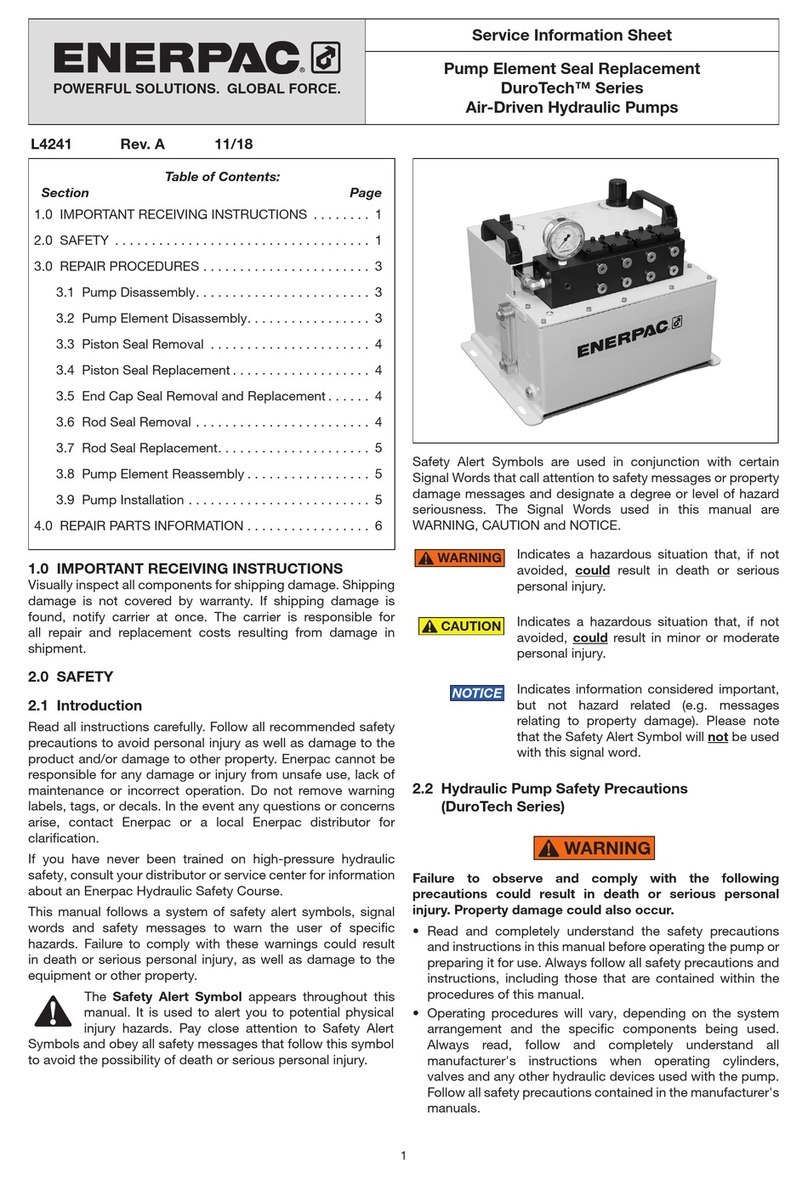

Service Information Sheet

POWERFUL SOLUTIONS. GLOBAL FORCE.

ZU4 Classic Bolting Pump

Single-Solenoid Control Valve Upgrade

INTRODUCTION

This document applies to all Enerpac ZU4 Classic Bolting Pumps

equipped with dual-solenoid valves. It includes instructions for

performing the following product upgrade procedures:

• Replacement of the existing VE Series dual-solenoid control

valve with the new single-solenoid VE Series control valve.

• Replacement of the existing front and middle brackets with

new brackets that are electrically compatible with the single-

solenoid control valve.

ELECTRICAL SERVICE KITS AND VALVES

To upgrade an existing pump to use the new single-solenoid

control valve, a new electrical service kit must rst be installed.

Refer to Table 1 for service kit model numbers and descriptions.

TABLE 1 - ELECTRICAL SERVICE KITS

Pump Voltage Service Kit

Model Number

Description

115V ZTERK-115 ZTW 115V Electrical

Service Kit

230V

NORTH AMERICA

ZTERK-230 ZTW 230V Electrical

Service Kit

230V CE

EUROPE AND ASIA (Contact Enerpac)

Each electrical service kit includes a new front electrical bracket,

middle electrical bracket and pendant. The pump's existing rear

electrical bracket is reused.

