Enersol MFLR09 User manual

User Manual

MFLR09 | Energy Meter

Table of Contents

1. Family Overview..........................................................................................3

2. Safety Precautions......................................................................................4

3. Enersol Toroidal Meters - Key things to consider........................................5

4. Technical details..........................................................................................6

Ordering Code.................................................................................7

5. List of parameters........................................................................................8

6. Validating parameters..................................................................................9

7. Parameter Description................................................................................10

7.1 Power...............................................................................................10

7.2 Energy..............................................................................................10

7.3 Power factor.....................................................................................11

7.4 Ampere.............................................................................................11

7.5 RPM.................................................................................................12

7.6 Energy Reset...................................................................................12

7.7 Meter Run Hours..............................................................................13

7.8 Power ON Hours..............................................................................13

7.9 Power Interruptions..........................................................................13

7.10 Diagnosis........................................................................................14

8. Interface and Input terminals.......................................................................17

8.1 Meter Front......................................................................................17

8.1.1 Screen Description.............................................................18

8.2 Meter Back Terminals......................................................................19

9. Display Manual............................................................................................20

10. Programming Guide...................................................................................23

11. Connection Diagram...................................................................................24

12. Enersol Current Transformer......................................................................25

13. MODBUS RTU...........................................................................................26

14 MODBUS register mapping.........................................................................28

Page 3

MFLR09 Family

Enersol MFLR09 is Multi-Function meter. It is easy

to operate and monitor basic electric parameters.

A Meter With Always ON Energy Display

Along with all basic electric parameters, MFLR09

family measures active, reactive as well as

apparent power/Energy, site configurable, which

makes it a perfect fit for majority of applications.

Meter Comes with optional RS485 capability for

IOT applications. User can access the device

remotely with ease.

1. Bright and easy to read 16x2 LCD display with

blue back light and white text.

2. All basic electric parameter along with Active,

reactive, apparent power/Energy (only one at

a time, site configurable).

3. Direct sense load till 60 Ampere with Enersol

CTs.

4. Site configurable for Star (3 Phase 4 wire), Delta

(3 Phase 3 Wire) and Single phase.

5. A meter with always ON energy display.

6. Optional RS485 over serial line for IOT based applications.

7. Meter configurable parameters are password protected to avoid unauthorized

access.

Meter Features

123 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

Voltage inputs 80 = 480VAC LL

Current Input: 50mA to 60A

Ph N

Aux. Sup.

90-300V, 2VA RS485

DANGER

Turn off power before working

R CT Y CT B CT RS485

V1 V2 V3 Vn +

-

1. Family Overview

2. Safety precautions

!

A voltage level of 415 volts is present at the meter

back side which can be lethal, Improper handling

can cause series injuries or death.

Before operating, it is advised to be friendly with the metering

and electrical devices basics.

Below are few things that one should follow to operate on

the meter

1. It is advised to always use skilled technicians to operate/

install the meter.

2. Always use complete personal protection equipments

before handing / operating / installing / maintaining any

electrical and electronic device.

3. A voltage level of 415 present at the back of the meter

terminals, so always turn off the meter and disconnect

all live wires before start working.

4. Never forcefully insert conductive materials like live wire

inside meter body, it can cause personal damage as well

Page 4

X

3. Enersol Toroidal Meters - Key things to consider

Page 5

123 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

Voltage inputs 80 - 480VAC LL

Current Input: 50mA to 60A

Ph N

Aux. Sup.

90-300V, 2VA RS485

R CT Y CT B CT RS485

V1 V2 V3 Vn +

-

Turn off power before working DANGER

CT Shorting Block

+

1. Never Connect CTs of this

toroidal meter to the electric

earth or any other earth

connection.

2. Never short S2 of all CTs. Use only

Enersol recommenced connection

diagram while making connections.

3. Never connect /5 CT

with toroidal meter.

4. *Always use Enersol

toroidal CTs provided

with the meter.

*Actual product may be some what different than shown in the image.

5. All Enersol Toroidal meters

are written with

50mA to 60A

at the meter back

+

123 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

Voltage inputs 80 = 480VAC LL

Current Input: 50mA to 60A

Ph N

Aux. Sup.

