engelmann SensoStar 2C Ultrasonic User manual

Engelmann

The heat meter specialists

®

Engelmann Sensor GmbH, Rudolf-Diesel-Straße 24-28 , 69168 Wiesloch-Baiertal, Germany

Phone.: +49 (0)6222-9800-217 , Fax: +49 (0)6222-9800-50, E-Mail: [email protected], www.engelmann.de

Article-No. 1080700010 - 2011-04-01 Page 1

Calculator with Ultrasonic

DE-09-MI004-PTB018 / 22.72/09.01

Installation and Operating Instructions

4.1 Safety instructions

– Look out for sharp edges (pipes, flanges).

– Installation and deinstallation should only be carried out by

qualified technical personnel.

– Mounting and dismounting may only be carried out without

pressure in the heating or cooling system.

– After installation a hydraulic pressure test should be carried out

using cold water to check for leaks.

– For safe operation, the instrument must be used only under the

stated operating conditions (see section 15: Technical Data).

In addition, the guarantee only applies if the allowed operating

conditions have been adhered to.

– The security seals may not be damaged, otherwise the guaran-

tee is no longer valid.

– Protection against lightning is not guaranteed; lightning protec-

tion must be implemented at the installation site.

4 Mounting the Flow Sensor

1 Application and Function

The

SENSOSTAR®2C US

Ultrasonic Meter is designed for the

measurement of heat and cooling energy. The connected flow sen-

sor must be installed in the return flow. Optionally, the meter can be

set in the factory to measure flow volume in the forward flow (state

when ordering – not for cooling meters!).

The instrument has an optical interface for read-out and parameteri-

zation. Optionally, the instrument can be equipped at the factory with

an M-bus interface, up to two pulse outputs (for energy and volume)

or alternatively with two pulse inputs. It is also possible to power the

instrument using a power pack (not available in combination with

M-bus power supply.)

4.2 General information on the flow sensor

– Be careful not to pick up the flow sensor on the plastic housing.

Always pick up and carry the sensor on the threaded or flanged

connections.

– All cables must be laid at a minimum distance of 20 cm to high-

voltage current cables.

– If more than one sensor is being installed in a unit, care must

be taken to be sure that all the meters have the same installati-

on conditions.

– Overpressure must be applied in order to avoid cavitation in the

complete measurement range; this means at least 1 bar up to

qp and approx. 3 bar at overload qs (specifications for approx.

80°C).

– The flow sensor left the factory in conformance with all ap-

plicable safety regulations. Calibration, maintenance, repairs

and the exchange of parts may only be carried out by qualified

technical personnel who are familiar with the dangers involved.

Further technical support can be provided by the manufacturer

upon request. Verification seals on the flow sensor may not be

damaged or removed – otherwise the guarantee and verifica-

tion of the instrument no longer apply!

4.3 Technical data of the flow sensor

– Environmental class A (EN1434), for indoor installation

– Mechanical class M1*)

– Electromagnetic class E1*)

*) as per Measurement Instrument Directive 2004/22/EU

2 Scope of Delivery

• Calculator

SENSOSTAR®2C US

• Installation kit: 1 O-ring; 5 selflock seals + 5 sealing wires;

2 screws + 2 dowels for direct screw mounting (if this

technique is used - see section 9.3)

• Installation and Operating Instructions

• 2 gaskets for the flow sensor

3General Information

All details and specifications listed in instrument data sheet or in

these installation and operating instructions must be adhered to:

• The valid statutory provisions and standards for the application of

instrument for the measurement of heat energy are: EN1434 parts

1+6 and the Directive 2004/22/EC with annexes I and MI-004.

• The instrument may only be installed or exchanged by qualified

and authorized technical personnel.

• The regulations for electrical installations must be adhered to

• The applicable verification regulations and periods for the country

in which the instrument is to be installed must be observed.

• The instrument left the factory in conformance with all applicable

safety regulations.

• The instrument must be stored and transported frost-free. The

temperature during storage or transport may not fall below 1°C.

The relative humidity during storage and transport may not be

more than 80%.

• The instrument identification and the seals required for verification

of the instrument must not be damaged or removed – otherwise

the guarantee and verification of the instrument no longer apply!

