Endura XL100 Owner's manual

INSTALLATION, OPERATION & MAINTENANCE

WARNING!

Manual 40100-32 12/20

Canada

1-800-461-1771

U.S.A

1-888-461-5307

GRE ASE I NTERC EPT OR

GREA SEINTER CEPTOR

GRE AROT

PECRE

T

N

I

E

S

GREASE IN TER CEPTO R

GRE ASE I NTERCE PTOR

GREASE INT ERCE PTO R

GRE ASE INTER CEP TOR

GREASE INT ERC EPTO R

*

*

*

ASME A112.14.3 (TYPE A*& TYPE C)

& CSA B481.1

PDI G-101, ASME A112.14.3 TYPE A, AND NSF ES 15741

APPLICABLE TO XL75 AND XL100 GPM MODELS ONLY

Technical Support: tech-support@endurainterceptor.com

DONOTPRESSURETEST RISKOF

SERIOUSINJURY

As a plumbing appurtenance your Endura® grease

interceptor MUST be isolated from the drainage system in

the event that final drain testing or other system pressure

testing is required. DO NOT under any circumstances

subject your interceptor to pressure test (Air, Water

or Otherwise). This action will result in damage to

the unit, invalidate your warranty and could cause

serious bodily injury.

WARNING–SAFETYFIRST!

GREASE INTERCEPTORSAREHAZARDOUS

ENVIRONMENTS ANDMUSTNEVERBELEFT UNCOVERED

ANDUNATTENDED,EVENDURINGMAINTENANCE.

• All access covers MUST be fully and completely secured

• All required bolts MUST at all times be in place and well tightened

• Missing bolts MUST be reported to management and replaced immediately

•

•

Covers MUST meet the required load rating for the application (see the

Technical Information section)

