EnergAir metacentre VSD-R User manual

MANY09117A.GB – VSD-R 4-20mA Box User Manual

bar

TM

VSD-R

4-20mA

Metacentre VSD-R 4-20mA Box

Page 1

Index

1.0 Introduction

1.1 VSD/VFD Basic Requirements

1.2 Compressor Basic Requirements

1.3 General Operation

2.0 Menu Navigation

2.1 Menu Map

2.2 Menu Item Settings

3.0 Operation

3.1 User Interface

3.2 Display

3.3 Status Symbols

3.4 Indicators

3.5 Operation

3.6 User Display Menu Items

3.6 Compressor Not Responding

3.8 VSD-R Box Status

3.9 VSD-R Box Fault Codes

3.10 Compressor Fault

4.0 Parts List

5.0 Technical Data

6.0 Installation Diagrams

7.0 Wiring Diagrams

Refere to Section Indicated

Note

Important or Caution, Safety

Health and Safety

Refer to Metacentre Safety Manual

User Manual

Page 2

1. INTRODUCTION

The VSD-R 4-20mA Box is a specialised air

compressor supervisory and control unit

designed to function in cooperation with a

‘Variable Frequency Inverter Drive’ panel

equipped with a drive unit that has a 4-20mA

speed control input. The VSD-R is also

designed to function in cooperation with a

management system unit.

The VSD-R can be integrated with a

compatible VSD/VFD panel to convert a fixed

speed, load/unload, air compressor into a

variable speed unit with advanced

management system supervisory and control

functionality. The VSD-R will provide all

required functionality to enable total synergy

with the energy control, VSD compressor

aware, functions of the management system

unit.

Each air compressor in a system, that requires

VSD-R integration, must be equipped with an

individual VSD-R Box and VSD panel. A

management system unit can accommodate

multiple VSD-R Boxes.

1.1 VSD/VFD Unit Basic Requirements

Variable Speed Drive

Variable Frequency Drive

Frequency Inverter Drive

Ensure the VSD/VFD is equipped with a 4-

20mA speed reference input and functions in

accordance with the 4-20mA signal:

20mA = maximum loaded motor speed.

4mA = minimum loaded motor speed.

Ensure the VSD/VFD is equipped with an input

that will allow the drive to start and stop in

response to a remote volt-free switching

contact.

Open Circuit = Stop

Closed Circuit = Start/Run

The VSD/VFD must be equipped with a volt-

free switching contact output that is normally

closed circuit and will open in the event of a

drive fault. The contact should close within 2

seconds at power-up, and remain closed when

the drive is stopped, unless a fault condition

occurs.

1.2 Compressor Basic Requirements:

Ensure all basic requirements are meet prior

to installation. Air compressors that fail to meet

all the basic requirements are not suitable for

variable speed conversion using this product.

1) The air compressor must be equipped with

a load/unload regulation system and, if not

regulated with a single electro-mechanical

pressure switch, have a facility for remote

load/unload control with the ability to accept a

volt free switching contact input for remote

load/unload.

A VSD-R will accommodate a pressure control

range, when fitted with an appropriate sensor,

of 1bar to 600bar.

2) The compressor main drive motor must be

suitable for variable speed ‘inverter drive’

operation. In general, the majority of standard

induction motors manufactured from 1990

onwards are suitable for ‘inverter drive’

operation; although they are generally

restricted to a maximum turndown capability of

50% full operating speed. If in doubt, contact

the air compressor or main motor supplier.

3) The compressor main motor must be fitted

with a contactor, or start/delta contactor set,

that is capable of isolating the motor from the

power supply in emergency stop situations.

4) The compressor must be equipped with a

controller or controlling system that has full

main motor and regulation control functionality

for the compressor.

5) The compressor must be equipped with a

controller or controlling system that has all

required air compressor unit safety functions

and features installed and operational.

Metacentre VSD-R 4-20mA Box

Page 3

1.3 General Operation

The VSD-R Box, in conjunction with a

compatible VSD/VFD panel, will control the

speed of an air compressor’s main motor in

response to pressure variations (demand).

