP Video Surveillance System

Installation Guidelines

for Endura® Equipment

C2670M-C (9/09)

Page2C2670M‐C

TABLEOFCONTENTS

INTRODUCTION............................................................................................................................................................................................... 3

POWERGUIDELINES ..................................................................................................................................................................................... 4

POWERDISSIPATIONANDCURRENTREQUIREMENTS..................................................................................................... 4

POWERQUALITY................................................................................................................................................................................... 5

GROUNDING............................................................................................................................................................................................. 7

ELECTROSTATICDISCHARGEPREVENTION ........................................................................................................................... 8

ENVIRONMENTALGUILDELINES............................................................................................................................................................ 9

ENVIRONMENTALELEMENTS........................................................................................................................................................ 9

OPERATINGTEMPERATURE .........................................................................................................................................................10

HEATINGVENTILATIONandAIRCONDITIONING(HVAC) .............................................................................................12

NETWORKINGGUIDELINES.....................................................................................................................................................................13

GENERALNETWORKISSUES.........................................................................................................................................................13

CABLING..................................................................................................................................................................................................13

NETWORKTIME ..................................................................................................................................................................................14

TURNINGONTHEENDURASYSTEM...................................................................................................................................................15

APPENDIX.........................................................................................................................................................................................................16

C2670M‐C Page3

INTRODUCTION

PURPOSEOFTHISDOCUMENT

ThisdocumentistoprovideEndura®‐certifiedintegratorswithaguidelineofinstallationrequirementsforthe

EnduraIPVideoManagementSystemcomponents.

TheEndurasystemisbuiltuponindustrystandardtechnologiesandutilizesInformationTechnology(IT)grade

components.Assuch,allbestpracticesforITequipmentsiteplanninganddeploymentapplytoEndura.

GiventheconstantdatabaseandfilemanagementactivitythatisnaturalwithanIPvideomanagementsystem,

caremustbetakentoavoidsuddenshutdownofanyofthecomponents.Aspowerfluctuationsanddisruptions

areacommonsourceforun‐intentionalequipmentreboots,conditionedpowershouldbeusedforallservers.As

harddiskdrivereliabilityisnegativelyimpactedbytemperatureextremes,caremustbetakentoensurethathard

diskdrivesareneverexposedtoelevatedoperatingtemperatures.Ifeitherconditionedpowerorthe

environmentalconditionsoftheserverroomareoutsidethespecifiedlimits,datacorruptionandequipment

failurecanoccur.TheEndurasystemshouldonlybeturnedonafterthepowerandenvironmentalconditioning

systemsarefullytestedandoperational.

WARNING:DonotturnonanyEnduraequipmentuntilalloftheitemssuggestedinthisdocument

havebeenconsidered.WithoutadequatepowerandventilationtheEnduraequipmentcansuffer

permanentdamage.

Shouldyouencounteranyquestionsaboutthetopicscoveredinthisdocument,pleasecontactthePelcoEndura

Hotlineat1‐800‐289‐9100(USAandCanada)or+1‐559‐292‐1981(international),e‐mail

Page4C2670M‐C

POWERGUIDELINES

POWERDISSIPATIONANDCURRENTREQUIREMENTS

Properdesignofthepowerdistributionsystemisessentialforreliable,long‐termoperationoftheEndurasystem.

Giventhemultitudeofactivedatabasetransactionsandfileoperationsthatsymbolizevideosurveillancesystems,

thereliabilityofthepowersupplyisacrucialelementinpreventingfileanddatabasecorruptionissues.When

designingtheelectricaldistributionsystem,considerthefollowing:

•Totalpowerbudgetrequiredforallequipmentatagivennode

•CircuitbreakerorUPSstrategythatincorporatesin‐rushandstart‐upcurrentloads

•Provideextraloadprojectedgrowthofthesystem

•Providecontinuousandreliablepowerunderallexpectedoperatingconditions

TableAprovidespowerdissipationandstart‐upcurrentrequirementsforEnduraequipment.Consultapplicable

regulationsandstandardsfordeterminingtheproperwiregaugetouse.Generally,youshouldinstallcircuit

breakersthatareratedat125percentoftheexpectedmaximumload.ForrecordingdevicesUPSbatterybackup

shouldbeused.

TableA.PowerandCurrentRequirementsforEnduraComponents

DeviceTypeModelNumberOperatingWatts

(@100VAC)

Start‐upCurrent

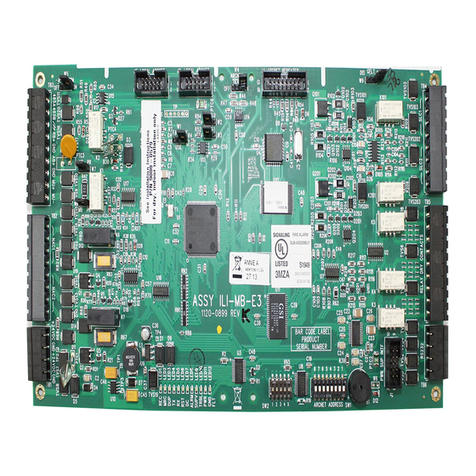

EnterpriseDVRDVR5300Series339W8A

iSCSIStorageExpansionSEB5100Series339W8A

NetworkStorageManagerNSM5200Series262W12A

DirectAttachedStorageDAS5200Series188W12A

VideoEncoderNET5301T8W1A

VideoEncoderNET5301T‐I14.5W1A

VideoEncoderNET5308T

(w/NET5300B)