90-300V, 2VA RS485

DANGER

Turn off power before working

R CT Y CT B CT RS485

V1 V2 V3 Vn +

-

70mm

89.5mm

89.5mm

R

Y

B

ND+ D-

RS485

Auxiliary

Supply

Ph N

12345678

14131211109 16

15

Relay -1 (NO)

Dg

+-

24V

230V

Ph N

Relay -2 (NO)

General

Instantaneous Values

Electric Characteristics: Input voltage

Electric Characteristics: Input Current

Display

Site Configuration

Direct sense loads up to 60A. No /5 CT requirements

Range

Nominal Voltage

45VLL to 550VLL (if PT ratio is 1 else depends upon PT ratio)

240VLN/415VLL

Range

Suppression currrent

Nominal Current 5Amp

<10mA

From 10mA to 60A.

Easy to read LCD display consisting of 2 rows and 16 characters in each row with Blue back light and white text.

Network

Selected Energy keeps on showing at second row while scrolling (While at summary page).

Load Type

Port Settings

PT Ratio

CT Ratio

User can configure the meter for the following connection configurations

1. Single: For single phase configuration.

2. Star: For 3 phase 4 wire systems (3 phase 1 neutral wire).

3. Delta: For 3 phase 3 wire configuration (3 phase wire).

Meter can be configured to display either Active or Reactive or Apparent Energy/Power

On site configurable port settings

1. Slave ID: from 1 to 247.

2. Baud: From 1200 to 38400

3. Parity: None, Even, Odd

On site configurable from 0.001 to 9999

Not Configurable.

True RMS Current. Measures average & per phase current. Including up to 15th harmonic component.

True total and per phase PF measurement along with Load type indication (Capacitive & Inductive load).

Total and per phase Active, Apparent & Reactive power (only one at a time. Site configurable)

Available in accuracy class 1 and 0.5.

Current

Impedance >= 5 MOhms

50/60Hz ±5%. ( Only Factory Configurable ).

50/60Hz ±5%

Available with and without port.

Power Factor

Frequency Range

Frequency Range

Available in 3 phase or in single phase configuration.

Power

VA Burden <0.2 VA at 240 V AC L-N

4. Technical Details

Page 6

Electric Characteristics: Auxiliary Supply

Operating Range

Nominal Voltage

90 to 300VAC/DC

240V

50/60Hz ±5%

Frequency Range

VA Burden <5VA

Frequency

Meter can operate on both 50 & 60Hz system. But this setting is factory configurable only.

Certifications

Immunity to fast transients

Immunity to impulse waves

Accuracy Tests

IEC 61000-4-4

IEC 61000-4-5

IEC 62053-21 for Class 1

IEC 62053-22 for Class 0.5

Mechanical Characteristics - weight

Communication (optional)

Calibration

Auto Page Save Feature

Ordering Codes

With 60Amp CT

MODBUS RTU over serial Line (RS-485), along with communication status LED.

Calibration LED to validate meter total KWh accuracy. Factory default meter constant is 1600 pulse/Kwh

Meter will automatically load the same page which it was displaying just before the power cut.

MFLR0905, 60A, 1ɸ

MFL0905, 60A, 1ɸ

MFLR0910, 60A, 1ɸ

MFL0910, 60A, 1ɸ

MFLR0905, 60A, 3ɸ

MFL0905, 60A, 3ɸ

MFLR0910, 60A, 3ɸ

MFL0910, 60A, 3ɸ

MFLR09 meter ( with RS485 port) / Class 0.5 / 60Amp Current rating / Single Phase Configuration.

MFL09 meter ( without RS485 port) / Class 0.5 / 60Amp Current rating / Single Phase Configuration.

MFLR09 meter ( with RS485 port) / Class 1 / 60Amp Current rating / Single Phase Configuration.

MFL09 meter ( without RS485 port) / Class 1 / 60Amp Current rating / Single Phase Configuration.

MFLR09 meter ( with RS485 port) / Class 0.5 / 60Amp Current rating / 3 Phase Configuration.

MFL09 meter ( without RS485 port) / Class 0.5 / 60Amp Current rating / 3 Phase Configuration.

MFLR09 meter ( with RS485 port) / Class 1 / 60Amp Current rating / 3 Phase Configuration.

MFL09 meter ( without RS485 port) / Class 1 / 60Amp Current rating / 3 Phase Configuration.

