Engel HFI22 Series User manual

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

Document History

Operating Manual Rev. 1.3 www.engelantriebe.de Page 1

Document History

Document

Date

(dd.mm.yyyy)

Rev

Changes

HFI_BA_Rev1.0_180627_de

27.06.2018

1.0

First revision of HFI_BA

HFI_BA_Rev1.1_180912_en

12.09.2018

1.1

Update of the reference standards in chapters 4 and 6

HFI_BA_Rev1.2_190628_en

28.06.2019

1.2

Update of System Data

HFI_BA_Rev1.3_201125_en

25.11.2020

1.3

-Addition of internal wiring of DOs in installation plan

(10.2)

-Complementation of Requirements of the STO line

(10.1.3)

-Complementation of chapter Digital inputs/limit

switches (8.3)

-Revision of chapter I²t monitoring (8.5)

Copyright

The information and specifications in this document have been compiled with great care and to the best of our

knowledge. However, specifications differing between the document and the product cannot be eliminated with absolute

certainty. ENGEL assumes no liability whatsoever for errors or consequential damages resulting from these deviations.

No liability is assumed for damages which arise from the use of the device with the use of applications or defective cir-

cuits, either. ENGEL reserves the right to change, supplement or improve the document or the product without prior

notice. This document may not, without the express authorization of the copyright holder, be reproduced in any way or

be transmitted in another natural or machine language or on data carrier, whether this would take place electronically,

mechanically, visually or in any other manner.

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

Table of Contents

Operating Manual Rev. 1.3 www.engelantriebe.de Page 2

Table of Contents

DOCUMENT HISTORY.........................................................................................................................................1

TABLE OF CONTENTS..........................................................................................................................................2

1 INTRODUCTION ..............................................................................................................................................4

2 SYMBOLS USED IN THIS DOCUMENT .............................................................................................................4

3 ABBREVIATIONS USED IN THIS DOCUMENT .................................................................................................4

4 SAFETY INFORMATION AND INSTRUCTIONS FOR USE .................................................................................5

4.1 Definition of the direction of rotation for motors............................................................................................. 5

5 FUNCTIONAL DESCRIPTION ...........................................................................................................................6

5.1 Type key ....................................................................................................................................................7

6 TECHNICAL DATA ............................................................................................................................................8

6.1 System Data ............................................................................................................................................... 8

6.2 System Data HFI22xx ..................................................................................................................................9

6.2.1 HFI2230 characteristics ................................................................................................................... 10

6.2.2 HFI2260 characteristics ................................................................................................................... 10

6.3 System Data HFI26xx ................................................................................................................................ 11

6.3.1 HFI2630 characteristics ................................................................................................................... 12

6.3.2 HFI2660 characteristics ................................................................................................................... 12

6.4 System Data HFI32xx ................................................................................................................................ 13

6.4.1 HFI3260 characteristics ................................................................................................................... 14

6.4.2 HFI3290 characteristics ................................................................................................................... 14

6.5 System Data HFI37xx ................................................................................................................................ 15

6.5.1 HFI3760 characteristics ................................................................................................................... 16

6.5.2 HFI3790 characteristics ................................................................................................................... 16

6.6 Important technical Information ................................................................................................................. 17

6.6.1 Regenerative operation ................................................................................................................... 17

6.6.2 Lead fuses ..................................................................................................................................... 17

6.6.3 Service life expectancy .................................................................................................................... 17

6.6.4 Safety installations .......................................................................................................................... 18

7 DSERV SERVICE SOFTWARE ........................................................................................................................ 19

7.1 System requirements................................................................................................................................. 19

7.2 Installation and start-up of the program ...................................................................................................... 19

7.2.1 Installation of the software .............................................................................................................. 19

7.2.2 Program start ................................................................................................................................. 20

7.2.2.1 Error messages after program start ..................................................................................... 20

7.2.2.2 Starting multiple instances of DSerV .................................................................................... 21

7.3 Using the DSerV service software ............................................................................................................... 22

7.3.1 File menu....................................................................................................................................... 23

7.3.2 Optimisation menu.......................................................................................................................... 25

7.3.3 Monitor menu................................................................................................................................. 26

7.3.4 Diagnostic menu ............................................................................................................................. 28

7.3.5 Options menu................................................................................................................................. 29

7.3.6 ? menu .......................................................................................................................................... 29

7.3.7 Note on language selection.............................................................................................................. 29

8 PARAMETERISATION ................................................................................................................................... 30

8.1 Control interface selection .......................................................................................................................... 30

8.2 Operating mode selection........................................................................................................................... 31

8.2.1 Current control/torque control mode................................................................................................. 32

8.2.1.1 Current control with/without speed limitation ....................................................................... 32

8.2.1.2 Current setpoint................................................................................................................. 34

8.2.1.3 Speed limit source ............................................................................................................. 35

8.2.1.4 Parameters of the current control loop................................................................................. 36

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

Table of Contents

Operating Manual Rev. 1.3 www.engelantriebe.de Page 3

8.2.2 Speed control mode ........................................................................................................................ 38

8.2.2.1 Speed control with/without torque limitation ........................................................................ 38

8.2.2.2 Speed setpoint .................................................................................................................. 40

8.2.2.3 Torque limit source ............................................................................................................ 41

8.2.2.4 Parameters of the speed control loop .................................................................................. 42

8.2.3 Positioning mode ............................................................................................................................ 47

8.2.3.1 Homing............................................................................................................................. 48

8.2.3.2 General positioning parameters........................................................................................... 54

8.2.3.3 Target positions................................................................................................................. 61

8.3 Digital inputs/limit switches ........................................................................................................................ 66

8.4 Digital outputs .......................................................................................................................................... 69

8.5 I²t monitoring ........................................................................................................................................... 71

9 CONNECTION ASSIGNMENT ........................................................................................................................ 72

9.1 X1 –Supply and signals ............................................................................................................................. 72

9.2 X2 –CAN signal plug ................................................................................................................................. 73

9.3 X3 –STO signal plug ................................................................................................................................. 74

9.4 X4, X5 –Fieldbus modules ......................................................................................................................... 74

10 INSTALLATION ........................................................................................................................................... 75

10.1 Cable type, cable length and shielding ....................................................................................................... 75

10.1.1 Requirements on the supply/signal line (connection to X1)................................................................ 75

10.1.2 Requirements on the CAN line (connection to X2) ............................................................................ 75

10.1.3 Requirements on the STO line (connection to X3) ............................................................................ 77

10.1.4 Requirements on the fieldbus lines (connection to X4 and X5)........................................................... 77

