ENERVEX BEF 225x Installation instructions

ENERVEX Inc.

1685 Bluegrass Lakes

Parkway

Alpharetta, GA 30004

USA

P: 770.587.3238

F: 770.587.4731

T: 800.255.2923

www.enervex.com

010.1220.0719 01.21 Installation & Operating Manual

ENERVEX

BEF 225-800X BOX VENTILATOR

MAKE-UP AIR FOR LAUNDRY ROOMS

TYPE I & II RESIDENTIAL & COMMERCIAL

CLOTHES DRYERS

KITCHEN HOOD, BATHROOM EXHAUST

INTAKE AND EXHAUST APPLICATIONS

FOR MULTI-STORY BUILDINGS

File No. E479840

READ AND SAVE THESE INSTRUCTIONS!

2

010.1220.0719 01.21

Symbol Legend

The following terms are used throughout this manual to bring

attention to the presence of potential hazards, or to important

information concerning the product.

DANGER: Indicates an imminent hazardous

situation which, if not avoided, will result in death,

serious injury or substantial property damage.

WARNING: Indicates an imminent hazardous

situation which, if not avoided, may result in

personal injury or property damage.

DANGER: Indicates an imminent electrical shock

hazard which, if not avoided, will result in death,

serious injury or substantial property damage.

How to use this manual

This installation manual does not contain any system design

documentation. System design documentation is available

from any authorized ENERVEX representative. Accessories,

fans, and variable frequency drives are not covered by

this manual. Please refer to these component’s individual

manuals.

TO REDUCE THE RISK OF FIRE,

ELECTRICAL SHOCK OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit in the manner intended by the manufacturer.

If you have questions, contact the manufacturer at the

address or telephone number listed on the front of the

manual.

2. Before servicing or cleaning the unit, switch off at service

panel and lock service panel to prevent power from being

switched on accidentally.

3. Installation work and electrical wiring must be done by a

qualied person(s) in accordance with applicable codes

and standards.

4. Follow the appliance manufacturer’s guidelines and safety

standards such as those published by the National Fire

Protection Association (NFPA), and the American Society

for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

5. This unit must be grounded.

This symbol shows that ENERVEX BEFx Box Ventilators are listed under Category Code ZACT.

UL File E479840

3

010.1220.0719 01.21

1. GENERAL INFORMATION

1.1 Introduction......................................................4

1.3 Components ....................................................4

1.4 Shipping...........................................................5

1.5 Accessories ......................................................5

1.6 Listings .............................................................5

1.7 Warranty ...........................................................5

2. SPECIFICATIONS AND DIMENSIONS

2.1 Specications ...................................................6

3. MECHANICAL INSTALLATION

3.1 Positioning........................................................7

3.2 Door Position....................................................8

3.3 Floor Or Roof Mounting....................................9

3.4 Ceiling Mounting...............................................9

3.5 Connection to Duct...........................................10

3.6 Connection to Flexible Duct ..............................10

3.7 Outdoor Termination.........................................10

3.8 Field Junction Box............................................11

4. ELECTRICAL INSTALLATION

4.1 General.............................................................12

4.2 Motor Controller ...............................................12

4.3 Mounting of EDrive Motor Controller .................13

4.4 Grounding Guidelines........................................13

4.5 EMC Filter Disconnect......................................13

4.6 Electrical Connection of the Motor and EDrive..14

4.7 Motor Terminal Connections.............................14

4.8 Wiring Diagram BEF 225-355x / 1x120V...........14

4.9 Wiring Diagram BEF 225-800x / 3x208-480V...15

4.10 Checking and Changing Rotation of Impeller...15

4.11 Installing a Proven Flow System......................16

5. STARTUP AND CONFIGURATION

5.1 Managing the Keypad.......................................17

5.2 Operating the Display........................................17

5.3 Changing Parameters .......................................18

5.4 Read Only Parameter Access ...........................18

5.5 Resetting Parameters.......................................18

5.6 Resetting a Fault ..............................................18

5.7 LED Display......................................................18

5.8 Start Up Sequence (Auto Tune) ........................19

6. MAINTENANCE AND TROUBLESHOOTING

6.1 Cleaning Intervals..............................................20

6.2 Cleaning ...........................................................20

6.3 Service..............................................................20

6.4 Replacement Parts Ordering.............................21

7. WARRANTY TERMS ......................................22

Content

WARNING

This product is equipped with an electronically

commutated (EC-motor) and can not be

connected directly to ac mains. Motor must

be connected to approved motor controller

to ensure proper function. Failure to use approved motor

controller may result in damage to the motor.

ATTENTION

Ce produit est équipé d’un commutateur électronique

(moteur EC) et ne peut pas être connecté directement au

secteur. Le moteur doit être connecté au contrôleur de

moteur approuvé pour assurer un fonctionnement correct.

Ne pas utiliser le contrôleur de moteur approuvé peut

endommager le moteur.

!

