1592025930 XEV23D GB r1.0 07.10.2011.doc XEV23D 3/4

Forced Opening percentage: (0 to 100; nU) if FoP=nU valve works with regulation

algorithm. If FoP is different from nU the valve stays at FoP opening percentage. This

function could be useful during plant starting or during service operations.

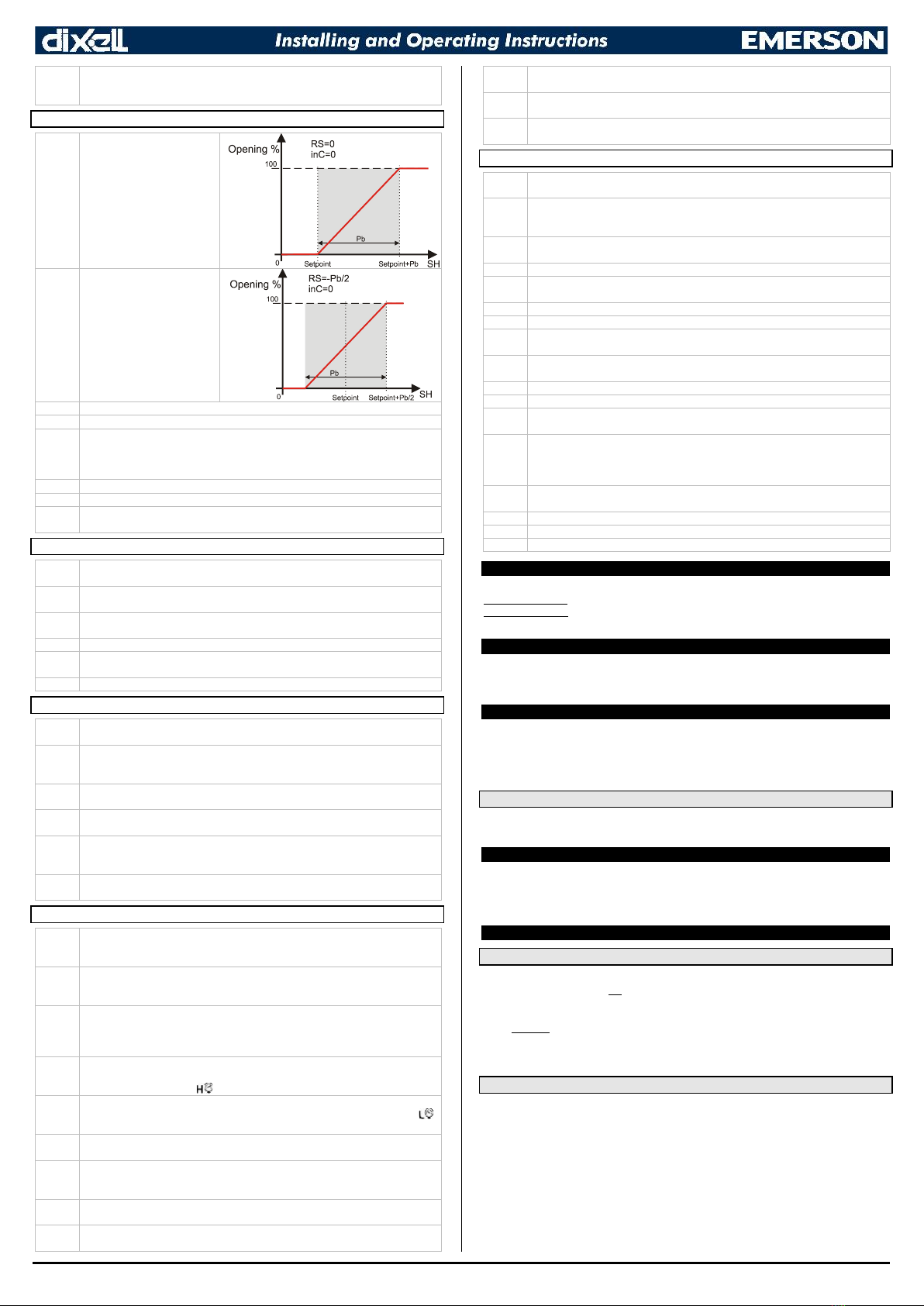

PID PARAMETERS (trained staff)

Proportional band in chill

mode:

(0.1 to 50.0°C; 1 to 90°F)

PI proportional band. A value

bigger than 5°C is advised.

Band Offset:

(-12.0 to 12.0°C; -21 to 21°F)

PI band offset. It permits to

move the proportional band of

the PI. With rS=0 the band is

between [SEt to SEt+Pb].

