SLOPE INDICATOR MEMS User manual

Copyright ©2009 Durham Geo-Enterprises. All Rights Reserved.

This equipment should be installed, maintained, and operated by technically qualified personnel. Any errors

or omissions in data, or the interpretation of data, are not the responsibility of Durham Geo-Enterprises. The

information herein is subject to change without notification.

This document contains information that is proprietary to Durham Geo-Enterprises and is subject to return

upon request. It is transmitted for the sole purpose of aiding the transaction of business between Durham

Geo-Enterprises and the recipient. All information, data, designs, and drawings contained herein are propri-

etary to and the property of Durham Geo-Enterprises and may not be reproduced or copied in any form, by

photocopy or any other means, including disclosure to outside parties, directly or indirectly, without permis-

sion in writing from Durham Geo-Enterprises.

SLOPE INDICATOR

12123 Harbour Reach Drive

Mukilteo, Washington, USA, 98275

Tel: 425-493-6200 Fax: 425-493-6250

E-mail: [email protected]

Website: www.slopeindicator.com

MEMS Vertical

In-Place

Inclinometer

57804199

MEMS Vertical In-Place Inclinometer, 2009/7/10

Contents

Introduction. . . . . . . . . . . . . . . . . . . . . . . 1

Preparations for Installation . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . .6

Manual Readings . . . . . . . . . . . . . . . . . . 8

Data Reduction . . . . . . . . . . . . . . . . . . . . .9

Connection to Data Logger . . . . . . . 11

MEMS Vertical In-Place Inclinometer, 2009/7/10 1

Introduction

Vertical In-Place

Inclinometers

The in-place inclinometer system

consists of inclinometer casing and a

string of in-place inclinometer

sensors.

The inclinometer casing provides

access for subsurface measurements,

controls the orientation of the sen-

sors, and moves with the surround-

ing ground.

In vertical installations, the casing is

installed in a borehole that passes

through a suspected zone of move-

ment into stable ground below. One

set of grooves in the casing is aligned

with the expected direction of move-

ment, as shown in the drawing at left.

The grooves in the casing control the

orientation of the in-place sensors. A

stainless steel cable keeps the sensors

at the required depth.

The sensors measure inclination

from vertical. As ground movement

occurs, the casing moves with it,

changing the inclination of the sen-

sors inside the casing.

The inclination measurements are

then processed to provide displace-

ment readings in mm or inches.

In most applications, sensors are

connected to a data acquisition

system and data processing is com-

pleted by a computer program.

Casing should be installed

with one set of grooves

aligned with the expected

direction of movement.

The wheels of the sensors are

inserted in these grooves.

Expected Direction

of Movement

Casing is installed with

one set of grooves

aligned with the

expected direction of

movement.

Sensors wheels are

inserted into these

grooves to maintain the

proper orientation of

the sensors.

The gauge length of

each sensor is the

distance between

the fixed wheels.

Sensors are suspended

in the casing by a cable

that is attached here.

MEMS Vertical In-Place Inclinometer, 2009/7/10 2

Sensor Components In-place sensors can be

installed as a single sensor

or as a string of linked sen-

sors. The drawing at right

shows both.

An individual sensor

includes a sensor body, a

gauge tube, a top wheel, and

a bottom wheel.

A string of linked sensors

includes n sensor bodies,

n gauge tubes, a top wheel,

a bottom wheel, and n-1

middle wheels.

Sensor bodies can contain

uniaxial or biaxial sensors,

but look the same.

Gauge tubes are sized to

make gauge lengths of 1, 2,

or 3 m (or 3, 5, and 10')

when joined to a sensor

body and wheels.

Top wheels have an eyelet

for attaching a stainless

steel suspension cable. They

also have a socket for con-

necting to a gauge tube.

Bottom wheels attach

directly to the bottom of the

sensor. They have no

socket.