10.2 Installation diagram ................................................................................................................................. 78

11 COMMISSIONING....................................................................................................................................... 79

12 STATUS DISPLAY, ERROR MESSAGES ....................................................................................................... 80

12.1 Status display.......................................................................................................................................... 81

12.1.1 HFI without communication module................................................................................................ 81

12.1.2 HFI with communication module .................................................................................................... 81

12.1.2.1 EtherNet/IP ..................................................................................................................... 82

12.1.2.2 EtherCAT......................................................................................................................... 82

12.1.2.3 PROFINET ....................................................................................................................... 83

12.2 General error messages ........................................................................................................................... 84

12.3 Error messages in positioning mode .......................................................................................................... 85

12.4 CAN status display ................................................................................................................................... 86

12.5 CAN error messages ................................................................................................................................ 86

13 CONTROLLER OPTIMISATION ................................................................................................................... 87

13.1 Current controller .................................................................................................................................... 87

13.2 Angle sensor offset determination, motor pole number ............................................................................... 87

13.3 Speed controller adjustment ..................................................................................................................... 88

14 MECHANICAL DIMENSIONS....................................................................................................................... 89

14.1 HFI 2230 / HFI 2260................................................................................................................................ 89

14.2 HFI 2630 / HFI 2660................................................................................................................................ 89

14.3 HFI 3260 / HFI 3290................................................................................................................................ 90

14.4 HFI 3760 / HFI 3790................................................................................................................................ 90

14.5 Mounting instructions for planetary gear GPK ............................................................................................. 91

HFI_BA_Rev1.3_201125_en

Technical changes reserved

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

Introduction

Operating Manual Rev. 1.3 www.engelantriebe.de Page 4

1Introduction

This document describes the technical data and functions of the HFI series of integrated synchronous servo drives. It

explains the functional capabilities of the drives, serves for the drive project design and explains the correct procedure

for installation and commissioning of the devices.

The drives of the HFI series are optionally equipped with different communication modules. The specific communication

protocols are described in the corresponding documents (CANopen® Manual, EtherCAT® Manual …).

2Symbols used in this document

Symbol

Signal

Word

Meaning

Attention!

This symbol refers to safety and warning notices. Non-observance can result in personal injury

and/or damage to property.

Note!

This symbol refers to useful hints, which should help to avoid or find errors.

3Abbreviations used in this document

Abbreviation

Meaning

AI

Analogue Input

CAN

Controller Area Network

CANopen

communication protocol for CAN-Bus systems

CiA

CAN in Automation - CAN users’ and manufacturers’ organization

DO

Digital Output

DI

Digital Input

DSP 402

CANopen device profile for drives and motion control

I/F

Interface

Node-ID

CAN Node Identifier

PMSM

Permanent Magnet Synchronous Motor

RPM

Revolutions per Minute

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

Safety information and instructions for use - Definition of the direction

of rotation for motors

Operating Manual Rev. 1.3 www.engelantriebe.de Page 5

4Safety information and instructions for use

Attention!

The safety instructions must be observed!

Non-observance of the safety instructions can result in personal injury and damage to prop-

erty.

During the installation, commissioning and maintenance, the applicable safety and

accident prevention regulations must be observed for the specific application.

The device applies as electronic equipment and is intended for operation in machines.

The safety instructions of the Machinery Directive (2006/42/EC) must be observed.

Prior to commissioning, it must be ensured that the drive does not pose any hazards

and that no uncontrolled movements can occur.

Do not plug or unplug connectors while energized!

The following regulations apply with no claim to completeness:

VDE 0100 Low-voltage electrical installations

EN 60204-1 Safety of machinery –Electrical equipment of machines

EN 61800 Adjustable speed electrical power drive systems

Attention!

Functional Safety

For devices with functional safety (HFIxxxx-Sx00-xx)the operating instructions supplement

Integrated Drives HFI equipped with STO-Module

must also be consulted.

