Energetiq LDLS EQ-400 User manual

Model EQ-400

LDLS™

Laser-Driven Light Source

Operation Manual

Revision 7 April 2018

Part Number DOC-7388

Copyright © 2018 Energetiq Technology Inc. All rights reserved.

Energetiq products are covered by the following patents: US 7435982, 7786455, 8525138,

8969841, 9048000, 9185786; Japan 5410958, 5628253; Korea 10-1507617; UK GB2450045.

All technical information, including drawings, schematics and specifications contained in this

manual are the property of Energetiq and shall not be reproduced in whole or in part without

the written consent of Energetiq. The content of this manual is subject to change without

notice.

Energetiq Technology Inc.

7 Constitution Way, Woburn, MA 01801 USA

Tel. +1 (781) 939-0763

Fax +1 (781) 939-0769

E-mail: support@energetiq.com

http://www.energetiq.com

EU Declaration of Conformity

TABLE OF CONTENTS

Chapter 1...................................................................................................................................................... 1

General Information........................................................................................................................... 1

Safety............................................................................................................................................... 1

Chapter 2...................................................................................................................................................... 9

Description ........................................................................................................................................... 9

General ........................................................................................................................................... 9

Specifications............................................................................................................................... 10

System Description .................................................................................................................... 12

Power/Control Unit (PCU) ..................................................................................................... 13

Lamp House................................................................................................................................ 14

Chapter 3.................................................................................................................................................... 17

Installation........................................................................................................................................... 17

Unpacking.................................................................................................................................... 17

Installation Procedure .............................................................................................................. 17

Chapter 4.................................................................................................................................................... 21

Operation............................................................................................................................................ 21

Starting.......................................................................................................................................... 21

Stopping ....................................................................................................................................... 21

Manual Reset............................................................................................................................... 22

Serial Interface ............................................................................................................................ 22

Appendix A................................................................................................................................................ 25

Engineering Drawings...................................................................................................................... 25

Appendix B................................................................................................................................................ 27

Revision History ................................................................................................................................ 27

EQ-400 Operation Manual Rev. Error! Reference source not found. 1

C h a p t e r 1

GENERAL INFORMATION

Safety

WARNING

CAUTION

This unit emits ultraviolet (UV) radiation that is

harmful to humans. Avoid exposure to the

direct or reflected output beam. Make certain

that the appropriate output beam shields and

optics are in place prior to energizing the unit.

All interlocks must be satisfied prior to

operation; failure to do so may lead to

hazardous conditions.

The EQ-400 emits dangerous levels of UV

radiation. Even short exposures to skin or eyes

may cause burns. Ensure that only authorized

personnel are in the vicinity of source during

operation. Personnel in vicinity of operating

source should wear protective eyewear, clothing,

and gloves. Lighted UV warning lights and signs

posted on doors to lab areas may help prevent

accidental exposure.

2 EQ-400 Operation Manual Rev. Error! Reference source not found.

WARNING

General Precautions

The output beam from the EQ-400 should be blocked when not in use with an electronic

shutter or other appropriate beam blocking device. Due to the possibility of generating ozone

with some models of EQ-400 when ambient oxygen is exposed to short wavelength light, the

beam should always be enclosed in an appropriate beam pipe, tube, or enclosed space. We

suggest purging any beam transport space with dry nitrogen gas.

The EQ-400 source must also be cabled correctly and connected to a power source with a

protective earth ground prior to operation.

Refer to the Installation section of this manual in Chapter 3 for details of the facilities

connections.

There are no user-serviceable parts inside the EQ-400. For any problems encountered during

operation, please contact Energetiq Technology for assistance. If there is a component

failure, do not attempt to open the Power/Control Unit or Lamp House enclosure of

the EQ-400.

No regular maintenance is required for the EQ-400. Any service to the system must be

performed only by factory authorized and trained technicians. To avoid injury, under no

circumstances should the user open or modify the Lamp House or Power/Control Unit

enclosure.

