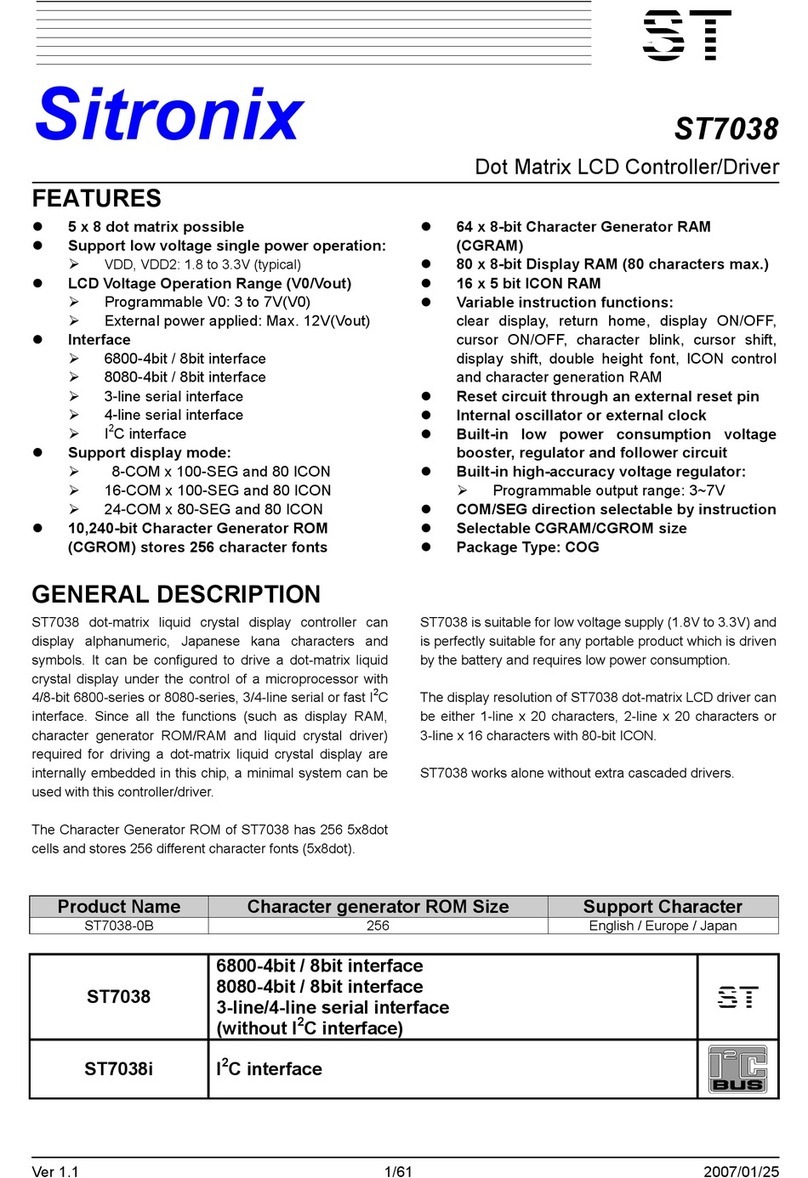

Sprinte ASP 116 evolution Instruction Manual

ASP116 EVOLUTION

Controller for powerful Lifts

INSTALLATION & MAINTENANCE MANUAL

v5-21

09-2018

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

2

SUMMARY

1PREAMBLE ...................................................................................................................................................................3

2BRAKING RESISTOR......................................................................................................................................................4

3TEMPORARY OPERATION ............................................................................................................................................5

4CAR’S SPEED SETTING ..................................................................................................................................................6

5ASYNCHRONOUS MOTOR............................................................................................................................................7

6GEARLESS MOTOR .................................................................................................................................................... 11

7SHAFT’S CAMS INSTALLATION ................................................................................................................................... 16

8FLAT CABLE INSTALLATION ........................................................................................................................................ 18

9SLOWDOWN DISTANCE ............................................................................................................................................. 20

10 FLAGS POSITIONNING............................................................................................................................................... 21

11 ABSOLUTE READER K04SP/K05SP ............................................................................................................................. 31

12 CHECKING THE CAR'S BALANCE................................................................................................................................. 37

13 SETTING OF THE ATVLIFT INVERTER ........................................................................................................................ 38