520 Grams (1.1464 lbs), Including 3 nos 60 Ampere CTs.

Page 7

Display Update

Integrated Values

Instantaneous Values 1 Sec

1 secs

Page 8

5. List of parameters

S.No. Parameter Description

1. Ampere Meter calculate phase wise as well as average Ampere.

Avg Ampere = (IR + IY + IB) / 3 (in case of Star/delta)

OR Avg Ampere = IR (In case of Single Phase)

2. *Watt Meter calculate phase wise as well as Total watt.

Total watt = WR + WY + WB

3. *VAR Meter calculate phase wise as well as Total VAR.

Total VAR = VAR_R + VAR_Y + VAR_B

4. *VA Meter calculate phase wise as well as Total VA.

Total VA =

5. PF Meter calculate phase wise as well as Total PF.

6 DG RPM Meter calculate DG RPM.

7. *Energy Meter calculate all 3 energies i.e. Wh, VArH & VAh

only one available at a particular time.

8. Run Hours Meter calculate Run hours i.e. total time for which

a non-zero current flow through the meter CTs.

It describes, for how much time meter operate under

load condition.

9. Meter On Hours It describes, for how much time meter was ON.

10. Power Intr. I describes how many times auxiliary supply has been

interrupted.

11. Old Intg Para Old Integrated parameters. After manual clearing or

of overflow, integrated value get store in old integrated

parameters before reset.

* Only one type of Power/Energy available at a time

W + VAr

22

tot tot

1. Watt Estimation (W):

(Only applicable when voltage and current have pure sinusoidal waveform. This formula

can only be used for approximation. This formula doesn't consider the effect of harmonics,

spikes, surges, sag & swell )

R Phase watt = R Phase Voltage x R Phase Current x R Phase PF

Y Phase watt = Y Phase Voltage x Y Phase Current x Y Phase PF

B Phase watt = B Phase Voltage x B Phase Current x B Phase PF

Total Watt = Absolute value of R Phase watt + Absolute value of Y Phase watt + Absolute

value of B Phase watt

*if watt of a particular phase is showing negative, that means CT of that phase is

in reverse direction.

2. VAR Estimation:

(Only applicable when voltage and current have pure sinusoidal waveform. This formula

can only be used for approximation. This formula doesn't consider the effect of harmonics,

spikes, surges, sag & swell )

R Phase VAR = R Phase Voltage x R Phase Current x Sin(cos (R Phase PF))

Y Phase VAR = Y Phase Voltage x Y Phase Current x Sin(cos (R Phase PF))

B Phase VAR = B Phase Voltage x B Phase Current x Sin(cos (R Phase PF))

Total VAR = R Phase VAR + Y Phase VAR + B Phase VAR

3. VA Estimation

(Only applicable when voltage and current have pure sinusoidal waveform. This formula

can only be used for approximation. This formula doesn't consider the effect of harmonics,

spikes, surges, sag & swell )

R Phase VA = R Phase Voltage x R Phase Current

Y Phase VA = Y Phase Voltage x Y Phase Current

B Phase VA = B Phase Voltage x B Phase Current

Total VA =

4. Estimation of Wh (Active Energy):

To approximate the energy, apply a constant load to the meter. Say 2 Kilowatt. We can say if a

constant load of 2 KW flow via meter, then after 1-hour meter will calculate 2.000 KWh (i.e. unit). Formula

for same is shown below

KWh (for a specified time) = Kw x t , where t is time in hours

For ex:- If watt = 2Kilowatt and suppose we want to calculate energy for 30 mins (0.5Hours), then

Kwh (for 30 mins) = 2 * 0.5 = 1Kwh (Similarly, KVAh and KVARh can be calculated)

4. List of parameters6. Validating Parameters

Page 9

W + VAr

22

tot tot

4. List of parameters

LCD

Series

ENERSOL MFLR09

PROG

COM

Tot: 1.79KW

0002504.3KWh

To validate the energy, meter has

calibration LED, this LED blinks 1600

times per Kwh.

A Meter Test equipment read this pulses

via an optical sensor and calculate the

% error in energy.

Calibration LED

-1

-1

-1

7. Parameter Description

Page 10

7.1 Power: Meter can either display W or VA or VAR (total and phase wise) one at a

time. This is site configurable. Refer to programming manual on how to

change load type.