• To clean the instrument (only if necessary) use a slightly moist

(not dripping wet!) cloth.

• To protect against damage and dirt the instrument should only be

removed from the packaging directly before installation.

• All electrical connections of the instrument must be laid at a

minimum distance of 50 cm to sources of electromagnetic

interference (switches, controllers, pumps, etc.)

• All instrument connections must be laid at a minimum distance

of 10 cm to other current-carrying wires.

Engelmann Sensor GmbH, Rudolf-Diesel-Straße 24-28 , 69168 Wiesloch-Baiertal, Germany

Phone.: +49 (0)6222-9800-217 , Fax: +49 (0)6222-9800-50, E-Mail: [email protected], www.engelmann.de

Article-No. 1080700010 - 2011-04-01

Engelmann

The heat meter specialists

®

Page 2

Straight pipe section none required

Accuracy class 1:100 or 1:50

Temperature range

• recommended for heat

• recommended for cooling

5 0C to 130 0C *)

10 0C to 130 0C **)

5 0C to 50 0C

*) national approvals may vary

**) Short model 150 mm only from 20 0C to 130 0C

Max. medium temperature 150 0C for 2000 h

Protection rating flow sensor

IP 54 for heat or

IP 65 for cooling (optional for

heat meter)

Maximum overload 2.8 x qp

Nominal pressure PN 16, PN 25

Electronics:

Storage temperature -20 0C to 60 0C

Ambient temperature 5 0C to 55 0C

Ambient humidity < 93 % rel. humidity

Flow sensors:

(Please note the specifications on the sensor itself!)

Flow sensor

Pulse output type

electromechanical switch (reed contact)