80W6.3A

VideoEncoderNET5308T‐EXP40W3.15A

VideoEncoderENC530840W3.15A

VideoEncoderENC531640W3.15A

RackMountRK5100PS‐5U46.8W4A

UniversalDeviceInterfaceUDI500028W3.15A

VideoDecoderNET5402R‐HD121W6.3A

VideoConsoleDisplayVCD5202129W6.3A

WorkstationWS5070129W6.3A

SystemManagerSM500073W6.3A

C2670M‐C Page5

POWERQUALITY

AswithanyITequipment,Enduracomponentsrelyonproperinstallationpracticestominimizepowersurgesand

otherfluctuationswiththepowersupply.UnlikeITequipment,Enduracomponentsusecustomdesignedpower

suppliesthatmeetEN50130‐4standardforalarmmonitoringequipment.Thisallowsthecomponenttowithstand

afive‐cycledipinpowersupplywithoutresetting.Evenwiththeseprecautionsincorporatedintothedesign,

powerfluctuationscanstilladverselyaffecttheequipmentandshouldbeavoided.

Powerqualitycanbemeasuredusingapowerqualityanalyzer.Thefollowinglistdescribesthecommonissuesthat

mustbemitigatedtoprotectyoursystemandequipment.Theequipmentproblemsassociatedwiththese

anomaliesrangefromvideodistortionandun‐intendedincreasesinbit‐ratestodamagedelectroniccomponents.

•Frequency:Variationofthepowerwaveform

•Harmonicdistortion:Multiplesofpowerfrequencysuperimposedonthepowerwaveform

•Linenoise:Distortionssuperimposedonthepowerwaveform

•Overvoltage:Increasedvoltagesforanextendedperiodoftime

•Powerfailure:Totallossofutilitypower

•Powersag:Shorttermunder‐voltage

•Powersurge(spike):Quickburstofovervoltage

•Switchingtransient:Under‐voltageorovervoltageforuptoafewnanoseconds

•Under‐voltage(brownout):Lowlinevoltagesforanextendedperiodoftime

NOTE:Iftheseissuesaresuspectedorknowntooccurforagivensite,ensurethatproperstepshavebeentaken

toisolatetheequipmentfromtheseanomaliespriortoturningontheEnduraequipment.

RECOMMENDEDPROTECTIONPRACTICES

TheEndurasystemcanbeprotectedfrommanysourcesofelectricaldisturbancesbyadheringtothefollowingthe

recommendations.Pleasenotethatitisbeyondthescopeofthisdocumenttoprovideexplicitinstructionsfor

electricaldistributionsystemdesignandconfiguration.Ifindoubt,pleaseconsultwithalicensedelectrical

contractor.

•Dedicateapowerdistributionsystemforthevideosurveillanceequipment

•Minimizetheuseofhigh‐currentdrawdevicessuchasheating,ventilation,andairconditioning(HVAC)

unitsplacedontheEndurapowerdistributionnetwork,asthesecancauseadiporinterruptionwhenthe

equipmentturnson

•DonotconnecttheEndurasystemtocircuitswithinductiveloads(forexampleHVAC,motors,andso

forth)

•Wherepossible,usepowerconditioningequipment(lineconditioner)thatsmoothesoutpeaksanddips

onthepowernetwork

•Wherepossible,useover‐andunder‐voltagedetectionandprotectioncircuits

•Installlightningarresters(surgeprotectors/suppressors)onpowercordstoprotectequipmentagainst

electricalstorms

•UseUPSsystemsand,asappropriate,abackupgenerator

Page6C2670M‐C

UNINTERRUPTIBLEPOWERSUPPLYGUIDELINES

Installinganuninterruptiblepowersupply(UPS)ishighlyrecommendedforanyrecordingdevicetoensurethat

poweriscontinuouslyandconsistentlydeliveredtotheEnduracomponent.AUPSistypicallyratedbythePractical

PowerRange,expressedinkVA.Theequivalentwattratingisroughly60to90percentoftheVArating,depending

ontheefficiencyoftheUPS.WhenselectingaUPS,usethepowerandcurrentrequirementspresentedinTableA

asaguideline.ThefollowingexampledescribeshowtocalculatetheUPSsizerequiredforaninstallationwithtwo

NSM5200sconnectedtothesameUPS:

Example:TwoNSM5200saretobeconnectedtothesameUPS.FromTableA,eachNSM5200dissipates262Wof

powerandhasastart‐upcurrentof6Aperpowersupplymodule.

