1.Safety

1.1 Before Power On

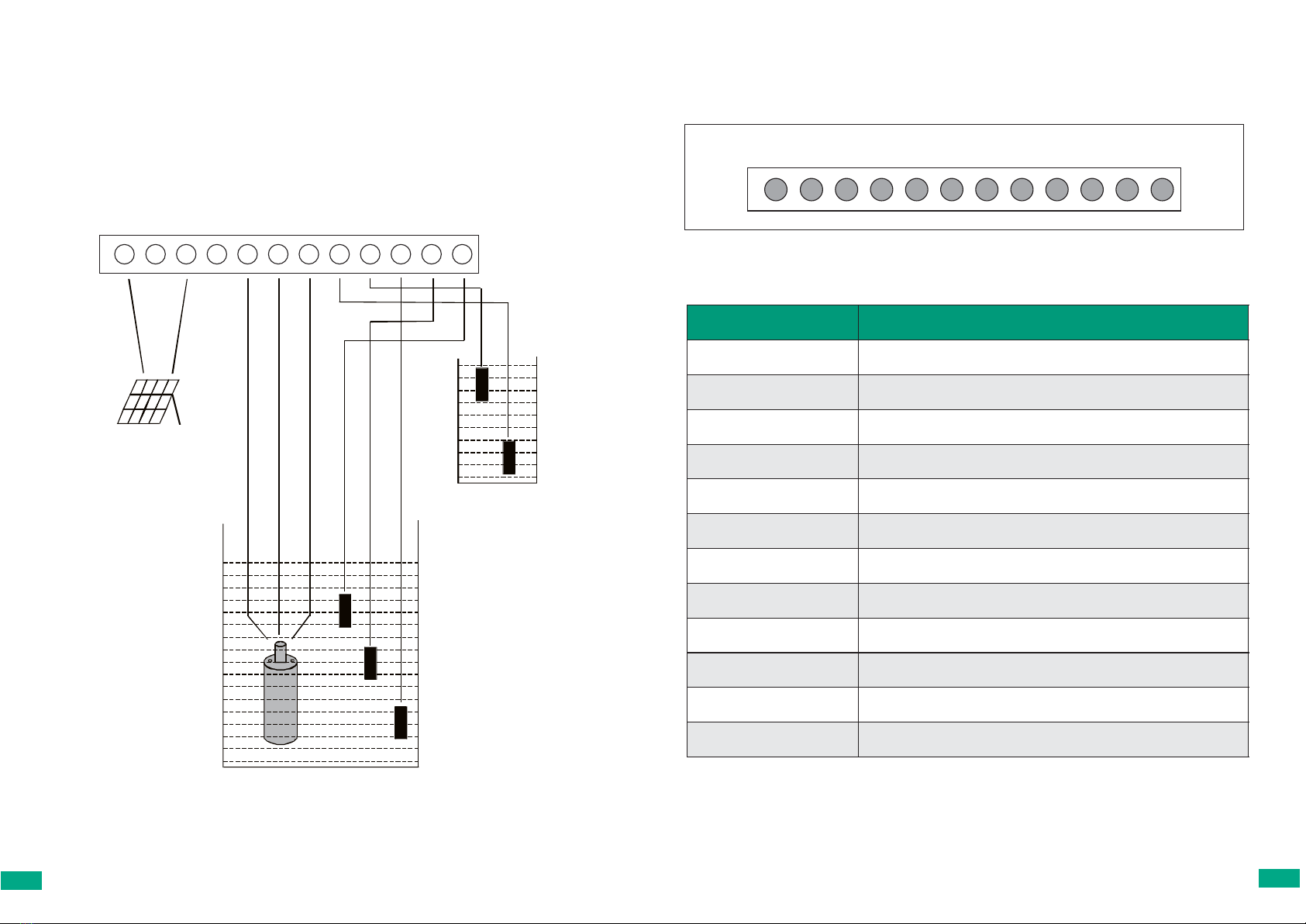

●Make sure the terminal wire connections are correct,“P+”、“P-”are for

panel connection,“1”、“2”、“3”for pump connection,wrong connection will

lead to controller damage.

●The voltage of panel system is not allowed to exceed the open-circuit

voltage of controller , avoid to use same power supply with strong

interference equipment , otherwise it will damage the controller.

●Match correct pump power with controller.

●Ensure the insulation of MOSFET and aluminum board during the

installation.

1.2 In running

●When the system is running,it is not allowed to disconnect the connection

between pump and controller,other wise it may damage the pump motor and

controller.