The VSD-R Box, VSD Panel and air

compressor combination can function as a

‘stand-alone’ VSD air compressor unit or

operate in conjunction with a management

system unit.

The VSD-R Box performs all pressure

regulation functions and controls the

compressor using load/unload commands (1).

This is achieved by integration of the

compressor unit’s pressure switch with an ‘i-

PCB’ or using the compressor controller’s

remote load/unload input. The air compressor

control system will respond in an identical

manner as if the VSD-R Box was a remote

regulation/sequencing unit.

Run operation of the main motor is derived

from the air compressor controller’s main

motor control outputs (2). The main drive

motor will only operate when the compressor’s

controller is requesting the main motor to run.

This functionality ensures all compressor

controller proprietary and safety features and

function, regardless of how they are

implemented or derived, remain intact.

The VSD-R Box controls the compressor’s

main motor contactor, or star/delta contactor

set, and will operate the contactor(s) in

response to a run request from the

compressor’s controller. The VSD-R Box

monitors the operation of the compressor

contactor(s) and will only operate the VSD

panel (5) to apply power to the compressor’s

main motor (6) when the contactor(s) have

energised correctly (4).

The compressor contactor(s) are used for

safety isolation only and will operate differently

than previous. The contactor(s) will energise

prior to power being applied to the main motor

and de-energise after power is removed from

the main motor. This functionality will

significantly prolong the service life of the

contactor(s) contacts; the contacts are no

longer subjected to high starting current flow

or high current disconnections during a motor

stop.

The compressor controller will be unaware of

the VSD-R Box control of it’s main motor and

will continue to respond as if the motor was

still under normal fixed speed control.

Any star/delta timing implemented in the

compressor controller can remain; the main

motor will use this time to accelerate to

operational speed.

Any motor run-on time implemented in the

compressor controller can also remain;

although in some instances it may enhance

efficiency to reduce this time.

The VSD-R Box monitors the compressor to

ensure that a response to a VSD-R Box load

request is actioned appropriately by the

compressor controller; a fault condition is

generated if correct response is not detected.

1

2

3

4

6

5

C

A

B

A) VSD-R Box

B) VSD Panel

C) Compressor Controller

When the compressor is loaded the VSD-R

Box will vary the speed of the compressor’s

main motor is response to pressure variations

(demand). When the compressor is unloaded,

but the compressor controller is still requesting

the main motor to run (run-on time), the VSD-

R Box will run the motor at a pre-defined ‘off

load’ speed regardless of pressure variation.

The VSD-R Box will stop the main motor, in a

controlled manner, when the compressor

controller no longer requests the motor to run.

This will occur when the VSD-R Box has

requested the compressor to ‘off load’ and the

compressor controller’s run-on time has

expired.

In an emergency stop, or trip, situation the

VSD-R Box will remove power from the main

motor and de-eneregise the compressor’s

contactor(s) immediately.

User Manual

Page 4

2. MENU NAVIGATION

Display Item Structure:

All value, parameter or option selection

displays are grouped into menu lists. Items are

assigned to a list according to type and

classification. Items that can be used to select

options or modify functions are assigned to

‘menu mode’ lists. Items that a User may

require to view during routine operation,

detected pressure for example, are assigned

to the normal operational mode list. Lists are

identified by page number; the normal User

display list is page ‘P00’. All parameters and

options are assigned to menu mode pages

‘P01’ or higher. All Page ‘P00’ items are view

only and cannot be adjusted.

Normal Operational Mode (Page P00):

At controller initialisation, all display elements

and LED indicators are switched on for three

seconds, the display will then show the

software version code for a further 3 seconds

before initialisation is complete and the normal

operating display (Page P0) is shown. In page

P00 ‘normal operational display mode’ the

main display will continuously show the

detected delivery pressure and the Item

display will show the first item of the ‘User’

menu. User menu ‘Items’ can be selected

using the Up or Down buttons at any time.