Step1:Calculatethetotalpowerinwattsrequired:

262Wx2=524W

Step2:ConvertthewattagetoVAbydividingby0.60

524W/0.6=873VA–NeedaUPSratedformorethan873VA

Step3:FindtheappropriateUPS:

ConsidertheAPCSmart‐UPS1000VAwithratedoutputpowerof800W/1000VA

NOTE:NSM5200sandDAS5200scomewithredundantpowersupplies.Eachsupplyfortheunitshouldbe

connectedtoadifferentcircuittoensurethattheunitdoesnotlosepoweronintheeventofacircuitfailure.

C2670M‐C Page7

GROUNDING

Aproperlygroundedinstallationiscriticalinensuringthefault‐freeoperationofEnduraequipment.Allconduit

usedshouldbesecurelyconnectedrigidmetal.Anearth‐groundconnectionshouldbemadebyoneofthe

followingmeans:

•Groundingrod

•Buildingsteel

•Conductivecoldwaterservicepipe

Allpowerpanelsshouldbegroundedtotheelectricalserviceentrance.Thegroundconnectionsthatwillbeused

throughouttheserverroomshouldbetestedtoensurealowresistancepathtoground.

NOTE:Besuretoverifythatthereisnodirectcurrent(DC)potentialbetweengroundsofdifferentcircuitsineach

rack.Anyreadingabove1Vmeasuredbetweengroundsshouldbeconsideredaproblemandinvestigated.

GroundingGuidelines

•Mainbuildingelectricalground:Themainelectricalserviceentranceequipmentshouldhaveanearth‐

groundconnectionasrequiredbyapplicablecodes.Connectionssuchasgroundingrod,buildingsteel,or

aconductive‐typecoldwaterservicepipeprovideanearth‐ground.

•Electricalconduitground:Allelectricalconduitsshouldbemadeofrigidmetallicconduitthatissecurely

connectedtogetherorbondedtopanelsandelectricalboxestoprovideacontinuousgroundingsystem.

•Powerpanelground:Eachpowerpanelshouldbegroundedtotheelectricalserviceentrancewithgreen

(green/yellow)wiregroundconductors.Thegreen(green/yellow)wiregroundconductorsshouldbe

sizedperapplicablecodes.

Page8C2670M‐C

ELECTROSTATICDISCHARGEPREVENTION

Electrostaticdischarge(ESD)occurswhenobjectsareseparatedorrubbedtogether.Thevoltagelevelofastatic

chargeisdeterminedbythefollowingfactors:

•Typeofmaterials

•Relativehumidity

•Rateofchangeorseparation

RefertoTableBforsampledataontheeffectofhumidityonchargelevels.

TableB.EffectofHumidityonESDChargeLevels

Humidity†andChargeLevels(voltages)‡

PersonnelActivity*26%32%40%50%

Personwalkingacrossalinoleumfloor6,150V 5,750V4,625V3,700V

Personwalkingacrossacarpetedfloor 18,450V17,250V13,875V11,100V

Persongettingupfromaplasticchair 24,600V23,000V18,500V14,800V

*Source:B.A.Unger,ElectrostaticDischargeFailuresofSemiconductorDevices(Bell

Laboratories,1981).

†Forthesamerelativehumiditylevel,ahighrateofairflowproduceshigherstatic

chargesthanalowairflowrate.

‡Somedatainthistablehasbeenextrapolated.

StaticProtectionMeasures

ObservethefollowingprecautionstominimizepossibleESD‐inducedfailuresintheserverroom:

•Maintaintherecommendedhumiditylevelandairflowratesintheserverroom.

•Installconductiveflooring(conductiveadhesivemustbeusedwhenlayingtiles).

•Useconductivewaxifwaxedfloorsarenecessary.

•Ensurethatallequipmentandflooringareproperlygroundedandareatthesamegroundpotential.

•Useconductivetablesandchairs.

•Useagroundedwriststrap(orothergroundingmethod)whenhandlingcircuitboards.

•Storespareelectronicmodulesinantistaticcontainers.

C2670M‐C Page9

ENVIRONMENTALGUIDELINES

ENVIRONMENTALELEMENTS

ThefollowingenvironmentalelementscanaffecttheoverallstabilityandperformanceoftheEnduraproduct

family:

•Serverroompreparation

•Coolingrequirements

•Humiditylevel

•Airconditioningducts

•Dustandpollutioncontrol

•ESDprevention

•Acoustics(noisereduction)

•Numberofemployeesworkingintheroom

SITECLEANLINESS

Itiscriticalthattheinstallationsitebecompletelycleananddevoidofdustanddebriscreatedduringthe

constructionprocess.Operationoftheequipmentshouldnotbegin(evenfortestingpurposes)untilall

constructionhasbeencompleted.

WARNING:DonotturnontheEndurasystemuntilallconstructioniscompleteandtheinstallationsite

isoperatingatthespecifiedoperatingtemperature.Unitsfunctioningunderhighoperating

temperaturescanexperiencedegradedperformanceandlifeexpectancy.