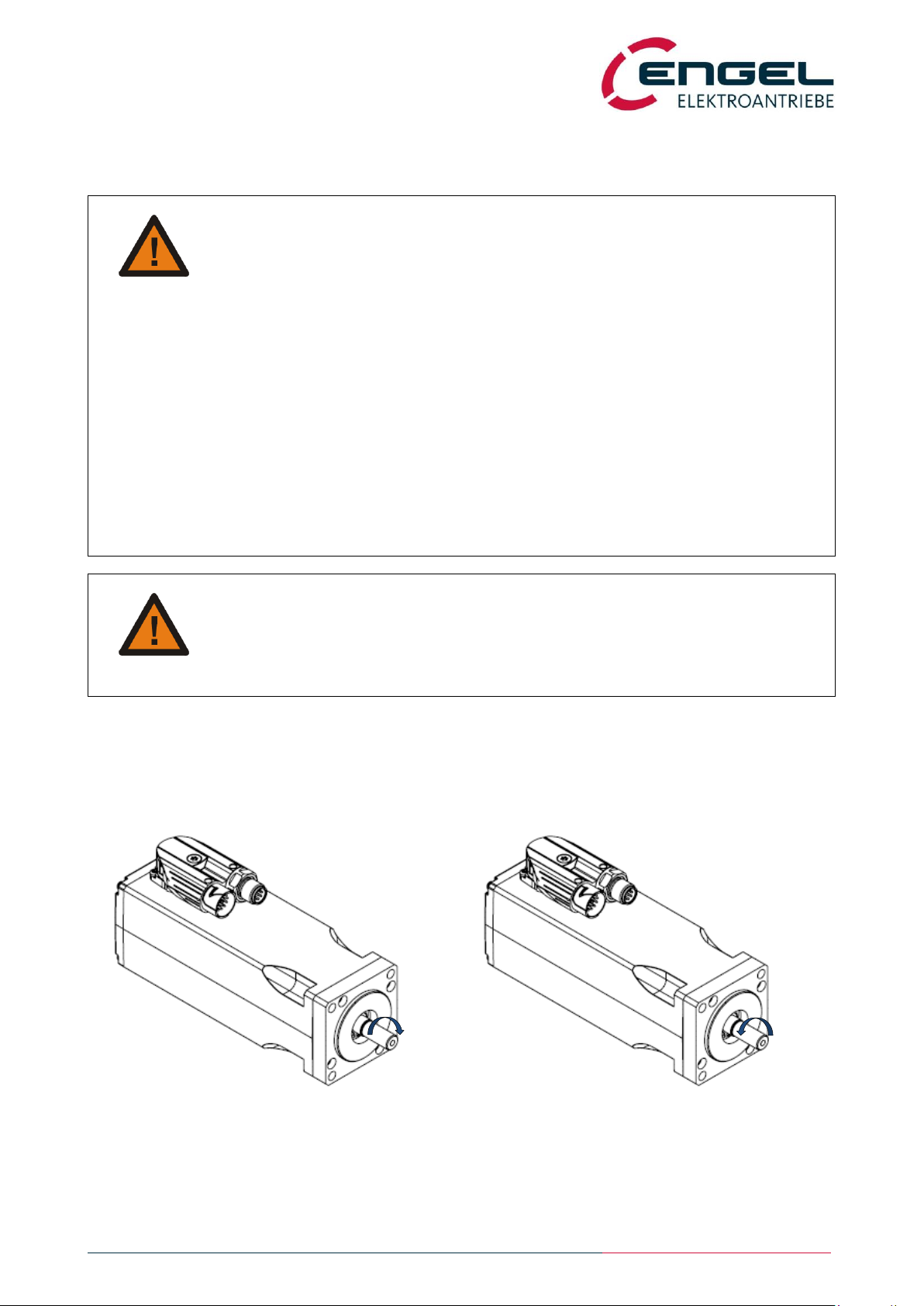

4.1 Definition of the direction of rotation for motors

In accordance with DIN EN 60034-8 the direction of rotation is the direction viewed from the drive end. I.e. with clock-

wise rotation the shaft turns clockwise and with counter-clockwise rotation the shaft turns counter-clockwise (viewing

direction onto the shaft end).

Figure 4-1: Direction of rotation for motors

clockwise rotation (cw)

counter-clockwise rotation (ccw)

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

Functional description

Operating Manual Rev. 1.3 www.engelantriebe.de Page 6

5Functional description

In the HFI series of integrated drives, powerful and dynamic synchronous servo motor systems (PMSM) designed in

concentrated winding technology are combined with compact electronics to form high-quality drive systems. The devices

are designed for operation at low voltage, their cascaded current, speed and position control loops provide a dynamic

operation. The integrated positioning control offers a temporally optimised point-to-point positioning with trapezoidal or

jerk-limited speed progression.

Operation of the device is possible either via fieldbus or via digital and analogue inputs and outputs. The flexibility of the

devices is provided through communication modules. The following variants are currently supported:

EtherCAT-communication module (Anybus CompactCom™40-series)

PROFINET-communication module (Anybus CompactCom™40-series)

EtherNet/IP-communication module (Anybus CompactCom™40-series)

Furthermore, the device is available in a CAN-variant. In this variant no communication module is required. Communica-

tion takes place via CANopen according to CiA DSP 402 V2.0.

The simple parameterisation/configuration of the device takes place with the parameterisation software DSerV (WIN-

DOWS, COM-Port).

Overview of features:

dynamic compact drives for decentralised use; no space in the control cabinet required

powerful designs with up to 1.8 Nm rated torque and 4.0 Nm peak torque

designs for operation at 24 VDC or 48 VDC

separated logic supply providing runtime data retention during power down conditions

short cycle times of the PI current (100 µs), PI speed (100 µs) and P position (200 µs) controllers with a powerful

signal processor

point to point positioning functionality with linear or Sin² speed ramp

12-bit high-resolution angle sensor system

variable fieldbus interface via communication module (optional)

CAN-interface (optional), galvanically isolated. CANopenwith implementation of device specification CiADSP 402

V2.0.

available with permanent magnet parking brake

available with planetary gear

high protection class IP54 (higher protection class on request)

parameterisation/configuration with the parameterisation software DSerV (WINDOWS, COM-Port)

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

Functional description - Type key

Operating Manual Rev. 1.3 www.engelantriebe.de Page 7

5.1 Type key

HFI

2660

N

2

00

-

options

Options:

see list of options below

Version:

00: standard type

xx: customer specific

Supply voltage:

2: 24 VDC; 4: 48 VDC

Safety:

N: non-safety

S: Safety

Drive size:

2230, 2260, 2630, 2660

3260, 3290, 3760, 3790

Series:

HFI

List of options (non-exhaustive)

HB

parking brake

permanent magnetic, installed in the motor

CO

CANopen Interface

additional M12 connector

EC

EtherCAT

fieldbus communication module

EI

EtherNet/IP

fieldbus communication module

PN

PROFINET

fieldbus communication module

SC

surface coating

housing

GPK-xxx

planetary gear GPK

mounted onto the motor, gear reduction xxx : 1

Attention!

Functional Safety

For devices with functional safety (HFIxxxx-Sx00-xx)the operating instructions supplement

Integrated Drives HFI equipped with STO-Module

must also be consulted.

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

Technical Data - System Data

Operating Manual Rev. 1.3 www.engelantriebe.de Page 8

6Technical Data

6.1 System Data

Designation

Unit

Value

additional information

Input Voltage*1)

VDC

24 / 48

20 %

Ambient Temperature

°C

0 ... 40

No condensation permissible

Storage Temperature

°C

-25 ... 60

No condensation permissible

Number of poles

6

Protection Class

IP54

(higher protection class on re-

quest)

Analogue Inputs

AI1 (differential input)

10 V, 12 bit, Ri=22 k

can optionally be used as digital

input (DI6)

Digital Inputs

DI1 ... DI8

V

0.0 Uoff 5.0

15.0 Uon 30

DI1 = control enable

DI4/DI5 can optionally be used

as digital output DO2/DO1

Digital Outputs

DO1, DO2

24 V, 50 mA

open collector, ground switch-

ing*3), 33 series resistance,

without pull-up resistor,

can optionally be used as inputs

Serial Interfaces

RS232

Communication with DSerV

parameterisation software

CAN 2.0B (max. 1 MBit/s)

galvanically isolated

without termination resistor

Electromagnetic compati-

bility

Emission *2)

DIN EN 61800-3: 2012-09

second environment/limited

availability (Cat. C3)

Immunity

DIN EN 61800-3: 2012-09

second environment

*1) Observe chapter 6.6.1 Regenerative operation

*2) Cable-conducted emissions must be suppressed through appropriate filtering measures in the energy supply (e.g.

power supply unit) of the device

.

*3) Internal wiring of DOs see chapter 10.2 Installation diagram.