class OA as per EN1434-2:2007

passive electronic current sink (open

collector) class OC as per EN1434-2:2007

Installation point

standard in return flow

optional

in forward flow (only for heat

meter), calculator must be set in

factory

Mounting position

Heat meter any

Mounting position

Cooling meter

see section 6: Installation for Cooling Applica-

tions

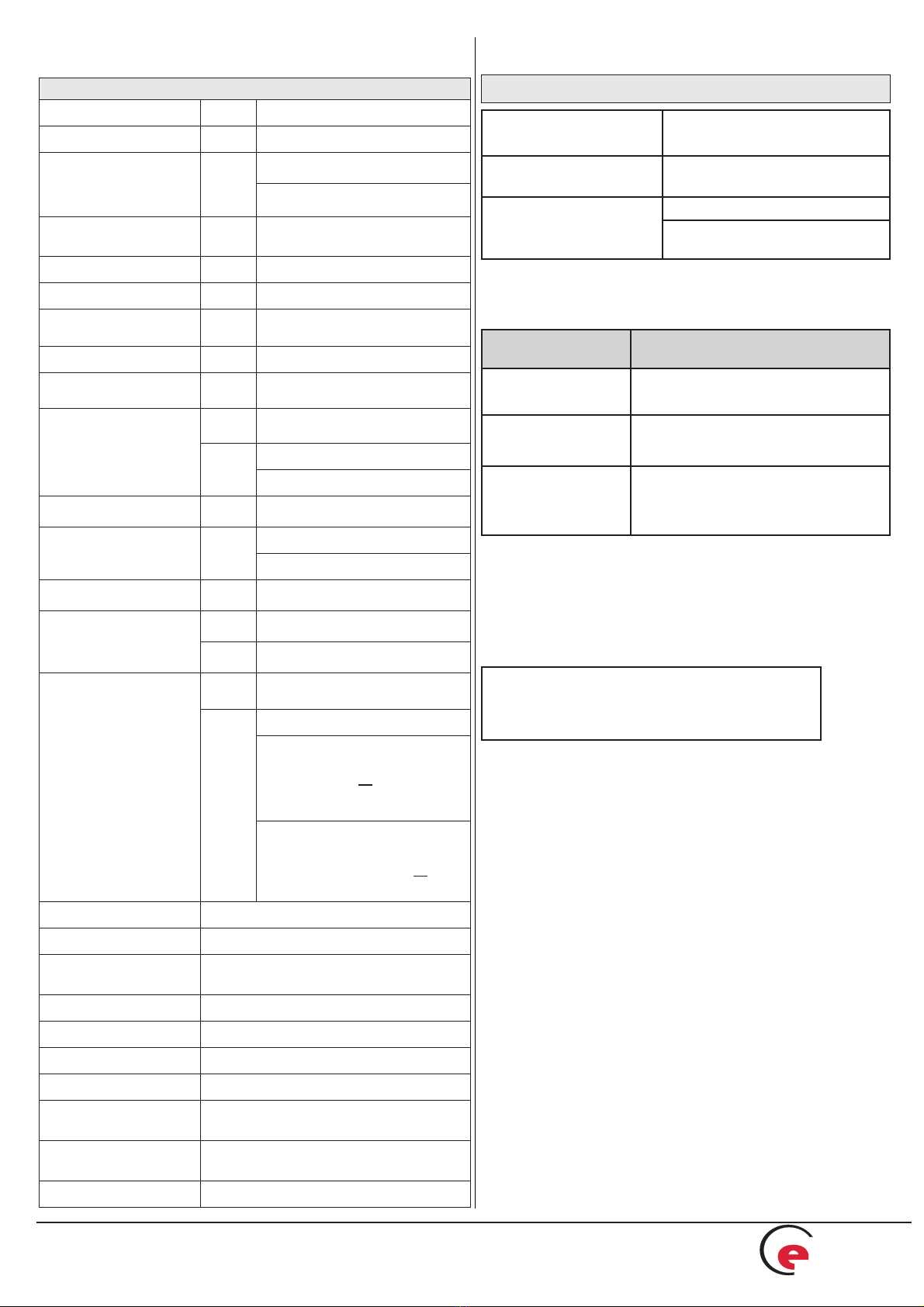

4.4 Small flow sensors

Nominal flow

qp

Installation length

Connection

Max. flow qs

Min. flow qi

Activation limit

(variable)

Pressure drop

at qs

Kv-Durchfluss

bei q1 bar

Kv-Flow at

q100 mbar

Weight

m3/h mm G / DN m3/h l/h l/h mbar m3/h m3/h kg

110 G ³/41

G 1 1,5

DN 20 125 1,7 3

110 G ³/4150 3,9 1

DN 20 3

130

DN 20 195 5,7 3

G 1 1/4 3

DN 25 5

G 1 1/4 3

DN 25 5

6 150 G 1 1/4 12 60 24 240 12 4,5 3

200

100 32 10 4

DN 40 165 25 7,8 7

200 115 44 14 5

270 100 47 15 8

25 300 DN 65 50 250 100 105 77 24,4 11

40 300 DN 80 80 400 160 160 100 31,6 13

60 360 DN 100 120 600 240 115 177 56 22

60

2,6

300

G 2 8,8

40

130 28

15 DN 50 30 150

190

10 20 100

14 60 14 4,53,5 260 7 35

25 10

1,51,2

160 3,8

1,5

24 180 14

2,5 G 1

6260 1260

5

4,5

200 5,6 1,8

1,5 3 15 6

130

190

G 1

0,6 190 1,2 6 2,4 150 1,5 0,5

Engelmann

The heat meter specialists

®

Engelmann Sensor GmbH, Rudolf-Diesel-Straße 24-28 , 69168 Wiesloch-Baiertal, Germany

Phone.: +49 (0)6222-9800-217 , Fax: +49 (0)6222-9800-50, E-Mail: [email protected], www.engelmann.de

Article-No. 1080700010 - 2011-04-01 Page 3

190

22,6

G 1

190

22,6

G 1

190

18 Ø 75

Ø 58

4.5 Large sensors with threaded connection

4.6 Large sensors with flange connection

qpm3/h PN bar a b c d

3,5 16 260 51 G 1 1/4 B

6 16 260 51 G 1 1/4 B

6 16 150*) 22 G 1 1/4 B

10 16 200 48 G 2 B

10 16 300 48 G 2 B

*) For the short models with length 150 mm, the temperature

range for the medium lies between 20 0C and 130 0C.

4.7 Premium Flow Sensors

Please note that the normal flow sensors may not be used

with salt water.