C2670M‐C Page10

OPERATINGTEMPERATURE

Operatingtemperaturehasasignificantimpactonthemeantimebetweenfailures(MTBF)ofharddiskdrivesand

othersensitiveelectroniccomponents.Variouspublishedfindingsindicatethataharddiskdriveexposedtoa

temperatureextremeissusceptibletoearlyfailure.Generally,forevery18°Fincrease(aboveroomtemperature)

inoperatingtemperature,thelifeexpectancyoftheharddrivedecreasesby35percent.Forexample,aharddrive

operatingat115°Fwouldsuffera58percentreductioninlongevity.Similarly,batterybackupinaUPSoperatingat

77°F(25°C)hasanaveragelifeexpectancyof3to5years.Thisdramaticallydropsto1.5yearsiftheUPSis

operatedat104°F(40°C).WhileEnduraequipmenthasaspecifiedrange,thebestperformanceandlongevityis

attainedwhentheoperatingtemperatureismaintainedatorunder77°F(25°C).

ForthepurposesofEnduraequipment,thespecifiedoperatingtemperatureistheactualtemperaturedirectlyin

frontofthebezelofthechassis.Pelcoproductshaveundergoneanextensiveamountofdesignandengineering

tokeeptheoperatingtemperatureofinternalcomponentsasclosetotheambienttemperatureoftheroomas

possible.Assuch,maintainingtherightambienttemperatureatthefrontoftheunitiscritical.Therack‐

mountableEnduraserversuseactivecoolingbydrawingairinfromthefronttotheback.Themostsensitive

componentsaretypicallymountedatthefrontoftheunittotakeadvantageofcoolerambientairtemperatures.

Properrackdesignandtemperaturecontrolarecriticalcomponentsforsystemstabilityandhealth.

WheninstallinganEndurasystem,followthesegeneralguidelines:

•Ensureproperambienttemperatureisalwaysmaintainedintherackroom

•Ensurethattheambienttemperatureatthefrontofeachunitiswithintheoperatingspecificationrange

•Ensureproperheatexhaustinthebackoftherack

•Ifmultiplecomponentsareplacedinthesamerack,ensurethatnoheattrapsexistintherack(whena

deepercomponentisplaceddirectlyaboveashortercomponent,theextradepthofoneunitcreatesa

heatpocketthatcantraptheheatgeneratedandexhaustedbytheshorterunit)

TableConpage11describestheenvironmentaloperatingconditionsforEnduracomponentsandservers.

C2670M‐C Page11

TableC.SpecifiedOperatingTemperature

DeviceTypeModelNumberOperatingTemperatureCoolingMethodBTU/H

(@100VAC)

EnterpriseDVRDVR5300Series50°to95°F(10°to35°C)

77°FRecommended

Fronttorear

airflow1157

iSCSIStorageExpansionSEB5100Series50°to95°F(10°to35°C)

77°FRecommended

Fronttorear

airflow1157

NetworkStorageManagerNSM5200Series50°to95°F(10°to35°C)

77°FRecommended

Fronttorear

airflow895

DirectAttachedStorageDAS5200Series50°to95°F(10°to35°C)

77°FRecommended

Fronttorear

airflow643

VideoEncoderNET5301T32°to122°F(0°to50°C)Conduction

throughchassis28

VideoEncoderNET5301T‐I41°to95°F(5°to35°C)Conduction

throughchassis50

VideoEncoderNET5308T50°to95°F(10°to35°C)Fronttorear

airflow274

VideoEncoderNET5308T‐EXP50°to95°F(10°to35°C)Fronttorear

airflow137

VideoEncoderENC530850°to95°F(10°to35°C)Fronttorear

airflow137

VideoEncoderENC531650°to95°F(10°to35°C)Fronttorear

airflow137

RackMountRK5100PS‐5U41°to95°F(5°to35°C)Bottomtotop

airflow159

UniversalDeviceInterfaceUDI500050°to95°F(10°to35°C)Fronttorear

airflow96

VideoDecoderNET5402R‐HD50°to95°F(10°to35°C)Fronttorear

airflow413

VideoConsoleDisplayVCD520250°to95°F(10°to35°C)Fronttorear

airflow440

WorkstationWS507050°to95°F(10°to35°C)Fronttorear

airflow440

SystemManagerSM500050°to95°F(10°to35°C)Fronttorear

airflow250

AllEnduraequipmentisratedfor:

•Storagetemperature‐40°to149°F(‐40°to65°C)

•Operatinghumidity20%to80%,noncondensing

•Maximumhumiditygradient10%perhour

•Operatingaltitude‐50to10,000ft(‐16to3,048m)

•Operatingvibration0.25Gat3Hzto200Hzatasweeprateof0.5octave/minute

Page12C2670M‐C

HEATINGVENTILATIONANDAIRCONDITIONING(HVAC)

TheHVACsystemshouldbesizedtomeettherecommendedrequirementsoftheEndurasystemandaccountfor

anyadditionalequipmentthatmayalsobeintheserverroom.Racksandroomlayoutneedtobeconfiguredto

ensurethatcoldairisavailableatthefrontofeachunitandheatedairisexhaustedattheback.RefertoTableC

onpage11forBTU/HfiguresforeachoftheEnduracomponents.