Do NOT use alternate covers

- 2 -

GREASEINTERCE PTOR

GREAS E INTERCEPTOR

GREASEINTERCEPT OR

GREAS E INTERCEP TOR

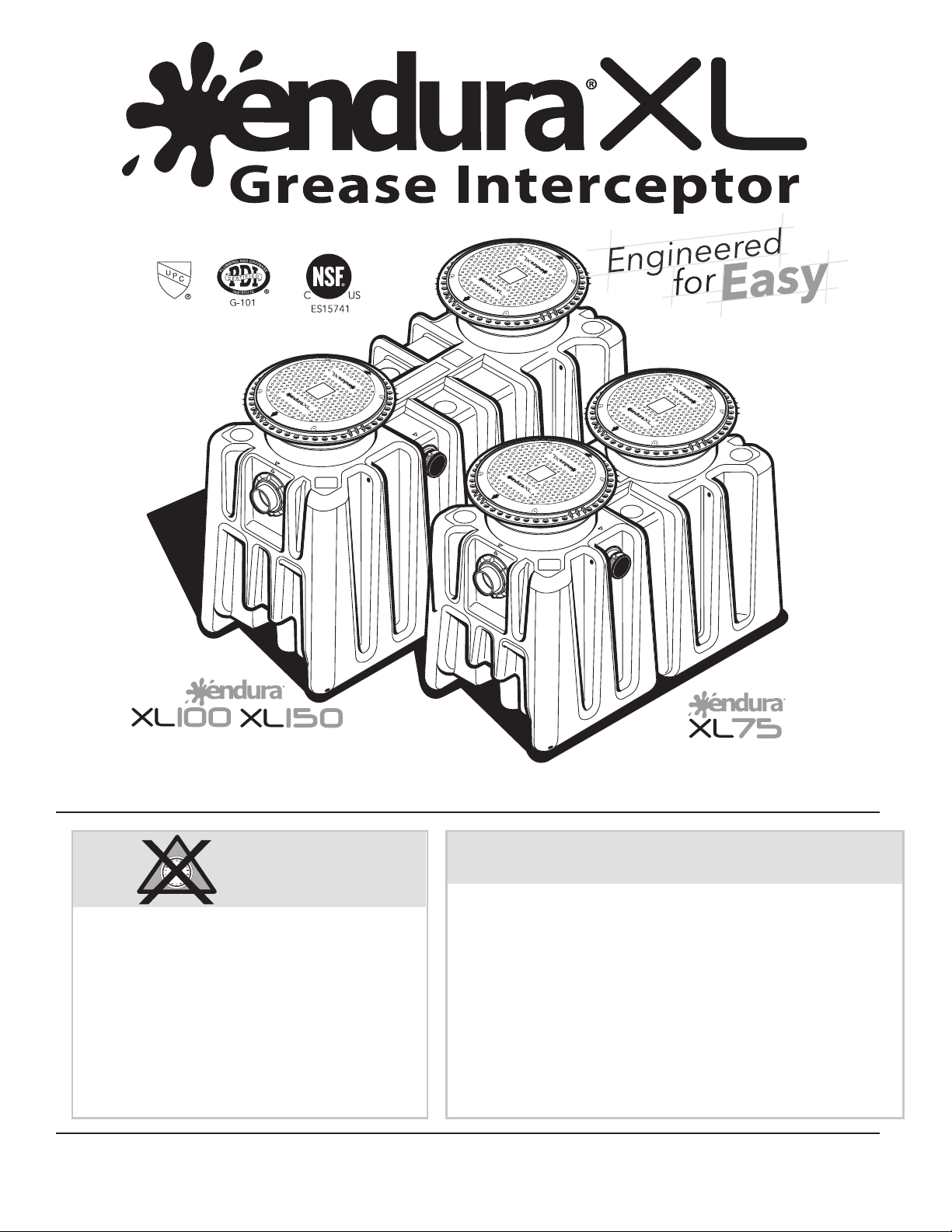

MANUAL

LIFTING

POINTS

FACTORY PLUMBED

3-WAY OUTLET

SYSTEM

REMOTE PUMP READY

AIR & WATER TIGHT

EXTENSION SYSTEM

INTEGRATED LIFTING

LOCATIONS

CLOSED RIBS FOR

FLOTATION RESISTANCE

INTEGRATED TIE DOWN

LOCATIONS

CORRUGATED WALLS

FOR STRENGTH

LOAD RATED

COVER & FRAME

CUT TO SUIT RISER

EXTENSION

BUILT-IN HEIGHT

ADJUSTMENT

AIR BALANCED

ENVIRONMENT

TANK PROFILE

RESISTS

FLOTATION

Features Overview

About Your Purchase:

The Endura® XL grease interceptor and it associated products are the latest addition to the proven line of Endura®

Grease Management products.

We have spent many thousands of hours in the development of Endura® XL, our aim being simple – to produce

the industry’s best Hydromechanical Grease Interceptor.

From the ground up, Endura® XL has been‘Engineered for Easy’. Working with distributors, installers, engineers,

the feedback gained and rolled it into one comprehensively designed solution to meet as broad a range of these

requirements as possible.

Endura® XL is the most widely evaluated and approved hydromechanical interceptor in the current marketplace,

being successfully tested by independent third parties to meet all requirements of PDI G-101*, ASME A112.14.3

(Type A* & C) / NSF ES15741* and CSA B481.1.

*PDI G-101, ASME A112.14.3 TYPE A, AND NSF ES 15741 APPLICABLE TO 75 AND 100 GPM MODELS ONLY

- 3 -

Glossary of Terms

Table of Contents

HGI: Industry abbreviation for Hydromechanical

Grease Interceptor. By denition an HGI is designed to use

managed ow, air entrainment and specically designed

features to provide an enhanced level of separation

eciency, removing non petroleum FOG (Fats, Oil and

Grease) from a transition ow of waste water, generated by

commercial foodservice activities (Restaurants, Cafeterias,

Institutional Kitchens , Sandwich Shops and Coee houses

for example). HGI’s are performance tested for eciency of

grease separation based on National Standards.

Operational Cost Index =1

GGI: Industry abbreviation for Gravity Grease

Interceptor. By denition a GGI has a minimum of 350USG

capacity and in operation 500USG to 1500USG of capacity

are most common. No ow control device. Separation

of FOG based on capacity and retention time of water

(minimum 30 min. to exchange volume). At this time no

performance Standards are published for GGI’s.

Operational Cost Index HGI = 5 GGI = 10+

GRD: Industry abbreviation for Grease Removal

Device. Designed rstly as an HGI, a GRD uses a heat source

and a timed or sensor based skimming (or draw-o ) device

to remove accumulated FOG from the separation chamber

into an external container for collection and disposal. These

units require daily maintenance for management of food

solids. Operational Cost Index HGI = 2.5 GGI = 5

AHJ: Authority Having Jurisdiction. This can be

one or more government departments - for example plan

check/review, building, plumbing, pretreatment, sewer and

waste water. Bottom line...those who enforce the rules and

regulations.

Cost Index: A way of indicating the relative cost

of dierent types of interceptor to each other for broad

comparison purposes. This includes product purchase,

installation cost and typical maintenance.

