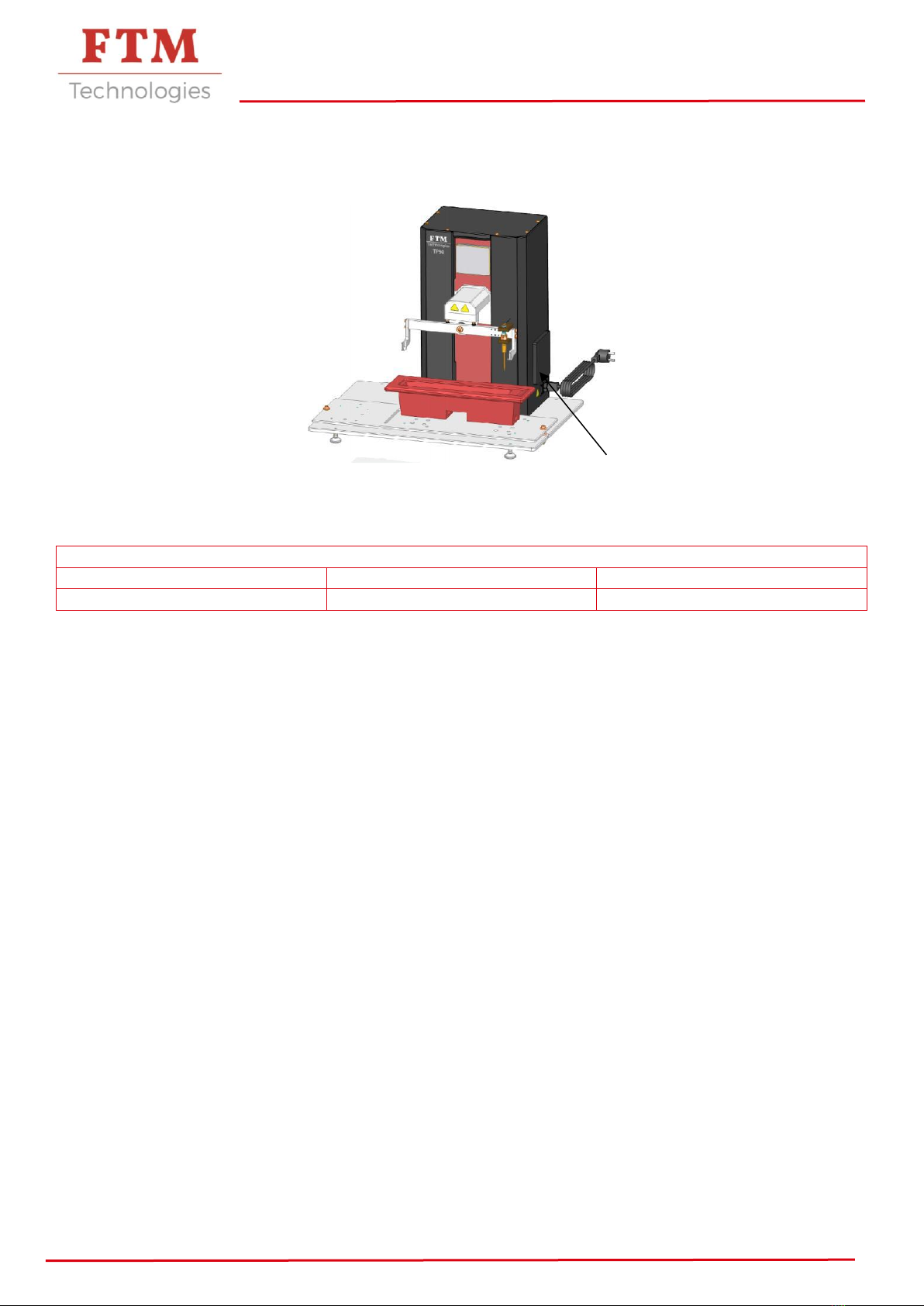

Fume hoods

Soldering - Desoldering

Specialized tools for wiring and tinning

Petit outillage, consommables et équipement de l’atelier

info@ftm-technologies.com –+33 (0)1 40 86 00 09 –www.ftm-technologies.com 3

INFORMATION FOR THE OPERATOR

Instructions for safe use

The responsibility of the user is to comply with the following instructions:

•Only entrust the use of the machine to responsible persons who are familiar with the instructions in

this manual.

•read, understand and follow all machine instructions and instructions.

•Familiarize yourself with the controls and operation of the machine before starting it.

•Take note of all the safety and operating labels present on the machine, equipment and accessories.

•Learn the location and operation of each command.

•Use the machine only for its intended use.

•Keep the work area clean and orderly. A messy workplace increases the risk of accidents.