Pressing the Enter button will lock any

selected Item display and inhibit return to the

default display. When an Item display is locked

the lock key symbol will slow flash. To unlock

an Item display press Up or Down to view an

alternative Item display or press Reset or

Escape. No Item values, options or

parameters can be adjusted in page ‘P00’. If a

fault condition occurs the fault code becomes

the first list item and the display will

automatically jump to display the fault code.

More than one active fault code item can exist

at any one time.

Access Code:

Access to page list displays higher than page

‘P00’ is restricted by access code. To access

menu mode pages press UP and DOWN

together, an access code entry display is

shown and the first code character will flash.

Use PLUS or MINUS to adjust the value of the

first code character then press ENTER. The

next code character will flash; use UP or

DOWN to adjust then press ENTER. Repeat

for all four code characters.

If the code number is less than 1000 then the

first code character will be 0(zero). To return

to a previous code character press ESCAPE.

When all four code characters have been set

to an authorized code number press ENTER.

An invalid code will return the display to

normal operational mode; page ‘P00’.

Access Code Timeouts:

When in menu mode, if no key activity is

detected for a period of time the display will

automatically reset to the normal operational

display; Page ‘P00’.

Menu Mode Navigation:

In menu mode the main value display will flash

and show the Page number. To select a page

press UP or DOWN. For each page the

display will show the first Item of the page list.

To view a page list press ENTER, the Page

number will stop flashing and the Item display

will flash. Press UP or DOWN to view the

selected page list items. To select an Item

value for modification press ENTER, the Item

display will stop flashing and the Value display

will flash. The value or option can now be

modified by pressing UP(Plus) or

DOWN(Minus). To enter a modified value or

option in memory press ENTER; alternatively

the modification can be abandoned, and the

original setting maintained, by pressing

ESCAPE.

Page 3

Page 2

Page 1

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

Page 0

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

Item 6 Value Page 5

Page 4

Metacentre VSD-R 4-20mA Box

Page 5

Press ESCAPE at any time in menu mode to

step backwards one stage in the navigation

process. Pressing ESCAPE when the page

number is flashing will exit menu mode and

return the display to normal operational mode;

page ‘P00’.

Press and hold RESET for two seconds at

any time to immediately exit menu mode and

return to the normal operational mode display.

Any value or option adjustment that has not

been confirmed and entered into memory will

be abandoned and the original setting

maintained.

A flashing Key symbol displayed with

any Item indicates the Item is locked and

cannot be modified. This will occur if the Item

is view only (non adjustable) or in instances

where the item cannot be adjusted while the

VSD-R Box is in the operational STARTED

state.

Page 3

Page 2

Page 1

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

Page 0

Item 1 Value

Item 2 Value

Item 3 Value

Item 4 Value

Item 5 Value

Item 6 Value Page 5

Page 4

User Manual

Page 6

2.1 Menu Map

MENU P00 - User

C> Information

SP Percent Speed

Tm Motor Temperature

T2 Second Temperature

USER ACCESS CODE

MENU P01 - Pressure Set Points

Pu Unload Pressure Set Point

PL Load Pressure Set Point

P> Pressure Units

T> Temperature Units

MENU P02 – Error Log

01 Error Log #1

to

15’Error Log #15

2.2 Menu Item Settings

5.6.1 Operating Pressure Set Points

Pu – Unload pressure set point

PL – Load pressure set point

(PL = VSD target pressure)

5.6.2 Pressure Units Select

Selects the display pressure units

(bar, psi or kPa)

5.6.3 Temperature Units Select

Selects the display temperature units (oC or

oF)

5.6.4 Error Log Menu

Each error log item will show the fault code.

The error log stores the last 15 faults in

chronological order; item ‘01’ is the most

recent fault.

Metacentre VSD-R 4-20mA Box

Page 7

3. OPERATION

bar

1

2

3

4

10

5

6

7

8

9

3.1 User Interface

1) LCD Display

2) No Function

3) No Function

4) RESET Button

5) ESCAPE Button

6) UP, PLUS Button

7) DOWN, MINUS Button

8) ENTER Button

9) VSD-R Box Active Indicator

10) FAULT Indicator

3.2 Display

bar

psi

kPa

A

B

The primary display value (A) will continuously

show the detected ‘Delivery’ pressure.