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

Technical Data - System Data HFI22xx

Operating Manual Rev. 1.3 www.engelantriebe.de Page 9

6.2 System Data HFI22xx

Designation

Unit

Value

additional information

HFI2230

HFI2260

Rated speed

min-1

4000

3000

Peak speed

min-1

5000

4000

Rated input current*1)

ADC

6.1 / 3.0

7.1 / 3.6

24V-Type/48V-Type

Rated motor current*2)

Aspk

9.5 / 4.8

12.3 / 6.2

24V-Type/48V-Type

Peak motor current*2)

Aspk

19.5 / 9.8

25.0 / 12.5

24V-Type/48V-Type

Motor current measurement

range

A

27.5 / 13.8

55.0 / 27.5

24V-Type/48V-Type

Rated power*3)

W

95

120

Rated torque*3)

Nm

0.23

0.38

Peak torque

Nm

0.50

0.8

Torque constant

Nm/A

0.027 / 0.054

0.033 / 0.066

24V-Type/48V-Type

Voltage constant

V/1kmin-1

3.3 / 6.6

4.0 / 8.0

24V-Type/48V-Type

Flange dimension

mm²

47 x 47

Drive length (without fieldbus

module)*4)

mm

129 / 161

159 / 191

without/with parking brake

Weight

kg

0.85 / 1.0

1.15 / 1.3

without/with parking brake

Parking Brake (optional):

automatically operated

Static braking torque

Nm

1.0

Power (electric)

W

10

*1) The rated input current is the direct current drawn in nominal operation (rated torque at rated speed) from the input

voltage (24 VDC or 48 VDC). The current drawn from the input voltage is proportional to the converted power, not

to be confused with the torque-building motor current, which is displayed as sine peak value in DSerV and is pro-

portional to the motor torque.

Please also observe that the supply line is lossy. This leads to a reduction in voltage and speed at the motor system

and to increased power consumption of the device. A connection line with a nominal cross-section of 1.5 mm² al-

ready has an overall loss resistance of approx. 2 x 12.5 mΩ/m (conductors and return conductors)! Appropriate pow-

er reserves must be provided in the supply!

*2) Motor phase current as a sine peak value, which is required for the generation of the rated or peak torque. Motor

phase current is displayed in DSerV. Not to be confused with the current taken from the supply.

*3) The specified values apply for the installation of the drive on a system surface made of aluminium (A = 0.1 m²,

d = 10 mm). It must be taken into consideration that the specified continuous output power must be derated for

thermally unfavourable couplings.

*4) With fieldbus module the length of the drive increases by 14 mm.