4

010.1220.0719 01.21

1. GENERAL INFORMATION

1.1 introduction

These instructions provide both general guidelines and

special requirements for all parts in the BEFx Ventilator Fan

product line. Before specifying a design or beginning an

installation please carefully review these instructions. Contact

local building or re ofcials about restrictions and installation

inspection in your area.

1.2 Features

The BEFx is a highly efcient box ventilator that uses a

backward curved centrifugal impeller for the movement of air

in exhaust and air supply systems by providing high capacity

at high static pressure. It is designed to exhaust lint-laden air

from multiple Type I and Type II residential and commercial

clothes dryers, exhaust commercial hoods, or to provide

make-up air for laundry or mechanical rooms. The ventilator

cannot be used for transport of large particles. Suitable uses

include, but are not limited to: comfort ventilation, make-up

air for laundry and mechanical rooms, and exhaust and air

supply in kitchens/bathrooms in multi-story, multi-family

buildings. The BEFx box ventilator can be installed indoors

as well as outdoors and used in both intake and exhaust

applications.

The BEFx ventilator housing is made in galvanized steel,

while the impeller is welded aluminum. The design is Type

B, Spark Resistant Construction, completely insulated

against re, noise, condensation and heat with 2” berglass

insulation. A service door is provided to allow easy access

to the motor and impeller. The welded aluminum impeller

is statically and dynamically balanced with permanently

attached balancing weights. The BEFx is equipped with

an extremely energy-efcient, totally enclosed, permanent-

magnet motor of class NEMA Super Premium EISA (IE4).

IP54 Protection Class. Sealed ball bearings. The motor

is protected from overloading, blocking, over and under

voltage, and over-heating by a factory programmed EDrive

motor controller by ENERVEX for optimal operation of the

ventilator.

The BEFx Box Ventilator is a component in the MCAS

Modulating Combustion Air System™, MDVS Mechanical

Dryer Venting System™ and MBES Modulating Building

Exhaust System™.

Exhaust temperature must be above 10°F (-12°C) but should

not exceed 400°F (200°C). The ambient temperature must

be within -20°F (-30°C) and 105°F (40°C).

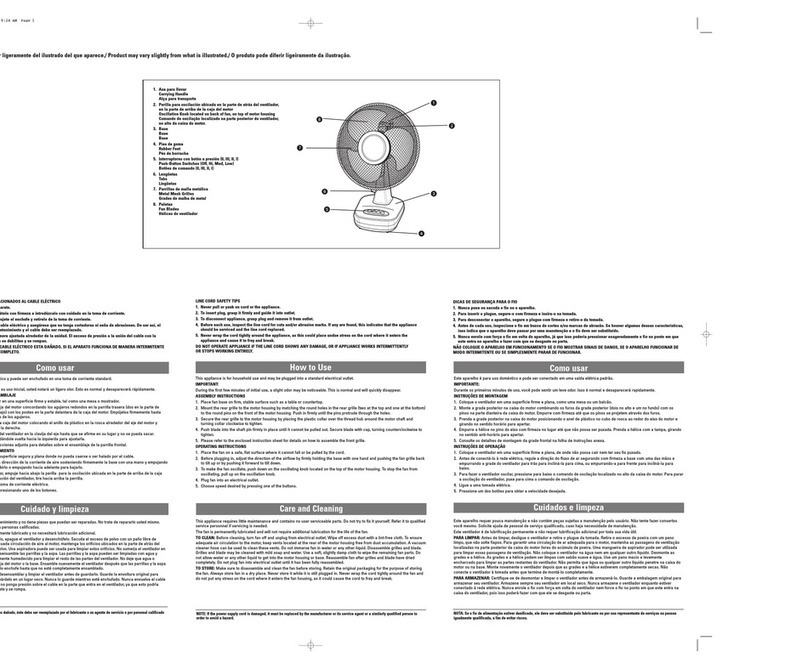

1.3 Components

The box ventilator comes with the components shown in Fig.

1.

Fig 1

Fig 2

WARNING

The ventilator is not to be used to transport solid

particles, nor in areas where there is a risk of

explosive gases.

!

1. Housing

2. Motor

3. Junction Box

4. Support legs with vibration dampers (2)

5. Kit with Allen key for door locking screws for door hinges

and (4 sheet metal screws for mounting junction box)

6. EDrive

7. Installation Manual

5

010.1220.0719 01.21

1.4 Shipping

BEFx ventilator fan units are shipped on a pallet and

protected by packaging.

Do not place other products or items on top of the

packaging.

After unpacking, the product must be handled in a way to

prevent damage to the collars and the ventilator housing.

The door handle should never be used to lift or carry the fan.

If necessary, the access door can be removed to facilitate

transport.

The ventilator is shipped with the motor installed on the

access door with a dedicated motor controller.

If other components are shipped, they will appear on the

shipment packing list.

NOTE: All fans are shipped with a Field Junction Box

connected via exible conduit.