HVACVENTLAYOUT

TheHVACstrategyshouldbecapableofexhaustingeverykilowattofheatproducedbytheEnduraequipment

housedintheroom.Generally,Enduraserversdonotdiscriminatebetweencoldairintakeandheatedairintake;

whateverispresentinfrontoftheunitwillbedrawnintotheunitandreliedupontocoolsensitiveelectronic

components.

Thelayoutoftheventsinrelationtotherackpositioniscritical.Thebasicprincipalinrackroomdesignisto

minimizetheimpedancetoairflowforcoldairgettingintotheequipmentandheatedairbeingremovedfromthe

room.Thermodynamicsprincipalsdictatethatairwillnaturallymovewherethereistheleastresistance;

therefore,itiscriticaltoensurethattherackroomandrackconfigurationiscarefullydesignedtodeliverthe

desiredairflowpattern.

Enduraserversuseactivecoolingtopullcoolairinthroughthefrontoftheunitandexhaustheatedairoutofthe

backoftheunit.Theidealserverroomconfigurationutilizescoldandhotaisles.HVACvents,placedeitherinthe

floorortheceiling,blowintotheaislewherethefrontoftheequipmentislocated.Eachserverusesinternalfans

todrawairinandacrosssensitiveelectronics.Theheatedairbeingexhaustedbythesystemispumpedintohot

aisleswheretheexhaustsystemremovesit,ensuringthatitdoesnotrecirculatetothefrontoftherack.Forthis

toworkproperly,theinstallationshouldensurethatheatedairisnotrecirculatedtothefrontoftheunit.Aneasy

waytodothisistouserackswithsolidsidepanelsandafan‐assistedexhaustsystemforheatremoval.

Dependingontheconfigurationofserversinsidetherack,pocketsofhotairmightbetrappedunderneathdeeper

servers.Makesuretodesignrackssothattheshallowercomponentsareplacedatthetopoftherackandthe

deepercomponentsatthebottomoftherack.

WARNING:Incorrectventlayoutcanresultinalackofairmovement,whichcouldleadtoequipment

overheating.Makesurethatanyfansinstalledwithintherackarepullingairoutoftherack,not

pushingairintotherack.Pushingairintotherackwillresultinthecabinetbecomingpressurized,

leadingtoalackofairflowandpossibleoverheating.Pleaserefertotherackmanufacturer’s

recommendations.Wherepossible,pleaseuseIT‐orientedracklayoutschemesinsteadofA/Vrack

equipmentandguidelines.

C2670M‐C Page13

NETWORKINGGUIDELINES

GENERALNETWORKISSUES

Enduraisahighperformance,IPVideoSurveillanceManagementsystem.Assuch,itheavilyleveragesandis

extremelysensitivetotheperformanceoftheunderlyingnetwork.Theuseofmanagedswitchesisarequirement.

Theseswitchesmusthavetheabilitytorouteandahighnumberofmulticastsessionsconcurrently.Internet

GroupManagementProtocol(IGMP)isaminimumrequirement,andmoresophisticatedmulticastrouting

protocolsmayalsobeutilized.RefertotheEnduraNetworkDesignGuide(C1640M‐C)fordetailsontheminimum

requirementsforthenetworkandthenetworkswitch.Youcanaccessthisdocumentatwww.pelco.comor

throughtheEnduraPartnerPortal.

WhiletheEnduraNetworkDesignGuidedescribesthebasicfunctionalitythattheEnduracomponentsrequireof

thenetwork,Pelcocannotguaranteethateveryswitchwilloperateunderallpossiblenetworkconfigurations.Itis

uptotheintegratortodeterminethefeasibilityofthechosennetworkswitchforthegivenapplication.Further,it

isuptotheintegratortodetermineifthenetworktopologyisadequate.Pelcorecommendstheconsultationofa

qualifiednetworkengineerwhohasacurrentEnduraDesignCertificationandcollaborateswithselectswitch

vendors.

Ifadditionalassistanceisrequired,PelcooffersprofessionalservicesfortheEndura‐certifiedintegrator.

CABLING

AllnetworkcablingshouldadheretotheIEEE,EIA,andTIAspecifications.Whenworkingwithnetworkcabling,

ensurethatyouadheretothefollowingminimumrequirements:

•Cat5eistheminimumcablingstandardforEndurawithCat6thepreferredcabletouse

•Maximumdistancebetweennetworkcomponentsshallnotexceed295ft(9m)withamarginof

10percent

•Minimumcablelengthshallneverbelessthan1munlessconnectingtoapatchpanel

•CablebendradiusshallnotexceedEIA/TIA‐568bendradiusof4xcablediameteror26mm

•Whendressingcables,ensurethatcablebundlesarenotinhibitingtheexhaustventsonthebackofthe

Enduraservers.Inaddition,ensurezip‐tiesdonotexertadditionalstrainonthecables.Wherepossible

useVelcro‐typetiesinsteadofzip‐ties.