Power will auto scale on the display and “K” or “M” will display accordingly

to represent the power in Kilo or Mega (depending upon load).

7.2 Energy: Meter can either display Kwh or KVAh or KVARh (total and phase wise)

one at a time. This is site configurable. Refer to programming manual on

how to change load type. Below are some sample screens.

Energy will reset to zero in 2 cases;-

a.) Energy Overflow: Meter caluculate energy till 42 Lakhs, after that it reset to zero.

b.) Manual Reset;- User can manually reset the energy in the programming mode.

In both cases, meter will automatically save the energy to old integrated parameters

before clearing.

LCD

LCD

LCD

LCD

LCD

Series

Series

Series

Series

Series

ENERSOL

ENERSOL

ENERSOL

ENERSOL

ENERSOL

MFLR09

MFLR09

MFLR09

MFLR09

MFLR09

PROG

PROG

PROG

PROG

PROG

COM

COM

COM

COM

COM

Watt: r-1.12K VAR: r-1.12K

VA: r1120

Tot: 3.59KVA Tot: 3.12KVAR

LCD

Series

ENERSOL MFLR09

PROG

COM

Tot: 1.79KW

0002504.3KWh

y1.12K b1.12K y1.12K b1.12K

y1112 b1120

0003904.3KVAh 0003504.3KVARh

Row 1: Total Watt. Display

reads as total 1.79 Kilo watt.

Row 2: Total KWh. Display

Reads as 2504.3 Kwh or

2504.3 units of active energy.

Row 1: Phase wise watt. Display

reads as R phase = -1.12 Kilo watt.

negative value means CT is installed

in reverse direction.

Row 2: Display reads as

Y phase = 1.12 Kilo watt

B phase = 1.12 Kilo watt

Row 1: Phase wise VAR. Display

reads as R phase = -1.12 Kilo VAR.

Row 2: Display reads as

Y phase = 1.12 Kilo VAR

B phase = 1.12 Kilo VAR

Row 1: Phase wise VA. Display

reads as R phase = 1120 VA

Row 2: Display reads as

Y phase = 1112 VA

B phase = 1120 VA

Row 1: Total VA . Display

reads as total 3.59KVA.

Row 2: Total KVAh. Display

Reads as 3904.3 KVA or

3904.3 units of apparent energy.

Row 1: Total VAR. Display

reads as total 3.12KVAR.

Row 2: Total KVARh. Display

Reads as 3504.3 KVArh or

3904.3 units of Reactive energy.

Page 11

7.3 Power Factor: Meter display Power factor along with load type indication. Meter

is capable to display both total as well as phase wise power factor

PF consists of 2 things, one is magnitude and second one is load

type. for example if meter is showing 0.855L that means PF

magnitude is 0.855 and load type is inductive. Below are some

sample screens.

At RS485 port, PF will be shown as below:

if PF IS 0.894L (Inductive load) then at port we get 0.894

if PF IS 0.894C (Capacitive load) then at port we get -0.894

7.4 Ampere: Meter can display average as well as phase wise ampere. Average

ampere is given by

in case of star and delta, Iavg = IR + IY + IB

3

In case of single phase, Iavg = IR

LCD LCD

LCD

Series Series

Series

ENERSOL ENERSOL

ENERSOL

MFLR09 MFLR09

MFLR09

PROG PROG

PROG

COM COM

COM

Tot: 0.855L PF PF: r0.855L

Amp: r5.000

0002504.3KWh

LCD

Series

ENERSOL MFLR09

PROG

COM

Avg: 4.978 Amp

0002504.3KWh

y0.869C b0.954L

y4.978 b4.785

Row 1: Total PF. Display

reads as total PF is 0.855

and load type inductive.

Row 2: Total KWh. Display

Reads as 2504.3 Kwh or

2504.3 units of active energy.

Row 1: Average Ampere. Display

reads as avg. ampere is 4.978

Row 2: Total KWh. Display

Reads as 2504.3 Kwh or

2504.3 units of active energy.