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

System Data HFI22xx - HFI2230 characteristics

Operating Manual Rev. 1.3 www.engelantriebe.de Page 10

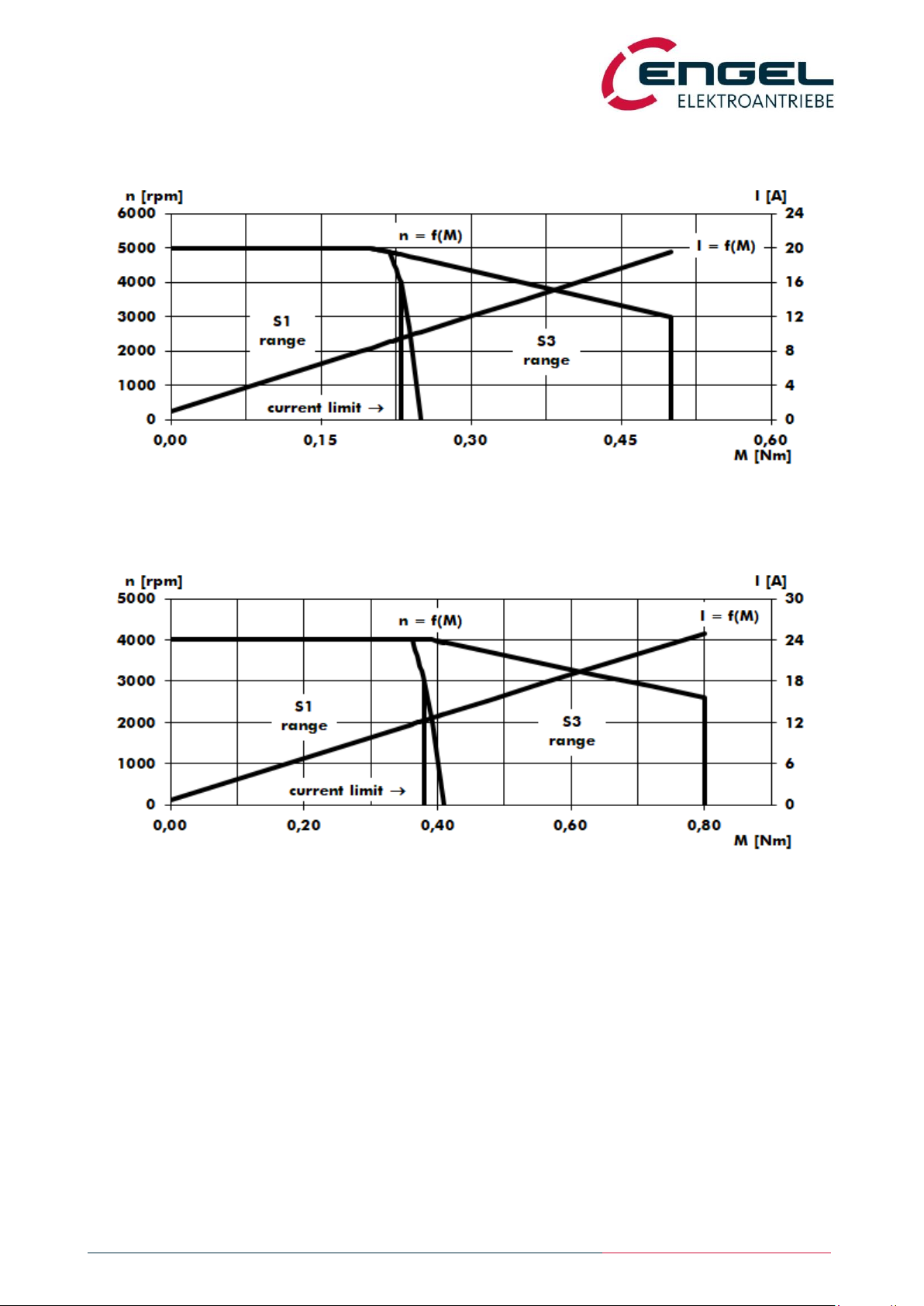

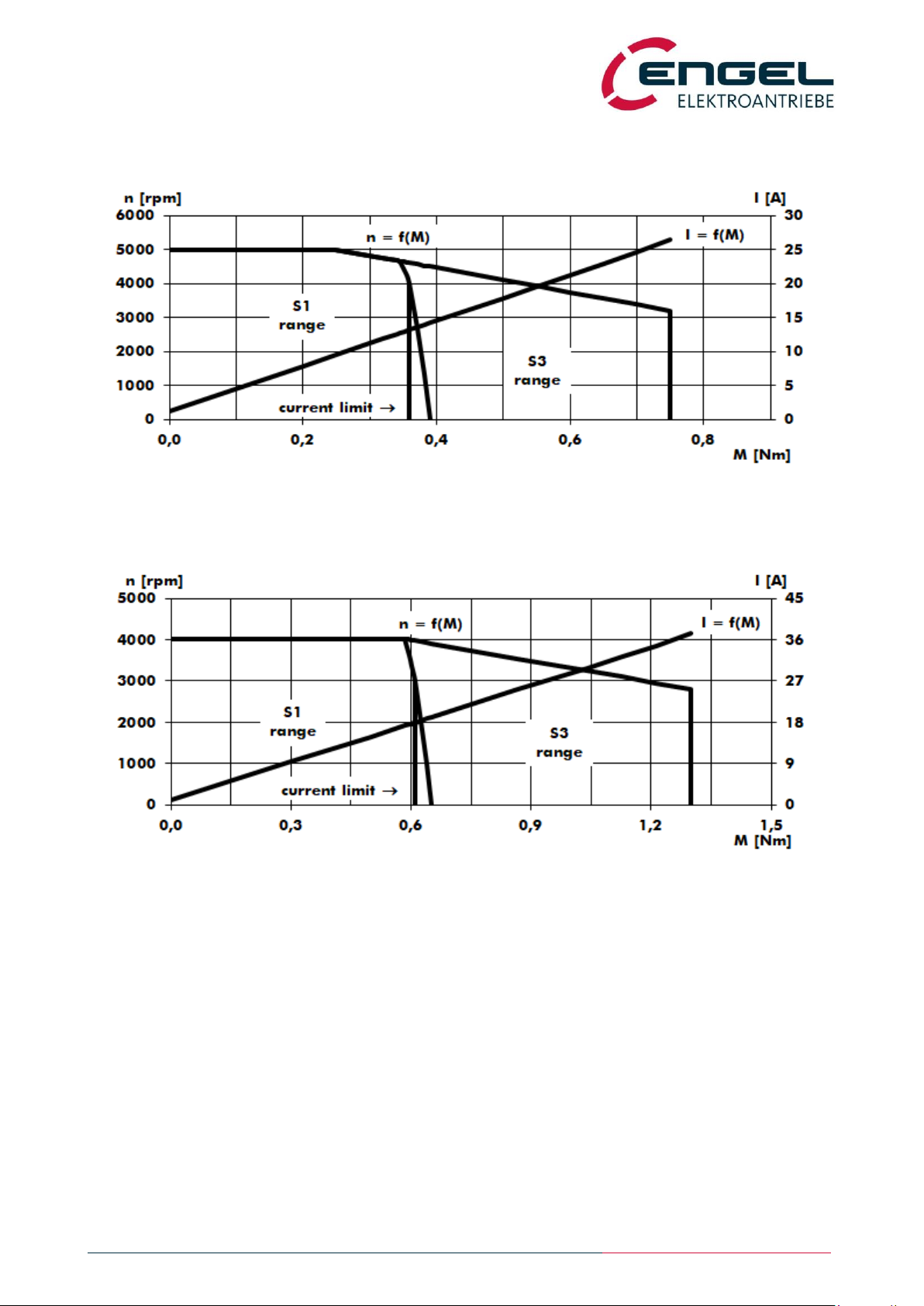

6.2.1 HFI2230 characteristics

Figure 6-1: HFI2230 characteristics, 24 V, 4000/5000 rpm

6.2.2 HFI2260 characteristics

Figure 6-2: HFI2260 characteristics, 24 V, 3000/4000 rpm

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

Technical Data - System Data HFI26xx

Operating Manual Rev. 1.3 www.engelantriebe.de Page 11

6.3 System Data HFI26xx

Designation

Unit

Value

additional information

HFI2630

HFI2660

Rated speed

min-1

4000

3000

Peak speed

min-1

5000

4000

Rated input current*1)

ADC

8.8 / 4.4

10.6 / 5.3

24V-Type/48V-Type

Rated motor current*2)

Aspk

13.2 / 6.8

17.9 / 8.9

24V-Type/48V-Type

Peak motor current*2)

Aspk

26.5 / 13.7

37.5 / 18.5

24V-Type/48V-Type

Motor current measurement

range

A

55.0 / 27.5

Rated power*3)

W

150

190

Rated torque*3)

Nm

0.36

0.61

Peak torque

Nm

0.75

1.30

Torque constant

Nm/A

0.030 / 0.058

0.036 / 0.073

24V-Type/48V-Type

Voltage constant

V/1kmin-1

3.6 / 7.0

4.4 / 8.8

24V-Type/48V-Type

Flange dimension

mm²

55 x 55

Drive length (without fieldbus

module)*4)

mm

136 / 166

166 / 196

without/with parking brake

Weight

kg

1.2 / 1.45

1.6 / 1.85

without/with parking brake

Parking Brake (optional):

automatically operated

Static braking torque

Nm

2.0

Power (electric)

W

10

*1) The rated input current is the direct current drawn in nominal operation (rated torque at rated speed) from the input

voltage (24 VDC or 48 VDC). The current drawn from the input voltage is proportional to the converted power, not to

be confused with the torque-building motor current, which is displayed as sine peak value in DSerV and is propor-

tional to the motor torque.

Please also observe that the supply line is lossy. This leads to a reduction in voltage and speed at the motor system

and to increased power consumption of the device. A connection line with a nominal cross-section of 1.5 mm² al-

ready has an overall loss resistance of approx. 2 x 12.5 mΩ/m (conductors and return conductors)! Appropriate pow-

er reserves must be provided in the supply!

*2) Motor phase current as a sine peak value, which is required for the generation of the rated or peak torque. Motor

phase current is displayed in DSerV. Not to be confused with the current taken from the supply.

*3) The specified values apply for the installation of the drive on a system surface made of aluminium (A = 0.1 m²,

d = 10 mm). It must be taken into consideration that the specified continuous output power must be derated for

thermally unfavourable couplings.

*4) With fieldbus module the length of the drive increases by 14 mm.

