ENERGY KINETICS 90+RESOLUTE BOILER User manual

Other ENERGY KINETICS Boiler manuals

ENERGY KINETICS

ENERGY KINETICS EK2C Supplement

ENERGY KINETICS

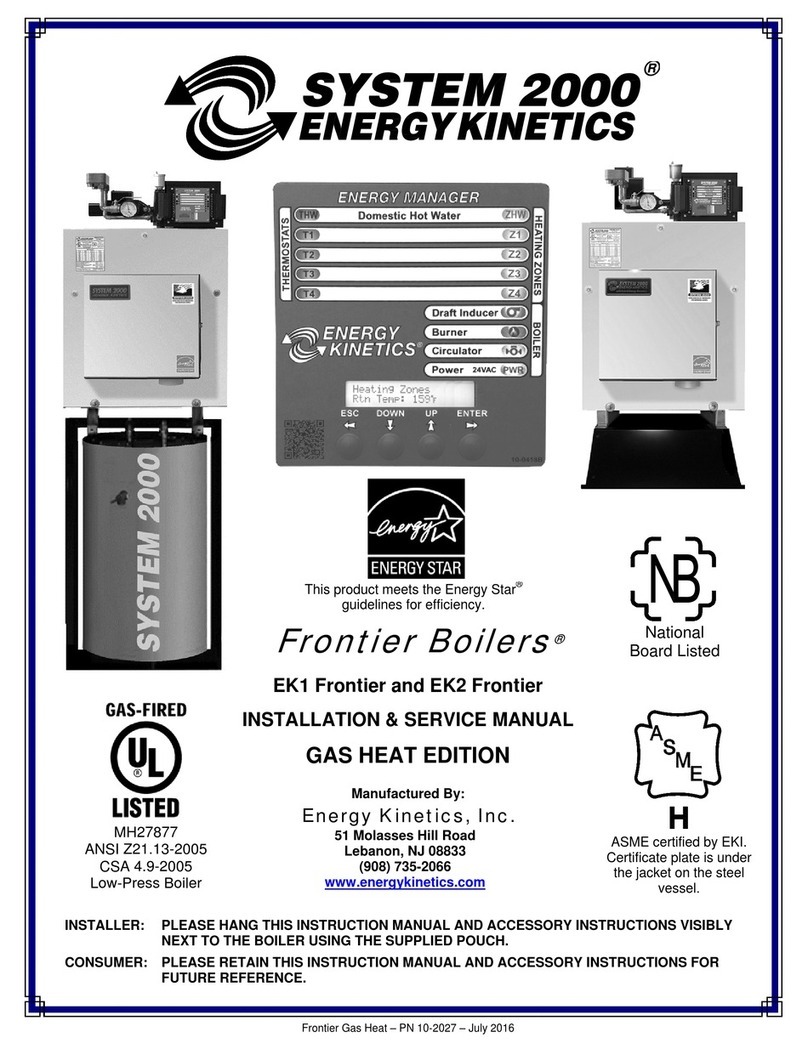

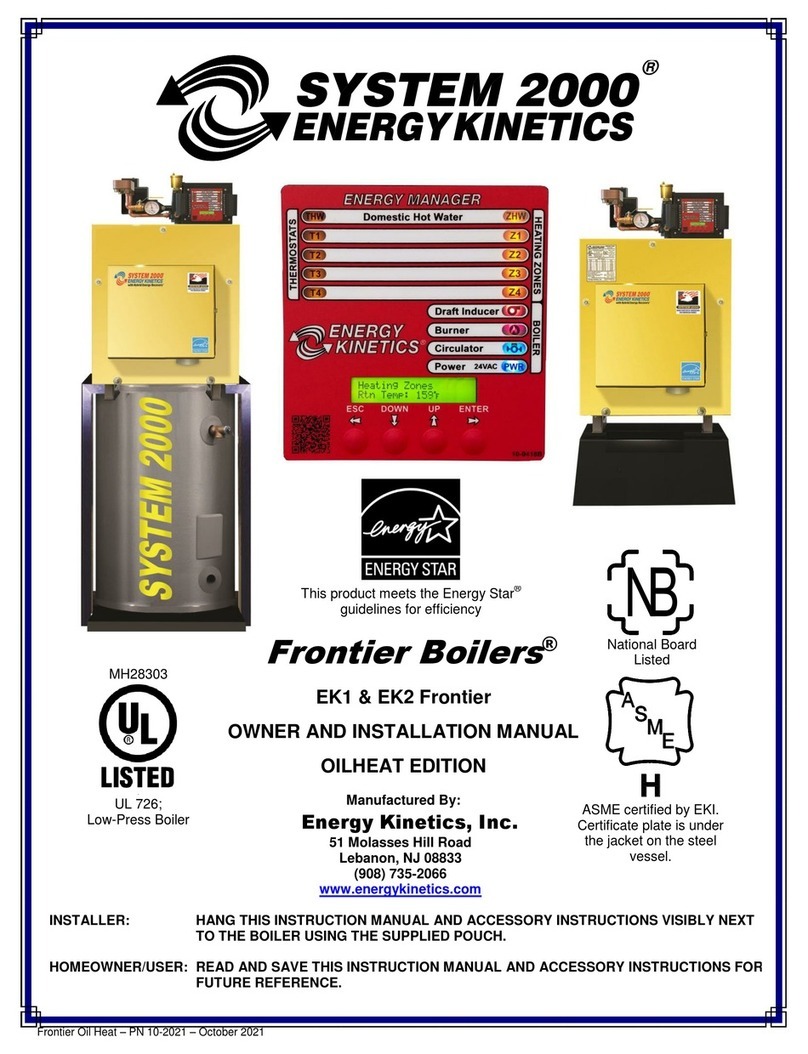

ENERGY KINETICS System 2000 EK1 Frontier Service manual

ENERGY KINETICS

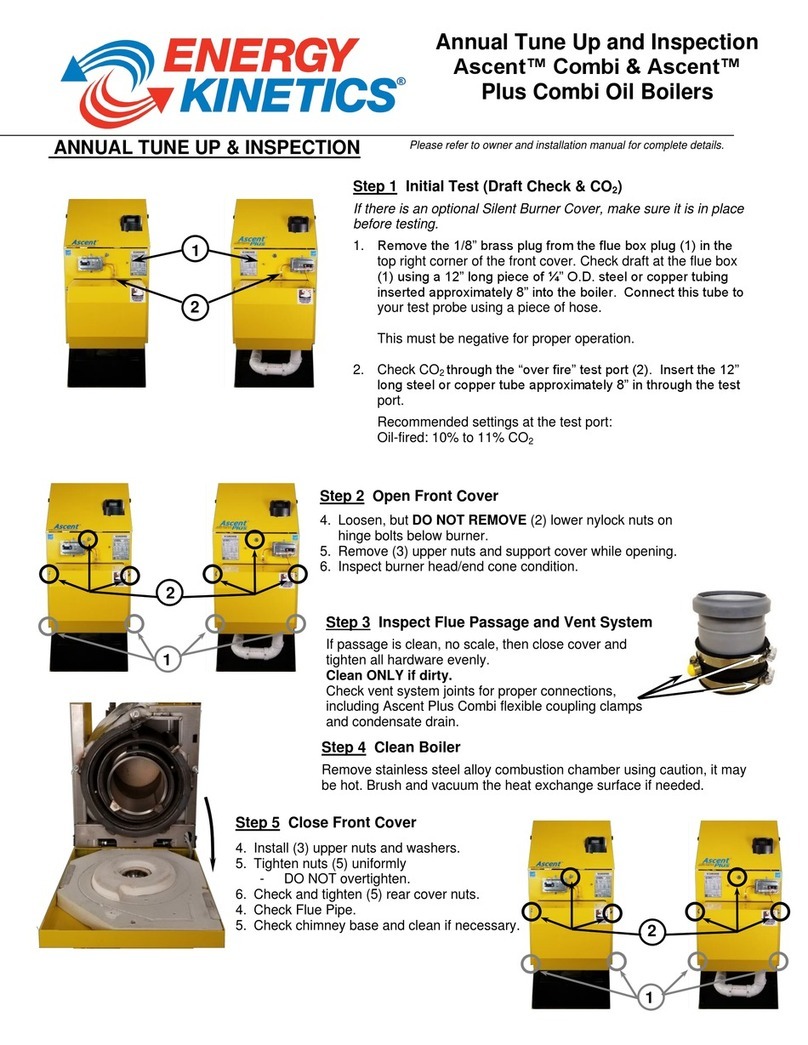

ENERGY KINETICS Ascent Combi Installation instructions

ENERGY KINETICS

ENERGY KINETICS EK1 Frontier User manual

ENERGY KINETICS

ENERGY KINETICS 90+RESOLUTE BOILER Service manual

ENERGY KINETICS

ENERGY KINETICS System 2000 Supplement

ENERGY KINETICS

ENERGY KINETICS Accel CS User manual

ENERGY KINETICS

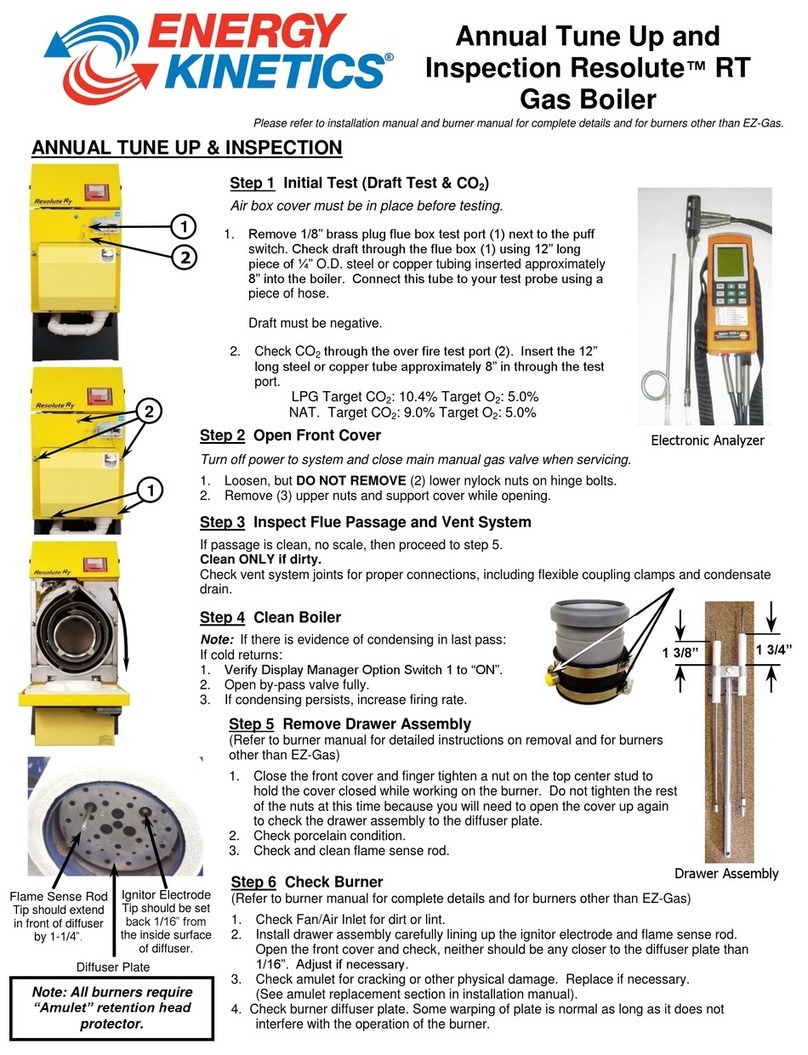