14 STOP PRECISION SETTINGS ....................................................................................................................................... 42

15 BUS LANDING BOARDS ............................................................................................................................................. 43

16 SAFETY RELAY WIRING..............................................................................................................................................47

17 THE INSTALLATION IS OVER ...................................................................................................................................... 47

ANNEX 1 –DIAGNOSING COMMON PROBLEMS ................................................................................................................48

ANNEX 2 –HELPFUL TESTS ................................................................................................................................................48

ANNEX 3 –COOL STUFF ..................................................................................................................................................... 48

ANNEX 4 –SOFTWARE UPDATE.........................................................................................................................................48

SAFETY INSTRUCTIONS

Risk of death or personal injury if the procedures/indications are not strictly observed.

Risk of personal injury or destruction of materiel if the procedures/indications are not

strictly observed.

Danger due to the presence of electrical voltage.

Risk of damage to the material by electrostatic discharge.

When handling the electronic boards/equipements, always wear a grounded anti-static

wristband or other appropriated equipments

Caution hot surface

Important information.

General requirement

Unplug before every maintenance operation.

PPE required

Document Reference : B-DP-13-007-06

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

3

1 PREAMBLE

This manual is valid only for VVVF drive connected to the controller via CANopen Bus, and for controller’s

software version v5-10 or higher

You will find here the start process of your controller ASP116 Evolution with CANopen connected

VVVF drive ATVLIFT.

If you follow all the different steps described hereafter, you will get your lift operational quickly and

easily.

Smartphone Application « EvoPad »

We recommend to use our Androïd Smartphone application « EvoPad » ; it will help you to

set all your parameters and diagnosis while you’re on the top or around the car :

EvoPad is available

on Google PlayStore

This application is nothing more than a remote terminal of the 216SP board’s terminal. There are

no differences, you will find exactly the same menus and settings available.

Throughout this manuel, each time you’ll meet the Application’s icon

this will point you out that the use of the EvoPad application is recommended in order to avoid travels to the cabinet for

the setting or diagnosis required.

VTA function or “Vocal Technical Assistance”

Enable this function to check your installation. A vocal message will be announced for

each lift’s input or lift’s switch activation.

Refer to ANNEX 3 - §1 for more details on this function.

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

4

2 BRAKING RESISTOR

MACHINEROOM

Safety area : a minimum 1 meter free space shall be created around the braking resistor.

Caution : the braking resistor may produce a very intense heat. Keep away any flammable

material to avoid fire hazard.

Braking resistor

Electrical cabinet

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

5

3 TEMPORARY OPERATION

Temporary operation shall be used during lift’s mounting step only, under

skilled and authorized technicians control.

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

6

4 CAR’S SPEED SETTING

Make this setting in Emergency or Temporary operation.

+

+ …

Remove the VVVF parameter’s protection

Set the maximum speed of your motor (speed after roping)

Example : motor speed is 2m/s, roping is 2:1

RATED CAR SPEED = 1m/s

Set the nominal load of your car

Set the nominal speed of your car

EMERGENCY OPERA

Choose

CONFIGURATION

CONFIGURATION

FREQ. INVERTER

MENU VF PROTECT.

PROTECTED

FREQ. INVERTER

LIFT DATA

RATED CAR SPEED

1,00 m/s

RATED CAR SPEED

x,xx m/s

LIFT CAPACITY

400 kg

LIFT CAPACITY

XXXX kg

LIFT TOP SPEED

0,70 m/s

LIFT TOP SPEED

x,xx m/s

MENU VF PROTECT.

NOT PROTECTED

ENTER

+

ENTER

-

-

ENTER

-

-

-

ENTER

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

7

5 ASYNCHRONOUS MOTOR

Encoder’s wiring

o The encoder’s cable shall be separated from power cables.

o Connect the encoder’s shield in the VVVF inverter (dedicated flange).

o Connect the motor’s shield on both sides , motor and cabinet.

Supported encoders : Incremental RS422 –5V.