The unit must not be operated if the covers are removed or it is defective in any way. Contact

Energetiq if any problems with the equipment are suspected.

The EQ-400 utilizes a quartz lamp containing a high-pressure gas fill. Explosion of

the lamp and possible injury from flying fragments can occur if the lamp is

mishandled.

Do not open the enclosure of either the Lamp House or the Power/Control Unit.

Dangerous invisible infrared laser beams and hazardous voltages exist inside the

Lamp House. Opening the chassis both voids the warranty and exposes the user to

dangerous radiation and hazardous voltages.

The EQ-400 utilizes an internal Class 4 IR laser

capable of causing severe injury to eyes or skin.

Do not open or attempt to service this unit.

Contact Energetiq regarding any problems with

the unit.

EQ-400 Operation Manual Rev. Error! Reference source not found. 3

CAUTION

The EQ-400 is a Class 4 Laser Product. All appropriate laser safety measures should be in

place before operating the system. Consult your facility's laser safety officer. Laser protective

eyewear should be worn at all times while operating the system.

The EQ-400 also produces high-intensity UV radiation. Eyewear should protect not only from

laser radiation at 1070 nm, but also from UV radiation in the band from 190 to 400 nm.

For further safety information, refer to ANSI Z136.1 Standard for Safe Use of Lasers,

available from Laser Institute of America (www.laserinstitute.org).

Laser Information

The EQ-400 uses a patented* laser drive system to excite a plasma that radiates in the UV as

well as the visible bands. A Class 4 laser is located in the Power/Control Unit enclosure. The

optical configuration of the Lamp House ensures that the direct laser beam cannot exit the

unit. The EQ-400 laser product is designated as Class 4 during all normal operation.

The parameters of the non-accessible internal laser are given below in Table 1.

Wavelength

1070 nm

Emission Type

CW

Laser Power for classification

400W

Beam Diameter

5 mm

Divergence

0.3 mRad

Transverse Beam Mode

Single Mode

Table 1: Embedded Laser Parameters

*US 7435982, 7786455, 8525138, 8969841, 9048000, 9185786 ; Japan 5410958, 5628253; Korea 10-1507617; UK

GB2450045; others pending

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

INVISIBLE LASER RADIATION

AVOID EYE OR SKIN EXPOSURE TO

DIRECT OR SCATTERED RADIATION

CLASS 4 LASER PRODUCT

4 EQ-400 Operation Manual Rev. Error! Reference source not found.

Nominal Ocular Hazard Distance (NOHD) based on 400W 1070nm pump laser under a

failure mode condition where aperture is itself accessible: 4 meters

Required Optical Density (OD) for safety eyewear: 6 or higher at 1070 nm

These values are based on a theoretical failure condition.

Labels and Safety Notification

The following safety labels appear on the product. Figure 1 shows the location of each label

on the EQ-400 system.

UV Hazard warning label –indicates hazardous levels of UV

light are present.

Manufacturer’s identification label – gives the manufacturer’s

name and address, and the model, serial number, and date of

manufacture of the equipment.

Explanatory label –states the classification of the laser product.

Certification label –states that the equipment has been tested

and verified to meet the standards indicated.

Aperture label –indicates the outlet aperture for laser radiation

EQ-400 Operation Manual Rev. Error! Reference source not found. 5

Hazard warning label –indicates that a laser hazard is present

Protective housing label –warns of an enclosed laser radiation

hazard

Protective housing label –warns of an enclosed laser radiation

hazard

6 EQ-400 Operation Manual Rev. Error! Reference source not found.

Aperture Label

Manufacturer’s

Identification label

UV Hazard

Warning Label

Hazard Warning

Label

Protective

Housing Label

EQ-400 Operation Manual Rev. Error! Reference source not found. 7

Figure 1: Safety Label Locations

Safety Interlocks

The EQ-400 is equipped with interlocks to prevent operation of the device when any of the

following conditions are present:

1. A remote interlock is open

2. Lamp House cover not installed

3. Laser fiber not connected to Lamp House

4. Power/Control Unit cover not in place

Explanatory

Label

Certification

Label

Protective Housing Label

(inside chassis on laser

module)

8 EQ-400 Operation Manual Rev. Error! Reference source not found.

Remote Interlock

Remote interlock pins are provided for the customer’s use (see Chapter 3 for connection

details). Any suitable normally-open contact or solid-state switch can operate the interlock

circuit. The contact or switch should be rated for 8mA minimum at 5VDC.

The interlock circuit must be connected to enable the operation of the unit. Should the

interlock connection open during operation or standby, the source is immediately disabled, and

all light output from the aperture ceases.

EQ-400 Operation Manual Rev. Error! Reference source not found. 9

C h a p t e r 2

DESCRIPTION

General

The EQ-400 is a broad-band lamp system for use in a wide variety of applications. The lamp

produces high brightness, broad-band light from DUV wavelengths through visible and

beyond. The output is very stable, and has a long lifetime before any service is required. A

simple control interface ensures ease of use.

Some of the advantages of the EQ-400 include:

Very high brightness across complete spectrum

–190nm through visible and beyond

Eliminates need for multiple lamps (replaces D2/Tungsten/Xenon Arc)

–Simplified optical system

Excellent spatial stability

–Repeatable measurements

Superior short and long term power stability

–Repeatable measurements

Electrodeless operation for long life

–Reduced consumable costs

–Minimal recalibration of instrument

The EQ-400 system consists of a Power/Control Unit (PCU), Lamp House unit, and

interconnecting cable. Connection to AC power is required for operation. Connections to

nitrogen purge gas and cooling water are required. See Chapter 3 for connection details.

10 EQ-400 Operation Manual Rev. Error! Reference source not found.

Specifications

Optical Performance

Typical output spectrum: see Figure 2.

Figure 2: Typical Output Spectrum

Physical Specifications

Dimensions (H x W x D)

Lamp House: 136 x 145 x 56 mm (5.4 x 5.7 x 2.2 in)

Power/Control Unit: 133 x 483 x 584 mm (5.2 x 19.0 x 23.0 in)

Weight

Lamp House: 2.7 kg (6.0 lb)

Power/Control Unit: 18.8 kg (41.5 lb)

Utility Requirements

Electrical: 200 –240 V~, 50/60 Hz, 7A, 1700 W max.

Purge gas: clean dry nitrogen, filtered to 5um, 20 psig (0.14 MPa) supply pressure,

maximum flow rate 0.7 liters/minute

–Fittings: 4mm push-to-connect

Cooling water (Power/Control Unit): 3 –4 liters/minute, 18 –24 °C

–Fittings: 8mm push-to-connect

Cooling water (Lamp House): >= 1 liter/minute, 18 –30 °C

–Fittings: 8mm Swagelok

EQ-400 Operation Manual Rev. Error! Reference source not found. 11

Remote Interface

Digital Inputs

Type: Optocoupler LED

Logic: Active High

Input voltage: 5VDC

Input current: 8mA

Digital Outputs

Type: Open collector to ground (digital common)

Logic: Active Low

Voltage: 30VDC max.

Sink current: 30mA max.

User Power

Voltage: 5VDC, referenced to digital common

Current: 200mA maximum

Serial Interface

Type: RS-485 4-wire (full duplex)

Connector: Male 9-pin d-sub

Termination: 120 ohms across receiver input (pins 2 and 7)

Interface protocol: see Chapter 4.

Port settings: 9600 bps, 8 data bits, 1 stop bit, no parity, no handshaking

Environmental Requirements

Operating

Ambient temperature: 15–35°C

Relative Humidity: non-condensing, 80% max. for temperatures up to 31°C,

decreasing linearly to 50% max. at 35°C.