New single-solenoid control valves are available in various

voltages and congurations as described in Table 2.

TABLE 2 - CONTROL VALVE MODELS, SINGLE-SOLENOID

Pump

Voltage

Valve Model Description

115V VE42Q-115 115V 10,000 PSI [700 bar]

VE42QM-115 115V 10,000 PSI [700 bar]

- Multiport

VE42E-115 115V 11,600 PSI [800 bar]

VE42EM-115 115V 11,600 PSI [800 bar]

- Multiport

230V VE42Q-230 230V 10,000 PSI [700 bar]

VE42QM-230 230V 10,000 PSI [700 bar]

- Multiport

VE42E-230 230V 11,600 PSI [800 bar]

VE42EM-230 230V 11,600 PSI [800 bar]

- Multiport

Note: Control valves and electrical service kits must be ordered

separately.

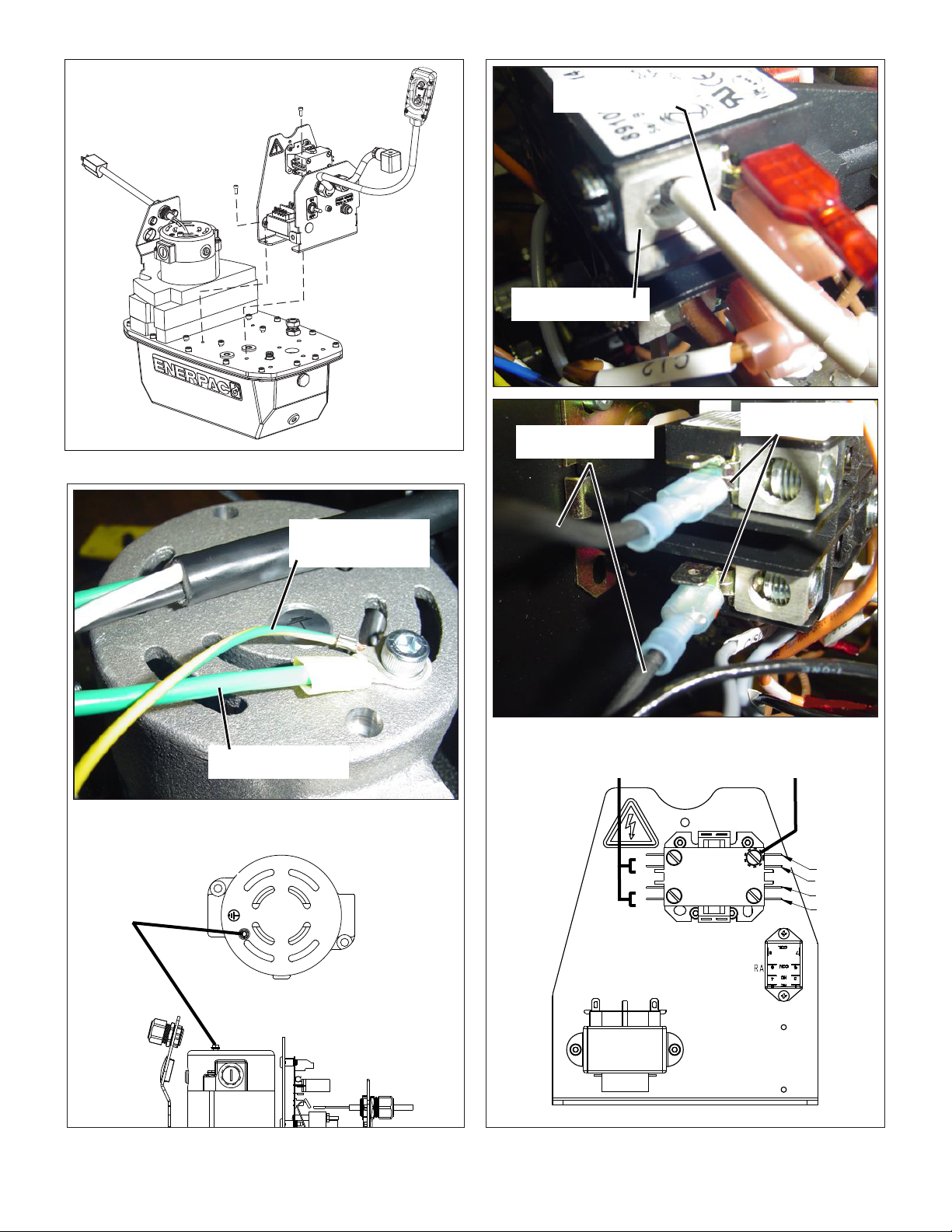

230 VOLT CE MODELS IMPORTANT NOTE

Consult your local Authorized Enerpac Service Center before

beginning electrical upgrade procedures on 230V pumps with

CE style electrical components. Power cord wire colors and

various other wiring details are dierent for 230V CE models.