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

System Data HFI26xx - HFI2630 characteristics

Operating Manual Rev. 1.3 www.engelantriebe.de Page 12

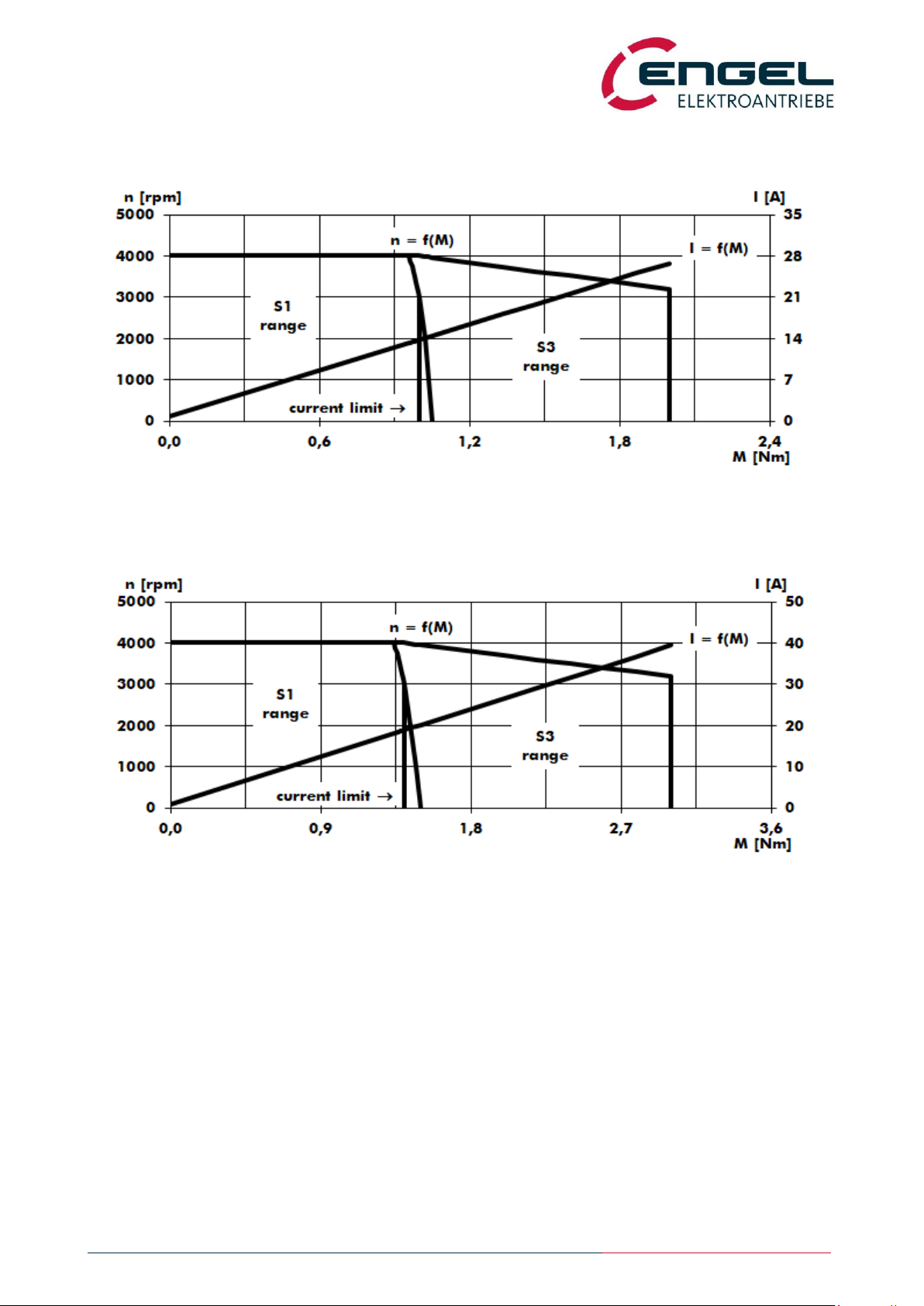

6.3.1 HFI2630 characteristics

Figure 6-3: HFI2630 characteristics, 24 V, 4000/5000 rpm

6.3.2 HFI2660 characteristics

Figure 6-4: HFI2660 characteristics, 24 V, 3000/4000 rpm

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

Technical Data - System Data HFI32xx

Operating Manual Rev. 1.3 www.engelantriebe.de Page 13

6.4 System Data HFI32xx

Designation

Unit

Value

additional information

HFI3260

HFI3290

Rated speed

min-1

2600 / 3000

- / 3000

24V-Type/48V-Type

Peak speed

min-1

4000

Rated input current*1)

ADC

14.0 / 8.0

- / 10.8

24V-Type/48V-Type

Rated motor current*2)

Aspk

25.3 / 13.7

- / 18.9

24V-Type/48V-Type

Peak motor current*2)

Aspk

51.5 / 26.8

- / 39.5

24V-Type/48V-Type

Motor current measurement

range

A

75

Rated power*3)

W

260 / 315

440

Rated torque*3)

Nm

0.95 / 1.00

1.40

Peak torque

Nm

2.00

3.00

Torque constant

Nm/A

0.040 / 0.077

- / 0.078

24V-Type/48V-Type

Voltage constant

V/1kmin-1

4.8 / 9.3

- / 9.4

24V-Type/48V-Type

Flange dimension

mm²

65 x 65

Drive length (without fieldbus

module)*4)

mm

163 / 193

193 / 223

without/with parking brake

Weight

kg

2.1 / 2.4

2.7 / 3.0

without/with parking brake

Parking Brake (optional):

automatically operated

Static braking torque

Nm

3.5

Power (electric)

W

12

*1) The rated input current is the direct current drawn in nominal operation (rated torque at rated speed) from the input

voltage (24 VDC or 48 VDC). The current drawn from the input voltage is proportional to the converted power, not

to be confused with the torque-building motor current, which is displayed as sine peak value in DSerV and is pro-

portional to the motor torque.

Please also observe that the supply line is lossy. This leads to a reduction in voltage and speed at the motor system

and to increased power consumption of the device. A connection line with a nominal cross-section of 1.5 mm² al-

ready has an overall loss resistance of approx. 2 x 12.5 mΩ/m (conductors and return conductors)! Appropriate pow-

er reserves must be provided in the supply!

*2) Motor phase current as a sine peak value, which is required for the generation of the rated or peak torque. Motor

phase current is displayed in DSerV. Not to be confused with the current taken from the supply.

*3) The specified values apply for the installation of the drive on a system surface made of aluminium (A = 0.1 m²,

d = 10 mm). It must be taken into consideration that the specified continuous output power must be derated for

thermally unfavourable couplings.

*4) With fieldbus module the length of the drive increases by 14 mm.