Upon request, we can provide salt-water resistant versions

of the flow sensors.

q

p

m³/h

PN

bar DN a b Øc Ød Øe

No. of

holes fg

3,5 25 25 260 51 115 85 14 4 68 18

6 25 25 260 51 115 85 14 4 68 18

10 25 40 300 48 150 110 18 4 88 18

15 25 50 270 46 165 125 18 4 102 20

25 25 65 300 52 185 145 18 8 122 22

40 25 80 300 56 200 160 18 8 138 24

60 16 100 360 68 235 180 18 8 158 24

60 25 100 360 68 235 190 22 8 158 24

Engelmann Sensor GmbH, Rudolf-Diesel-Straße 24-28 , 69168 Wiesloch-Baiertal, Germany

Phone.: +49 (0)6222-9800-217 , Fax: +49 (0)6222-9800-50, E-Mail: [email protected], www.engelmann.de

Article-No. 1080700010 - 2011-04-01

Engelmann

The heat meter specialists

®

Page 4

7 Starting Up

Open close-off valves. Check the heating system for leaks and

vent thoroughly. After 100 seconds at the latest the flow sensor

will begin to operate.

When the response threshold has been exceeded and the flow

is positive, volume pulses will be generated as determined by

the instrument parameterization.

Check the measured flow values on the connected calculator

for plausibility. Vent the system until the flow display on the

connected calculator is stable. Then affix the user seals on the

connections.

8 Important Notes

– Regulations for the application of meters are to be obser-

ved, see Standard EN 1434, part 6! In particular, cavitation

must be avoided.

– When installing the flow sensor, make sure to protect

against overflow and dripping water

– All technical data specified in the flow sensor data sheet

and instructions must be adhered to.

– The instrument identification and the seals required for

verification of the flow sensor must not be damaged or

removed – otherwise the guarantee and verification of the

instrument no longer apply!

– Transport of the flow sensor is only permissible in the origi-

nal packaging.

.

Permissible mounting positions for cooling applications

30

o

C

80

o

C

10 DN

Black housing of transducers

5 Integration in the Heating System

Please inspect and check all dimensions to be sure that there

is sufficient space in the intended location for installation of the

flow sensor.

No minimum straight pipe sections are required upstream or

downstream for the flow sensor.

If the flow sensor is being installed in the common return flow

of two heat systems, e.g. heating and hot water, the mounting

location must be sufficiently separated from the T-piece, that

is, at least 10 x DN from the T-piece, so that the different water

temperatures are well-mixed before reaching the sensor.

Mixture of different return flow temperatures

Flush the system thoroughly before installing the flow sensor.

Following the instructions in the illustrations below, mount the

flow sensor horizontally or vertically between two close-off

valves, making sure the arrow on the sensor corresponds to the

actual direction of flow.

Connection pieces are to be sealed against manipulation.

Mounting considerations

Point 1: Avoid air pockets

Point 2: Install any valves or controllers downstream from

the flow sensor.

6 Installation for Cooling Applications

When mounting the flow sensor for cooling applications make

sure that the transducers (black housing) are to the side of, or

under, the measuring tube (to prevent accumulation of conden-

sation water). The flow sensor must always be mounted in the

return flow. The calculator should be mounted on the wall, for

example.

Attention must be paid that the cables connected to the calcu-

lator are laid such that condensation water cannot run along

them and into the calculator. Cable loops should hang under-

neath.

Engelmann

The heat meter specialists

®

Engelmann Sensor GmbH, Rudolf-Diesel-Straße 24-28 , 69168 Wiesloch-Baiertal, Germany

Phone.: +49 (0)6222-9800-217 , Fax: +49 (0)6222-9800-50, E-Mail: [email protected], www.engelmann.de

Article-No. 1080700010 - 2011-04-01 Page 5

9.2 With commonly available mounting rail

9.3 Direct screw mounting

10 Connection of Components

Important: First mount the temperature sensors and then connect

the flow meter to the calculator. This way unnecessary error mes-

sages can be avoided.

At delivery, the display shows ‘ERR 03’ until temperature sensors

have been attached. This message disappears as soon as tempe-

rature sensors have been connected and the first measurement is

carried out (every 30 seconds for standard instruments).