Row 1: Phase wise PF . Display

reads as

R Phase PF = 0.855 (Inductive Load)

Row 2: Display read as

Y Phase PF = 0.869 (Capacitive Load)

B Phase PF = 0.954 (Inductive Load)

Row 1: Phase wise Amp . Display

reads as

R Phase Amp = 5.000

Row 2: Display read as

Y Phase Amp = 4.978

B Phase Amp = 4.785

7.5 RPM: Meter can calculate DG RPM. User can configure the number of poles

DG have, on the meter. Below is sample screen.

7.6 Energy Reset: Energy reset means Kwh or KVAh or KVArh (for which meter is

configured) reset to zero. it can happen due to following reason.

a.) Manually resetting/clearing energy by the operator

(refer to programming manual on how to clear energy)

b.) Due to energy register overflow (after 42 Lakhs).

in both cases, value got stored to Old parameters before

clearing the energy register.

LCD

LCD

LCD

LCD

LCD

Series

Series

Series

Series

Series

ENERSOL

ENERSOL

ENERSOL

ENERSOL

ENERSOL

MFLR09

MFLR09

MFLR09

MFLR09

MFLR09

PROG

PROG

PROG

PROG

PROG

COM

COM

COM

COM

COM

RPM:

Total:

Total:

Last Total Kwh:

Last Total Kwh:

1500

0000549.1 Kwh

0000549.1 Kwh

00000000.0 Kwh

00000000.0 Kwh

Row 1: DG RPM

Row 2: DG RPM = 1500

Display Reads as total Kwh is 549.1

Display Reads as total Kwh is 0

Display Reads as energy before last

clear operation was 0 Kwh

Display Reads as energy before last

clear operation was 549.1 Kwh

Page 12

Before

clearing

After

clearing

7.7 Meter Run Hours: It calculates for how much total time meter was under load

condition. Below sample display reads as

Total Meter Run Hours: 0 hours 33 Minutes 43 Seconds

7.8 Power ON Hours: It calculates for how much total time meter was ON. Below

sample display reads as

Total Power ON Hours: 26 Hours 45 Minutes 50 Seconds

7.9 Power Interruptions: It calculates for many times auxiliary supply interrupted.

Below sample display shows increment in the power

interruptions before and after auxiliary power interruptions.

LCD

LCD

LCD LCD

Series

Series

Series Series

ENERSOL

ENERSOL

ENERSOL ENERSOL

MFLR09

MFLR09

MFLR09 MFLR09

PROG

PROG

PROG PROG

COM

COM

COM COM

Run Hours:

Power ON Hours:

Power Intr: Power Intr:

00000000:33:43

00000026:45:50

0006 0007

Row 1: Run Hours

Row 2: Total Meter Run Hours

(HHHHHHHH:MM:SS)

Row 1: Power ON hours.

Row 2: Total Power ON Hours

(HHHHHHHH:MM:SS)

Row 1: Power interruptions

Row 2: value of power interruptions

(After auxiliary power

interruption)

Row 1: Power interruptions

Row 2: value of power interruptions

Page 13

Seconds

Seconds

Minutes

Minutes

Hours

Hours

Page 14

7.10. Diagnosis: Site engineer can diagnose voltage, Current transformer connection

& phase sequence.

a.) Voltage Diagnosis: Site engineer can check whether voltage

is present at voltage input or not. if voltage

is below 45 VLL or 25 VLN, meter will read it

as no voltage.

Reasons for Voltage not present:

a.) Loose connections

b.) Wire break.

c.) Phase missing from the source.

d.) Fuse connected at input voltage might got blown off.

LCD

Series

ENERSOL MFLR09

PROG

COM

V RV: No

YV: Yes BV:Yes

Input voltage connection is at terminal

10, 11 & 12 (13 for neutral).

if voltage present only at Y and B

terminal, than display will be shown

like this.

Sample Display read as

R Voltage - No connected

Y Voltage - Connected & greater than 25 VLN.

B Voltage - Connected & greater than 25 VLN. 1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

Voltage inputs 80 = 480VAC LL

Voltage inputs 80 = 480VAC LL

Current Input: 50mA to 60A

Current Input: 50mA to 60A

Ph N

Ph N

Aux. Sup.

90-300V, 2VA

Aux. Sup.