Motors

Terminal VW3A3404

A

/A

B

/B

+Vdc

0Vdc

SASSI

LIKA C80-C81-C82

yellow

blue

green

orange

red

black

LIKA Ixx & MIxx

yellow

blue

green

orange

red

black

MONTANARI

LIKA

yellow

blue

green

orange

red

black

ELTRA

green

brown

yellow

orange

red

black

TEKEL

green

brown

yellow

pink

red

black

ALL

KÜBLER

green

yellow

grey

pink

brown

white

Carte / Board VW3A3404

0Vdc

+Vdc

/B

B

/A

A

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

8

Mandatory settings

Make these settings in Emergency or Temporary operation

+

+ …

Remove the VVVF parameter’s protection

…

Choose « STANDARD »

Choose « ASYNC OL »

Set the Motor’s plate speed.

Set 1380 for a 1500 value on motor’s plate.

Set the Motor’s plate power.

CONFIGURATION

FREQ. INVERTER

MENU VF PROTECT.

PROTECTED

MENU VF PROTECT.

NOT PROTECTED

FREQ. INVERTER

MOTOR DATA

MACHINE TYPE

STANDARD

RATED SPEED

1380 rev/mn

RATED SPEED

XXXX rev/mn

CONTROL TYPE

ASYNC OL

EMERGENCY OPERA

Choose

CONFIGURATION

ENTER

ENTER

ENTER

ENTER

+

-

-

-

-

-

-

-

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

9

Set the Motor’s plate nominal voltage

Set the Motor’s plate nominal current.

See tables below according to the inverter model

See tables below according to the inverter model

Choose « ABC »

Set the Motor’s plate nominal frequency

400V Inverter

Thermal current

limitation

230Vac Inverter

Thermal current

limitation

ATVLIFT 10A

14,2A

ATVLIFT 27A

37,4A

ATVLIFT 14A

19,4A

ATVLIFT 33A

44,8A

ATVLIFT 17A

23,4A

ATVLIFT 27A

37,6A

ATVLIFT 33A

44,8A

ATVLIFT 48A

65A

ATVLIFT 37kW

107,4A

RATED POWER

4,00 kW

RATED POWER

x,xx kW

RATED VOLTAGE

380 V

RATED VOLTAGE

xxx V

RATED CURRENT

10,0 A

RATED CURRENT

XX,x A

THERM.CURRENT

15,0 A

THERM.CURRENT

XX,x A

CURRENT LIMIT.

15,0 A

CURRENT LIMIT.

XX,x A

PHASE ROTATION

ABC

RATED FREQUENCY

50 ,0 Hz

RATED FREQUENCY

XX,x Hz

-

-

-

-

-

-

-

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

10

Auto Tuning procedure

Mandatory step to get the lift move. Make this setting in Emergency or Temporary

operation.

Set “YES” to launch the auto-tuning

+

MOTOR’S MOVEMENT TEST

Go to chapter 7

Choose « ACB »

Restart from

Auto-tuning wihout emergency operation’s box

If you don’ t have the specific box, switch to emergency operation by removing the AR1-M plug from the 216SP board

(bottom right corner) ; the « MR » led will light and you will see « EMERGENCY OPERATION » on the terminal

screen. Follow the steps above as described and the auto tuning will be launched as soon as the safety chain will be

closed.

AUTO TUNING

NO

AUTO TUNING

YES

PUSH ON

UP IN EMCY

AUTO TUNING

DONE

STEP 1

STEP 2

STEP 3

PHASE ROTATION

ACB

STEP 4

STEP 1

ENTER

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

11

6 GEARLESS MOTOR

Encoder’s wiring

o The encoder’s cable shall be separated from power cables.

o Connect the encoder’s shield in the VVVF inverter (dedicated flange).

o Connect the motor’s shield on both sides , motor and cabinet.

Supported encoders : SinCos / EnDatsincos.

Wiring :

Terminal

VW3A3409

0

V+

CL-

CL+

D-

D+

S-

S+

C-

C+

Heidenhain

encoder

(0V UN)

(5VUP)

(CLOCK-)

(CLOCK)

(DATA-)

(DATA+)

(B-)

(B+)

(A-)

(A+)

Other encoders

UN

(GND)

UP

(5V)

CLOCK-

(C-)

CLOCK+

(C+)

DATA-

(D-)

DATA+

(D+)

B-

B+

A-

A+

Carte / Board VW3A3409

GND

+5V

CLOCK-

CLOCK+

DATA-

DATA+

B-

B+

A-

A+

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

12

Mandatory settings

Make these settings in Emergency or Temporary operation

+

+ …

Remove the VVVF parameter’s protection

…

Choose « NO »

Choose the type of your encoder.