The ‘User Menu’ item display (B) will show the

selected user menu item. Press UP or DOWN

to scroll through the display ‘items’ list.

3.2 Status Symbols

System Management Unit

(remote pressure control)

Flashing - system management unit ‘off’

or RS485 communications disrupted

(local pressure control)

Compressor Running (i-PCB)

Waiting for compressor to Run

Compressor Loaded (i-PCB)

Waiting for compressor to Load

Service Maintenance function active

Compressor ‘Not Ready’

VSD-R Box or VSD unit Fault or

Auxiliary Input Alarm/Trip

Compressor Offload

Requesting compressor to Load

Requesting compressor to Offload

Loaded, Speed Regulation Control

3.3 Indicators

Run Indicator (Green LED)

OFF: Compressor Not Running

Flashing: Compressor Offload

ON: Compressor Loaded

Fault Indicator (Red LED)

OFF: No Fault

Flashing: Fault

(see Fault Codes)

The VSD-R Box will report the compressor as

‘Not Available’ to the management system unit

when the VSD-R Box or VSD Panel is in a trip

fault condition.

User Manual

Page 8

3.4 Operation

The VSD-R Box and VSD Panel operate in

conjunction with the compressor; all units must

be functional for the compressor to operate

and run.

The compressor must be in a started state

(running or in standby) before VSD-R Box

motor and pressure control will function. The

VSD-R Box will show a compressor fault

indication if the compressor is not locally

started.

The VSD-R Box is always active and does not

need to be started; start and stop have no

function. The VSD-R Box will automatically

recover and become active when power is re-

established after a power disruption or lose. It

is recommended that the compressor

controller is equipped with a ‘power failure

automatic restart’ facility.

Pressure regulation control will

default to ‘local’ (in accordance with the set

VSD-R Box upper and lower pressure

settings) if communications with the

management system is disrupted or lost.

When communications are re-

established the VSD-R Box will automatically

re-activate ‘Remote regulation control’ and

function in accordance with the management

system.

The detected status of the compressor is

indicated by the VSD-R Box display status

symbols (see Status Symbols)

3.5 User Display Menu Items

To view the ‘User Menu Items’ press UP or

DOWN. The ‘Item’ display value will scroll

through the available items.

C> VSD-R Box status

SP Percent motor speed (%)

Tm Motor temperature

T2 2

nd temperature (optional)*

(*) Only shown if the optional 2nd temperature

is activated.

After a period of time the User menu item

display will default back to the ‘SP’ percent

speed item. To lock the display on a selected

menu item press ENTER; the ‘lock’ key

symbol will appear. Press UP or DOWN at any

time to select another item and unlock the

User menu item display.

Percentage Motor Speed:

The percentage of detected motor speed

compared to maximum motor speed. This

value provides a direct indication of variable

speed compressor output regulation.

3.6 Compressor Not Responding

When the VSD-R Box requires the

compressor to operate a ‘Remote Load’ signal

is activated. The compressor must respond to

this by returning a ‘Run Request’ signal to the

VSD-R Box to start and run the main motor

(the compressor has full control of motor

start/stop). If a ‘remote load’ signal is issued

but no ‘run request’ response is detected

within 60 seconds, the VSD-R Box will assume

the compressor is ‘not available’ regardless of

a good ‘Ready’ condition signal from the

compressor.

In this instance the ‘remote load’ signal is

pulsed every 10 seconds and the VSD-R Box

will indicate the compressor as ‘Not Available’

until a response is detected.

The ‘Not Available’ condition will automatically

reset when a response is detected.

If this condition occurs, check that the

compressor has been started.

Metacentre VSD-R 4-20mA Box

Page 9

3.7 VSD-R Box Status (C>):

The VSD-R Box User menu ‘Status’ display

item (C>) continuously shows the network

address and the VSD-R Box status block

number.