90-300V, 2VA

RS485

RS485

DANGER

DANGER

Turn off power before working

Turn off power before working

R CT

R CT

Y CT

Y CT

B CT

B CT

RS485

RS485

V1 V2 V3 Vn

V1 V2 V3 Vn

+

+

-

-

R

Voltage

B

Voltage

Y

Voltage

a.) CT Connections: Site engineer can check whether CT is

connected in correct direction or in reverse

direction

Q: What is P1 and S1, S2 in CT label ?

A: P1 is a label on the CT, which assist us in mounting the

CT in correct orientation. The face of CT where P1 is

written, must be facing toward line side or source side.

S1 and S2 are the secondary wire of CT. MFLR09 whole

current meter comes with 60 Amp CT. The black wire of

CT is S1 and Red wire is S2. Black wire must be connected

to terminal with black rectangle at meter back side as

shown

123 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

Voltage inputs 80 = 480VAC LL

Current Input: 50mA to 60A

Ph N

Aux. Sup.

90-300V, 2VA RS485

DANGER

Turn off power before working

R CT Y CT B CT RS485

V1 V2 V3 Vn +

-

Black Wire

of R Phase

CT

Black Wire

of B Phase

CT

Black Wire

of Y Phase

CT

Red Wire

of R Phase

CT

Red Wire

of B Phase

CT

Red Wire

of Y Phase

CT

CT Black wire

indication.

Page 15

Q: What is meant by reverse CT connections ?

A: CT is said to be connected in reverse direction if

1. either P1 is facing towards load.

2. S2 (CT red Wire) is connected to the terminal

with rectangle.

Q: What if CT is connected in reverse direction?

A: If CT of a particular phase connected in reverse

direction, then

if load type is Active: Watt of that phase start showing

negative

if load type is Reactive: VAR power sign of that phase

get reverse.

if load type is Apparent: No Effect.

Q: Will reverse CT effect the total power and Energy?

A: No. Meter will internally correct the CT, if it is connected

in wrong direction. Total power and Energy will remains

unaffected.

Q: How meter notify the site engineer about CT direction ?

A: Meter reflect CT direction under diagnosis parameter.

following conditions must meet for meter to correctly

calculate CT direction

1. Current must be grater than 10mA (0.010A).

2. If voltage is connected in phase sequence R, Y & B

then, current should also be in R, Y & B sequence.

sample screen shown below.

Reasons for Voltage not present:

a.) Loose connections

b.) Wire break.

c.) Phase missing from the source.

d.) Fuse connected at input voltage might got blown off.

LCD

Series

ENERSOL MFLR09

PROG

COM

V RV: No

YV: Yes BV:Yes

Input voltage connection is at terminal

10, 11 & 12 (13 for neutral).

if voltage present only at Y and B

terminal, than display will be shown

like this.

Sample Display read as

R Voltage - No connected

Y Voltage - Connected & greater than

25 VLN.

B Voltage - Connected & greater than

25 VLN.

Sample Screen reads as

Row 1: No current (or less than

10mA) current is flowing via

CT of R Phase

Row 2: Y phase CT installed in

correct direction,

B Phase CT is installed in

reverse direction.

123 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

Voltage inputs 80 = 480VAC LL

Current Input: 50mA to 60A

Ph N

Aux. Sup.

90-300V, 2VA RS485

DANGER

Turn off power before working

R CT Y CT B CT RS485

V1 V2 V3 Vn +

-

123

R CT

CT Black wire

indication.

LCD

Series

ENERSOL MFLR09

PROG

COM

I rCT: NL

yCT:CR bCT: RE

a.) Phase Sequence: Site engineer can check the phase sequence

of input voltage supply. Meter consider

10th terminal as reference. For correctly

measurement of phase sequence following

condition must meet

1. R Phase voltage input must be connected

at 10th terminal of the meter.

2. In case of delta configuration, All of 3

phase must be connected.

Sample screen for some possibilities is

depicted below

Let it be a case of star (3P4W) configuration. As seen

from the connections, phase sequence is R, B & Y. This

same thing can be seen on display under diagnosis

para meters, As seen in sample screen, phase

sequence is R B Y. (R phase is not shown as it is

taken as reference.)

Let it be a case of delta (3P3W) configuration. As seen

from the connections, phase sequence is R, Y & B. This

same thing can be seen on display under diagnosis

para meters, As seen in sample screen, phase

sequence is R Y B. (R phase is not shown as it is

taken as reference.)

If network is configured as Single phase, then phase

sequence doesn’t matter and meter start showing

“----”.