1.5 Accessories (Optional)

• MEC 24 Exhaust Control

• EBC 30/31 Modulating Pressure Control

• Proven Draft Switch PDS

1.6 Listings

UL705, Standard for Power Ventilators with special

consideration for venting lint-laden air from single or multiple

dryers and CSA 22.2 No. 113, Standard for Fans and

Ventilators.

CSA C22.2 NO. 113-12 Fans and Ventilators Edition 9 -

Revision Date 2012/10/01

UL 705 Standard for Power Ventilators Edition 6 - Revision

Date 2013/12/17

Complies with and meets Type B, Spark Resistant

Construction per AMCA standard 99-0401 classications of

Spark Resistant Construction.

1.7 Warranty

2-year factory warranty (see back cover). Complete warranty

conditions are available from ENERVEX Inc.

WARNING

Never use access door handle as a carrying

handle.

AVERTISSEMENT

N’utilisez jamais la poignée de la porte d’accès comme

poignée de transport.

!

WARNING

This duct fan shall be installed a minimum of

one meter from any accessible opening of the

duct.

AVERTISSEMENT

Ce ventilateur de conduit doit être installé au moins un

mètre d’une ouverture accessible du conduit.

!

6

010.1220.0719 01.21

2. SPECIFICATIONS AND DIMENSIONS

2.1 Specifications

Fan Type

Motor

Voltage Conguration

Motor Rating

Max Speed

Max Motor Torque

EDrive Model

EDrive Rating

Supply Voltage

Power

Max Input Current

Max Output Current

Operating Temperature

A - in / mm

B - in / mm

C - in / mm

D - in / mm

E - in / mm

F - in / mm

G - in / mm

H - in / mm

Weight

BEF 315x

1x120 / 3x240 V

2100 RPM

3.0 Nm

321.2208.1200

321.2208.2200

1x120 / 3x240 V

0.75 kW

15.8 / 5.6 A

4.3 / 4.3 A

22.64 / 575

30.79 / 782

12.60 / 320

7.12 / 181

9.80 / 249

24.41 / 620

11.34 / 288

1.97 / 50

84 lbs / 38 kg

BEF 355x

1x120 / 3x240V

1950 RPM

3.0 Nm

321.2208.1200

321.2208.2200

1x120 / 3x240V

0.75 kW

15.8 / 5.6 A

4.3 4.3 A

25.00 / 635

33.35 / 847

13.11 / 333

7.12 / 181

11.77 / 299

24.41 / 620

12.48 / 317

1.97 / 50

99 lbs / 45 kg

BEF 500x

3x240 / 3x480V

1750 RPM

24.0 Nm

321.2214.2200

321.2214.4200

3x240 / 3x480V

5.5 kW

26.4 / 17.2 A

24.0 / 14.0 A

33.54 / 852

42.36 / 1076

16.42 / 417

9.06 / 230

19.65 / 499

31.50 / 800

16.77 / 426

1.97 / 50

208 lbs /95 kg

BEF 800x

3x480V

1750 RPM

137.9 Nm

321.2220.4200

3x480V

22.0 kW

51.9 A

46.0 A

51.26 / 1302

61.69 / 1567

24.09 / 612

20.83 / 529

35.83 / 910

41.77 / 1061

25.63 / 651

1.97 / 50

652 lbs / 296 kg

BEF 710x

3x480V

1750 RPM

70.0 Nm

321.2220.4200

3x480V

15.0 kW

34.2 A

30.0 A

46.10 / 1171

55.98 / 1422

22.36 / 568

14.57 / 370

31.46 / 799

45.71 / 1161

23.03 / 585

1.97 / 50

385 lbs / 175 kg

BEF 630x

3x240 / 3x480V

1750 RPM

50.0 Nm / 44.0 Nm

321.2218.2200

321.2218.4200

3x240 / 3x480V

11.0 / 7.5 kW

33.3 / 21.2

30.0 / 18.0

41.22 / 1047

41.26 / 1048

20.00 / 508

9.69 / 246

27.83 / 707

37.80 / 960

20.63 / 524

1.97 / 50

357 lbs / 153 kg

BEF 560x

3x240 / 3x480V

1850 RPM

50.0 Nm

321.2216.2200

321.2216.4200

3x240 / 3x480V

5.5 kW

26.4 / 17.2 A

24.0 / 14.0 A

37.09 / 942

45.43 / 1154

17.83 / 453

9.69 / 246

23.82 / 605

37.80 / 960

18.54 / 471

1.97 / 50

264 lbs / 120 kg

BEF 450x

3x240 / 3x480V

1500 RPM

6.0 Nm

321.2212.2200

321.2212.4200

3x240 / 3x480V

1.5 kW

12.1 / 7.5 A

10.5 / 5.8 A

30.60 / 777

39.80 / 1011

15.28 / 388

8.35 / 212

15.83 / 402

31.22 / 793

15.32 / 389

1.97 / 50

142 lbs/ 64.5 kg

Centrifugal

EC - motor

NEMA 3R / IP54

NEMA 4X / IP54

14-122°F / -10-50°C

BEF 225x

1x120 / 3x240 V

3100 RPM

3.0 Nm

321.2206.1200

321.2206.2200

1x120 / 3x240 V

0.75 kW

7.8 / 7.8 A

2.3 / 2.3 A

17.33 / 440

17.36 / 441

10.13 / 257

7.12 / 181

7.84 / 199

20.3 / 509

10.36 / 263

2.00 / 51

60 lbs / 27 kg

7

010.1220.0719 01.21

3. MECHANICAL INSTALLATION

3.1 Positioning

The ventilator can be oriented in multiple positions.