For Example:

Network Address = 1 (Compressor 1)

State Block No. = 4 (Compressor Ready)

The ‘status block number’ enables VSD-R Box

operational status to be established from the

status block diagram:-

Compressor

RUNNING

Offload

Initialise

9

Compressor

Running

ON LOAD

10

Compressor

READY

4

2

VSD-R Box

Fault State

1

Power On

Compressor

NOT READY

3

Ready + Running = True

AND

Loaded = True

Loaded

= False

Ready

= False

Ready = True

AND

Load Request = True

Load Request

= False

Ready

= True

No Fault

VSD Panel

Fault or

VSD-R Box

Fault Initialisation

Complete

Waiting For

Run

Request

5

Run Request

= False

RUNNING

Run Request

= False

READY

Ready

= False

Ready

= False

No Response

compressor

NOT READY

6

Run Request

time-out

Ready = False

OR

RESET Pressed

Contactor ON

Waiting For

C.Feedback

7Ready

= False

Ready

= False

Ready = True

AND Run Request = True

AND Load Request = True

Ready = True

AND

Run Request = True

AND

C.Feedback = True

ON LOAD

Run

Request

= False

Ready = True

AND

Run Request = True

AND

Running = True

Motor Start

'Acceleration'

8Ready

= False

Run

Request

= False

Ready = True

AND Run Request = True

AND Load Request = True

AND C.Feedback = True

User Manual

Page 10

3.8 VSD-R Box Fault Codes

Shutdown:

0010E Emergency Stop (option)

0040E Frequency Inverter Drive, VSD, Fault

Examine the drive unit display for

fault type/description – refer to the

drive unit manual.

0080E Contactor feedback fault (CF)

0115E 4-20mA Delivery P. Sensor Fault

0125E Motor temperature sensor fault

0135E 2

nd Temperature sensor fault

0821E Short circuit condition detected

Check all VSD-R inputs and outputs

0836E PLL unlocked error

Alarm:

2050A Auxiliary Alarm input

3.9 Compressor Fault

The VSD-R Box is not designed to detect

individual compressor faults; view the

compressor controller for compressor related

fault conditions. The VSD-R Box will detect

any compressor shutdown, or run inhibit, as a

‘not ready’ signal. No VSD-R Box fault code is

displayed.

The VSD-R Box will display a continuous

(not flashing) ‘Alarm’ symbol. VSD motor

operation is inhibited. The management

system (if connected) will show the

compressor as ‘not available’.

Press VSD-R Box RESET to reset a

fault code display when the fault condition is

resolved.