ENERGY KINETICS RESOLUTE RT Service manual

ENERGY KINETICS

ENERGY KINETICS EK1 Frontier Service manual

ENERGY KINETICS

ENERGY KINETICS Resolute Boiler Supplement

ENERGY KINETICS

ENERGY KINETICS System 2000 Service manual

ENERGY KINETICS

ENERGY KINETICS System 2000 Guide

ENERGY KINETICS

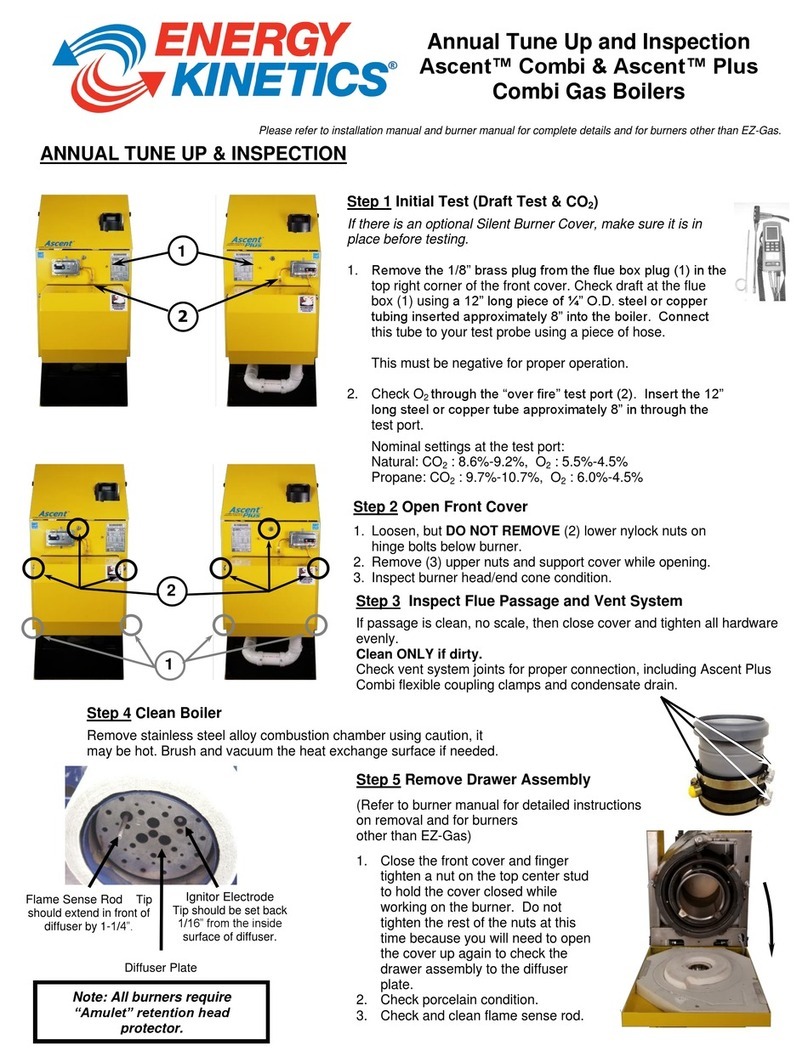

ENERGY KINETICS SYSTEM 2000 Ascent Combi Service manual

ENERGY KINETICS

ENERGY KINETICS 90+RESOLUTE BOILER Installation instructions

ENERGY KINETICS

ENERGY KINETICS Ascent Combi Boilers Guide

ENERGY KINETICS

ENERGY KINETICS EK3 Frontier Quick start guide

ENERGY KINETICS

ENERGY KINETICS Resolute RT Installation instructions