Middle wheels are used to

link sensors. The middle

wheel attaches directly to

the bottom of the sensor

sensor and has a socket for

connecting to the gauge

tube from the sensor below.

Bottom

Wheel

Top

Wheel

Gauge

Tubing

Top

Wheel

Middle

Wheel

Bottom

Wheel

Sensor

Body

Single

Sensor

Linked

Sensors

MEMS Vertical In-Place Inclinometer, 2009/7/10 3

Suspension Kits Top Suspension Kit is used

to suspend the IPI sensor or

string of Apia sensors from

the top of the casing. Stain-

less steel cable is ordered

separately.

In-Line Suspension Kit is

used to suspend a string of

deeper sensors from a string

of shallower sensors. This

allows economical monitor-

ing of two or more separate

zones of interest.

Safety Cable (not shown) is

sometimes attached to the

bottom sensor and used to

prevent loss of sensors

downhole during installa-

tion. A safety cable is also

helpful when sensors are

withdrawn from the casing.

Top Suspension Kit

In-Line

Suspension Kit

MEMS Vertical In-Place Inclinometer, 2009/7/10 4

Preparations for Installation

Check Sensors 1. Check each sensor. See the “Manual Readings” for instructions.

2. Make a note of the serial number of each sensor and its intended

depth of installation.

3. Check that cable lengths are correct and that each cable has an ID tag.

4. Mark sensors for order of installation.

Prepare

Suspension Cable

1. Check project specifications for intended

depth of top sensor.

2. Determine the required depth of the top

wheels of the top sensor.

3. Determine the distance between the top wheels

and the top of the casing. Cut the stainless steel

suspension cable to this length.

4. Connect suspension cable to top wheel as

shown in the drawing.

5. Connect suspension cable to the chain as

shown in the drawing.

Attach

Gauge Tubing

1. Remove screw from socket.

2. Align hole in gauge tube with hole in socket,

then insert gauge tube into socket.

3. Insert screw and tighten to secure the gauge

tube.

4. No further pre-assembly is recommended.

Gather Tools Vice grips (clamping pliers) for holding gauge tubing while

connecting adjacent sensors.

Allen wrench for screws that securing gauge tubing.

Cable ties or vinyl tape to secure cable to gauge tubing.

Optional: safety cable connected to bottom sensor to prevent loss of

sensors down hole. The safety cable is also helpful when the sensors

are withdrawn from the casing.

MEMS Vertical In-Place Inclinometer, 2009/7/10 5

Installation

Installation

Overview

1. Lay out sensors in order of installation.

2. Attach safety cable to first sensor (optional), then insert the first sen-

sor into the preferred set of grooves.

3. Lower the sensor into the casing. Clamp the top of the gauge tube to

hold the sensor while you connect the next sensor.

4. Align the next sensor with the preferred set of grooves as in step 2,

and connect it to the gauge tubing of the downhole sensor.

5. Lower the two sensors. Repeat steps 4 and 5 until all sensors have

been installed.

6. Connect the top wheel and suspension kit and lower the sensors to

their final elevation.

Install the

First Sensor

1. Attach safety cable to bottom sensor. Secure the safety cable. Insert

first sensor in selected set of grooves. The fixed wheel should point to

the expected direction of movement.

2. Secure signal cable to gauge tubing and then lower sensor into casing.

Clamp the top of gauge tubing to hold it at the top of the casing.

Secure signal cable and

safety line to gauge tubing.

Safety cable can be looped

through wheel assembly.

Lower sensor,

then clamp

gauge tube.

Orient sensor so that fixed wheel

points to direction of movement.

Insert sensor wheels into

grooves that are aligned

with expected direction

of movement.

Fixed

Wheel

Sprung

Wheel

MEMS Vertical In-Place Inclinometer, 2009/7/10 6

Install the

Next Sensor

Connect next sensor to the gauge tubing of the sensor below, as shown

in the drawing. Continue adding sensors until the sensor string is com-

plete. Keep the following points in mind:

Do not allow the installed sensor to twist in the casing, as this may

damage the wheels or pop them out of the grooves.