Acceptable ventilator orientations are shown in Fig 3.

The BEFx can be installed indoors and outdoors without any

modications.

Wherever the ventilor is installed, make sure there is

space enough to open the access door to an angle of

approximately 90°, as shown in Fig 4, and to access the

locking screws.

Fig 3

Fig 4

CAUTION

Never operate the ventilator with open access

door

MISE EN GARDE

Ne jamais utiliser le ventilateur avec la porte d’accès

ouverte.

A

C

B

D

90°

8

010.1220.0719 01.21

3.2 Door Position

The ventilator can be oriented in multiple positions.

Acceptable ventilator orientations are shown in Fig 3.

The BEFx can be installed indoors and outdoors without any

modications.

Wherever the ventilor is installed, make sure there is space

enough to be able to open the access door to an angle of

approximately 90°, as shown in Fig 4, and to access the

locking screws.

Fig 4

9

010.1220.0719 01.21

3.3 Floor Or Roof Mounting

To minimize transfer of noise and vibration, the ventilator

unit should be mounted on a level, stable and vibration-free

surface. If mounting on a wooden surface, a cement tile

should be placed on the oor prior to mounting as shown in

Fig 5.

Once the installation location is selected the support legs

must be installed. To facilitate support leg installation, keep

ventilator unit on pallet.

For the standard position (Fig 5), bolt holes are pre-drilled

and support legs should be aligned and secured with the

enclosed hardware.

For all other positions, the legs should be placed in proper

position using variable mounting points.

DO NOT FASTEN THE VENTILATOR TO THE BASE.

The ventilator is tted with sound dampers suited to the

requirements of the operating area.

Fig 5

Fig 6

3.4 Ceiling Mounting

If hung from the ceiling, brackets with eye hooks (not

included) must be installed as shown in Fig. 6..

Ceiling bolts must be properly sized to safely carry weight of

the ventilator unit.

10

010.1220.0719 01.21

3.5 Connection To Duct

The ventilator can be connected to a duct. To acheive

maximum performance with minimal energy consumption,

the ventilator should be connected to the duct system with

the specied lengths of duct before and after the ventilator.

NOTE: The distance “3 x D” is not a requirement. It is a

recommendation that will help achieve maximum performance with

minimal energy consumption

3.6 Connection To Flexible Duct

Flexible duct sections can be used to reduce vibrations in the

duct system. If used, the FLF should be connected between

the fan inlet/outlet and the main duct as shown in Fig 8.

This will decrease system vibration and prevent fan housing

deection.

NOTE: The distance “3 x D” is not a requirement. It is a

recommendation that will help achieve maximum performance with

minimal energy consumption

3.7 Outdoor Termination

The BEFx box ventilator is suitable for outdoor installations. It

can mount directly to the roof or on a roof curb as shown in

Fig. 9 and Fig. 10. When the ventilator is used at an exhaust

termination point, local codes may require a gooseneck to

be installed at the outlet, preventing rain entering into the

ventilator. See Fig. 9.

Fig 8

Fig 7

Fig 9

11

010.1220.0719 01.21

Attach the gooseneck directly to the outlet collar of the fan

unit.

DO NOT use sheet metal screws or other fasteners that will

penetrate the gooseneck and obstruct airow. Building code

prohibits the placement of mesh screens on the ventilator

outlet because of the potential re hazard from lint build-up.

Fig 10

3.8 Field Junction Box

The BEFx ventilator comes with a eld junction box that is

attached to the motor via a exible conduit.

After mounting the BEFx in its proper location and

orientation, the Field Junction Box MUST be permanantly

attached to the fan housing with the supplied sheet metal

screws. Orient the the Field Junction Box in a manner that

will minimize water ingress, and verify the BEFx access door

can open without straining, or kinking the exible conduit.

FAILURE TO FOLLOW THIS PROCEDURE VOIDS THE UL

LISTING AND CAN DAMAGE THE MOTOR.

Fig 11

WARNING

Do not install the Field Junction Box on the

service door.

AVERTISSEMENT

N’installez pas la boîte de jonction Field sur la porte de

service.

!

12

010.1220.0719 01.21

4. ELECTRICAL INSTALLATION

4.1 General

All wiring must be in compliance with the local codes or in

their absence, with the National Electric Code, NFPA70.

All wiring should meet these requirements: installed in rigid

metal conduit, intermediate metal conduit, rigid non-metallic

conduit, electrical metallic tubing, or be otherwise suitably

protected from physical damage. All BEFx units are equipped

with an EC-motor and operate at different voltages so it’s

important to pay attention to the wiring details.