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

System Data HFI32xx - HFI3260 characteristics

Operating Manual Rev. 1.3 www.engelantriebe.de Page 14

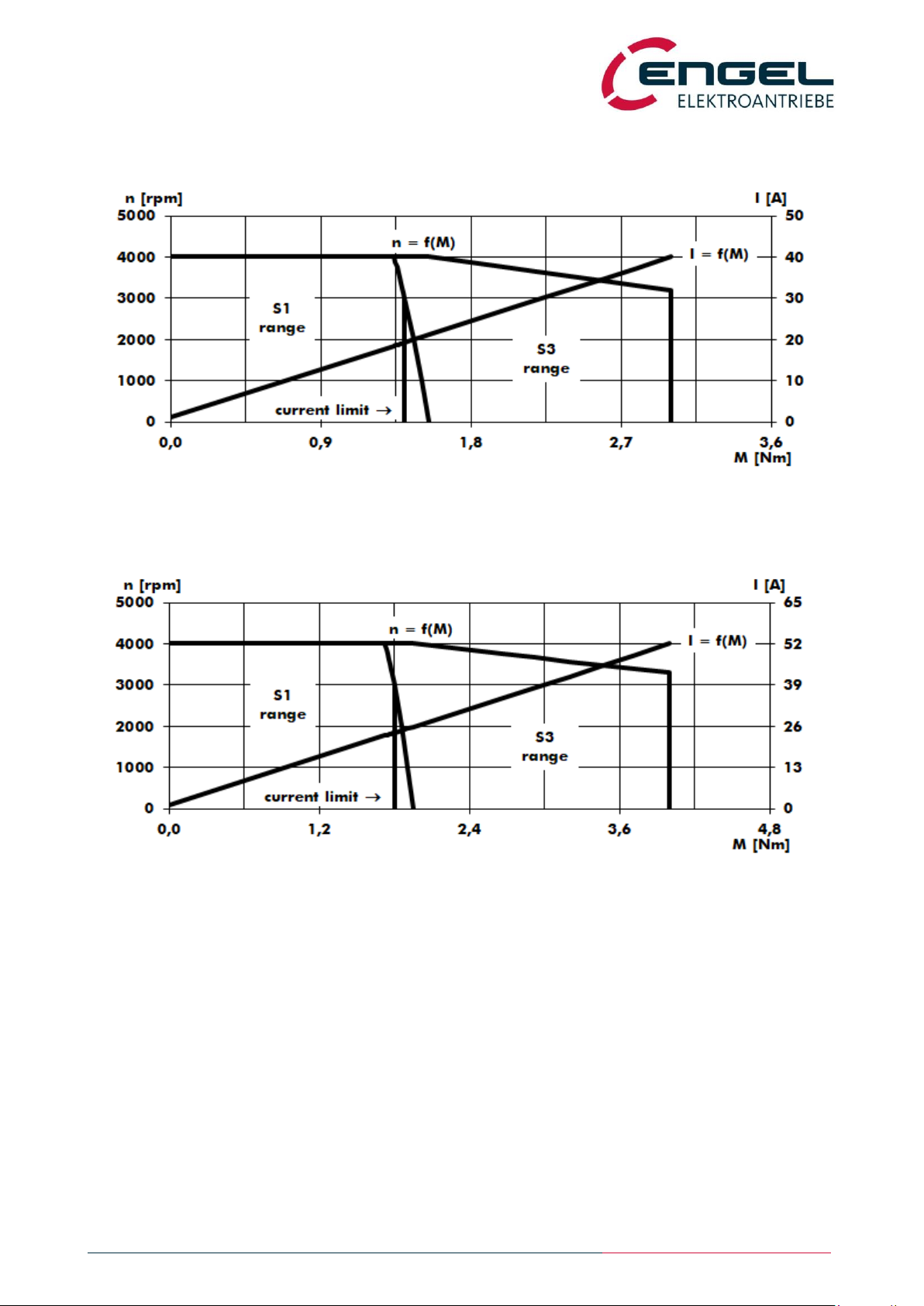

6.4.1 HFI3260 characteristics

Figure 6-5: HFI3260 characteristics, 48 V, 3000/4000 rpm

6.4.2 HFI3290 characteristics

Figure 6-6: HFI3290 characteristics, 48 V, 3000/4000 rpm

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

Technical Data - System Data HFI37xx

Operating Manual Rev. 1.3 www.engelantriebe.de Page 15

6.5 System Data HFI37xx

Designation

Unit

Value

additional information

HFI3760

HFI3790

Rated speed

min-1

3000

Peak speed

min-1

4000

Rated input current*1)

ADC

- / 10.7

- / 13.4

24V-Type/48V-Type

Rated motor current*2)

Aspk

- / 19.2

- / 23.9

24V-Type/48V-Type

Peak motor current*2)

Aspk

- / 40.0

- / 52.0

24V-Type/48V-Type

Motor current measurement

range

A

75

Rated power*3)

W

440

565

Rated torque*3)

Nm

1.4

1.8

Peak torque

Nm

3.00

4.00

Torque constant

Nm/A

- / 0.077

- / 0.079

24V-Type/48V-Type

Voltage constant

V/1kmin-1

- / 9.3

- / 9.5

24V-Type/48V-Type

Flange dimension

mm²

75 x 75

Drive length (without fieldbus

module)*4)

mm

168 / 198

198 /228

without/with parking brake

Weight

kg

2.95 / 3.5

3.8 / 4.15

without/with parking brake

Parking Brake (optional):

automatically operated

Static braking torque

Nm

3.5

Power (electric)

W

12

*1) The rated input current is the direct current drawn in nominal operation (rated torque at rated speed) from the input

voltage (24 VDC or 48 VDC). The current drawn from the input voltage is proportional to the converted power, not to

be confused with the torque-building motor current, which is displayed as sine peak value in DSerV and is propor-

tional to the motor torque.

Please also observe that the supply line is lossy. This leads to a reduction in voltage and speed at the motor system

and to increased power consumption of the device. A connection line with a nominal cross-section of 1.5 mm² al-

ready has an overall loss resistance of approx. 2 x 12.5 mΩ/m (conductors and return conductors)! Appropriate pow-

er reserves must be provided in the supply!

*2) Motor phase current as a sine peak value, which is required for the generation of the rated or peak torque. Motor

phase current is displayed in DSerV. Not to be confused with the current taken from the supply.

*3) The specified values apply for the installation of the drive on a system surface made of aluminium (A = 0.1 m²,

d = 10 mm). It must be taken into consideration that the specified continuous output power must be derated for

thermally unfavourable couplings.

*4) With fieldbus module the length of the drive increases by 14 mm.

