ENERGY KINETICS Accel CS User manual

Other ENERGY KINETICS Boiler manuals

ENERGY KINETICS

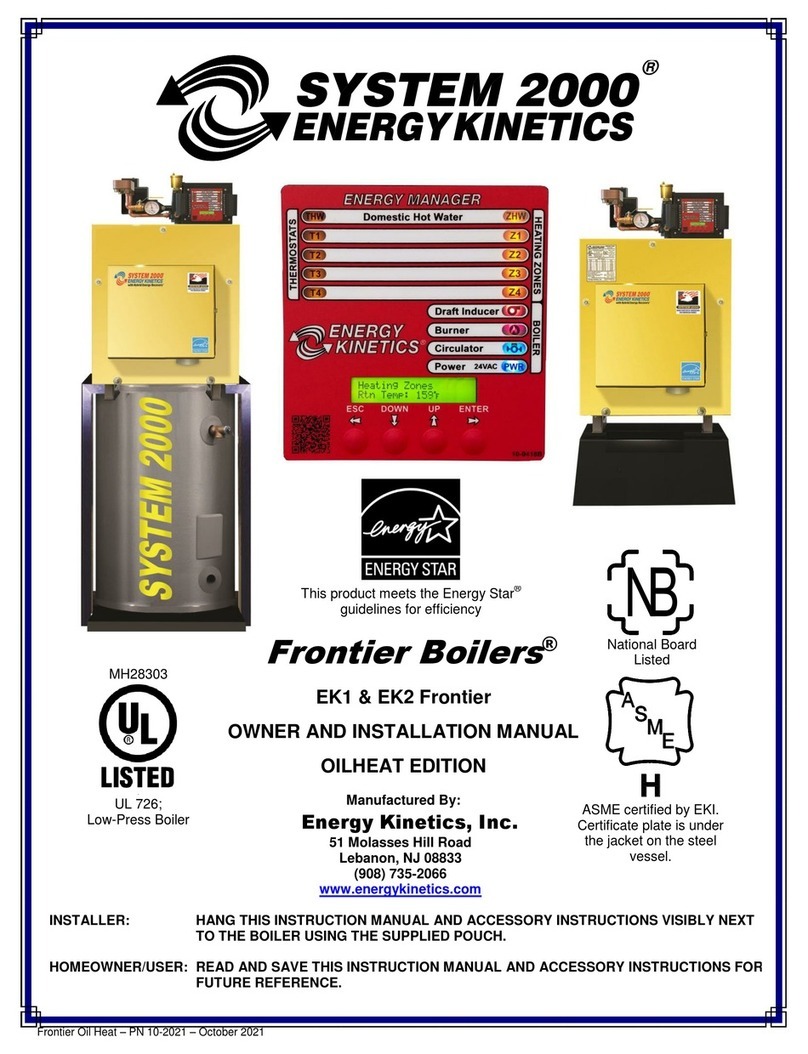

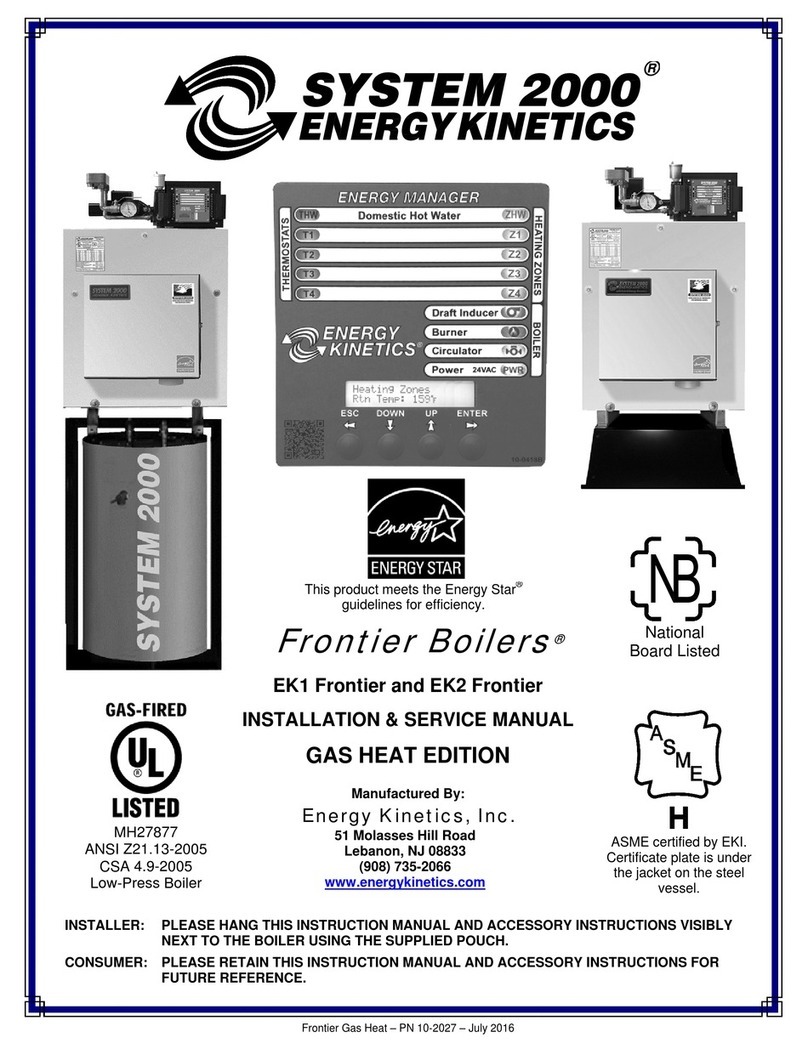

ENERGY KINETICS System 2000 EK1 Frontier Service manual

ENERGY KINETICS

ENERGY KINETICS 90+RESOLUTE BOILER User manual

ENERGY KINETICS

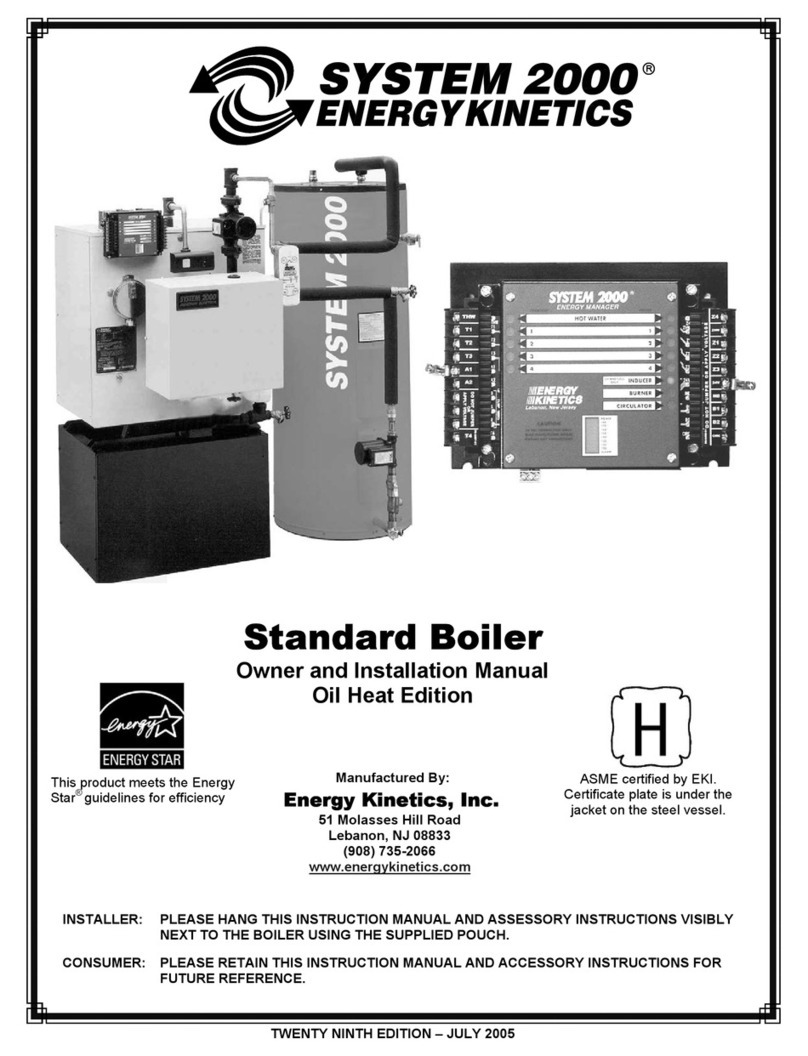

ENERGY KINETICS System 2000 Service manual

ENERGY KINETICS

ENERGY KINETICS System 2000 Frontier User manual

ENERGY KINETICS

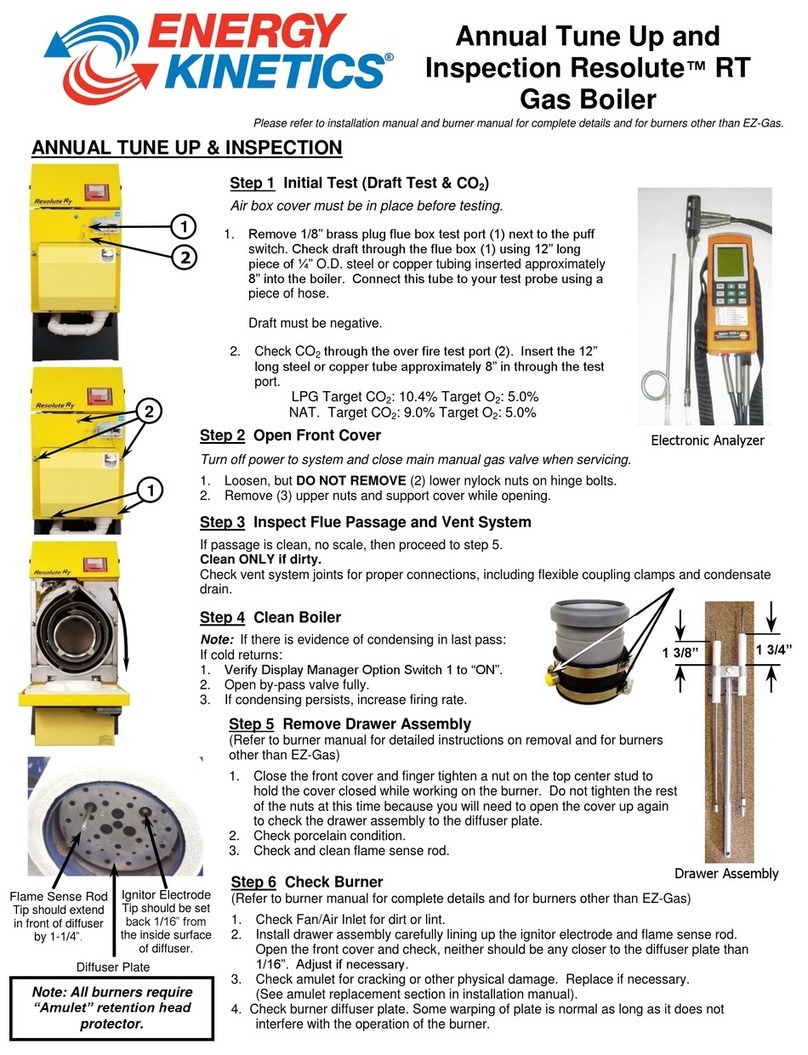

ENERGY KINETICS Resolute RT Installation instructions