When you lower the sensor into the casing, check that the fixed wheel

is aligned in the proper direction.

Secure cables neatly, so that they do not cross each other.

Check that fixed wheel

points to expected

direction of movement

Secure cable neatly.

Do not allow cable to

interfere with wheels

MEMS Vertical In-Place Inclinometer, 2009/7/10 7

Install the

Install Top Wheel

1. Connect top wheel to gauge tubing.

2. Check that suspension cable is

attached securely.

Suspend

the Sensors

1. Check that suspension cable is

securely clamped.

2. Use the chain and S-hook to make

fine adjustments to the final depth of

the sensors.

Note on

Retrieving Sensors

When you withdraw the sensors, you must disassemble the string and

remove sensors one at a time from the casing. Otherwise there is a good

chance that sensor wheels and gauge tubes will be damaged.

1. Draw each sensor upwards.

2. Clamp the gauge tube of the sensor below

3. Disconnect the sensor, and repeat. If you intend to reinstall the sen-

sors, check that they are still numbered for order of installation

Top Wheel

Suspension

Cable

MEMS Vertical In-Place Inclinometer, 2009/7/10 8

Manual Readings

Introduction Manual readings are useful for testing the system before the

data acquisition system is set up.

EL/MEMS

Data Recorder

1. Connect sensor to readout as shown in the table below.

2. Switch on. Choose uniaxial or biaxial sensor.

3. Tilt is displayed in volts. Temperature is displayed in degrees C.

Test Readings 1. When the sensor body is vertical, you should see a reading of about

0.0 Vdc in both axes.

2. The A-axis sensor measures tilt in the plane of the wheels. Tilting the

sensor to 10 degrees should provide a reading of ±2.2 to 2.3 Volts.

The fixed wheel points to the positive direction. See drawing on in

the data reduction section.

3. The B-axis sensor (available with biaxial sensors only) is rotated 90

degrees from the A-axis sensor. Tilting the sensor to 10 degrees

should provide a reading of ±2.2 to 2.3 Volts. The plane 90 degrees

clockwise from the fixed wheel is the positive direction.

4. At 25 degrees C, the thermistor reading should be about 1 Vdc.

Data Recorder Terminal Signal Cable Wire

1TiltA Orange

2TiltB Blue

3 Temp Red

4 Sig Common Yellow

5 Sense Violet

6 Power + Green

7Power- Black

8Shield DrainWire

MEMS Vertical In-Place Inclinometer, 2009/7/10 9

Data Reduction

Introduction Data reduction is usually automated because it involves a large number

of readings and a large number of calculations.

Here, we explain how to use the sensor calibration record and provide

an example of converting a single reading in volts to tilt in mm per

meter and tilt in degrees.

Calibration Record A calibration record is provided with each sensor. Use sensor serial

numbers to match sensors with their calibrations. Calibrations are

unique for each sensor.

The sensor calibration record provides two sets of factors. One set lists

factors to convert readings in volts to tilt in mm per meter and also

includes factors to calculate temperature corrections.

The other set lists factors to convert readings in volts to tilt in degrees

and also includes factors to calculate temperature corrections.

Factors for A-axis sensors have a _A suffix. Factors for B-axis sensors

have a _B suffix.

The bottom section of the calibration record shows how the factors are

applied.

Converting Volts

to Tilt

To convert a reading in volts to mm/m or degrees of tilt,

use the following formula:

Tilt = C3 × Volts³+ C2 ×Volts²+ C1 × Volts + C0

Where:

Tilt is a value in mm/m or degrees, depending on the factors used.

C3...C0 are factors for A-axis or B-axis.

Volts is the sensor reading in volts.

Correcting for

Temperature

The formula below shows how to adjust the tilt value for temperature:

Temp-Corrected Tilt = Tilt – (T1 × TdegC +T0)

Where:

Tilt is the value calculated above.