Metacentre VSD-R 4-20mA Box

Page 11

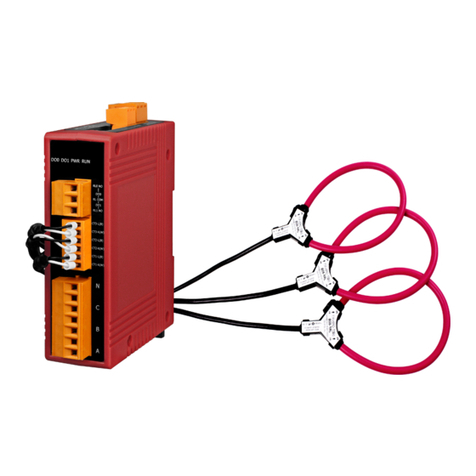

4.0 Parts List

VSD-R ‘mA’ Box

Item Part No. Description

- Y07ENER24.00 Kit, VSD-R 4-20mA

- Y07ENER26.00 Unit, VSD-R 4-20mA

- Y07ENER14.00 Manual, User CD

- OVLY0502.00 Label, EnergAir

1 Y07CMC5.00 Controller, S1

2 Y05CM31.00 Unit, XPM-TAC24

3 KPY05AC.01 PCB, Terminal VSD

4 Y07CM49.00 Gland, Set - Pg13.5

5 Y04CM59.00 Unit, i-PCB

6 Y04CM29.00 Sensor, Pressure

0-16bar

7 Y01ENER35.00 Module, Relay 24Vac

8 Y01ENER20.00 Sensor, KTY Motor

Eye-Bolt; M16

9 Y01ENER21.00 Sensor, KTY Motor

Eye-Bolt; M20

10 Y01ENER22.00 Sensor, KTY Motor

Eye-Bolt; M24

11 Y01ENER24.00 Sensor, KTY

Ring Tag; M4

5.0 Technical Data

VSD-R ‘mA’ Box

Dimensions 291mm x 241mm x 152mm

Weight 6.5kg (14lb)

Mounting wall, 4 x screw fixings

Enclosure IP54, NEMA 12

Supply 230Vac +/- 10%

115Vac +/- 10%

Power 50VA

Temperature 0°C to 46°C (32°F to 115°F)

Humidity 95% RH non-condensing

Mounting Dimensions

24mm 238mm

24mm

188mm

8mm Ø

236mm

286mm

i-PCB

4

5

2

1

3

6

8

9

10

11

M4

M16

M20

M24

KTY

A2 A1

22 12

24 14

21 11

7

User Manual

Page 12

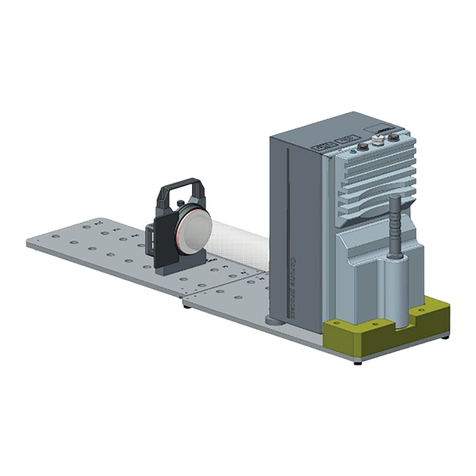

6.0 Installation Diagrams

1VFD must be rated suitable for actual

compressor main motor full load current; do

not rate in accordance with nominal

compressor or motor kW rating.

2Main power supply cable and fuse rated same

as for standard fixed speed compressor of the

same kW rating.

3Main motor cable from VFD rated same as

main power supply cable.

4No air filter(s), dryer unit(s) or other potential

cause of pressure differential permissible

between compressor discharge and pressure

sensor if sensor fitted at location ‘B’.

5If air isolation valve fitted, and sensor fitted at

location ‘B’, ensure compressor has

independent excess pressure protection.

VFD Rating:

Measure actual main motor full load current (FLC),

at full working pressure, before selecting suitable

VFD.

4-20mA Pressure Sensor:

Location ‘A’ is preferential

VFD Panel:

Inlet and outlet ‘chokes’ are recommended.

3ph + E

400Vac (+-10%)

50/60Hz

a

b

a

i-PCB

b b

P

a

Multi485

A5

4

a

115/230Vac

50/60Hz, 2A

d

c

21

2

3

m3/min FAD

(Bar.g) - 1

= m3min

KTY

4-20mA

VSD-R

VFD

> 10m

kW

4-30 2.5mm2

4mm2

6mm2

110-315

37-90 15A

32A

50A

SWA MCB

VFD

B

Metacentre VSD-R 4-20mA Box

Page 13

Frequency Inverter Drive Connections:

Aux Alarm

T2 KTY(option)

Temperature

SEQ

i-PCB

R1

24681012141618202224262830

31323334

5

3

19

711131517192123252729

LOAD

GND

Ready/Run

Load/Service

+20VDC

R4

Di2

R1

R3

GND

GND

GND

R2

+C

+C

Di8

+C

Di3

+C

Di4

+C

Di5

A-GND

Ao

Ai3

4-20mA

Pressure

Sensor

Motor KTY

Temperature

R5

R6

Di6

+

-

+

-

+

Contactor

Feedback

VSD Drive

Stop/Run

DriveFault

Ai2

Ai1

Di7

-

4-20mA

Speed

Control

notused

VSD Drive

Fault

Fan Contactor

(option)