Note: If any of the original wire supplied with the system

must be replaced, use similar wire of the same temperature

rating. Otherwise, insulation may melt or degrade, exposing

bare wire.

WARNING

This product is equipped with an electronically

commutated (EC-motor) and can not be

connected directly to ac mains. Motor must

be connected to approved motor controller to

ensure proper function. Failure to use approved

motor controller may result in damage to the motor.

AVERTISSEMENT

Ce produit est équipé d’un commutateur électronique

(moteur EC) et ne peut pas être connecté directement au

secteur. Le moteur doit être connecté au contrôleur de

moteur approuvé pour assurer un fonctionnement correct.

Ne pas utiliser le contrôleur de moteur approuvé peut

endommager le moteur.

!

WARNING

All BEF models must be operated with the

approved factory-programmed motor drive.

DO NOT CONNECT DIRECTLY TO LINE

VOLTAGE!

AVERTISSEMENT

Tous les modèles BEF doivent être utilisés avec

l’entraînement motorisé approuvé en usine.

NE PAS CONNECTER DIRECTEMENT À LA TENSION DE

LIGNE!

!

DANGER

Turn off electrical power before servicing.

Contact with live electric components can

cause shock or death.

DANGER

Éteignez l’alimentation électrique avant de procéder à

l’entretien. Le contact avec des composants électriques

sous tension peut provoquer un choc ou la mort.

ABOUT SHAFT GROUNDING

Bearing currents are very common problem of Variable

Frequency Drives (VFD/Motor Controller) and electronic

commutated motors. The electric-discharge machining

(EDM) bearing currents are generated in motors because

of unbalanced modulated voltage from drive to the motor.

Because of stray capacitances in motor, bearing currents

are generated in rotor and there is usually no other way to

discharge except through bearings. This drastically lowers

the life time of the bearings.

The BEFx’s EC-motor integrates an insulated rotor system,

which means that electrical insulation is inserted between

rotor and motor shaft. This system provide up to 80%

lower shaft voltages and very low bearing current values

which eliminates bearing damage.

DANGER

The motor speed drive is suitable for use in a

circuit capable of receiving not more than 100

KA RMS symmetrical Amperes at the maximum

reated voltage.

DANGER

Le variateur de vitesse peut être utilisé dans un circuit

capable de recevoir des ampères symétriques de plus de

100 KA à la tension maximale.

4.2 Motor Controller

All ENERVEX BEFx fans come with, and must use, a factory

programmed EDrive motor controller with an enclosure rated

to NEMA 4X/IP66 for indoor and outdoor installation.

The EDrive E3 motor controller must be mounted within 300

feet of the BEFx Fan. This distance can be increased up to

600 feet with the addition of a line lter (Contact ENERVEX

for details).

A motor disconnect switch must be installed between the

motor controller and the BEFx Fan, either within sight of the

BEFx Fan, or within 50 feet of the BEFx Fan.

Do not activate the motor service disconnect switch

while the BEFx motor is running - damage could occur to

the motor controller.

For more information about the EDrive E3, please refer to

the Installation & Operating Manual.

13

010.1220.0719 01.21

4.3 Mounting of EDrive Motor Controller

Mount the EDrive motor controller in a location that is only

accessible to qualied personal.

The EDrive must be installed within 300 ft of the BEFx Fan.

See Fig 12. For more information about the EDrive E3 please

refer the Installation & Operating Manual.

4.4 Grounding Guidelines

The ground terminal of each EDrive E3 should be individually

connected DIRECTLY to the source breaker panel ground

bus bar (through the lter if installed). EDrive E3 ground

connections should not loop from one drive to another, or

to, or from any other equipment. Ground loop impedance

must conrm to local industrial safety regulations. To meet

UL regulations, UL approved ring crimp terminals should be

used for all ground wiring connections.

The drive Safety Ground must be connected to system

ground. Ground impedance must conform to the

requirements of national and local industrial safety

regulations and/or electrical codes. The integrity of all ground

connections should be checked periodically.

Protective Earth Conductor

The Cross sectional area of the ground conductor must be at

least equal to that of the incoming supply conductor.

Safety Ground

This is the safety ground for the drive that is required by

code. One of these points must be connected to adjacent

building steel (girder, joist), a oor ground rod, or bus bar.

Grounding points must comply with local codes.

Motor Ground

The motor ground must be connected to one of the ground

terminals on the drive.

Ground Fault Monitoring

As with all inverters, a leakage current to earth can exist.

The EDrive E3 is designed to produce the minimum possible

leakage current whilst complying with worldwide standards.

The level of current is affected by motor cable length and

type, the effective switching frequency, the earth connections

used and the type of RFI lter installed. If an ELCB (Earth

Leakage Circuit Breaker) is to be used, the following

conditions apply:

• A Type B Device must be used.

• The device must be suitable for protecting equipment with

a DC component in the leakage current.