RoutingofDataCommunicationCables

Powertransformerscreatehigh‐energyfieldsintheformofelectromagneticinterference(EMI).Heavyfoottraffic

cancreateESDthatcandamageelectroniccomponents.Makesuretoroutedatacommunicationcablesaway

fromtheseareas,usingshieldeddatacommunicationcablesthatmeetindustry‐approvedstandardstoreducethe

effectsofexternalfields.Theseshieldedcommunicationcablesmustbegroundedatbothends.

Page14C2670M‐C

NETWORKTIME

TheEnduraSystemManageriscapableofservingastheNetworkTimeProtocol(NTP)serverfortheEndura

system;however,asthesystemmanagerisbuiltuponastandardserverplatform,itwillsufferdriftovertime.

Tomaintainanaccuratetimefortheentiresystem,PelcorecommendspointingtheEndurasystemtoeitherthe

NTPserverfortherestofanorganization’snetworkoraglobalpositioningsystem(GPS)timesourceinstalled

exclusivelyforthevideosurveillancesystem.

C2670M‐C Page15

TURNINGONTHEENDURASYSTEM

EnduraequipmentisofthesameclassificationasITequipment;allbestpracticesforITequipmentsiteplanning

anddeploymentsapplytoEndura.

Conditionedpowermustbeavailable100percentofthetime,andtheenvironmentalconditionsoftheequipment

locationmustbemaintainedwithinspecification.

WARNING:Ifeitherconditionedpowerortheenvironmentalconditionsoftheserverroomare

outsidethespecifiedlimits,datacorruptionandequipmentfailurecanoccur.TheEndurasystem

shouldonlybeturnedonafterthepowerandenvironmentalconditioningsystemsarefully

operational.

Page16C2670M‐C

APPENDIX

CONVERSIONFACTORS

Theconversionfactorsprovidedareintendedtoeasedatacalculationforsystemsthatdonotconformspecifically

totheconfigurationslistedinthisdocument.Listedbelowaretheconversionfactorsusedinthisdocument,as

wellasadditionalconversionfactorsthatmaybehelpfulindeterminingthosefactorsrequiredforsiteplanning.

•Refrigeration

–1W=0.86kcal/h

–1W=3.412BTU/H

–1W=2.843x10‐4tons

–1ton=200BTU/minute

–1ton=12,000BTU/H

–1ton=3,517.2W

•MetricEquivalents

–1centimeter=0.3937inches

–1meter=3.28feet

–1meter=1.09yards

–1inch=2.54centimeter

–1feet=0.305meters

–1CFM=1.4m3/h

•KVAConversions

–Threephase

kVA=VxAx

3

1000

------------

–SinglephaseFormulas

kVA=Vx

A

1000

------------

FORMULAS

•KVA=VoltagexCurrent(amperes)

•Watts=VAxPF

•BTU=Wattsx3.41

PRODUCT WARRANTY AND RETURN INFORMATION

WARRANTY

Pelco will repair or replace, without charge, any merchandise proved defective in

material or workmanship for a period of one year after the date of shipment.

Exceptions to this warranty are as noted below:

• Five years:

– Fiber optic products

– TW3000 Series unshielded twisted pair (UTP) transmission products

– CC3701H-2, CC3701H-2X, CC3751H-2, CC3651H-2X, MC3651H-2, and

MC3651H-2X camera models

• Three years:

– Pelco-branded fixed camera models (CCC1390H Series, C10DN Series,

C10CH Series, IP3701H Series, and IX Series)

– EH1500 Series enclosures

– Spectra®IV products (including Spectra IV IP)

– Camclosure®Series (IS, ICS, IP) integrated camera systems

– DX Series digital video recorders, DVR5100 Series digital video recorders,

Digital Sentry®Series hardware products, DVX Series digital video

recorders, and NVR300 Series network video recorders

– Endura®Series distributed network-based video products

– Genex®Series products (multiplexers, server, and keyboard)

– PMCL200/300/400 Series LCD monitors

• Two years:

– Standard varifocal, fixed focal, and motorized zoom lenses

– DF5/DF8 Series fixed dome products

– Legacy® Series integrated positioning systems

– Spectra III™, Spectra Mini, Spectra Mini IP, Esprit®, ExSite®, and PS20

scanners, including when used in continuous motion applications.

– Esprit Ti and TI2500 Series thermal imaging products

– Esprit and WW5700 Series window wiper (excluding wiper blades).

– CM6700/CM6800/CM9700 Series matrix

– Digital Light Processing (DLP®) displays (except lamp and color wheel). The

lamp and color wheel will be covered for a period of 90 days. The air filter is

not covered under warranty.

– Intelli-M®eIDC controllers

– PMCL542F, PMCL547F, and PMCL552F FHD monitors

• One year:

– Video cassette recorders (VCRs), except video heads. Video heads will be

covered for a period of six months.

•Sixmonths:

– All pan and tilts, scanners, or preset lenses used in continuous motion

applications (preset scan, tour, and auto scan modes).