Delta Contactor

(option)

Line Contactor

4-20mA

Speed

Control

+24V DC

Stop Run

Fault OK

Drive

Fault

Stop/Run

20mA

4mA

Variable Frequency

Inverter Drive

rpm

a

b

b

a2 wire,twisted pair,

earthshielded

0.35mm

2

- 1.0mm

2

6wire,earthshielded

0.75mm

2

- 1.5mm

2

TerminalPCB

10m(33ft) max

10m (33ft) max

CE: 240V

UL:115V

4Amax

4mA

rpm

20mA

4mA

4mA

Stop

Run

Fault

OK

OK

rpm

4mA

20mA

User Manual

Page 14

Compressor Connections:

AuxAlarm

T2 KTY(option)

Temperature

SEQ

i-PCB

R1

24681012141618202224262830

31323334

5

3

19

711131517192123252729

LOAD

GND

Ready/Run

Load/Service

+20VDC

R4

Di2

R1

R3

GND

GND

GND

R2

+C

+C

Di8

+C

Di3

+C

Di4

+C

Di5

A-GND

Ao

Ai3

4-20mA

Pressure

Sensor

Motor KTY

Temperature

R5

R6

Di6

+

-

+

-

+

Contactor

Feedback

VSD Drive

Stop/Run

Drive Fault

Ai2

Ai1

Di7

-

4-20mA

Speed

Control

AuxTrip

VSD Drive

Fault

Fan Contactor

(option)

Delta Contactor

(option)

Line Contactor

a

b

b

a2wire,twisted pair,

earthshielded

0.35mm

2

- 1.0mm

2

6 wire,earth shielded

0.75mm

2

- 1.5mm

2

Terminal PCB

10m (33ft) max

CE: 240V

UL:115V

4Amax

i-PCB

1

2

3

4

5

6

C03

DC

FC

RS

24Vac

24Vac

24Vac

b

D

b

a

10m (33ft) max

Metacentre VSD-R 4-20mA Box

Page 15

7.0 Wiring Diagram

AuxAlarm

T2 KTY(option)

Temperature

SEQ

i-PCB

R1

VSD-R(4-20mA)Box

24681012141618202224262830

31323334

X07

X06

X05

X04

X03

X02

X01X08X09

5

3

19

711131517192123252729

LOAD

GND

Ready/Run

Load/Service

+20VDC

R4

Di2

R1

R3

GND

GND

GND

R2

+C

+C

Di8

not used

+C

Di4

+C

Di5

A-GND

Ao

Ai3

4-20mA

Pressure

Sensor

Motor KTY

Temperature

R5

R5

R6

R6

Di6

R1

R2

R3

R4R5

R6

L2

C+

1

2

3

4

5

6

7

8

L1

Ao

X05

X06

X03

X04

RS485#1

C035

J1

X02

X01

Ai3

A-GND

Ai2

Ai1

+VDC

A-GND

L2L1

RS485#2

XPM-TAC24

S1Controller

24Vac

+

-

+

-

+

1

2

1

2

2

1

X03

X02

X08X07

Multi485

X01

E

N

L

E

E

N

L

230Vac 10%

115Vac 10%

24Vac

0Vac

Contactor

Feedback

VSD Drive

Stop/Run

DriveFault

Ai2

Ai1

Di7

10k

-

4321

L2

L1Enercon

Network

C023

C036

C037

C038

C039

C040

C034

C033

C031

C030

C029

C028

C027

C026

C025

C024

C032

C044

C045

C046

C047

C048

C049

C041

C042

C043

A-GND

4-20mA

Speed

Control

VSD Drive

Fault

Fan Contactor

(option)

Delta Contactor

(option)