123 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

Voltage inputs 80 = 480VAC LL

Current Input: 50mA to 60A

Ph N

Aux. Sup.

90-300V, 2VA RS485

DANGER

Turn off power before working

R CT Y CT B CT RS485

V1 V2 V3 Vn +

-

123 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

Voltage inputs 80 = 480VAC LL

Current Input: 50mA to 60A

Ph N

Aux. Sup.

90-300V, 2VA RS485

DANGER

Turn off power before working

R CT Y CT B CT RS485

V1 V2 V3 Vn +

-

123 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

Voltage inputs 80 = 480VAC LL

Current Input: 50mA to 60A

Ph N

Aux. Sup.

90-300V, 2VA RS485

DANGER

Turn off power before working

R CT Y CT B CT RS485

V1 V2 V3 Vn +

-

123 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

Voltage inputs 80 = 480VAC LL

Current Input: 50mA to 60A

Ph N

Aux. Sup.

90-300V, 2VA RS485

DANGER

Turn off power before working

R CT Y CT B CT RS485

V1 V2 V3 Vn +

-

Page 16

Must connect R phase Voltage

input at this terminal

LCD

LCD

LCD

Series

Series

Series

ENERSOL

ENERSOL

ENERSOL

MFLR09

MFLR09

MFLR09

PROG

PROG

PROG

COM

COM

COM

Phase Sq.: BPH

Phase Sq.: YPH

Phase Sq.: ---

YPH

BPH

---

LCD

Series

ENERSOL MFLR09

PROG

COM

Tot: 1.79KW

0002504.3KWh

ENERSOL

MFTR42

MVLN

VLL

W

A

VAR

PF

Hz

VA

M

M

K

K

K

R

Y

B

CAL

COM Wh

VArh VAh

PROG

Calibration LED

Up Button

Communication Status LED

Programming Button

Enter Button

Page Button

Down Button

6

7

9

8

10

5

4

Page 17

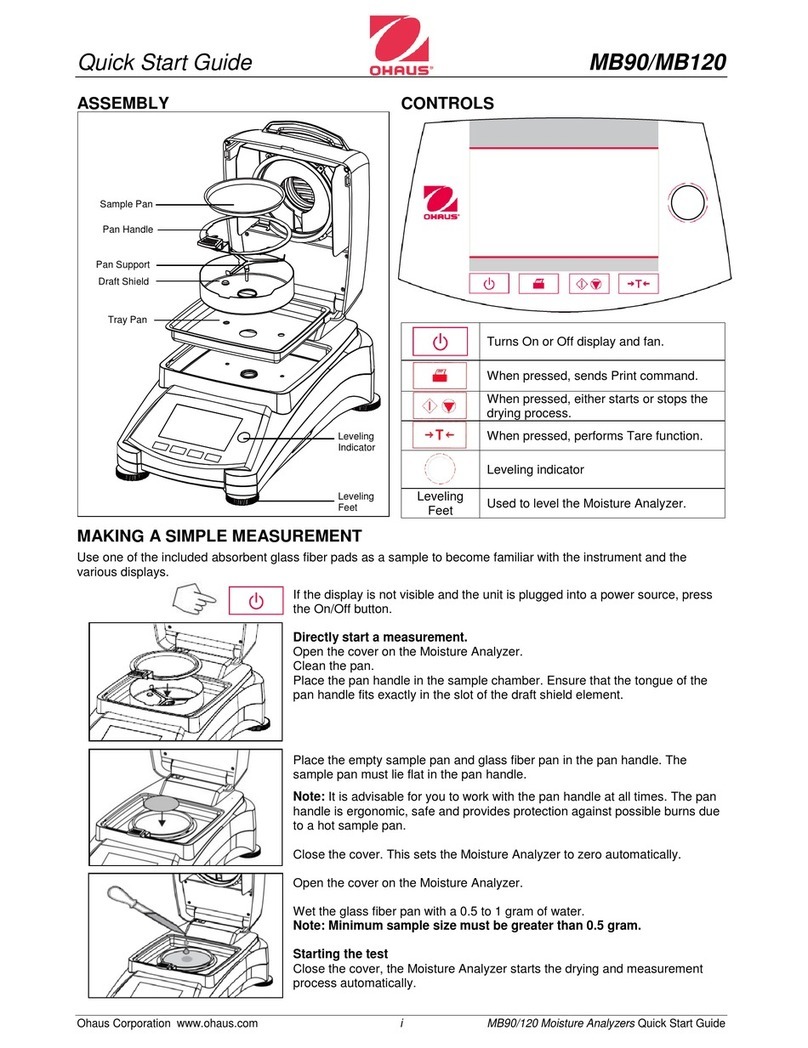

8. Interface & Input Terminals

8.1 Meter Front

Row 1

Meter Type

Row 2

2

1

3

1

3

4

5

6

8

9

10

7

2

# Display Functions Description

---- Meter Family Type

---- Row 1. It can display up to 16 characters (Alphabets, Numbers, special Characters)

---- Row 2. It can display up to 16 characters (Alphabets, Numbers, special Characters)

Enter Button.

Page Button, use for scrolling among available Electric parameter category.

Available Categories are:

1. Instant Parameters 2. Integrated Parameters. 3. Set Parameters.

4. Old Integrated Parameter. 6. Diagnosis.

Down Button, use for scrolling Electric parameter in Backward direction.

UP Button, long press (5 secs) for auto scrolling.

programming Button. Press both button simultaneously.

COM Communication LED. It will blink while responding to Client Query.

