2

3000775 12.12

5. This unit must be grounded.

How to use this manual

This installation manual does not contain any system design

documentation. System design documentation is available from any

authorized EXHAUSTO representative.

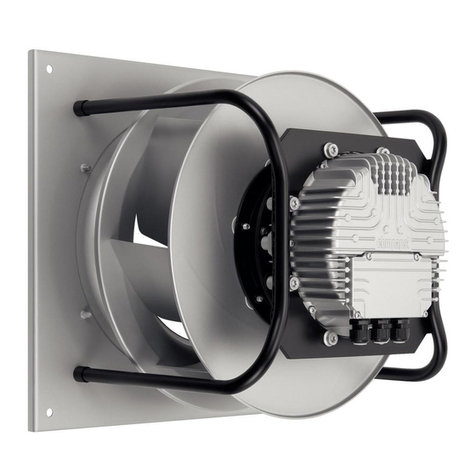

Accessories, fans and variable frequency drives are not covered by

this manual. Please refer to these component’s individual manuals.

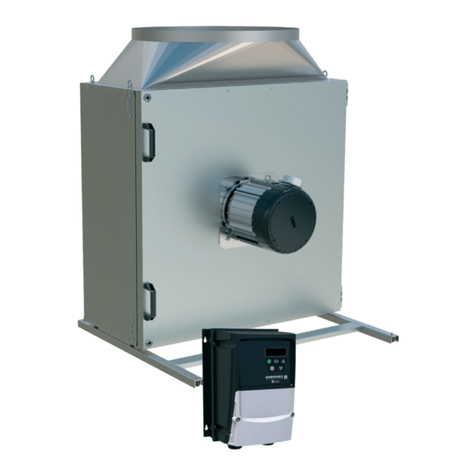

1. Product Information

1.1 Function .....................................................................................................3

1.2 Components...............................................................................................3

1.3 Shipping .....................................................................................................4

1.4 Warranty.....................................................................................................4

2. Specications

2.1 Dimensions & Capacities ...........................................................................4

3. Mechanical Installation

3.1 Transport Safety Device............................................................................. 5

3.2 Single Fan on Steel Chimney..................................................................... 5

3.3 Singel Fan on Roof Curb............................................................................ 5

3.4 Single Fan on Brick Chimney.....................................................................6

3.5 Side-Wall Mounting of Chimney Fan..........................................................6

3.6 Multiple Fan Installations............................................................................ 7

3.7 Installation for High Temperatures .............................................................7

3.8 Installation of Proven Draft Switch (PDS) ..................................................7

4. Electrical Installation

4.1 Electrical Requirements .............................................................................8

4.3 Wiring Diagram for RSV 400-450............................................................... 9

5. Startup & Conguration

5.1 System Testing.........................................................................................10

5.2 Adjusting Fan Speed ................................................................................ 10

5.3 Testing Safety System ............................................................................. 10

6. Maintenance & Troubleshooting

6.1 Maintenance Intervals .............................................................................. 11

6.2 Cleaning ................................................................................................... 11

TO REDUCE THE RISK OF FIRE, ELECTRICAL SHOCK OR INJURY TO PERSONS,

OBSERVE THE FOLLOWING:

Caution: Indicates an imminent hazardous situation

which, if not avoided, may result in personal injury or

property damage.

Symbol Legend:

The following terms are used throughout this manual to bring attention

to the presence of potential hazards or to important information

concerning the product.

Danger: Indicates an imminent hazardous situation

which, if not avoided, will result in death, serious injury or

substantial property damage.

1. Use this unit in the manner intended by the manufacturer. If

you have questions, contact the manufacturer at the address or

telephone number listed on the front of the manual.

2. Before servicing or cleaning the unit, switch off at service panel

and lock service panel to prevent power from being switched on

accidentally.

3. Installationworkandelectricalwiringmustbedonebyaqualied

person(s) in accordance with applicable codes and standards.

4. Follow the appliance manufacturer’s guidelines and safety

standards such as those published by the National Fire Protection

Association (NFPA), and the American Society for Heating,

Refrigeration and Air Conditioning Engineers (ASHRAE), and the

local code authorities.