●When the system is running,do not tough or exam the The parts of the circuit

board or signal.

●Do not tough the radiator or any heat parts,in case of burns.

●Unprofessinal operators are not allowed to operate or exam the controller.

2.Technical Specification

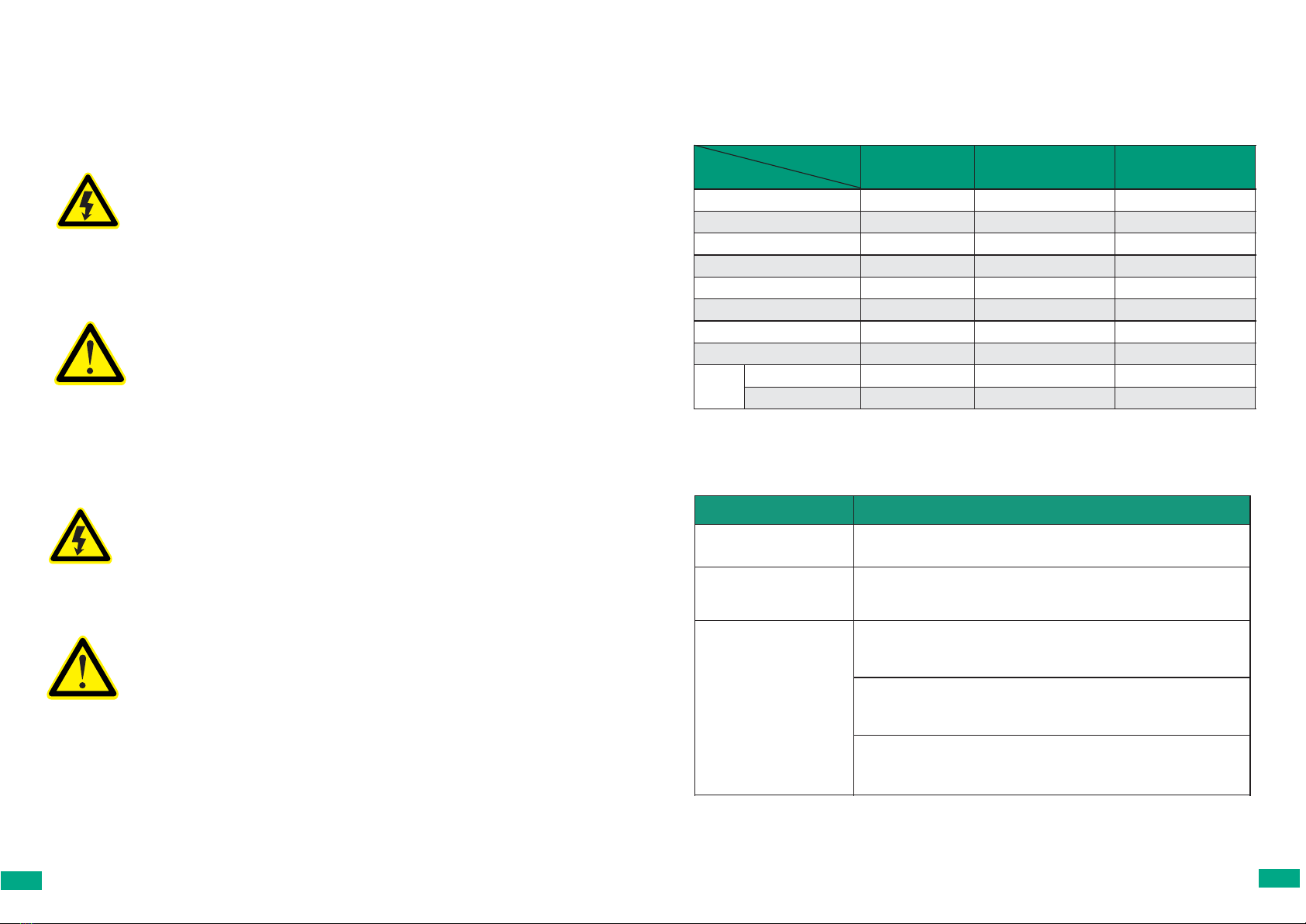

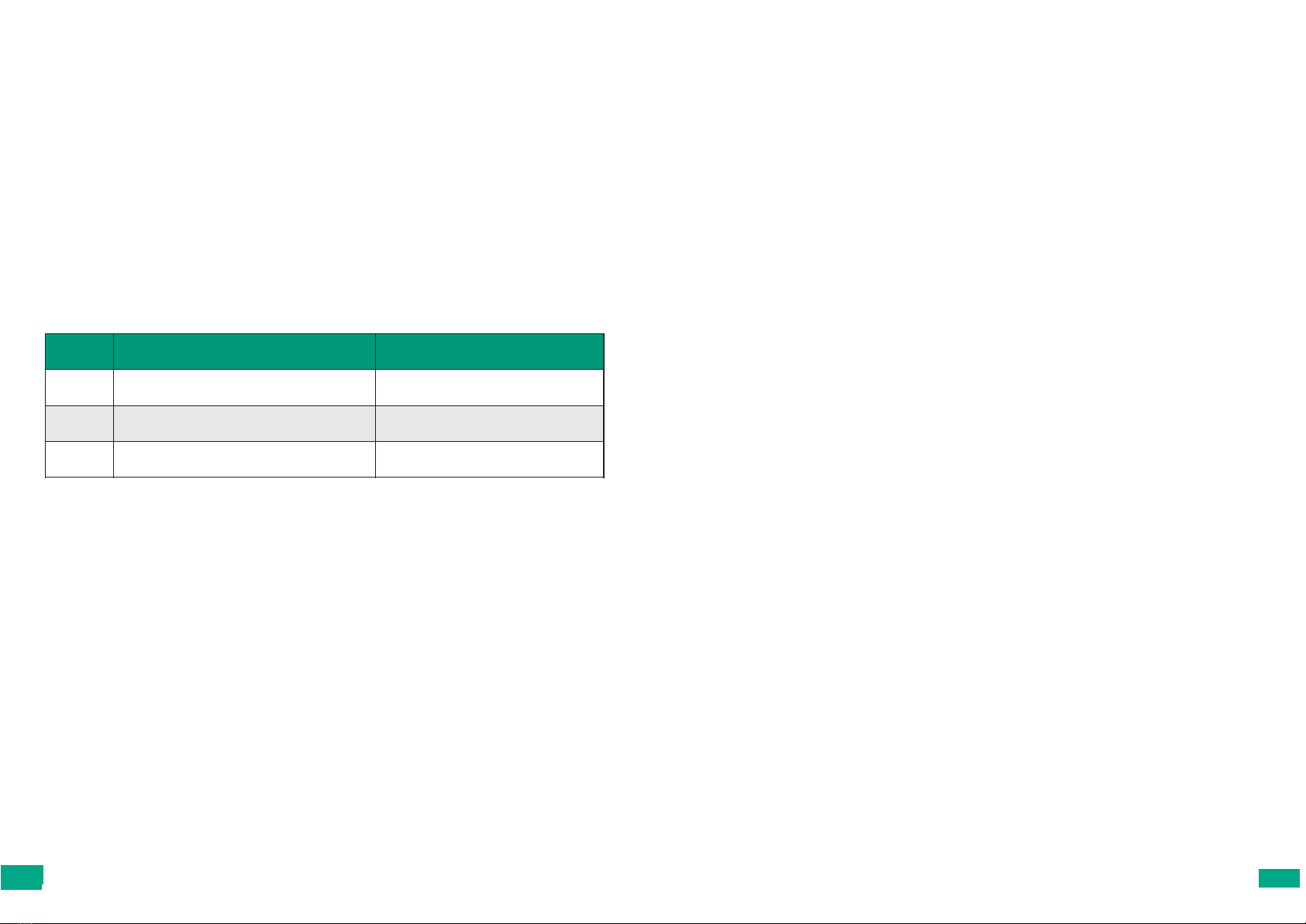

Table 1 Specification

150V 220V 300V

Rated Voltage 150VDC 220VDC 300VDC

Rated Current 10A 10A 10A

Max working Current 12A 12A 12A

Min working Current 1.3A 1.3A 1.3A

Open circuit voltage input >170VDC >272VDC >340VDC

Open circuit voltage Max 250VDC 350VDC 450VDC

Open circuit voltage Min 90VDC 150VDC 220VDC