CAL LED for the Active Energy Calibration. Default meter constant is 1600Pulse/KWH

Page 18

8.1.1 Screen Description

+

Page 19

123 4 5 6 7 8 9

10 11 12 13 14 15 16 17 18

Voltage inputs 80 = 480VAC LL

Current Input: 50mA to 60A

Ph N

Aux. Sup.

90-300V, 2VA RS485

DANGER

Turn off power before working

R CT Y CT B CT RS485

V1 V2 V3 Vn +

-

Left Side Mounting Lock Right Side Mounting Lock

Terminal Numbering

Terminal Numbering

Input - R Phase Voltage

Input - R Phase CT Black Wire

Input - R Phase CT Red Wire

Input - Y Phase Voltage

Input - B Phase Voltage

Input - RS485 “+” wire

Input - Neutral (no connection in case of delta configuration)

Input - Aux. Supply Neutral

Input - Aux. Supply Phase

Input - RS485 “-” wire

Input - Y Phase CT Red Wire

Input - Y Phase CT Black Wire

Input - B Phase CT Red Wire

Input - B Phase CT Black Wire

8.2 Meter Back Terminals

Summary

Instant Parameters(Per Phase )

Press and then press to navigate to the page

Page 20

9. Display Manual

Tot Watt

Total Wh

Phase Wise

Amp

Tot VA

Total VAh

Phase wise

Amp

Tot VAR

Total VARh

Phase wise

Amp

Avg. Amp Tot. PF

Total Wh

Phase wise

PF

Total Wh

Phase wise

Watt RPM

Avg. Amp Tot. PF

Total VAh

Phase wise

PF

Total VAh

Phase wise

VA RPM

Avg. Amp Tot. PF

Total VARh

Phase wise

PF

Total VARh

Phase wise

VAR RPM

If load type

is Active.

If load

type is

Active.

If load type

is Apparent.

If load

type is

Apparent.

If load type

is Reactive.

If load

type is

Reactive.

Back to page

Back to page

Back to page

Back to page

Back to page

Back to page

Summary

Press and then press to navigate to the page

Tot Watt

Total Wh

Tot VA

Total VAh

Tot VAR

Total VARh

Avg. Amp Tot. PF

Total Wh Total Wh

Avg. Amp Tot. PF

Total VAh Total VAh

Avg. Amp Tot. PF

Total VARh Total VARh

If load type

is Active.

If load type

is Apparent.

If load type

is Reactive.

Back to page

Back to page

Back to page

This manual suits for next models

2

Table of contents

Popular Measuring Instrument manuals by other brands

Redback

Redback A 4567A manual

GE

GE Optica Operator's manual

Galvanic Applied Sciences

Galvanic Applied Sciences 943-TGS Operation manual

Clarion

Clarion Drive Eye manual

PCB Piezotronics

PCB Piezotronics IMI Sensors 625B61 Installation and operating manual

Screening Eagle

Screening Eagle Profometer PM8000 Pro user manual