T1 and T0 are temperature factors for mm/m or degreesC .

TdegC is the temperature in degrees C at the time of reading.

MEMS Vertical In-Place Inclinometer, 2009/7/10 10

Example:

Tilt in mm/m

Sensor 14295 gives an A-axis reading of 2.3V at 18C. The calibration

factors are: C3_A = -1.2508E-2, C2_A = -3.6652E-2, C1_A = 7.2839E1, and

C0_A = -3.9469. Use these factors in the formula from the previous page:

Tilt = C3 × Volts³+ C2 ×Volts²+ C1 × Volts + C0

Tiltmm/m = -1.2508E-2 × 2.3³ + -3.6652E-2 × 2.3² + 7.2839E1 x 2.3 + -3.9469

Tiltmm/m = 163.24

The same sensor has temperature factors T0_A = -3.3162E-1 and

T1_A = 2.4139E-2. Use these factors to adjust for temperature.

Temp-Corrected Tilt = Tilt – (T1 × TdegC +T0)

Temp-Corrected Tiltmm/m = 163.24 – (-3.3162E-1 x 18 + 2.4139E-2)

Temp-Corrected Tiltmm/m = 162.65

Example:

Tilt in Degrees

Sensor 14295 gives a reading of 2.3V at 18C. The calibration factors are:

C3_A_deg = -3.0241E-3, C2_A_deg = -2.7405E-3, C1_A_deg = 4.1733E0,

and C0_A_deg = -2.2612E-1. Use these factors in the formula from the

previous page:

Tilt = C3 × Volts³+ C2 ×Volts²+ C1 × Volts + C0

Tiltdeg = -3.0241E-3 × 2.3³ + -2.7405E-3 × 2.3² + 4.1733E0 x 2.3 + -2.2612E-1

Tiltdeg = 9.3635

The same sensor has temperature factors T0_A_deg = -1.9109E-2 and

T1_A_deg = 1.3911E-3. Use these factors to adjust for temperature.

Temp-Corrected Tilt = Tilt – (T1 × TdegC +T0)

Temp-Corrected Tiltdeg = 9.2972 – (-1.9109E-2 x 18 + 1.3911E-3)

Temp-Corrected Tiltdeg = 9.3611

Calculating Deviation To calculate deviation over the gauge length of the sensor, use either

formula below:

Deviationmm = Tiltmm/m x gauge_lengthm

or

Deviationmm = sin(Tiltdeg) x gauge_lengthmm

Example:

Calculating Deviation

Sensor 14295 has a gauge length of 2 meters. The examples below use

the temperature corrected tilt values.

Deviationmm = 162.65mm/m x 2 m

Deviationmm = 325.30

Deviationmm = sin(9.3611) x 2000 mm

Deviationmm = 325.31

Calculating

Displacement

Displacement (movement) is the change in deviation:

Displacement = Deviation current – Deviation initial

MEMS Vertical In-Place Inclinometer, 2009/7/10 11

Direction of

Tilt & Displacement

Uniaxial sensors respond to tilt in the plane

parallel to the wheels of the sensor. This

plane is called the A axis. A-axis readings

may be positive or negative. Positive read-

ings indicate that the sensor is tilted in the

direction of the fixed wheel. Negative read-

ings indicate that the sensor is tilted in the

direction of the sprung wheel.

Biaxial sensors respond to tilt in the plane

of the wheels (A-axis) and the plane rotated

90 degrees to the wheels (B-axis). Positive

A-axis readings show tilt in the direction of

the fixed wheels. Positive B-axis readings

show tilt in the direction rotated 90 degrees

clockwise. Displacement directions follow

the same convention. In the drawing below,

the sensor is viewed from the top.