Line Contactor

User Manual

XPM-TAC24

230V

115V

24Vac/1

isolated

24Vac/2

earthed

EE

L

N

N L E

BLUE

BROWN

RED

GREEN VIOLET

WHITE

ORANGE

BLACK

FH1

FH2FH3

FH4

FH5

1

VOLTAGE SELECT

2 3 4 X04

212

X03 X02 X01

T3.15A T1.6A T1.6A T1.0A

T1.0A

1 2 3 4

115V +-10%

230V +-10%

1 2 3 4

IEC

5x20mm

Module – Relay, 24Vac

A2 A1

22 12

24 14

21 11

A1 14 12 24 22

A2 11 21

Page 16

Table of contents

Popular Measuring Instrument manuals by other brands

Zeiss

Zeiss Corona process Service manual

RST Instruments

RST Instruments MEMS Digital Inclinometer System instruction manual

Endress+Hauser

Endress+Hauser Proline Promass A 300 PROFINET operating instructions

Delta X

Delta X 100/12 user manual

Waters

Waters ionKey/MS Guide

ZyAura

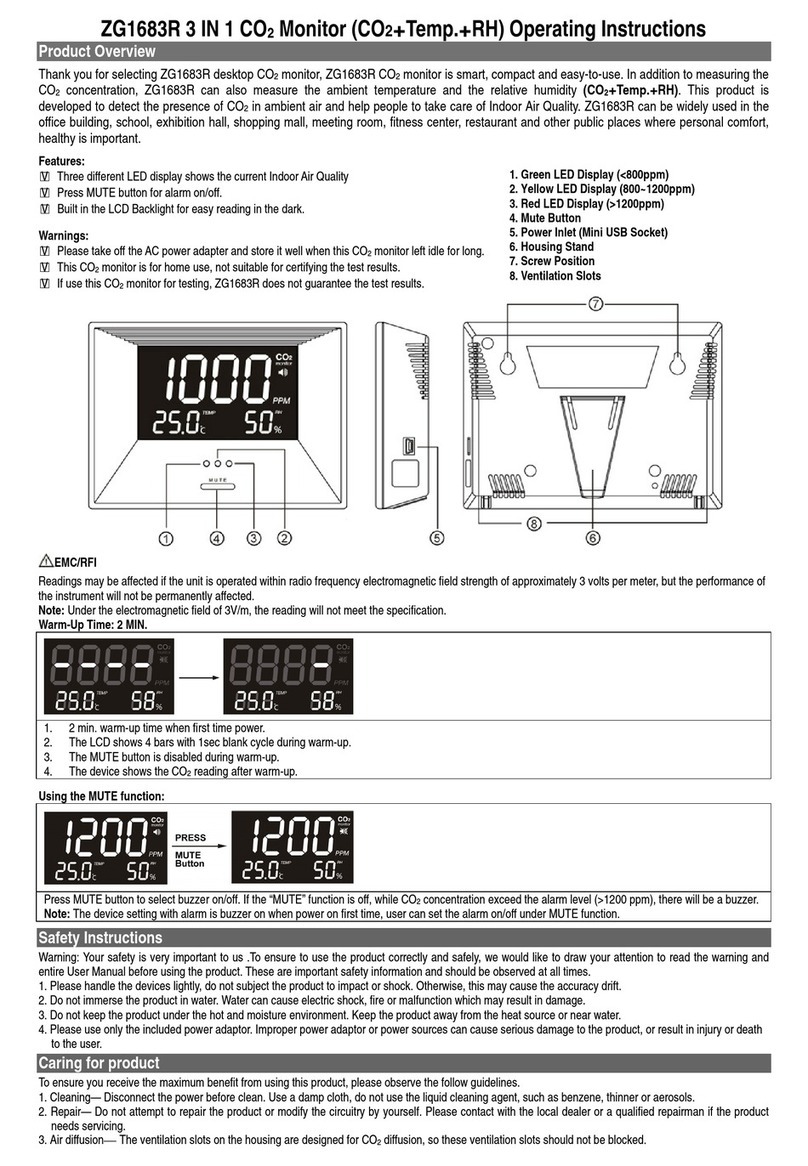

ZyAura ZG1683R operating instructions