Integration time in chill mode: (0 to 255s) PI integration time.

Derivative time in chill mode: (0 to 255s) PID derivative time.

Proportional band in heat-pump mode:

(0.1 to 50.0°C; 1 to 90°F)

PI proportional band. A value bigger than 5°C is advised.

Integration time in heat-pump mode: (0 to 255s) PI integration time.

Derivative time in heat-pump mode : (0 to 255s) PID derivative time.

Dead band: (0.0 ÷ 25.5 °C; 0 ÷ 45°F) if the superheat is inside the band SH-db/2÷

SH+db/2 the position of the valve is not updated

PROBE PARAMETERS

Type of Pressure transducer: (420; 5V) it sets type of pressure transducer to use. 420

= 4 to 20mA pressure transducer; 5V = 0 to 5V ratiometric transducer.

Probe value at 4mA or at 0V: (-1.0 to P20 bar; -14 to P20 psi) pressure value

measured by probe at 4mA or at 0V (related to PrM parameter).

Probe value at 20mA or at 5V: (PA4 to 50.0 bar; PA4 to 725 psi) pressure value

measured by probe at 20mA or at 5V (related to PrM parameter).

Pressure probe calibration: -12.0 to 12.0 bar; -174 to 174 psi.

Type of temperature probe: (PtM; ntC) it allows to set the kind of probe used by the

instrument: PtM = PT1000 probe, ntC = NTC-US probe.

Temperature probe calibration: -12.0 to 12.0°C; -21 to 21°F.

DIGITAL INPUTS

Digital Input 1 (Free of voltage) digital input polarity: (cL, oP) CL = activated when

closed; oP = activated when opened.

Digital Input 1 (Free of voltage) digital input function: (CCL, rL)

-CCL = cooling call;

-rL = digital input activates relay.

Digital Input 1 (Free of voltage) activation delay: (0 to 255 min) this activation delay is

used only if digital input is configured as rL.

Digital Input 2 (Free of voltage) digital input polarity: (CL, oP) CL = activated when

closed; oP = activated when opened.

Digital Input 2 (Free of voltage) digital input function: (CCL, P-C)

- CCL = cooling call;

- P-C = Switch form chiller to heat pump mode.

Digital Input 2 (High voltage) activation delay: (0 to 255 min) this activation delay is

used only if digital input is configured as rL.

ALARM

Alarm delay after restarting regulation: (0.0 to 42min 00s, res. 10s) time between

digital input activation (configured as CCL) and alarm signalling. The LSH alarm is

always signalled also during this time.

Type of alarm signalled by relay: (ALL, SH, PrE, di) ALL = all alarm; SH = superheat

alarm; PrE = pressure alarm; di = activation only when digital input configured as rL is

active.

Lower Pressure Limit for superheat regulation: (PA4 to P20 bar; PA4 to P20 psi)

when suction pressure comes down to LPL, the regulation is performed with a LPL fixed

value for pressure. When suction pressure comes back to LPL, the normal pressure

value is used (related to PrM parameter).

Maximum Operating Pressure threshold: (LoP to P20bar; LoP to P20 psi) if suction

pressure exceeds maximum operating pressure value, the instrument signals this

situation with an alarm LED (related to PrM parameter).

Lowest Operating Pressure: (PA4 to MoP bar; PA4 to MoP psi) if the suction pressure

comes down to this value, a low pressure alarm will be signalled with an alarm LED

(related to PrM parameter).

Pressure alarm Hysteresis: (0.1 to 5.0 bar, 1 to 72 psi) pressure hysteresis to disable

alarm signalling.

Delta MoP-LoP: (0 to 100%) when a MoP alarm occurs valve will close of the dML

percentage every one second until MoP alarm is active. When LoP occurs, valve will

open of the dML percentage every one second until LoP alarm is active.

Maximum SuperHeat alarm: (LSH to 80.0°C; LSH to 144°F) when superheat exceeds

this value, an high superheat alarm will be signalled after interval SHd.

Lowest SuperHeat alarm: (0.0 to MSH°C; 0 to MSH°F) when superheat goes down to

this value a low superheat alarm is signalled after interval SHd.

SuperHeat alarm Hysteresis: (0.0 to 25.5°C; 1 to 77°F) hysteresis for superheat alarm

deactivation.

SuperHeat alarm activation delay: (0 to 255 s) when a superheat alarm occurs, the

delay time SHd have to expire before signalling this alarm.

Fast-recovery Constant: (0 to 100 s) permits to increase integral time when SH is

below the set-point. If FrC=0 fast recovery function is disabled.