Pollution Degree 2 (normally only non-conductive pollution; occasional,

temporary condensation possible)

Installation Category II

Indoor use only

Transport

Temperature: -5–70°C

Relative Humidity: non-condensing, 95% max.

12 EQ-400 Operation Manual Rev. Error! Reference source not found.

System Description

The EQ-400 system consists of a Power/Control Unit (PCU), Lamp House, Controller to

Lamp House interconnect cable, and power input cable. Laser light is generated in the PCU

and transmitted to the Lamp House by an optical fiber permanently attached to the PCU.

The following sections provide descriptions of the system components and controls, and give

an overview of their functions. Refer to the “Installation” section of this manual (Chapter 3)

for more detailed information.

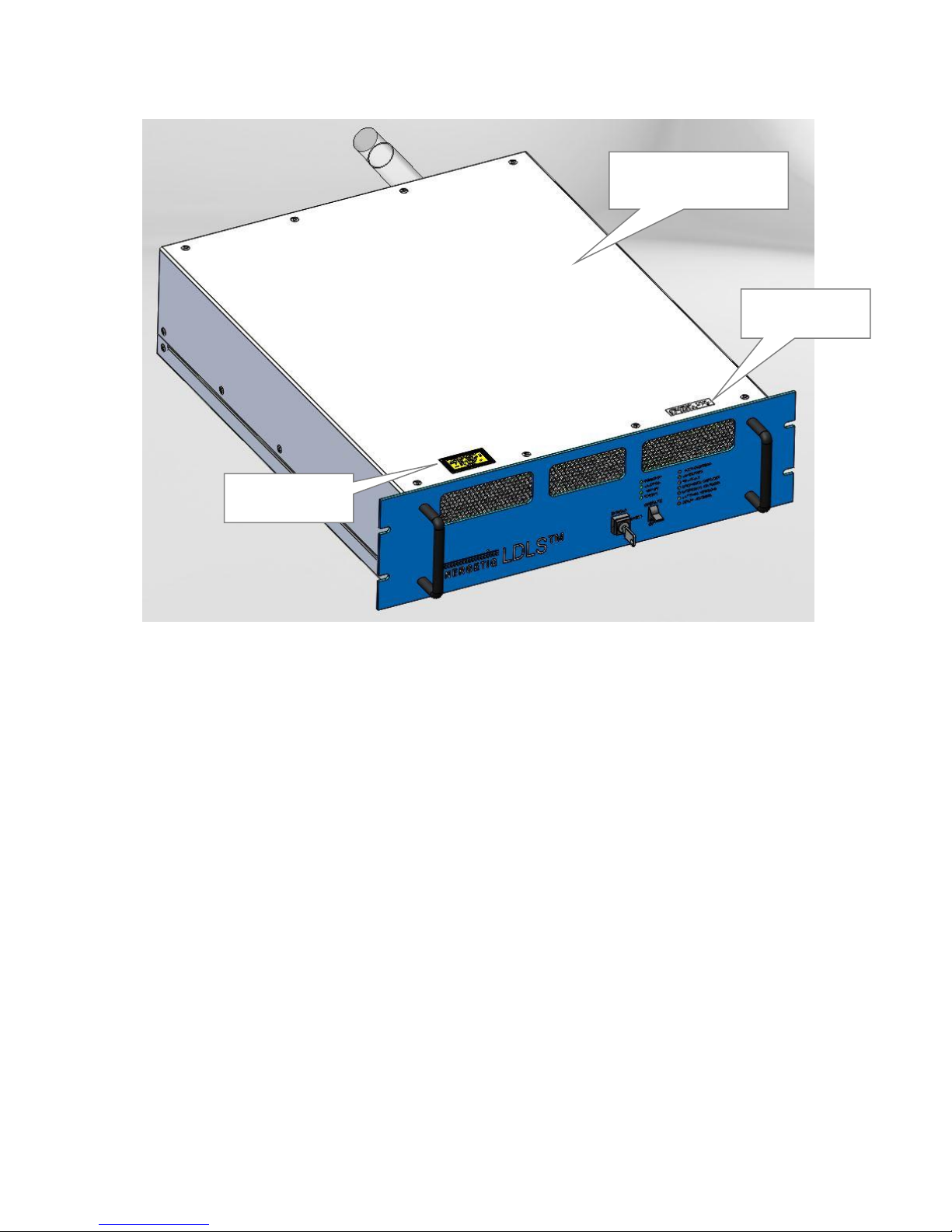

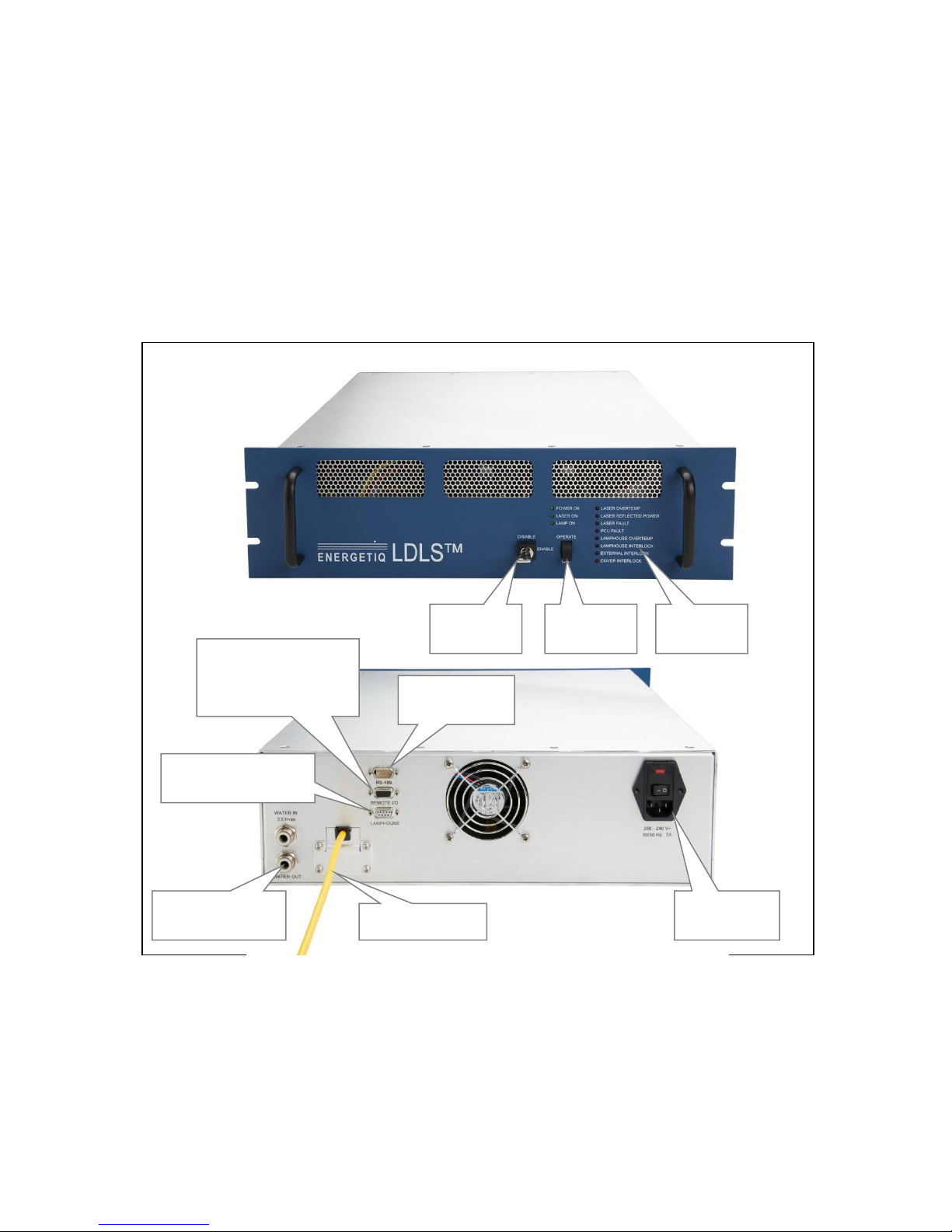

Figure 3: EQ-400 Power/Control Unit

Power Input

Connector

RS-485

Connector

Lamp House Control

Connector

Water inlet/outlet

fittings

Status

Indicators

I/O Interface

Connector

(includes remote

interlock connection)

Laser fiber

Operate

switch

Key

switch

EQ-400 Operation Manual Rev. Error! Reference source not found. 13

Power/Control Unit (PCU)

The Power/Control Unit contains:

Laser module

Laser power supply

Control electronics

Status indicator LEDs

Operate switch

Keyswitch

Interface connectors

Cooling water connectors

External features (refer to Figure 3):

Status Indicator LEDs

These LEDs indicate the system status. The function of these indicators is shown below in

Table 2.