•Wear appropriate clothing.

•Wear safety glasses.

•Wear gloves suitable for the use of the machine.

•Wear safety shoes.

General contraindications

•Do not wear loose clothing, wide hanging belts or anything that can be grabbed.

•Do not operate the machine while under the influence of alcohol, drugs or medication which may

cause drowsiness or affect the ability to use it.

•Never operate the machine without its safety devices, risk of serious injury (casing, radar, etc.).

•Do not operate the machine when a person is present in the secure enclosure.

•Do not handle the machine without having read the paragraph "Description of Handling"

•Do not use the machine with any other parts than those defined in the paragraph “List of incoming

products”

•Disconnect the electric cable before dismantling the casing

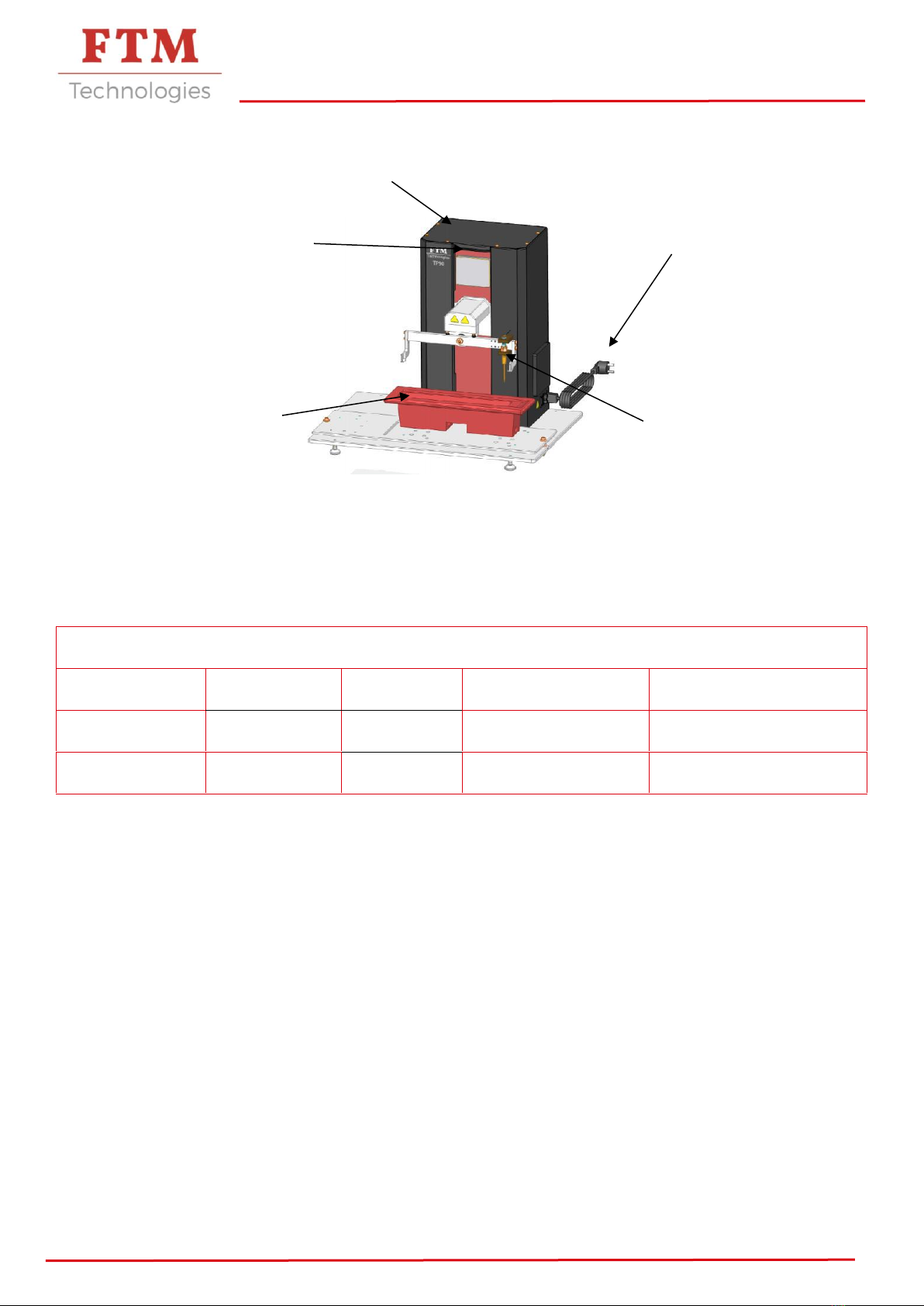

Specific Risks

Electrical risks Risks of pinching Risks of burns