–

Sprung

Wheel

+

Fixed

Wheel

A+ (Fixed Wheel)

B+

A- (Sprung Wheel

B-

MEMS Vertical In-Place Inclinometer, 2009/7/10 12

Connection to Data Loggers

CR10X or CR1000 These instructions provide information needed for reading uniaxial and

biaxial IPIs with the Campbell Scientific CR1000 datalogger system.

Sample Program: A sample CR1000 monitoring program is available at

the Slope Indicator website. Go to www.slopeindicator.com. Then navi-

gate to Support -> TechNotes -> DataLoggers, and look for sample pro-

grams.

Wiring Diagrams: The wiring diagrams on the following pages show

how to connect uniaxial and biaxial IPIs to the Campbell Scientific

CR1000 datalogger system.

Wiring Diagram 1 Uniaxial sensor connected directly to CR1000

Wiring Diagram 2 Biaxial sensor connected directly to CR1000

MEMS Vertical In-Place Inclinometer, 2009/7/10 13

Wiring Diagram 3 Uniaxial sensor connected to AM16/32 multiplexer

Wiring Diagram 4 Biaxial sensor connected to AM16/32 multiplexer

This manual suits for next models

1

Table of contents

Other SLOPE INDICATOR Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

KEPCO

KEPCO MINI-BATCHER MB2 Installation & operating instructions

Prostat

Prostat PHT-771 user manual

Co2meter

Co2meter Aranet4 PRO USER MANUAL & DATASHEET

Promax

Promax PROLITE-20 instruction manual

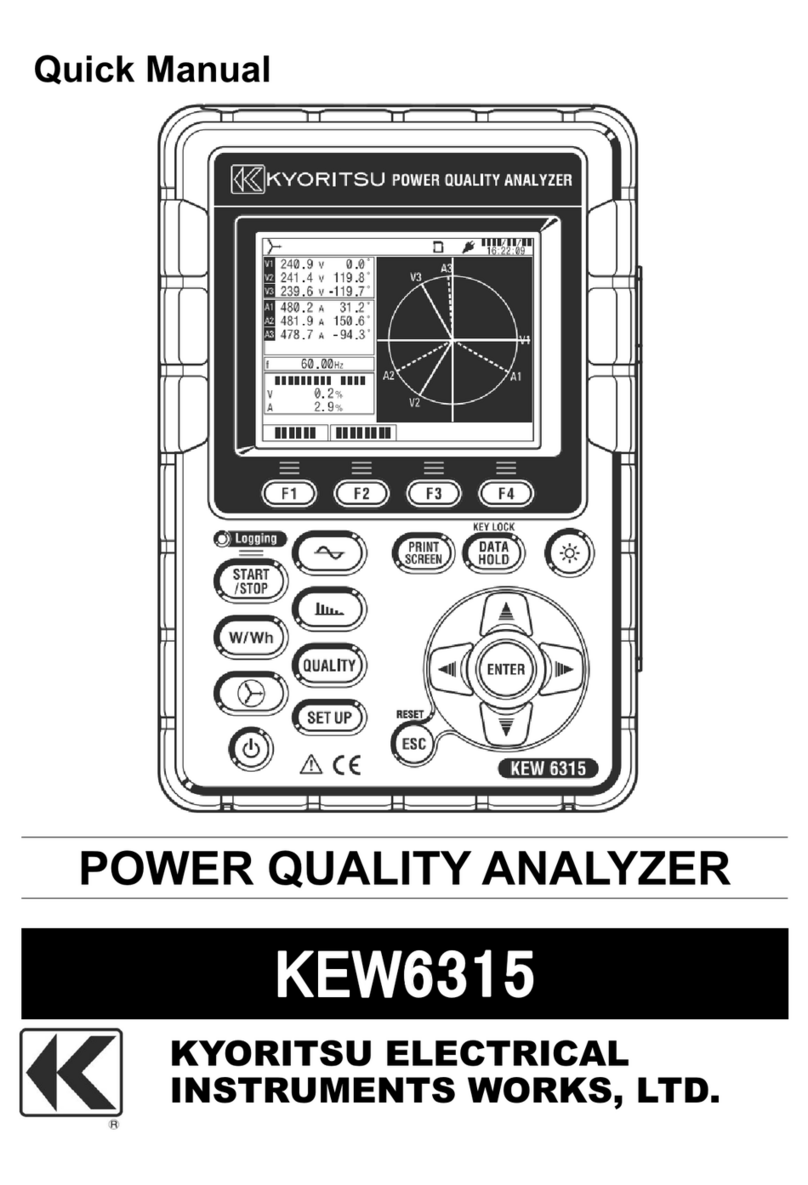

Kyoritsu Electrical Instruments Works, Ltd.

Kyoritsu Electrical Instruments Works, Ltd. KEW6315 Quick manual

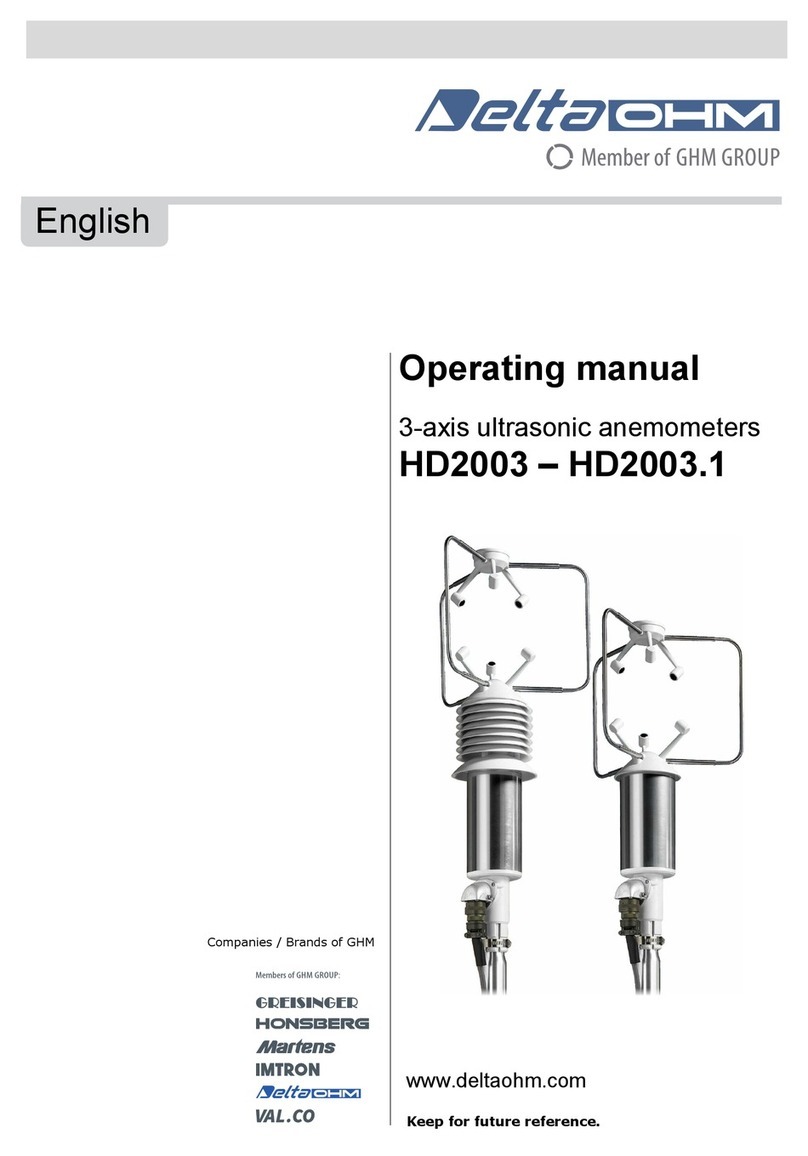

Delta OHM

Delta OHM HD2003 operating manual