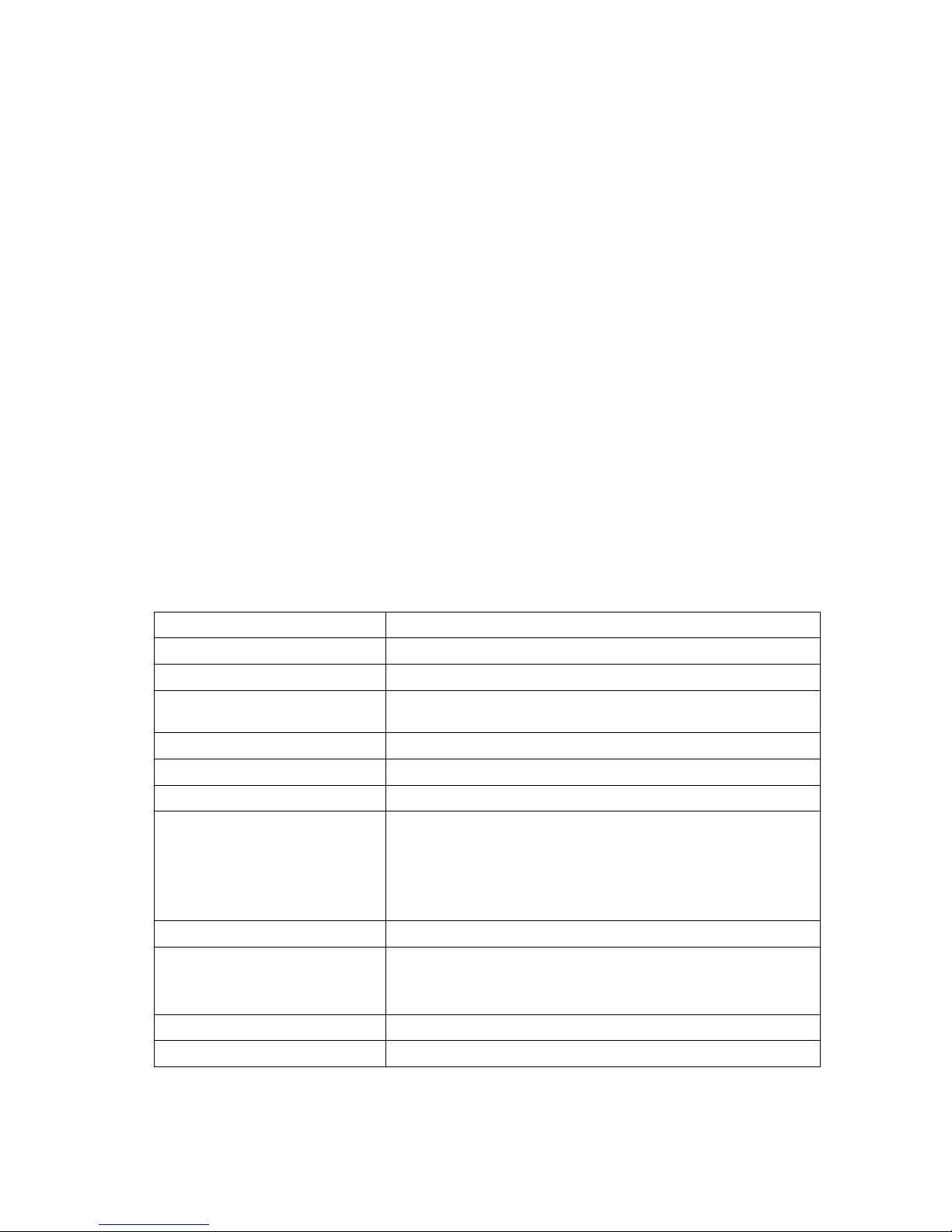

LED Label

Meaning (when lit)

POWER OK

AC power is connected to the EQ-400 PCU

LAMP ON

UV Light is on

LASER ON

Laser power is ON and laser light is being produced within the Lamp

House

REMOTE

System is in remote control mode

LASER OVERTEMP

Laser internal temperature too high

LASER FAULT

Laser module internal fault

PCU FAULT

One of the following has occurred in the Power/Control Unit:

1. Controller internal temperature too high

2. Laser power not reaching setpoint

3. Internal power supply voltage low

4. Lamp failed to ignite

LAMPHOUSE OVERTEMP

Lamphouse internal temperature too high

LAMPHOUSE INTERLOCK

One of the following has occurred in the Lamp House module:

1. Control Cable not connected properly

2. Laser fiber not connected properly

EXTERNAL INTERLOCK

External interlock open

COVER INTERLOCK

PCU cover(s) not in place

Table 2: Status Indicator LED Functions

14 EQ-400 Operation Manual Rev. Error! Reference source not found.

Operate switch

Turns the lamp on or off.

Key switch

Enables or disables operation of the lamp. The keyswitch must be in the ENABLE position

for the lamp to operate. The key can only be removed in the DISABLE position.

I/O Interface Connector

Provides access to control and status signals. Control signals are only active when the system