ENERGY KINETICS

ENERGY KINETICS 90+RESOLUTE BOILER Service manual

ENERGY KINETICS

ENERGY KINETICS EK1 Frontier User manual

ENERGY KINETICS

ENERGY KINETICS SYSTEM 2000 Accel CS Installation instructions

ENERGY KINETICS

ENERGY KINETICS EK1 Frontier Service manual

ENERGY KINETICS

ENERGY KINETICS RESOLUTE RT Service manual

ENERGY KINETICS

ENERGY KINETICS System 2000 Guide

ENERGY KINETICS

ENERGY KINETICS EK2C Supplement

ENERGY KINETICS

ENERGY KINETICS Resolute Boiler Supplement

ENERGY KINETICS

ENERGY KINETICS 90+RESOLUTE BOILER Installation instructions

ENERGY KINETICS

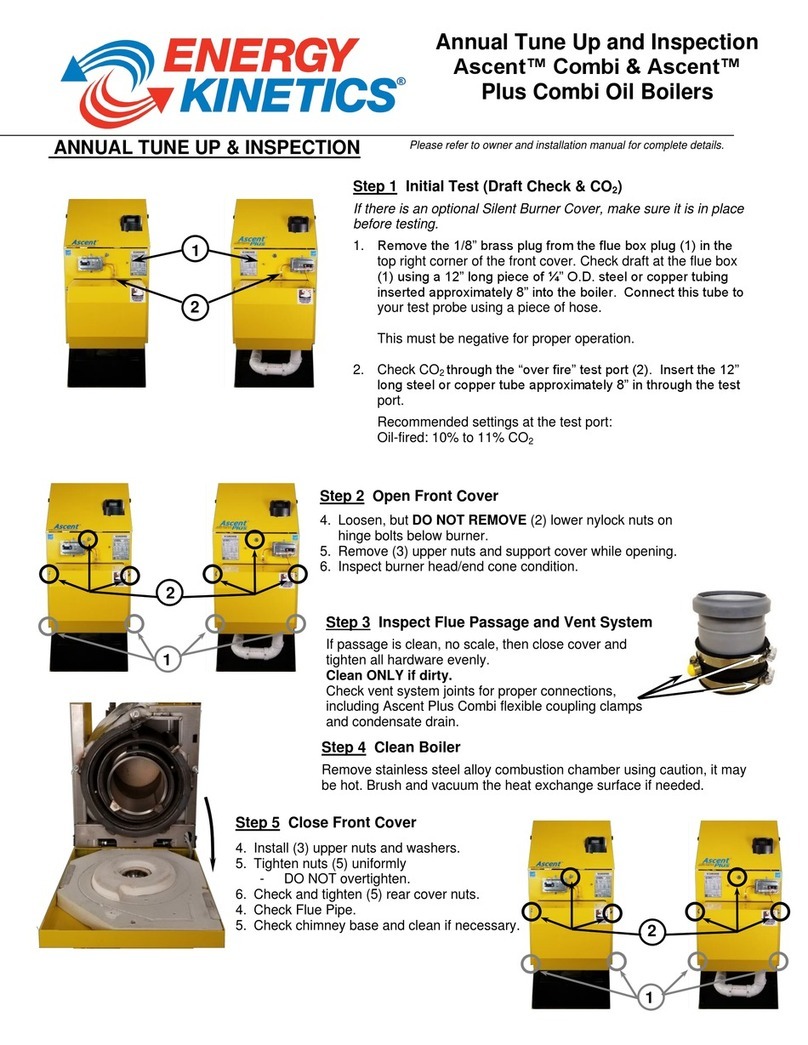

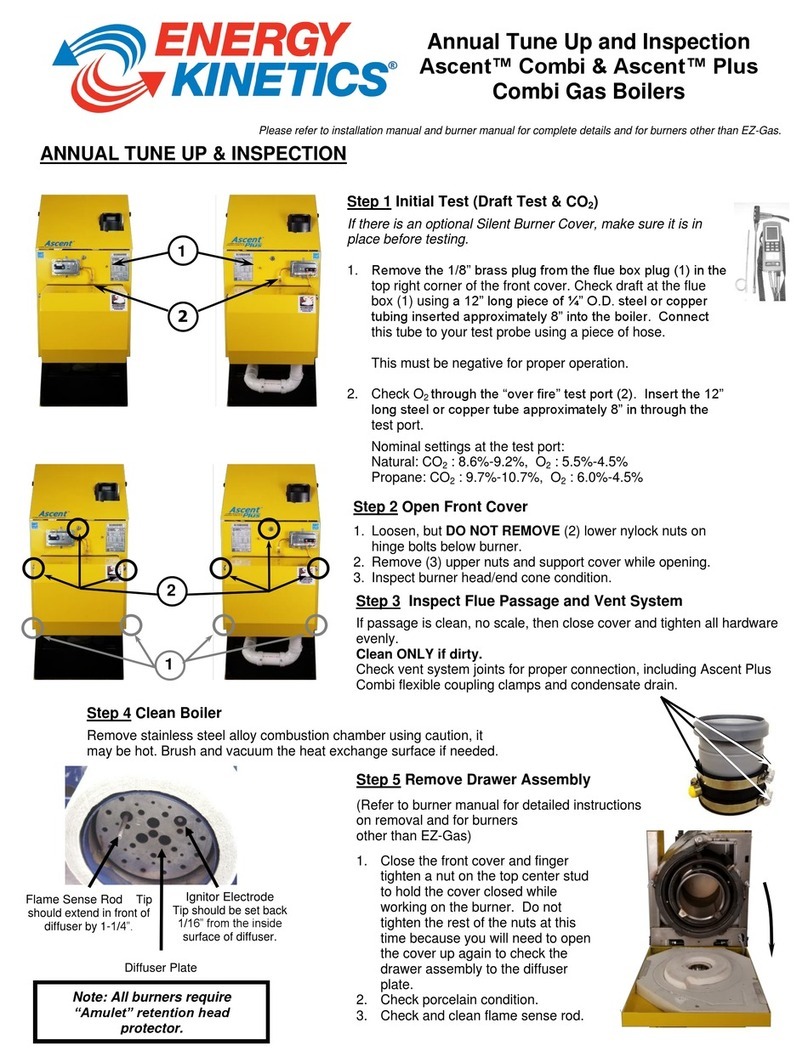

ENERGY KINETICS Ascent Combi Boilers Guide

ENERGY KINETICS

ENERGY KINETICS SYSTEM 2000 Ascent Combi Service manual

ENERGY KINETICS

ENERGY KINETICS Ascent Combi Installation instructions

ENERGY KINETICS

ENERGY KINETICS Ascent Combi Installation instructions

ENERGY KINETICS

ENERGY KINETICS System 2000 Supplement

ENERGY KINETICS

ENERGY KINETICS Ascent Combi Service manual

Popular Boiler manuals by other brands

Vaillant