• Individual ELCBs should be used for each EDrive E3.

4.5 EMC Filter Disconnect

Drives with an EMC lter have an inherently higher leakage

current to Ground (Earth). For applications where tripping

occurs the EMC lter can be disconnected (on IP20 units

only) by completely removing the EMC screw on the side of

the product.

Remove the screw as indicated right.

The EDrive product range has input supply voltage surge

suppression components tted to protect the drive from line

WARNING

For installation in the United States, branch

circuit protection must be provided in

accordance with the National Electrical Code

(NEC).

!

AVERTISSEMENT

For installation in Canada, branch circuit

protection must be provided in accordance with

the Canadian Electrical code

Pour l’installation au Canada, la protection de circuit

de branche doit être fournie conformément au Le code

canadien de l’électriticé.

!

Fig 12

DANGER

Only qualied electrical personnel familiar

with the construction and operation of

this equipment and the hazards involved

should install, adjust, operate, or service this

equipment. Read and understand this manual and other

applicable manuals in their entirety before proceeding.

Failure to observe this precaution could result in severe

bodily injury or loss of life.

Seul un personnel qualié en électricité, familiarisé avec

la construction et le fonctionnement de cet équipement

et les risques encourus, doit installer, ajuster, utiliser ou

entretenir cet équipement. Lire et comprendre ce manuel

et les autres manuels applicables dans leur intégralité avant

de continuer. Le non-respect de cette précaution peut

entraîner des blessures graves ou la mort.

14

010.1220.0719 01.21

voltage transients, typically originating from lightning strikes

or switching of high power equipment on the same supply.

When carrying out a HiPot (Flash) test on an installation

in which the drive is built, the voltage surge suppression

components may cause the test to fail. To accommodate

this type of system HiPot test, the voltage surge suppression

components can be disconnected by removing the VAR

screw After completing the HiPot test, the screw should

be replaced and the HiPot test repeated. The test should

then fail, indicating that the voltage surge suppression

components are once again in circuit.

4.6 Electrical Connection of the Motor and EDrive

The motor should be connected to the EDrive E3 U, V, and

W terminals using a suitable 3 or 4 core cable. Where a 3

core cable is utilised, with the shield operating as an earth

conductor, the shield must have a cross sectional area at

least equal to the phase conductors when they are made

from the same material. Where a 4 core cable is utilised, the

earth conductor must be of at least equal cross sectional

area and manufactured from the same material as the phase

conductors.

The motor earth must be connected to one of the EDrive E3

earth terminals.

Maximum permitted motor cable length for all models: 100

meters shielded, 150 meters unshielded.

Where multiple motors are connected to a single drive using

parallel cables, an output choke must be installed..

The BEFx Fan sizes 225-355 require four (4) 14AWG

conductors between the EDrive and the Fan motor. (Three

(3) Power lines, and one (1) dedicated Ground wire.)

The BEFx Fan Sizes 225-800 require four (4) 12AWG

conductors between the EDrive and the Fan motor. (Three

(3) Power lines, and one (1) dedicated Ground wire.)

Make all necessary connections to the power and low-

voltage terminals (see wiring diagram).

4.7 Motor Terminal Box Connections

Do not install any mechanical or electro-mechanical switching

devices between the drive and motor. Where a local isolator

is installed close to the motor, this should be interlocked with

the drive control circuit to ensure the drive is disabled when

the motor is isolated.

Most general purpose motors are wound for operation on

dual voltage supplies. This is indicated on the nameplate

of the motor. This correct voltage setting must be selected

when installing the motor by selecting either STAR or DELTA

connection. STAR always gives the higher of the two voltage

ratings.

4.8 Wiring Diagram - BEF 225-355x / 1X120V

NOTE: All published voltages relate to power supplied to the

EDrive and NOT the motor.

BEF 225-355x fans operate at 1x120 VAC.

The wiring diagram in Fig. 14 is a typical wiring diagram for a

BEF 225-355x with 120V supply voltage to the motor drive.

The BEFx is listed with an EDrive motor controller which is

DANGER

This EDrive contains high voltage capacitors

that take time to discharge after removal of

the main supply. Before working on the drive,

ensure isolation of the main supply from line

inputs. Wait ten (10) minutes for the capacitors to discharge

to safe voltage levels. Failure to observe this precaution

could result in severe bodily injury or loss of life.

Cette EDrive contient des condensateurs à haute tension

qui mettent du temps à se décharger après le retrait de

l’alimentation principale. Avant de travailler sur le variateur,

veillez à isoler l’alimentation principale des entrées de

ligne. Attendez dix (10) minutes que les condensateurs se

déchargent à des niveaux de tension sûrs. Le non-respect

de cette précaution peut entraîner des blessures graves ou

la mort.

Fig 13

15

010.1220.0719 01.21

Fig 14

shipped with the fan. The wiring diagram reects the use of

this controller.

Fan rotation can be changed on the EDrive by switching the

attachment position of any two power leads.