25% Rule: The rule of thumb, sometimes mandated

by jurisdiction, used to determine frequency of pump

out for GRAVITY GREASE INTERCEPTORS. The 25% refers

to the combined volume or retained FOG and food solids

which shall not exceed 25% of the working volume of the

interceptor. This rule should not typically be applied to HGI’s

particularly those with extended capacity.

Air Entrainment: Mixing of air with Inuent using

a ow control device. Air and grease are attracted to each

other, the air wanting to separate more easily than grease.

Because they become mixed together the air increases the

eciency of separation.

Euent: Waste water containing little to no FOG,

being discharged out of the interceptor.

Inuent: Waste water containing uncontrolled

and variable levels of FOG based on the nature and

practices of the foodservice operation.

Separation Chamber: Zone inside the

interceptor where grease separates from water and is

retained.

– Available online – Mobile Friendly

– Best Management Practices

BMP

Page

Features Overview 2

Glossary 3

Quick Start Installation Guide 4

Technical Information 6

Installation Specifications 8

Installation 11

Installation - Flow Controls 12

Remote Pump (optional) 13

Page

Installer Checklist 14

Operation 15

Maintenance 16

Pumper Checklist 18

Trouble Shooting 19

Frequently Asked Questions 20

Warranty 23

Registration Card 24

Quick Start Guide

- 4 -

Quick Start Guide

Before you begin, be sure to review this document in full for important information regarding

sized for the intended installation. Be sure to reference and be familiar with local code and

municipal FOG Program requirements. The Authority Having Jurisdiction (AHJ) can be your

best friend and your worst enemy.