is in remote control mode. See Chapter 3 for pin assignments and functions.

This connector also functions as the remote interlock connector.

Lamp House Control Connector (9-pin D-sub)

Provides various power and control signals to/from the Lamp House module. No other

connector or cable may be used with the EQ-400 other than the one supplied.

RS-485 Connector (9-pin D-sub)

Connector for optional RS-485 interface. See Chapters 3 and 4 for electrical details and

commands.

Power Input Connector

This is a fused IEC 320 inlet connector for AC power input. Fuses are 5 x 20mm, 10A, 250V,

time delay type. See Chapter 3 for detailed information.

Water inlet/outlet fittings

Connections for cooling water for the internal laser module.

Laser fiber

Transmits laser energy from the PCU to the Lamp House.

Lamp House

The Lamp House assembly contains:

Lamp

Igniter

IR pumping optics

Output windows

Laser ON indicator

Control connector

Table of contents

Other Energetiq Portable Generator manuals

Popular Portable Generator manuals by other brands

Westinghouse

Westinghouse iGen1200 user manual

Champion Global Power Equipment

Champion Global Power Equipment 500559-EU Operator's manual

BANDELIN

BANDELIN SONOREX TECHNIK TG Series Assembly instructions

pela tools

pela tools BK10 manual

Westinghouse

Westinghouse WGen5300 user manual

Winco

Winco DR130F4 Installation and operator's manual