Pelco will warrant all replacement parts and repairs for 90 days from the date of

Pelco shipment. All goods requiring warranty repair shall be sent freight prepaid

to a Pelco designated location. Repairs made necessary by reason of misuse,

alteration, normal wear, or accident are not covered under this warranty.

Pelco assumes no risk and shall be subject to no liability for damages or loss

resulting from the specific use or application made of the Products. Pelco’s liability

for any claim, whether based on breach of contract, negligence, infringement of

any rights of any party or product liability, relating to the Products shall not exceed

the price paid by the Dealer to Pelco for such Products. In no event will Pelco be

liable for any special, incidental, or consequential damages (including loss of use,

loss of profit, and claims of third parties) however caused, whether by the

negligence of Pelco or otherwise.

The above warranty provides the Dealer with specific legal rights. The Dealer may

also have additional rights, which are subject to variation from state to state.

If a warranty repair is required, the Dealer must contact Pelco at (800) 289-9100 or

(559) 292-1981 to obtain a Repair Authorization number (RA), and provide the

following information:

1. Model and serial number

2. Date of shipment, P.O. number, sales order number, or Pelco invoice number

3. Details of the defect or problem

If there is a dispute regarding the warranty of a product that does not fall under

the warranty conditions stated above, please include a written explanation with

the product when returned.

Method of return shipment shall be the same or equal to the method by which the

item was received by Pelco.

RETURNS

To expedite parts returned for repair or credit, please call Pelco at (800) 289-9100

or (559) 292-1981 to obtain an authorization number (CA number if returned for

credit, and RA number if returned for repair) and designated return location.

All merchandise returned for credit may be subject to a 20 percent restocking and

refurbishing charge.

Goods returned for repair or credit should be clearly identified with the assigned

CA or RA number and freight should be prepaid.

8-13-09

REVISION HISTORY

Manual # Date Comments

C2670M 1/07 Original version.

C2670M-A 7/07 Updated cover/title, added ESD information, appendices, Pre-Site Checklist, and updated original checklist. Also added pre- and post-site worksheets, and added

additional equipment and values.

C2670M-B 9/07 Updated cover/title, worksheet and checklist titles, and removed the required warranty activation materials.

C2670M-C 9/09 Removed Endura installation checklist, updated equipment list for Endura 2.0 components, and added maximum potential start-up current information.

Pelco, the Pelco logo, Camclosure, Digital Sentry, Endura, Esprit, ExSite, Genex, Intelli-M, Legacy, and Spectra are registered trademarks of Pelco, Inc. © Copyright 2009, Pelco, Inc. All rights reserved.

Spectra III is a trademark of Pelco, Inc.

DLP is a registered trademark of Texas Instruments Incorporated.

All product names and services identified throughout this document are trademarks or registered trademarks of their respective companies.

The absence of a trademark or registered trademark from this document does not constitute a waiver of intellectual property rights.