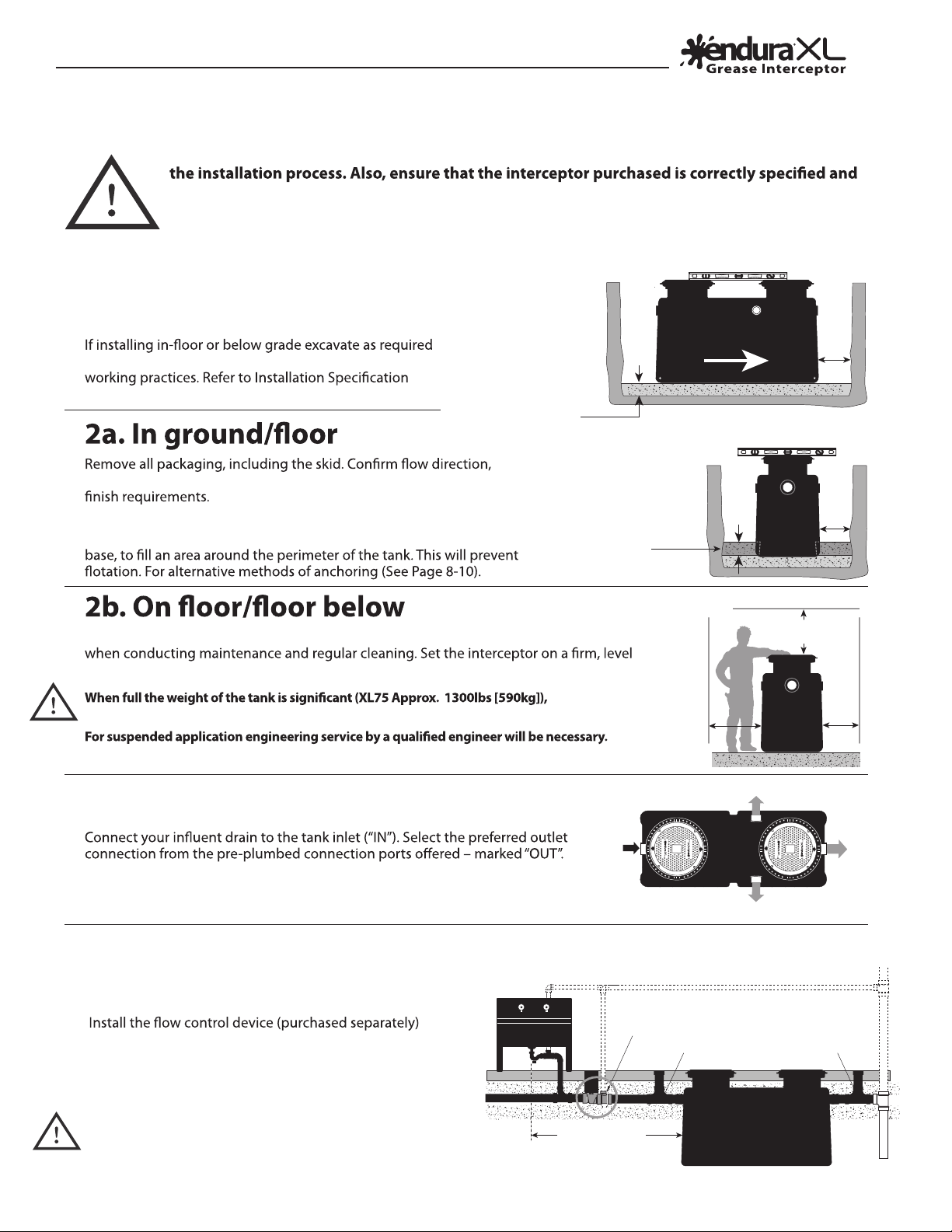

1. Prepare your

installation area

to accommodate the interceptor and ensure safe

section of this document (See Page 8-10).

3. Select preferred outlet connection

Side connection is accessed by removal of the caps supplied, that cap then being

used to seal the end outlet.

lower in and level interceptor accounting for anticipated surface

Note: For installations where high ground water is anticipated,

once located pour at least 8”of concrete on top of your prepared

Remove all packaging including the skid. Locate the interceptor so as to allow for accessibility

surface ensuring tank is equally supported.

XL100/ XL150 Approx. 2150lbs [975kg])

A minimum safety factor of 2 shall be applied in calculation/design.

Concrete Anchor

Base (if anchoring

is required)

Min.

6"

Inle Ot utlet

Min.

12"

Min.

12"

Min.

8"

6" Minimum Base

of Crushed aggregate

material approximately

3/4" size rock, pea

gravel or sand

Ensure adequate roomfor

piping connections

and inspections

G ET

NI

E

S

A

ER P

ECR TR

O

T

NI

E

S

A

ER

GCR

ERO

TP

E

G E

T

NI

E

S

A

ER P

ECR TRO

CR

E

T

NI

E

S

A

ER

GRO

TP

E

OUTSIDE -

SIDE - OUT

END - OUT

IN

Max. 25ft

(for PDI)

PDI

External Flow

Controlinstallation

Cleanout

Cleanout

FCD Air Intake

Sink

Inlet Outlet

4. Installations with External Flow Control

(PDI G-101/ASME A112.14.3 - Type A)

See page 6 for

cleanout part numbers

Min. Base

Anchoring

(if required)

Level end to end

Flow Direction

Level side to side

For PDI G-101/ASME A112.14.3 (External Flow Control)–

upstream, after the last branch connection discharging to the

interceptor. A maximum of 25ft from last branch discharge

to the entry of the interceptor is required to meet published

recommendations. See Page 12 for connection formats.

Plumbing code typically requires provision of a cleanout

to grade immediately before and after the inlet and outlet

connections.