DISPLAY

Local display: (SH; PEr; P1; P2) SH = superheat; PEr = valve opening percentage;

P1 = value of temperature measured; P2 = pressure measured by P2 probe.

Temperature measurement units: (°C; °F) °C= Celsius degree; °F = Fahrenheit

degree. NOTE: by changing measurement unit, the regulation parameters have to be

correctly changed.

Pressure Measurement units: (bAr, PSi) bAr = bar; PSi = psi. NOTE: by changing

measurement unit, the regulation parameters have to be correctly changed.

Resolution (only °C): (dE; in) dE = decimal format; in = integer format.

Pressure visualization Mode: (rEL; AbS) rEL = relative pressure; AbS = absolute

pressure. All pressure parameters depend on this parameter.

Cooling Percentage (read only): Display the cooling percentage.

Temperature Probe value (read only): it shows temperature probe value from P1.

Pressure probe value (read only): it shows pressure probe value. The value depends

on PrM.

Temperature from P2 (read only): it shows temperature obtained from conversion of

pressure value.

Opening Percentage (read only): it shows the actual opening percentage of the valve.

Free of voltage digital input State (read only): it shows the free of voltage digital input.

High voltage digital input State (read only): it shows the high voltage digital input

state.

ModBus: (AdU; Std) AdU = (Only for XWEB systems) in this case XEV and

thermostatic controller are considered an alone instrument (it requires a custom library

for XWEB); Std = to use XEV in stand-alone mode, in this case normal Modbus-RTU

protocol is used.

RS485 Serial Address: (1 to 247) Identifies the instrument address when connected to a

ModBUS compatible monitoring system.

Parameters map: (read only) it identifies parameters map written by factory.

Release Firmware: (read only) it shows firmware release.

9. DIGITAL INPUTS

The device is provided with two digital inputs.

The first one (13-15) is free of voltage and is used to enable the regulation

The second one (8-9) is free of voltage and is used to switch form chiller to heat-pump mode.

One of these inputs must be configured as cooling call.

10. FORCED OPENING

If necessary, by changing FoP parameter it’s possible to force the valve opening. For example, by

setting FoP=50 the valve will be open at half of full scale. To disable this function it’s necessary to

set FoP=nU (default value). The valve opening is enabled only when CCL digital input is enabled.

11. ELECTRICAL CONNECTIONS

The instrument is provided with pluggable screw terminal block to connect cables with a cross section

up to 2.5 mm2. Heat-resistant cables have to be used. Before connecting cables make sure the power

supply complies with the instrument’s requirements. Separate the probe cables from the power supply

cables, from the outputs and the power connections. Do not exceed the maximum current allowed on

each relay, in case of heavier loads use a suitable external relay.

11.1 PROBES

Temperature probe placement: between hour 3 and 9 respect to horizontal pipe section. For suction

pressure probe there aren’t any particular prescriptions

12. RS485 SERIAL LINE

All models can be connected to the monitoring and supervising system XWEB3000. If Mod=Std

standard ModBUS-RTU protocol is used, if Mod=AdU custom XWEB library is required. This last

configuration makes possible to use the same serial address of the thermostat that gives the cooling

request to XEV. In this way, it’s possible to reduce the number of addresses used.

13. HOW TO: USE THE HOT-KEY

13.1 PROGRAM A HOT-KEY FROM THE INSTRUMENT (UPLOAD)

1) Program one controller with the front keypad.

2) When the controller is ON, insert the HOT-KEY and push UP button; the “uPL” message

appears followed a by flashing “End”.

3) Push SET button and the “End” will stop flashing.

4) Turn OFF the instrument, remove the HOT-KEY and then turn it ON again.

NOTE: the “Err” message is displayed in case of any failed programming operation. In this case, push

again UP button if you want to restart the upload again or remove the HOT-KEY to abort the operation.

13.2 PROGRAM AN INSTRUMENT USING A HOT KEY (DOWNLOAD)

1) Turn OFF the instrument.

2) Insert a pre-programmed HOT-KEY into the 5-PIN connector and then turn the Controller ON.

3) Automatically the parameter list present into the HOT-KEY will be downloaded into the Controller

memory. The “doL” message will blink during this operation, followed a by a flashing “End” label.

4) After 10 seconds the instrument will restart working with the new parameters.

5) Remove the HOT-KEY.

NOTE: the “Err” message is displayed in case of any failed programming operation. In this case, push

again UP button if you want to restart the upload again or remove the HOT-KEY to abort the operation.