Page 1-2 June 13, 2005

A. INSTALLATION

In selecting a location for the line, consider these factors:

•Working weight (including oil tank filled to capacity) in relation to the building structure for

proper support.

•Access to the selected location where the machine will be installed.

•An adequate area to allow sufficient working space around the machine (a clearance of

at least 3 feet or 914 mm) for proper ventilation and maintenance.

Some thought should also be given to availability of the required power source (refer to the

electrical drawing shipped with the machine or in the back of the manual). The machine

should also be located away from grinding machines, sanding machines, spray painting areas

and other sources of contamination if practical.

Answers to questions regarding site preparation and other technical assistance is available

free of charge via telephone between the hours of 8 AM and 4:30 PM CST Monday through

Friday by calling the Engel Customer Service Department at 314-638-0100.

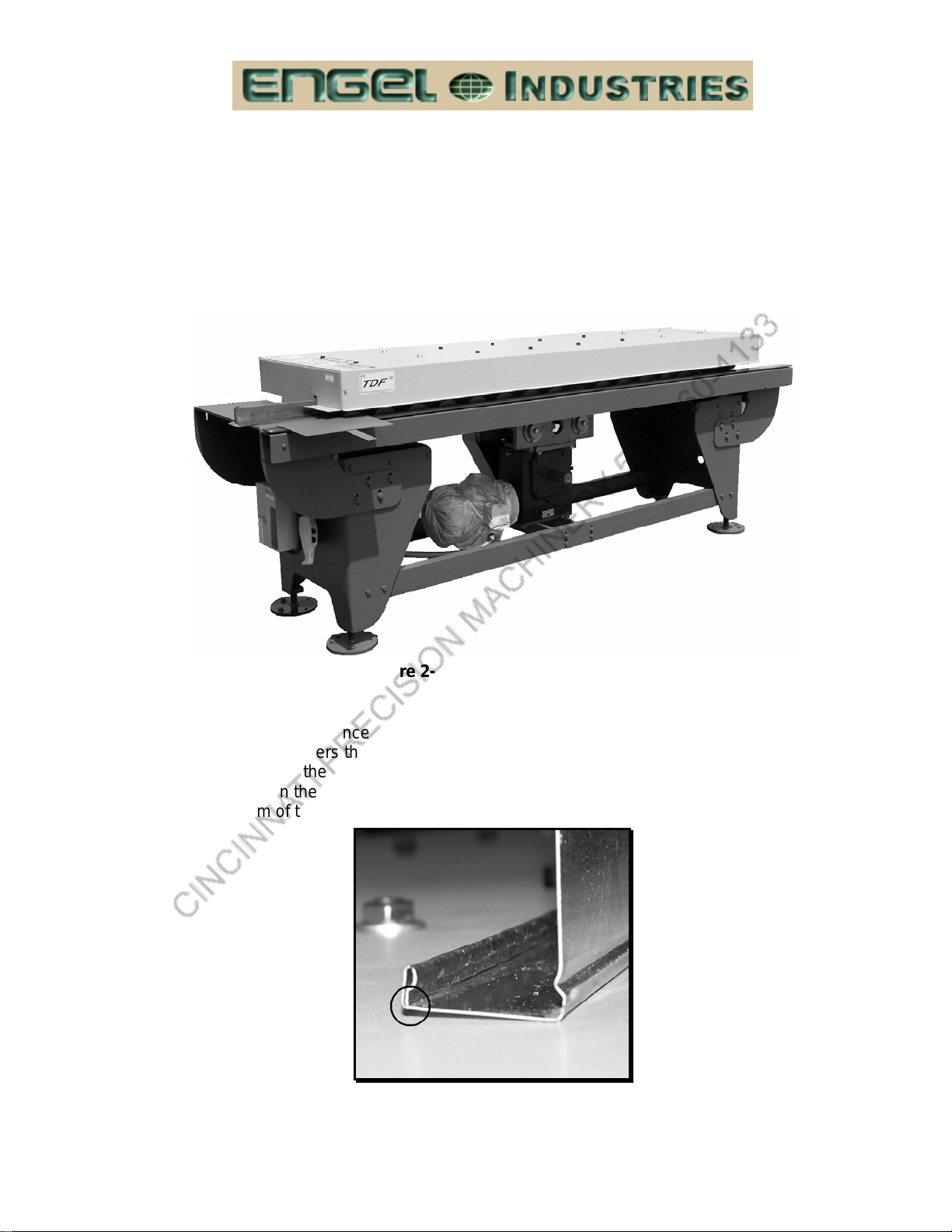

(1) Unpacking The Machine

When the machine arrives, inspect it carefully before accepting the shipment. It is

important to note any damage on the Bill of Lading or other shipping documents so that a

claim can be filed with the carrier.

Pay special attention to the control console, because it contains delicate electronic

devices. Check for physical damage to the switches and the components inside. If

anything looks damaged, notify both the carrier (to file a claim) and our Customer Service

Department (to order replacement parts). It is important to notify the factory promptly so

the new parts arrive before the machine is installed, as it may not be possible to start up

and run the machine without them.

Normal procedures should be used to unpack the machine. Remove any covering, steel

strapping or skids that may be present. Remove all wooden blocks (used as spacers to

prevent movement of the machine parts during shipment). After inspection and

unpacking, prepare to move the machine into position, using the floor layout drawing in

the back of this manual. This can be done with a fork truck or overhead crane. Once the

equipment is in position, fill the hydraulic tank with Mobile Dte 25 hydraulic oil (or

equivalent) if applicable and make the necessary electrical connections. Then bring in the

required power source to the main control console. When doing the electrical hookups,

refer to the electrical drawings supplied with the equipment if necessary.

To safely operate this machinery, all personal must read and understand the safety

section of this manual. Study and follow the safety precautions in this section, which are

intended to prevent injury to you and your fellow workers. However, they cannot cover all

possible situations. Therefore, consider the consequences of your actions before

executing any procedure or operation.

B. SAFETY

(1) Safety Precautions (Before Starting The Machine)

¾Protect yourself. Wear safety glasses and leather gloves while handling the material.

Do not wear loose clothing, neckties, or jewelry. If long sleeves must be worn, avoid

cuffs and buttons.