Set the encoder’s power supply voltage

Set the encoder’s pulses per revolution

CONFIGURATION

FREQ. INVERTER

MENU VF PROTECT.

PROTECTED

MENU VF PROTECT.

NOT PROTECTED

FREQ. INVERTER

ENCODER DATA

REVERSE ROTATION

NO

SUPPLY VOLTAGE

5 V

SUPPLY VOLTAGE

xx V

RESOLUTION

2048

RESOLUTION

xxxx

EMERGENCY OPERA

Choose

CONFIGURATION

ENCODER TYPE

ENDATSINCOS

ENCODER TYPE

xxxxxxx

ENTER

ENTER

ENTER

ENTER

-

-

-

-

-

+

-

-

-

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

13

Choose « YES » . Do not change

Choose « 10 ms » . Do not change

+

Set the motor’s type

For a « GEARLESS SPRINTE » only:

Set the Gearless SPRINTE’s type

Set the lift’s reeving

Choose « SYNC.BF» . Do not change

Set the Motor’s plate speed

Set the Motor’s plate nominal current

FILTER

YES

FILTER VALUE

10 ms

FREQ. INVERTER

MOTOR DATA

GEARLESS TYPE

103 02.1/4.6KW

RATED SPEED

167 rev/mn

RATED SPEED

XXXX tr/min

REEVING

1 :1

MACHINE TYPE

STANDARD

MACHINE TYPE

xxxxxxxx

CONTROL TYPE

SYNC. CL

RATED CURRENT

10,0 A

RATED CURRENT

XX,x A

ENTER

BACK

+

-

-

-

-

-

-

-

-

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

14

See tables below according to the inverter model.

See tables below according to the inverter model.

Choose « ABC »

Set the Motor’s plate nominal torque

Set the Motor’s plate poles pairs number

Some motor’s plates indicate the poles number.

400V Inverter

Thermal current

limitation

230Vac Inverter

Thermal current

limitation

ATVLIFT 10A

14,2A

ATVLIFT 27A

37,4A

ATVLIFT 14A

19,4A

ATVLIFT 33A

44,8A

ATVLIFT 17A

23,4A

ATVLIFT 27A

37,6A

ATVLIFT 33A

44,8A

ATVLIFT 48A

65A

ATVLIFT 37kW

107,4A

PHASE ROTATION

ABC

MOTOR TORQUE

670 Nm

MOTOR TORQUE

xxx Nm

THERM.CURRENT

15,0 A

RATED CURRENT

XX,x A

CURRENT LIMIT.

15,0 A

CURRENT LIMIT.

XX,x A

POLE PAIRS

12

POLE PAIRS

xx

-

-

-

-

-

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

15

Auto Tuning procedure

Mandatory step to get the lift move. Make this setting in Emergency or Temporary

operation. The auto-tuning of a gearless motor is very noisy but this is quite

normal.

Set “YES” to launch the auto-tuning

+

MOTOR’S MOVEMENT TEST

Go to chapter 7

Other possible combinations :

Choose « ACB » and « NO »

Choose « ACB » and « YES »

OR

Choose « ABC » and « YES »