Quick Start Guide

- 5 -

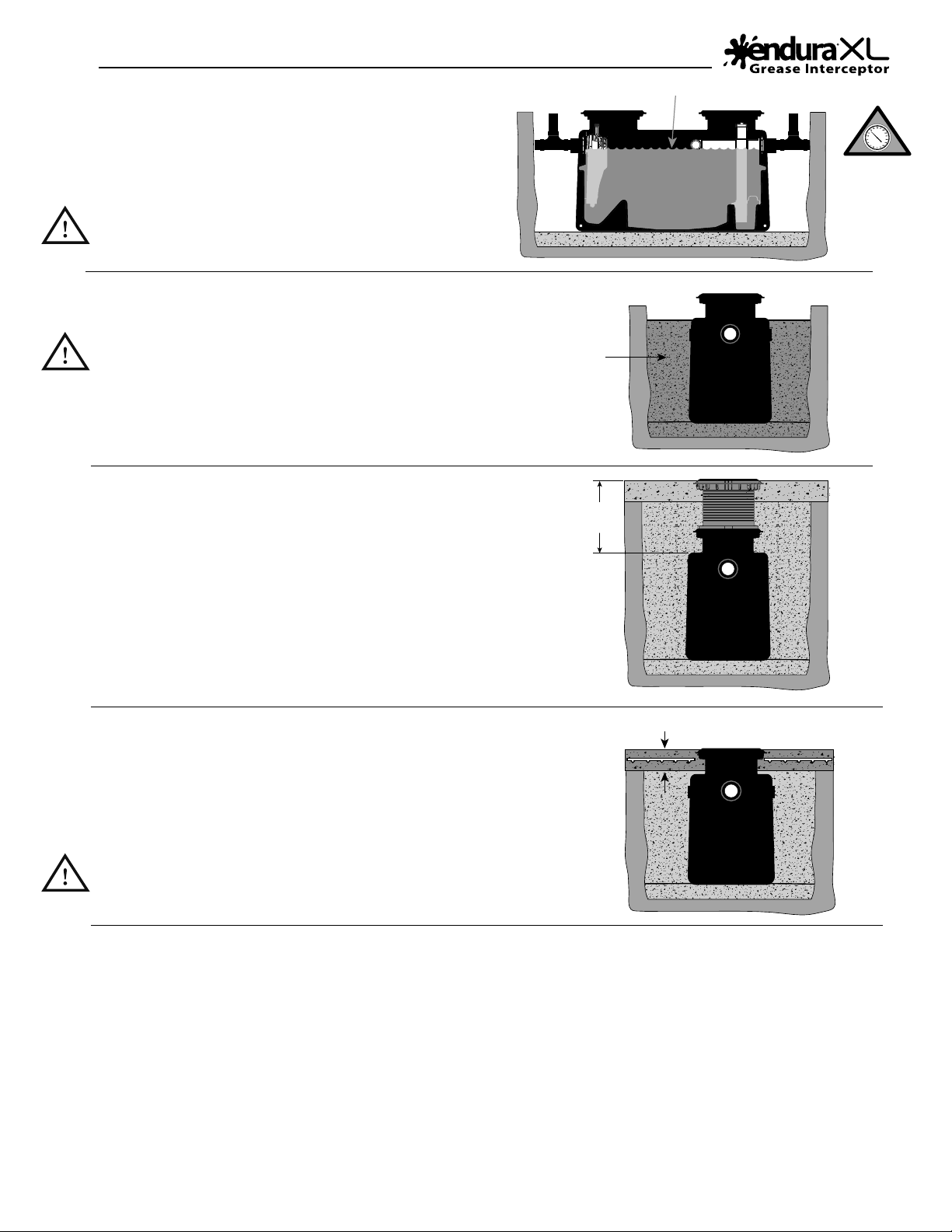

Fill with water to static level

Continue fill of

Crushed aggregate

material approximately

3/4" size rock,

pea gravel or sand

6. Replace cover(s) and backll

Replace cover(s) and protect with cardboard or similar

during back lling. Backll per specication (See Page 8).

If installing Remote Pump option do so now (See Page 13)

5. Fill tank

Fill tank with water to static water level. This provides stability

and crush resistance during backlling. Check connections made

for any leaks.

For inspection testing DO NOT PRESSURE the tank. Plug

lines inside interceptor to test upstream and downstream

integrity.

7. Riser Extensions (optional)

Depending on your application, extend the tank risers

(using 40100AX35) to grade/oor level. Be sure to account

for nishing. (Refer to Manual 40100X35-8 – Riser Extension

Installation Guide)

8. Finish to grade / oor

For in ground applications with vehicular trac, the upper 8” requires a

reinforced concrete slab. Refer to the Installation Specication section of

this document (See Page 8-9). This details backll materials and concrete

reinforcement requirements.

If installing in internal application with tiled oor, ensure adequate

protection to prevent mortar from covering bolts, and/or entering

around cover perimeter.

9. Completion documentation

Having completed installation and successful inspection, hand-over to the client all installation documentation, with page 14

completed. Fill out your sections of the Limited Lifetime warranty registration (See Page 24).

If submitting on behalf of your client you can do so at www.EnduraWarranty.com or by sending to the locations shown on

the back cover of this document.

72”

Maximum

height

Reinforced concrete pad for traffic rated installations

8"

WARNING!

X

DO NOT

PRESSURE TEST.

RISK OF SERIOUS

INJURY.

For Spec See Page 8-9

Other manuals for XL100

1

This manual suits for next models

8

Table of contents

Popular Water Filtration System manuals by other brands

Atlantic Ultraviolet

Atlantic Ultraviolet Mighty Pure MP16A owner's manual

SunSun

SunSun CBG-500 Operation manual

Hayward

Hayward XStream Filtration Series owner's manual

Contech

Contech DownSpout StormFilter Operation and maintenance

Teka

Teka Airfilter MINI operating instructions

Wisy

Wisy LineAir 100 Installation and operating instructions

Schaffner

Schaffner Ecosine FN3446 Series User and installation manual

Pentair

Pentair FLECK 4600 SXT Installer manual

H2O International

H2O International H20-500 product manual

Renkforce

Renkforce 2306241 operating instructions

Neo-Pure

Neo-Pure TL3-A502 manual

STA-RITE

STA-RITE VERTICAL GRID DE FILTERS S7D75 owner's manual