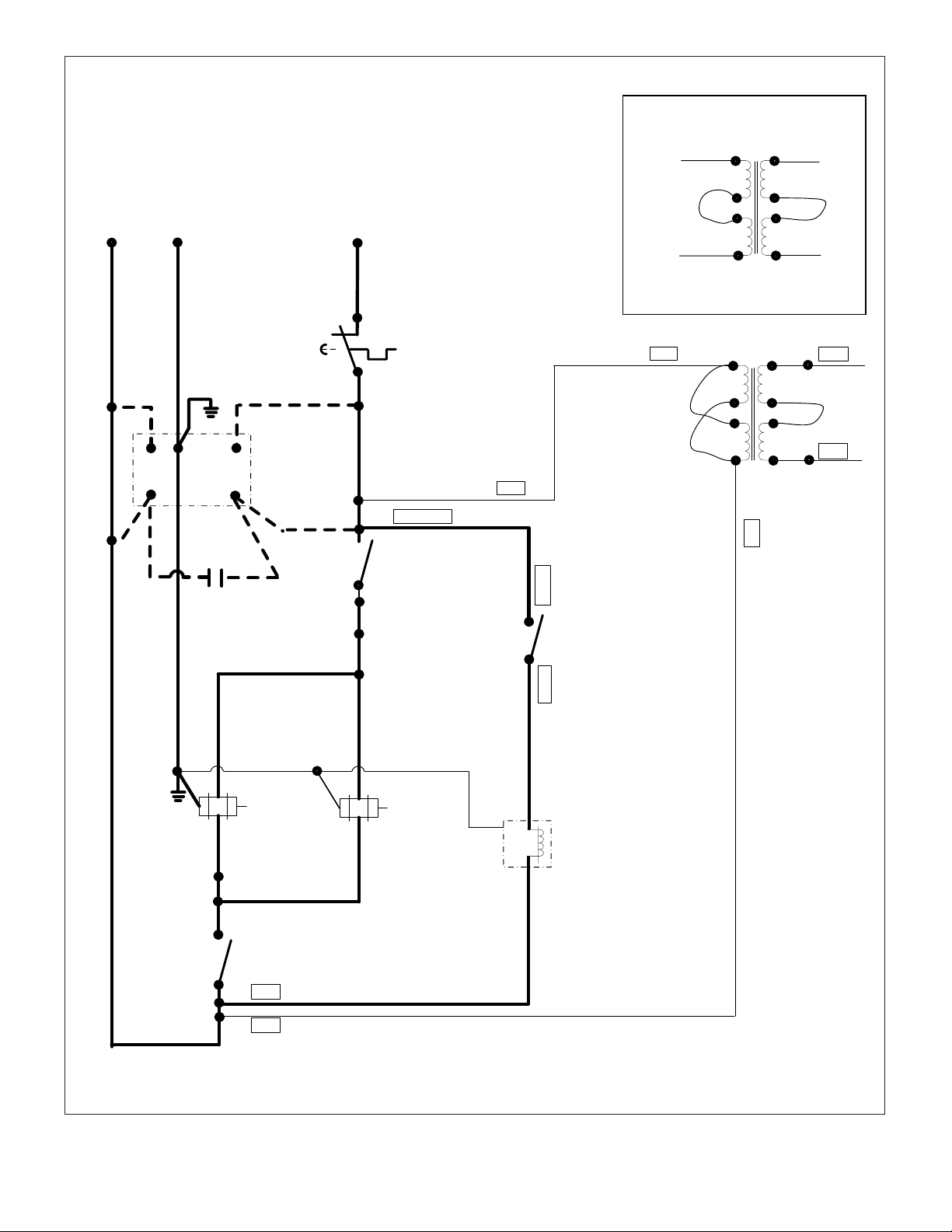

A complete wiring diagram covering all pump wiring

congurations and voltages - including 230V CE models - is

shown in Figure 14 of this document.