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

System Data HFI37xx - HFI3760 characteristics

Operating Manual Rev. 1.3 www.engelantriebe.de Page 16

6.5.1 HFI3760 characteristics

Figure 6-7: HFI3760 characteristics, 48 V, 3000/4000 rpm

6.5.2 HFI3790 characteristics

Figure 6-8: HFI3790 characteristics, 48 V, 3000/4000 rpm

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

Important technical Information - Regenerative operation

Operating Manual Rev. 1.3 www.engelantriebe.de Page 17

6.6 Important technical Information

6.6.1 Regenerative operation

Attention!

Regenerative operation (generator mode) leads to an increase in operational voltage!

Observe permissible voltage values of the power supply and consumers connected in paral-

lel!

The device is equipped with an internal ballast circuit (brake chopper), which is capable of converting a low brake power

into heat for a short duration. Brake power conversion leads to a temperature rise in the motor system. Together with

the intermediate circuit (DC-link) capacity, dynamically occurring brake energies can be accommodated.

If the device operates quasi-statically in generator mode, suitable measures must be taken for the removal/conversion of

the energy (e.g. through an external ballast circuit).

Regenerated energy leads to an increase of the DC-link voltage, which is returned directly to the power connection of

the device and/or to the feeding direct current source (if necessary, provide a diode for the decoupling of the operating

voltage). The effect of the voltage increase when braking can be reduced, if necessary, by selecting a less abrupt, that is

a longer deceleration ramp.

If applicable, regenerated energy can be distributed to other loads connected to the supply voltage in parallel.

If regenerated braking energy cannot be converted, the terminal voltage rises until an overvoltage error (Error 4) is

triggered (see chapter 12.2 General error messages). The following voltage limits are specified in the devices:

Devices with 24 V operating voltage:

Ballast circuit working voltages: VBallast ON 30 V , VBallast OFF 27 V

Triggering of the overvoltage error: VError4 32 V

Devices with 48 V operating voltage:

Ballast circuit working voltages: VBallast ON 60 V , VBallast OFF 55 V

Triggering of the overvoltage error: VError4 65 V

6.6.2 Lead fuses

The device is not internally fused. A suitable external fuse must be provided (see chapter 10.2 Installation diagram and

chapter 8.5 I²t monitor).

6.6.3 Service life expectancy

The service life of the device is largely determined by the stress of the DC-link capacitors. With an ambient temperature

of 40 °C and motor current = motor rated current, a service life expectancy of approx. 15,000 h can be assumed. With

lower motor currents and/or lower ambient temperatures, higher service life expectancies arise.

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

Important technical Information - Safety installations

Operating Manual Rev. 1.3 www.engelantriebe.de Page 18

6.6.4 Safety installations

The device has extensive sensor equipment for the monitoring of the controller, power stage, motor and communication

with the outside. All occurring errors lead to the shut-down of the power stage (motor de-energised, no torque) and are

signalled by the red LED of the status display with a blinking code. Switching the power stage on again is only possible if

the cause of the error has been remedied and the error has been acknowledged by the control enable or –with fieldbus

control –has been reset via fieldbus.

The following safety functions are implemented:

The overcurrent/short-circuit monitor detects excessive current flow in the motor phases.

The I²t monitor protects the motor and power stage from thermal overload by limiting the motor current to

the rated current (see chapter 8.2.1.4 Parameters of the current control loop) after the lapse of a permissible

overload duration. The overload duration depends on various factors. For a detailed description of the I²t moni-

tor see chapter 8.5 I²t monitor.

The overvoltage monitor triggers as soon as the DC-link voltage exceeds a maximum permissible value (see

chapter 6.6.1 Regenerative operation).

The undervoltage monitor triggers as soon as the DC-link voltage falls below 18 V.

The temperature of the power stage is measured and the power stage is switched off when the temperature

exceeds 90 °C.

The signals of the internal angle sensor system are monitored for valid statuses. Invalid signal combina-

tions lead to the shut-down of the power stage.

Integrated Synchronous Servo Drives

HFI 22xx / HFI 26xx / HFI 32xx / HFI 37xx

DSerV service software - System requirements

Operating Manual Rev. 1.3 www.engelantriebe.de Page 19

7DSerV service software

The DSerV service software provides a simple and clearly laid out configuration of the devices. Important operating

statuses, such as speed, current, enable, etc. can be seen at a quick glance. Scalings, current limits and operating

modes are adjustable through menus. Device settings can be saved on the hard disk of the PC. The program language is

selectable: German/English.

7.1 System requirements

For the installation and operation of the DSerV service software, the following requirements apply:

PC/Laptop with Microsoft Windows XP, Windows 7, Windows 8, Windows 10

CDROM-Drive

RS232 serial interface (COM1 ... COM99):

On-Board or USB/RS232 converter, supported baud rate at least 115,2 kBaud

serial connection cable (see chapter 10.2 Installation diagram)

7.2 Installation and start-up of the program

Note!

Read the licence agreement on the provided data carrier of the software before installation.

With the installation of the DSerV service software, you agree to the conditions of the li-

cense agreement.

7.2.1 Installation of the software

For the installation of DSerV it is sufficient to copy the program files to a working directory:

1. Start WINDOWS.

2. Insert the CDROM with DSerV service software in an appropriate drive.

3. Start WINDOWS Explorer and display CDROM contents (main directory).

Alternative 1 (recommended):

4. Start the file DSerV.exe directly from the CDROM. An installation menu opens.

Note: The installation menu only opens, if DSerV.exe is started from a removable data carrier such as a

CDROM.

5. Follow the further instructions in the installation menu.

Alternative 2:

6. Manually copy the entire directory tree from the CDROM to a previously created working directory on the inter-

nal hard disk of the PC.

(This process can also be applied if the software was supplied in electronic form and not on CDROM.)

This manual suits for next models

11

Table of contents

Popular DC Drive manuals by other brands

Toshiba

Toshiba ATAPI installation manual

SOMFY

SOMFY Sonesse 40 RTS manual

ABB

ABB DCS800 Hardware manual

KB Electronic

KB Electronic KBVF Series Installation and Operation Manual Supplemental Information

American Control Electronics

American Control Electronics PAT450-10 quick start guide

Control Techniques

Control Techniques Commander SK Getting started guide

Lenze

Lenze AC Tech MCH Series Communications guide

Aura

Aura VENOM-8 owner's manual

ZIEHL-ABEGG

ZIEHL-ABEGG PMIcontrol Basic-M Series operating instructions

Emerson

Emerson Dixell XEV23D Installing and operating instructions

ABB

ABB ACS580MV quick guide

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 6000 user manual