OR

Restart from

AUTO TUNING

NO

AUTO TUNING

YES

STEP 1

PHASE ROTATION

ACB

STEP 4

STEP 1

REVERSE ROTATION

NO

PHASE ROTATION

AACB

REVERSE ROTATION

YES

PHASE ROTATION

AABC

REVERSE ROTATION

YES

PUSH ON

UP IN EMCY

AUTO TUNING

DONE

STEP 2

STEP 3

ENTER

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

16

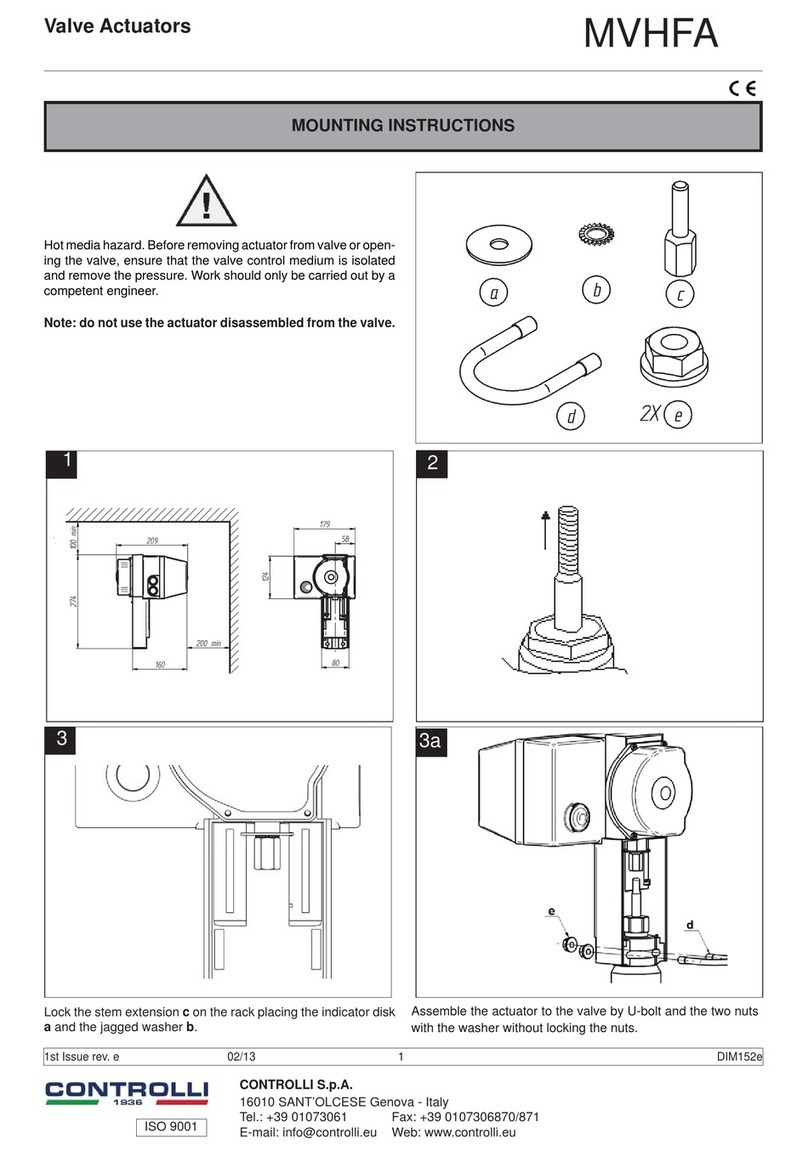

7 SHAFT’S CAMS INSTALLATION

Upper end cams

End limit cam

Inspection Upper end limit cam

Lower end cams

Inspection Lower end limit cam

End limit cam

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

17

Limit switches

Located on the roof of the car

End limit switch

Inspection upper end limit

switch

Inspection lower end limit

switch

Silent-Blocks

Place it inside the cams.

Silent-Block

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

18

8 FLAT CABLE INSTALLATION

Mounting brackets

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

19

Multiple flat cables

When several flat cables are necessary, there must a separation distance of 300mm or more to ensure the correct

communication between the controller and the car’s roof board..

Special case with 2 flat cables : 24G + 16G

When it’s not possible to space out both flat cables, you may place one over the other as described below :

Every unused wires of the flat cable shaIl be grounded.

Flat Cable

Flat Cable

Flat Cable

Flat Cable

Place the 2 flat cables in such a way that wires 1 to 8 of

Flat Cable 24G aren’t aligned with flat cable 16G

Flat Cable

Flat Cable

ASP 116 EVOLUTION –INSTALLATION MANUAL

Sprinte SAS. All rights reserved , including translations.

20

9 SLOWDOWN DISTANCE

NOMINAL CAR’S

SPEED

ACCELERATION

COMFORT

ACCELERATION

TIME

DECELERATION

LENGTH

LEVELING

SPEED

LEVELING TIME

STOP LENGTH

(m/s)

m/s²

Sec.

cm

m/s

sec

cm

0.40

2

4

70

0,08

2

2,5

0.60

2

4

90

0,08

2

2,5

0.80

2

4

110

0,08

2

2,5

1.00

2

4

140

0,08

2

2,5

1.20

2

4

170

0,08

2

2,5

1.40

2

4

200

0,08

2

2,5

1.60

2

4

220

0,08

2

2,5

Theorical lift’s movement diagram , with main settings :

speed

time

Other manuals for ASP 116 evolution

3

Table of contents

Other Sprinte Controllers manuals