BEFORE YOU BEGIN

WARNING:

Disconnect power from pump before

beginning the following procedure. Be sure hydraulic

pressure is zero (0) psi/bar.

CAUTION:

Standard safety procedures are to be

followed during disassembly and reassembly to

minimize any possibility of injury.

CAUTION:

Allow only trained and qualied personnel

to perform the electrical wiring procedures described in

this document.

IMPORTANT: Some components on the new front and middle

brackets are pre-wired at the factory, prior to shipment Be

careful not to disturb wiring when unpacking the shipment or

during installation procedures.

Note: The graphics contained in this document are provided for

reference and instructional purposes only. Various pump features

and/or congurations may be dierent than shown for your pump.

Optional features may be shown that are not present on your pump.

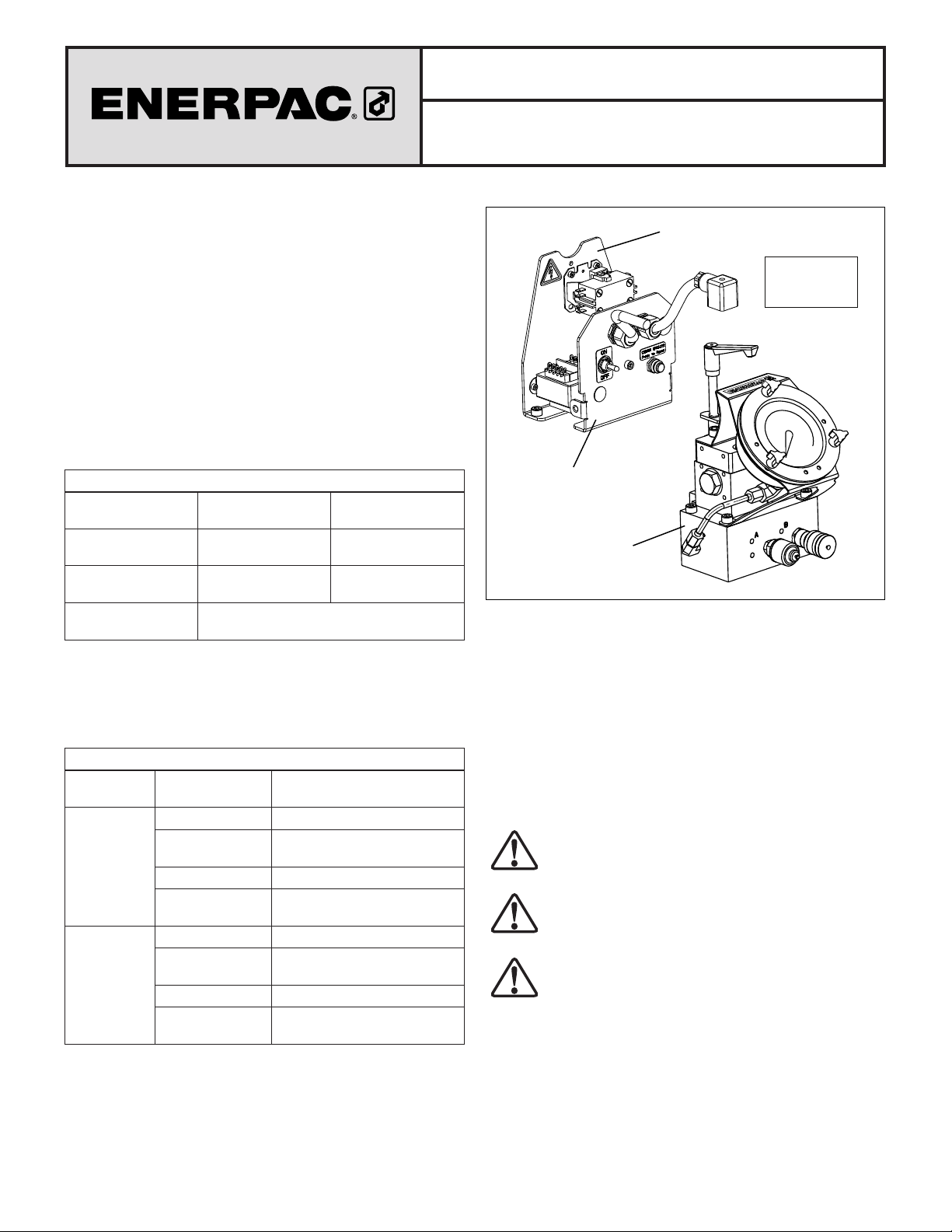

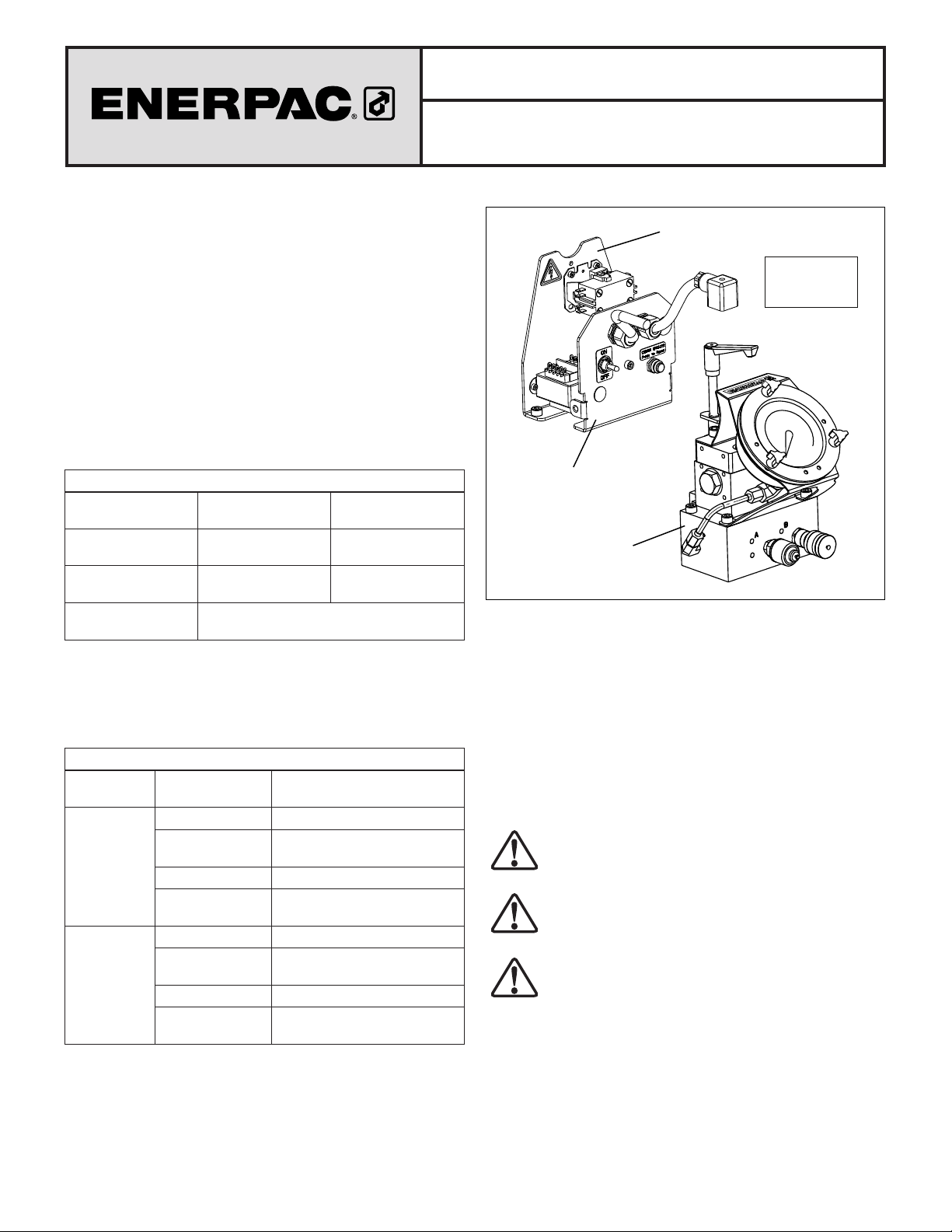

Figure 1, New Components (typical)

L2915 Rev. B 08/22

*

Middle Bracket*

VE Series Control

Valve Assembly

(single-solenoid)

Included with

Electrical

Service Kit

*

Front Bracket

and Pendant

(not shown)