Doc PS1398

Page 1

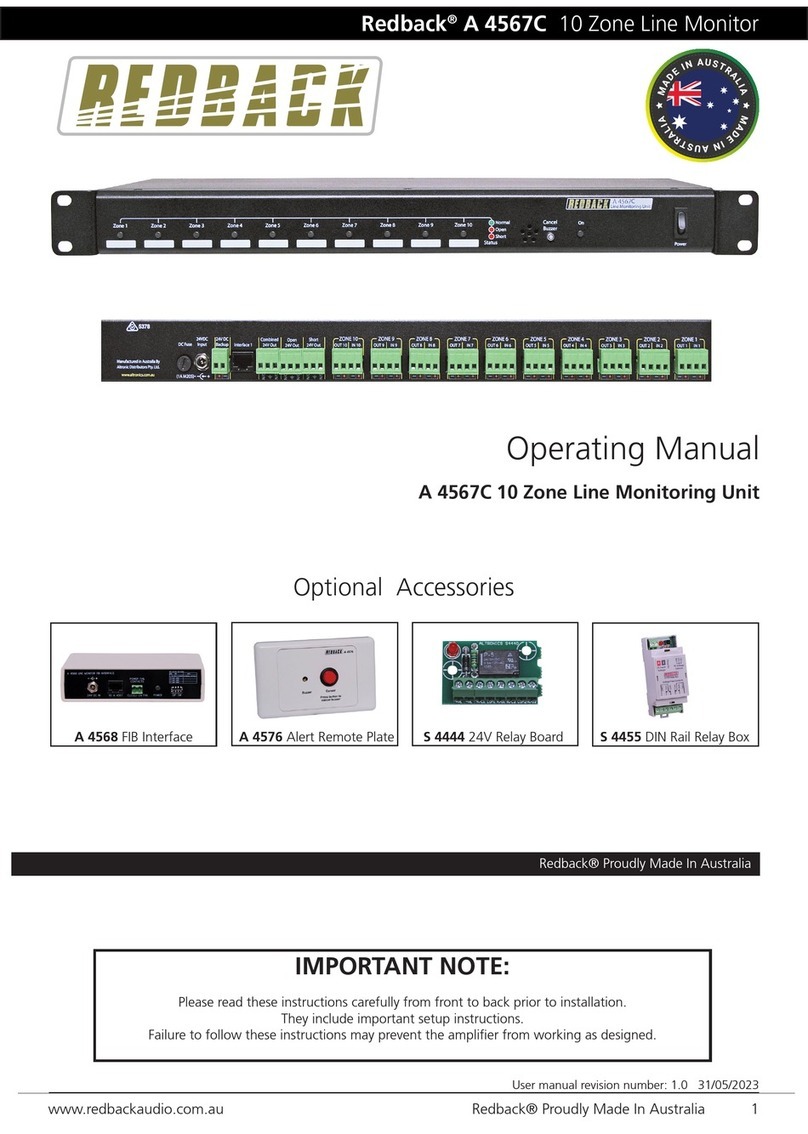

The A 4567A is a line monitoring unit or LMU. An

LMU monitors the condition of 100V PA speaker

lines and alerts you if there is a problem with the

wiring.

The A 4567A comes standard with ten separate

zones that have individual LEDs to indicate the

condition of the Line.

Features

• Up to 10 zones monitored

• LED’s to indicate condition of the Line

• Loud alert sound if there is a fault

• Separate rear outputs for the condition LED’s

Installing the A 4567A LMU

The A 4567A can be powered by a 240Vac or

24Vdc. Terminals on the rear are supplied for both.

Hook up the 100V PA amplifier/s to the inputs on

the rear. All the inputs are isolated from each other

so up to 10 amplifiers can be used or any

combination below that number e.g. one amplifier

connected to 2 or more inputs. NEVER connect 2 or

more amplifiers to one zone it will cause major

damage to the A 4567A and the amplifiers.

The output terminals can now be connected to

the speaker lines. A maximum of 500 Watts of load

per zone is allowed. Any more than this will damage

the A 4567A. Any number of 100V line transformer

/ speaker combinations can be used as long as the

total load for each zone is below 500 Watts.

Setting up the speaker runs so they work with the

A 4567A is as easy as installing a 22uf BP capacitor

at the input of each transformer / speaker (please

see figure 3). Install an end of line resistor or EOL at

the very end of the wiring run before the final

transformer / speaker. The end of line resistor must

be 100K Ohm in value and at least .25 Watt or

above. Unused outputs from the A 4567A need to

have a EOL resistor installed across positive and

negative terminals. If these are not installed the

A 4567A will bring up a fault condition for the non

EOL terminated zones.

Powering up the A 4567A

When the A 4567A is powered up the unit then

pauses for about 10 seconds to allow the protected

zones to be checked for the condition they are in.

If there is a fault the A 4567A will alert you with a

loud pulsing beep and the Cancel switch LED will

flash. A short on a zone is indicated on the front

panel by a red LED. An open condition on a zone

will be indicated on the front panel by a yellow LED.

If there are no faults detected, all zones will indicate

good condition with a green LED.

If the A 4567A goes into alarm mode and the

beeping is heard it can be stopped by pushing the

CANCEL button. The fault LED indicators will remain

on until the fault on the zone is corrected. Any new

fault conditions will result in the alarm tone

sounding again and the Cancel switch LED to flash.

From then on no matter how many times the

cancel button is pushed the A 4567A will go into

alarm mode any time there is a new fault condition

on any of the zones. The alarm will not sound again

if a zone goes from a fault (open or short) condition

to good condition.

Remote monitoring of faults

The fault status of the zones can be monitored

remotely by connecting an external buzzer or

warning light to 24Vdc switched outputs. There are

three switched outputs.

One for an open condition, another for a short

condition and a third for either a short or open

circuit condition (combined out). All three outputs

switch 24Vdc in either failsafe or normal mode.

Fault Finding

The A 4567A does not power up: Check that

power is applied to the unit either by a 240Vac or

an external 24V dc source.

Unit continues to go into alarm mode and emits

a loud continuous beep: Push the cancel button

and check the LED display. See which zone is

causing the problem (if all zones are showing

“normal” the buzzer will not sound continuously).

The SHORT LED is coming up on a zone: First

check and see if you have installed the 100K EOL

resistor at the end of the line and the 22uf BP

capacitors on each of the transformer / speakers

that are installed on that line (see Fig.3). If they are

all installed there must be a short across the line,

once removed the A 4567A will go into NORMAL.

The OPEN LED is coming up on a zone: First

check and see if you have installed the 100K EOL

Resistor at the end of the line and the 22uf BP

Capacitors on each of the transformer / speakers

that are installed on that line (see Fig 3.). If they are

all installed there must be a break in the line, once

this is removed the A 4567A will go into NORMAL.