Pelco, Inc. Worldwide Headquarters 3500 Pelco Way Clovis, California 93612 USA

USA & Canada Tel (800) 289-9100 Fax (800) 289-9150

International Tel +1 (559) 292-1981 Fax +1 (559) 348-1120

www.pelco.com

This manual suits for next models

15

Table of contents

Popular Security System manuals by other brands

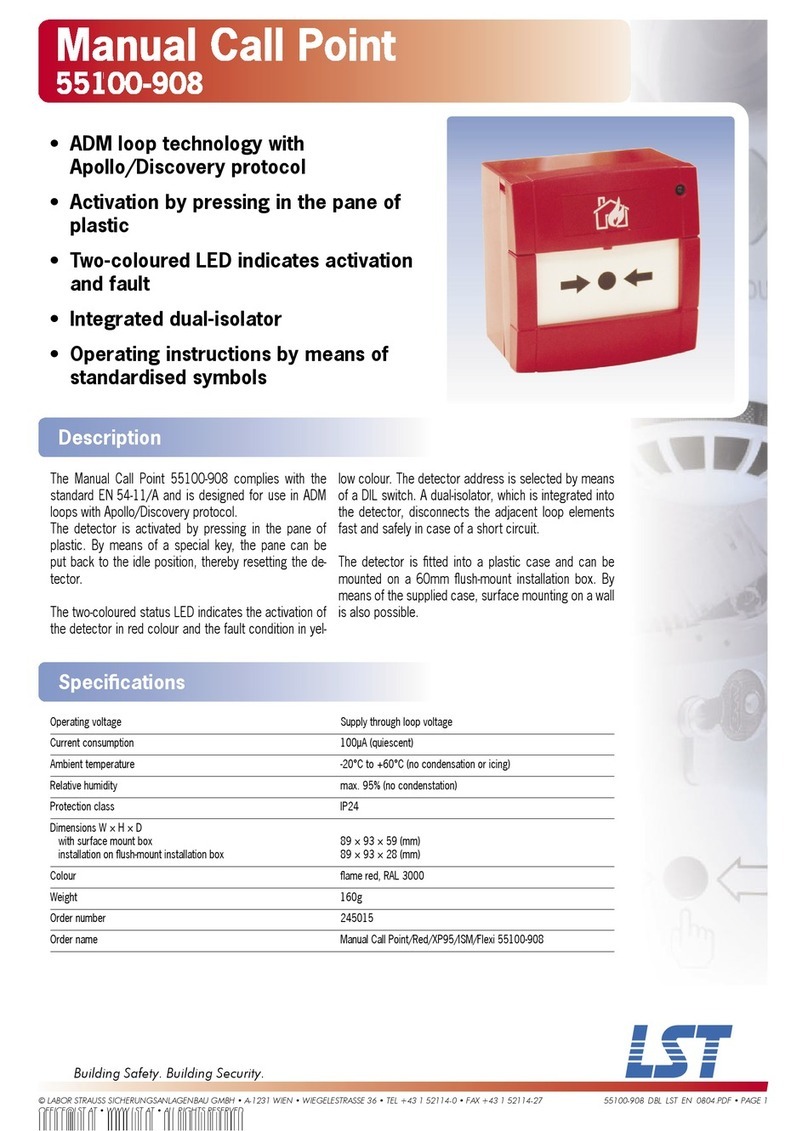

LST

LST 55100-908 Specification sheet

Lorex

Lorex WIRELESS HOME MONITORING SYSTEM user guide

MobileHelp

MobileHelp IGM-02 Complete user guide

VoiceAlert

VoiceAlert WirelessAlert System 6 VA6000S user manual

Yale

Yale HSA3400 Installation, programming, operating

Assa Abloy

Assa Abloy Yale HSA6610 Installation, Programming, Operating Manual

Pacific Communications

Pacific Communications IDR 016 Series Training Course Notes

Gardsman

Gardsman CTC-1131 Installation, programming, operating

Honeywell

Honeywell Gamewell-FCI E3 Series Installation & operation manual

Compur Monitors

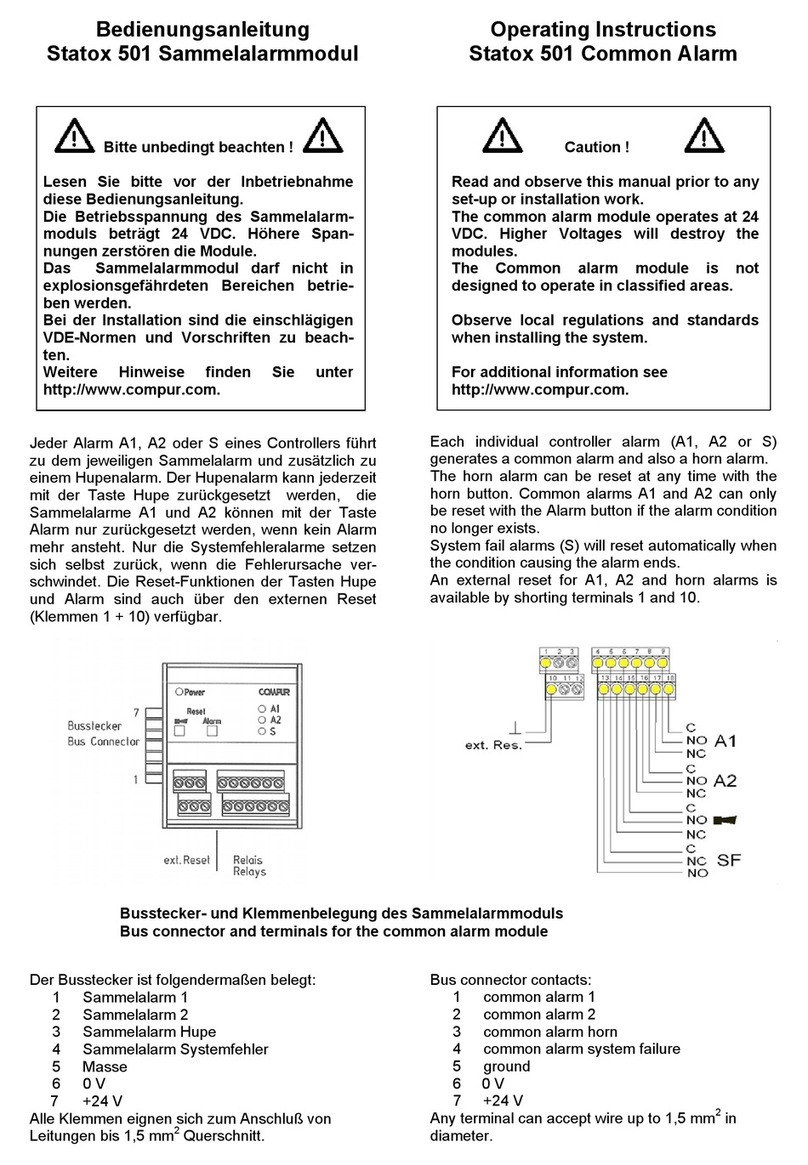

Compur Monitors Statox 501 operating instructions

ITI

ITI SX-V installation manual

Hitachi

Hitachi SPX-WDC7 Installation & operation manual