Max Power 1.5KW 2.2KW 3KW

Current

Overload 15±0.5A 15±0.5A 15±0.5A

Over current 32±0.5A 32±0.5A 32±0.5A

Model

Specification

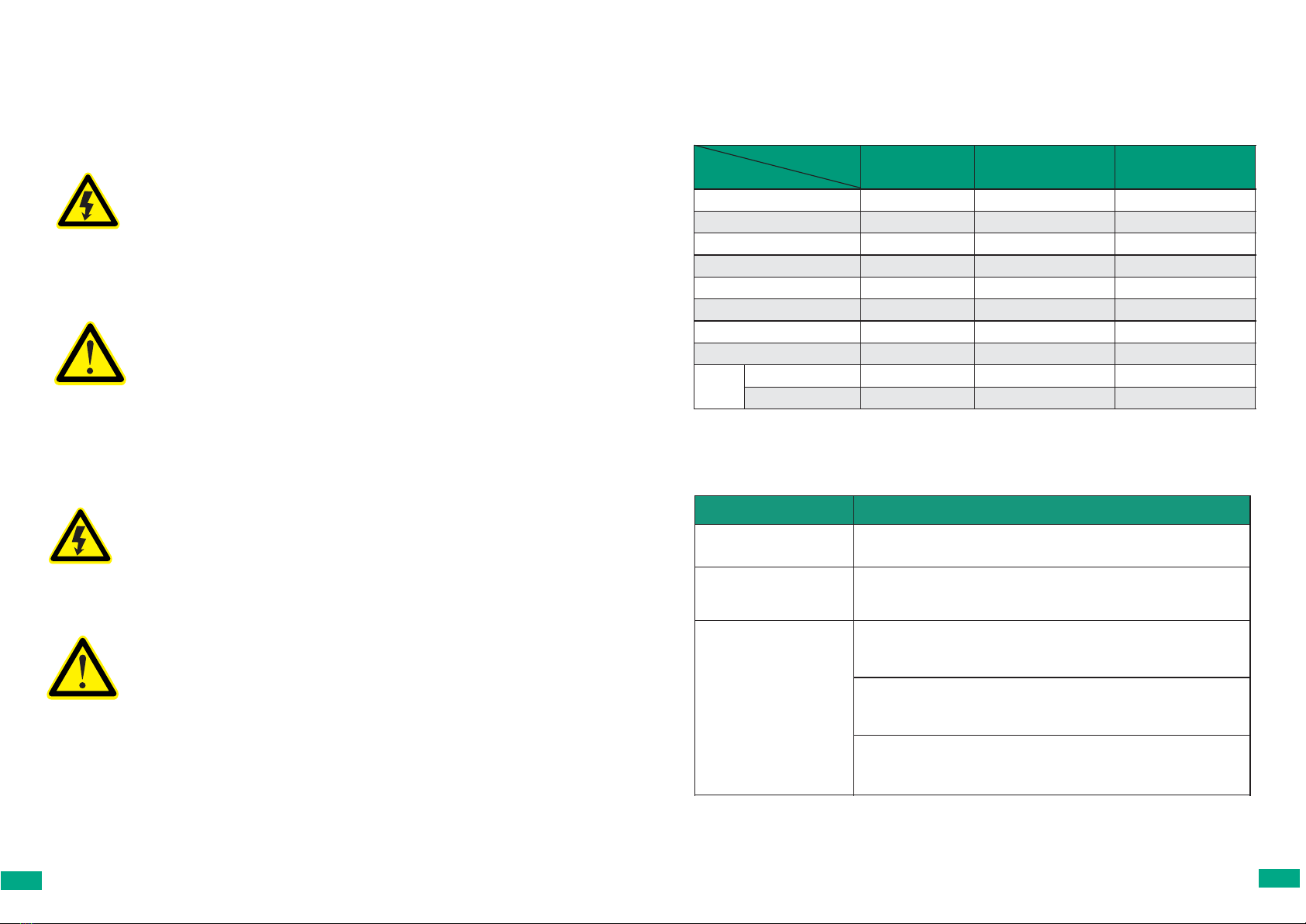

3.Protect Function Manual

Table 2 Protect Function Instruction

Protection Manual

Protection of opposite

connection

Solar Panel “PV+”“PV-”polarity are opposite connected, controller can

continue working after adjust.

Load over current and short

circuit protection

If the load current is more than15A and longer than 10s,the controller will

be in protection mode; If more than 32±0.5A,the controller will stop

working immediately. Try to re-start the controller 15mins later.

Weak Power Protection

(Details See Table 4)

50V: The working current smaller than 1.3A;Solar Panel input voltage

smaller than 60VDC or bigger than 250VDC;Come into Protection mode

Try to re-start the controller 6mins later.

220V: The working current smaller than 1.3A;Solar Panel input voltage

smaller than 110VDC or bigger than 350VDC;Come into Protection

mode. Try to re-start the controller 6mins later.

300V: The working current smaller than 1.3A;Solar Panel input voltage

smaller than 220VDC or bigger than 450VDC;Come into Protection

mode. Try to re-start the controller 6mins later.

03 04