FM 169 A&M Instr. for Gamma type Z..D Rev.01 2018-06-11 1

Table of contents

1Safety........................................................................................................................2

1.1 Symbols used............................................................................................................ 2

1.2 Intended use.............................................................................................................. 2

1.3 General safety........................................................................................................... 3

1.4 Use in potentially explosive areas.............................................................................. 3

1.5 Technical condition of the linear unit.......................................................................... 3

1.6 Changes to the linear unit.......................................................................................... 4

1.7 Requirements for personnel....................................................................................... 4

1.8 Responsibilities of the operator.................................................................................. 5

2Warranty ...................................................................................................................5

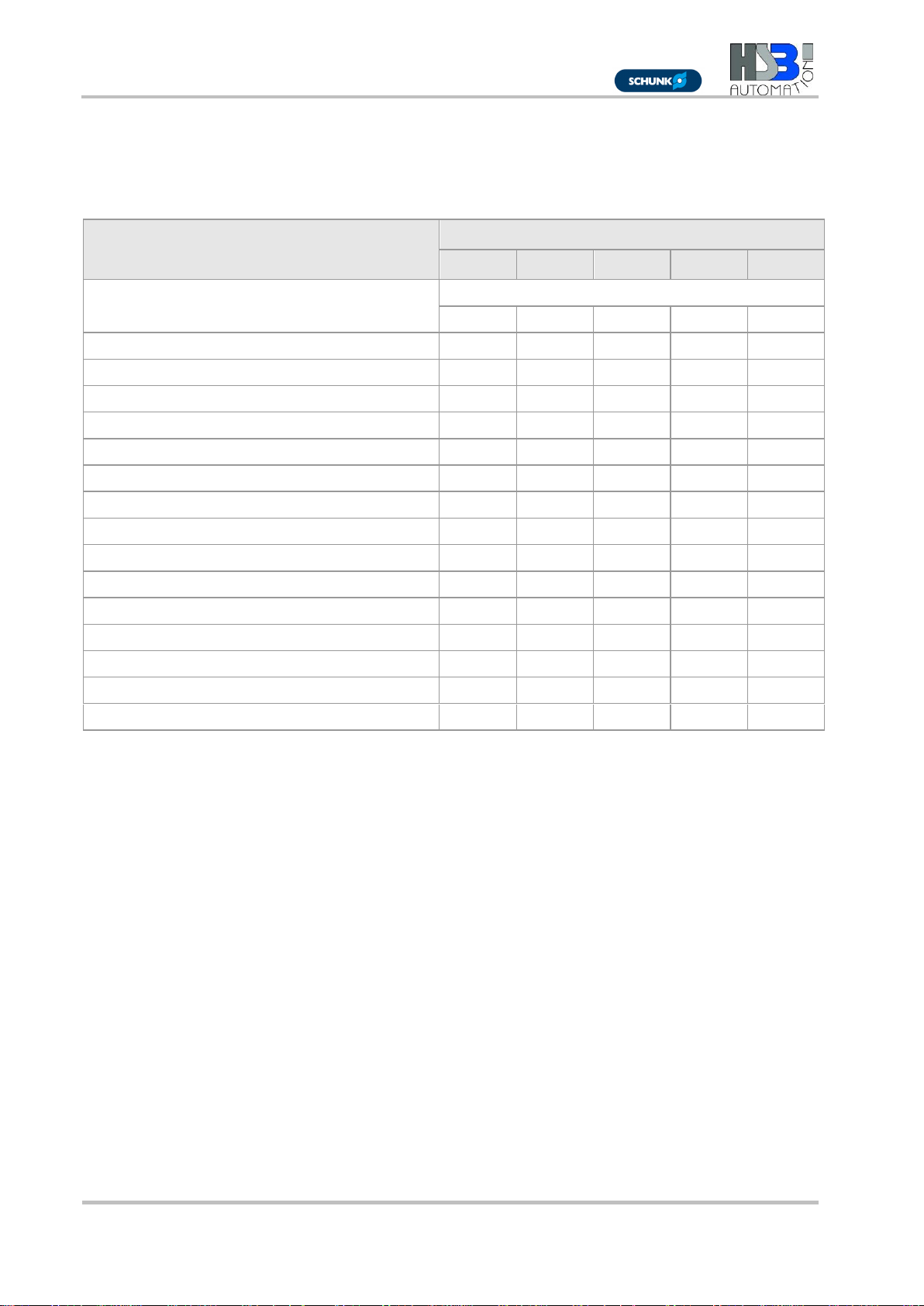

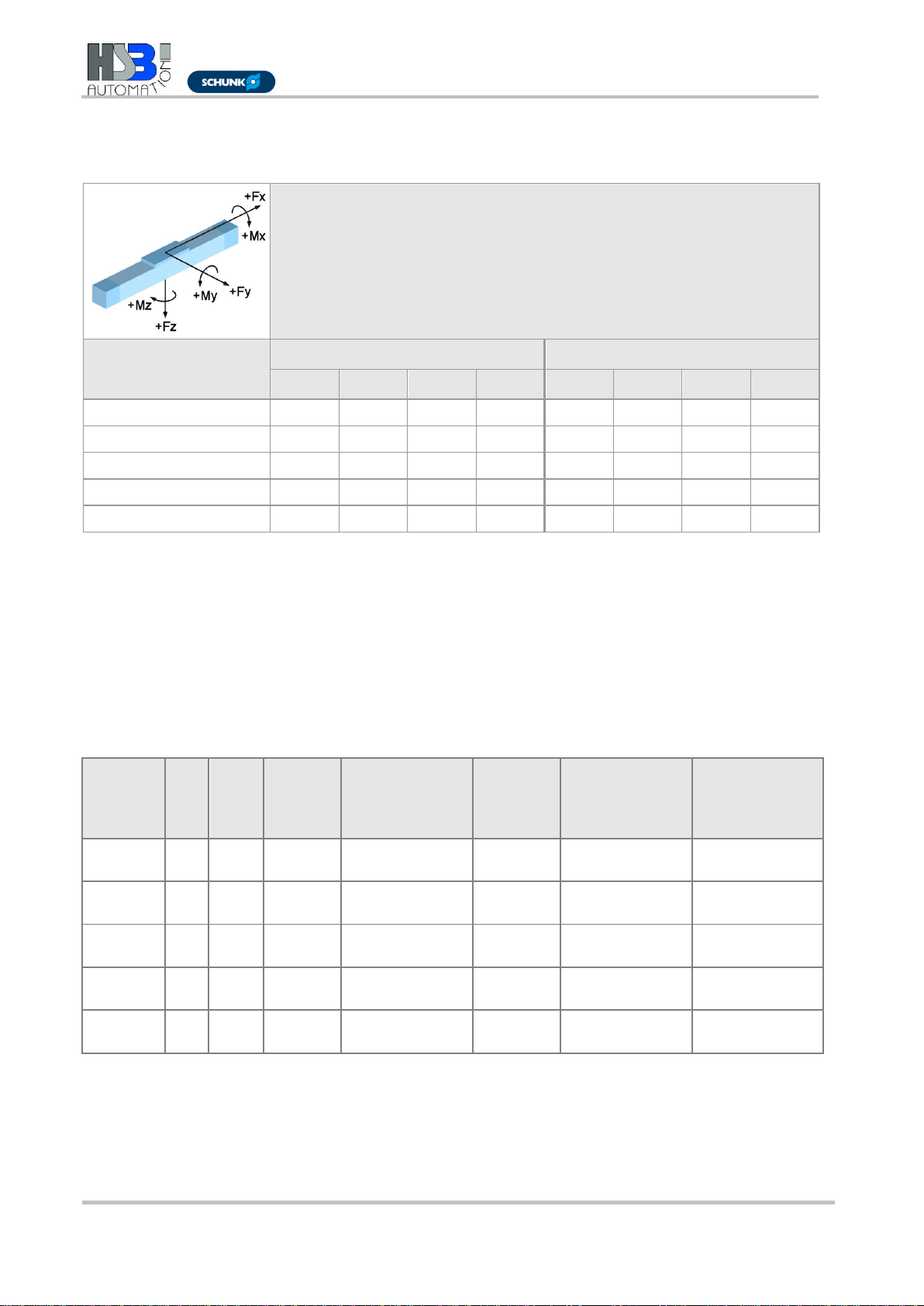

3Technical Data - Standard design ..........................................................................6

4Product description.................................................................................................9

5Transport and Storage ..........................................................................................10

6Assembly and Alignment......................................................................................11

6.1 Screw linear unit into place from underneath........................................................... 11

6.2 Set maximum stroke................................................................................................ 12

6.3 Installing the drive.................................................................................................... 12

6.3.1 Installing the motor...................................................................................12

7Commissioning......................................................................................................14

8Operation................................................................................................................15

9Decommissioning..................................................................................................15

10 Maintenance...........................................................................................................16

10.1 Lubrication............................................................................................................... 16

10.2 Replacing the toothed belt....................................................................................... 19