4.9 Wiring Diagram - BEF 225-800x / 3X208-480V

NOTE: All published voltages relate to power supplied to the

EDrive and NOT the motor.

The BEF 225-800x fans operate at 3x208-240 VAC or 3

x 400-480 VAC. The BEF 700-800x can only operate at

3x400-480 VAC.

The BEFxs are listed with an EDrive motor controller which

is shipped with the fan. The wiring diagram in Fig. 14 reects

the use of this controller.

4.10 CHECKING AND CHANGING ROTATION OF

IMPELLER

To check the rotation of the impeller, it is necessary to be able

to see the impeller or the rotation of the cooling vanes at the

end of the motor housing.

Standing in front of the fan with the motor pointing towards

you, the rotation must be counterclockwise. This is indicated

BEF 225-800x

DANGER

Only qualied electrical personnel familiar

with the construction and operation of

this equipment and the hazards involved

should install, adjust, operate, or service this

equipment. Read and understand this manual and other

applicable manuals in their entirety before proceeding.

Failure to observe this precaution could result in severe

bodily injury or loss of life.

Seul un personnel qualié en électricité, familiarisé avec

la construction et le fonctionnement de cet équipement

et les risques encourus, doit installer, ajuster, utiliser ou

entretenir cet équipement. Lire et comprendre ce manuel

et les autres manuels applicables dans leur intégralité avant

de continuer. Le non-respect de cette précaution peut

entraîner des blessures graves ou la mort.

DO NOT CONNECT LINE VOLTAGE

DIRECTLY TO THE MOTOR. IT WILL

DAMAGE THE MOTOR AND VOID

ANY WARRANTY!

16

010.1220.0719 01.21

by an arrow on the motor end cover. There are holes in the

end cover that allow you to see the cooling vanes, but it is

hard to see the rotation unless the fan is running very slowly.

For a more precise determination, you can also look inside

the fan housing as shown in Fig. 15. The arrow shown (not

actually inside fan housing) shows the proper rotation. It

is possible for the fan to operate with improper rotation.

However, the fan will only provide 25–30% of full capacity, will

cause damage to components and should be avoided.

Fan rotation can be changed on the EDrive by switching the

attachment position of any two power leads.

4.11 INSTALLING A PROVEN FLOW SYSTEM

If required by local codes, a safety system can be interlocked

with the appliance(s) to prove fan operation. The safety

system could utilize a Proven Draft Switch (PDS), a thermal

switch, a ow switch or a sail switch. The device must be

interlocked with the appliance(s) so it shuts down in case of

fan failure or power failure.

Please refer to the PDS Installation Manual for wiring

instructions.

If the installation includes a MEC24 Exhaust Control or

EBC 30/31 Modulating Pressure Fan Control, a PDS is not

required as the function is integrated into the control.

For more information about alternative safety system, please

consult ENERVEX.

Fig 15

AVERTISSEMENT

La turbine doit impérativement tourner dans le bon

sens. Une rotation en sens inverse entraînerait de

mauvaises performances de soufage, une surcharge

du moteur voire un grillage du moteur.

!

WARNING

Correct direction of wheel rotation is critical.

Reversed rotation will result in poor air performance,

motor overloading and possible burnout.

!

17

010.1220.0719 01.21

5. STARTUP AND CONFIGURATION

5.1 Managing the Keypad

The EDrive is congured and its operation monitored via the

keypad and display.

NAVIGATE Used to display real-time information, to access and exit parameter

edit mode and to store parameter changes

UP Used to increase speed in real-time mode or to increase parameter

values in parameter edit mode

DOWN Used to decrease speed in real-time mode or to decrease parameter

values in parameter edit mode

RESET / STOP Used to reset a tripped drive.

When in Keypad mode is used to Stop a running drive.

START When in keypad mode, used to Start a stopped drive or to reverse the

direction of rotation if bidirectional keypad mode is enabled

5.2 Operating the Display

Drive Stopped / Disabled Drive is enabled / running,

display shows the output

frequency (Hz)

Press the Navigate key for

< 1 second. The display

will show the motor current

(Amps)

Press the Navigate key for

< 1 second. The display will

show the motor Power (kW)

If P-10 > 0, pressing the

Navigation key for < 1

second will display the motor

speed (RPM)

18

010.1220.0719 01.21

5.4 Read Only Parameter Access 5.5 Resetting Parameter

5.3 Changing Parameters

Press and hold the

Navigate button >2

seconds

Use the UP and

DOWN buttons to

selected the required

parameter

Press the Navigate

button for <1 second

Adjust the value using

the UP and DOWN

buttons

Press for <1 second

to return to the

parameter menu

Press for >2 seconds

to return to the

operating display

Press and hold the

Navigate button >2

seconds

Use the UP and

DOWN buttons to

selected the required

parameter

Press the Navigate

button for <1 second

Adjust the value using

the UP and DOWN

buttons

Press for <1 second

to return to the

parameter menu

Press for >2 seconds

to return to the

operating display

To reset parameter

values to their factory

default settings, press

and hold UP, DOWN

and STOP buttons

for >2 seconds. The

display will show

“P-dEF”

Press the STOP

buttons This will

display “StoP”

Press the STOP

button. The display

will show “StoP”.