Vaillant ecoTEC plus 806 VU GB 806/5-5 Installation and maintenance instructions

Dunkirk

Dunkirk DXL-50 Installation, operation & maintenance manual

Viessmann

Viessmann VITODENS 333 Service instructions

Thermsaver

Thermsaver White Cased Oil Boiler Installation and user guide

TANGRA

TANGRA HP 30 Installation and operation manual

Riello

Riello TAU 350 N INSTALLATION, TECHNICAL ASSISTANCE SERVICE AND SYSTEM MANAGEMENT MANUAL

U.S. Boiler Company

U.S. Boiler Company SERIES 3 Installation, operating and service instructions

IDEAL

IDEAL Esprit eco 30 user guide

Sime

Sime MURELLE HM ErP Series manual

NESTOR MARTIN

NESTOR MARTIN Harmony 1 operating instructions

Hoval

Hoval CompactGas 200 operating instructions

HARGASSNER

HARGASSNER Classic 12 Operation manual

PeerlessBoilers

PeerlessBoilers PSC II Installation, operation & maintanance manual

Marco

Marco ECOBOILER T20-3 instructions

Baxi

Baxi Avanta Heat Only 15h User's operation instruction

Weil-McLain

Weil-McLain CG Series 12 owner's manual

Weil-McLain

Weil-McLain GV90+3 Brochure & specs

Green Mountain

Green Mountain GMHB125 Installation, operation & maintenance manual