ENERGY KINETICS

ENERGY KINETICS SYSTEM 2000 Accel CS Installation instructions

ENERGY KINETICS

ENERGY KINETICS Ascent Combi Service manual

ENERGY KINETICS

ENERGY KINETICS Ascent Combi Installation instructions

Popular Boiler manuals by other brands

Market Forge Industries

Market Forge Industries M24E24A Installation, operating, maintenance and parts manual

Benchmark

Benchmark BMK 1500 user manual

Worcester

Worcester GREENSTAR II HE OIL 12/22 Installation and servicing instructions

Lochinvar

Lochinvar 250000 BTU Installation and service manual

Rotex

Rotex R2CND024A4AA Operation manual

Viessmann

Viessmann Vitocrossal 100 operating instructions

Radiant

Radiant R2C 28 Installation, use and maintenance manual

Ferroli

Ferroli Optima 900 Technical information installation and service instructions

Max-Ox

Max-Ox MX-900B Operator's manual

BURNiT

BURNiT PyroBurn Alpha 18 Installation and operation manual

Rapido

Rapido F 310 installation manual

Biasi

Biasi RINNOVA ADAPTIVE 30S User manual and installation instructions

Vocera

Vocera Linea Plus AG Installation & servicing instructions

Harman

Harman HydroFlex 60 Pellet Boiler Installation & operating manual

FireBird

FireBird Silver Series Technical manual

IDEAL

IDEAL Europa 24 installation & servicing

Linear

Linear Boiler user manual

IDEAL

IDEAL Classic Combi NF 280 User instructions