5.6 Resetting A Fault

5.7 LED Display

The EDrive E3 has a built in 6-digit 7-Segment LED

display. In order to display certain warning, the

following methods are used.

5.7.1 LED Display Layout

See Page 17

5.7.2 LED Display Meaning

See table below

Fig 7

19

010.1220.0719 01.21

5.9 INSTALLING A PROVEN FLOW SYSTEM

If required by local codes, a safety system can be interlocked

with the appliance(s) to prove fan operation. The safety

system could utilize a Proven Draft Switch (PDS), a thermal

switch, a ow switch or a sail switch. The device must be

interlocked with the appliance(s) so it shuts down in case of

fan failure or power failure.

Please refer to the PDS Installation Manual for wiring

instructions.

If the installation includes a MEC24 Exhaust Control or

EBC 30/31 Modulating Pressure Fan Control, a PDS is not

required as the function is integrated into the control.

For more information about alternative safety system, please

consult ENERVEX.

5.8 Start up Sequence (Auto Tune)

This start up process covers a BEFx Box Ventilator with

EDrive E3 controlled by an EBC 24 or EBS 31 Modulating

Draft Controller, which is the most common conguration

for a BEFx Box Ventilator. Start up processes for other

congurations are available from ENERVEX.

Note, that one of the most important steps in the start up

process is to activate “Auto Tune”. Any time a parameter

change is taking place, the last part is always to activate

“Auto Tune”.

These are the steps needed to perform a successful Auto

Tune & start up.

Start Signal: From EBC to Terminal 1 (eDrive).

From EBC to Terminal 2 (eDrive).

Speed Ref: From EBC to Terminal 6 (eDrive).

From EBC to Terminal 7 (eDrive).

1. Remove the control wire from EDrive Terminal 1.

2. Press and hold the button on the eDrive for 5+

seconds. The will take you to the parameter list

(likely P01).

3. Scroll to P14 & Set P14 to “1685” (with the keys),

press the button to accept.

4. Scroll to P38, Set P38 to “0” (with the keys), press the

button to accept.

5. Scroll to P52 and set P52 to “1” then press and hold the

button until the display indicates the drive is in “Auto

Tune”, then let go of the button.

After Auto Tune is complete, the eDrive should display

“STOP”.

6. Program the EBC Controller, if needed.

7. Re-connect the control wire to EDrive Terminal 1. The

EDrive should display H xxx (Hertz to the motor).

8. Conrm that the motor rotation direction is correct.

9. Press & Release the button on the EDrive until

“Amps” is displayed, note the Amp draw. Note the Amp

screen is designated by Axxxx

10. When done: If it is desired to lock the parameters: return

P38 to “0” then return P14 to “1700”.

20

010.1220.0719 01.21

6. MAINTENANCE AND TROUBLESHOOTING

6.1 CLEANING INTERVALS

The BEF ventilator is designed for prolonged use. It must be

inspected and cleaned at least every 12 months. The need

for cleaning is dependent on application type and ventilator

operation. In dryer applications, periodic cleaning is required

and during the rst couple months the ventilator should be

inspected every two weeks to determine lint build up rate. If

lint accumulates, it must be removed to prevent a lint re and

to ensure efcient operation of the dryers.

6.2 CLEANING

Deposits should be removed from the impellers and the

bottom of the ventilator:

1. Turn fan off at the repair switch.

2. When ventilator wheel no longer rotates, open access

door.

3. Clean inside housing and wheel with suitable water

detergent solution.

4. Dry all parts thoroughly with cloth.

5. Close and secure access door.

6. Turn ventilator on.

Vibrations can be caused by a dirty impeller. If necessary,

the impeller wheel can be removed. Prior to removal, mark

the impeller position on the shaft. Do not remove balancing

weight(s) on the impellers. No other maintenance is required.

6.3 SERVICE

Available spare parts are shown in Section 6.4 Replacement

Parts Ordering.

The motor has sealed and permanently lubricated bearings.

Bearing replacement should only be done by ENERVEX or an

authorized motor repair shop.

Fig 16

DANGER

Always disconnect, lock and tag power source

before installing or servicing. Failure to disconnect

power source can result in re, shock or serious

injury.

AVERTISSEMENT

L’appareil doit être rendu non opérationnel lors du

nettoyage de la turbine ou du caisson (fusibles,

retirés, sectionneur verrouilur).

!

WARNING

This unit should be made non-functional when

cleaning the wheel or housing )fuses removed,

disconnect locked off).

DANGER

Pour écarter les risques d’incendie, de choc

électrique ou de blessure grave, veiller à toujours

débrancher, verrouiller et étiqueter la source de

courant avant l’installation ou l’entretien

This manual suits for next models

8

Table of contents

Other ENERVEX Fan manuals