Recognition of switched temperature sensors is only activated for

meters which are purely heat meters or cooling meters.

Recognition of switched sensors is not possible for dual-purpose

heat / cooling meters.

The

SENSOSTAR®2C US

connections have been designed to

meet the valid standard EN1434-2. All terminal strips have been

labeled according to this standard.

The terminal strips are located under the cover of the calculator

housing.

10.1 Temperature sensor connection

Before connecting the temperature sensors to the calculator ple-

ase check the following points:

– The temperature sensors (up to DN 100) must installed

against the flow direction.

– The temperature sensor with the red identification must

always be installed in the forward flow.

– The temperature sensor with the blue identification must

always be installed in the return flow.

– The temperature sensors are not to be installed within the

influence of other sources of heat.

– Do not kink, lengthen or shorten the cables.

– Cables that are too long should not be rolled up tightly into an

‘air-core coil’. The cables should either be laid out unordered,

or rolled up loosely into a wide coil which can be turned and

tied into an ‘8’.

Mounting

– Loosen two cable glands and glide them over the sensor

cables. Remove the two blind plugs from the cable gland

openings.

– Feed the temperature sensor cables through the appropriate

openings of the cable glands into the terminal box.

– Clamp the wires as shown in the illustrations. Make sure the

temperature sensor connection is correct:

Sensor with red identification →forward flow

Sensor with blue identification →return flow

9 Wall Mounting of Calculator

The housing cover can be opened by pulling the two snap-fit

hooks at the base of the calculator (between the cable glands)

towards you.

After mounting, all calculators must be sealed against manipula-

tion at the holes provided on the housing cover (see section 9.1)

using the seals and wires included in the delivery (see 2 ′Scope of

Delivery′).

Before mounting, check to make sure that the cable lengths of the

instruments to be connected are correct for the individual installa-

tion situation.

For existing mounting positions an optional adapter panel

- meeting EN1434-2:2007 (D) specifications – is available which

makes it possible for the wall-mounting support to be mounted

using standardized drill holes. The center to center drill hole

separation for the wall-mounting unit (see 9.1) and direct screw

mounting (see 9.3) is 119 mm.

9.1 With wall-mounting support

holes for

sealing

holes for

sealing

Engelmann Sensor GmbH, Rudolf-Diesel-Straße 24-28 , 69168 Wiesloch-Baiertal, Germany

Phone.: +49 (0)6222-9800-217 , Fax: +49 (0)6222-9800-50, E-Mail: [email protected], www.engelmann.de

Article-No. 1080700010 - 2011-04-01

Engelmann

The heat meter specialists

®

Page 6

– Check that the connections are tight.

– Screw the cable glands tight by hand.

Connection for 4-wire technique

Connection for 2-wire technique

10.2 Connection of optional interfaces

• The following are options that the calculator can be equip-

ped with at the factory (state when ordering) and will vary

depending on the individual calculator.

• Feed the cable to be connected (cable diameter Ø 3.5 to 6.5

mm) through an opening on the bottom edge of the calcula-

tor housing into the space containing the terminal strips.

• The terminal clamps are designed to fit strands with ends

with a cross-section of 0.5 – 1.5 mm2.

• Clamp on the cable according to the following illustrations

that apply depending on the interface.

Depending on the option,

here there are located two

additional pulse inputs (IN)

for further meters or two

pulse outputs (OUT) for

connection to an additional

system.

For connection of meters

with open collectors atten-

tion must be paid to the

polarity.

Polarity is not important for

these connections so the wires

can be clamped arbitrarily.

When the M-bus network is in

operation a triangle will appear

in the lower right corner of the

display.

(Power supply from the M-bus

network is functioning.)

Connection of M-bus

Connection of pulse outputs or inputs

Connection of power pack

It is strongly recom-

mended to use only the

Engelmann Sensor

power pack.

It is imperative to pay

attention to the polarity

Important note: The flow sensor is not powered by the

power pack!

Attention: Please check the unused cable glands to make

sure that the necessary blind plugs are inserted

and then tighten the cable glands by hand.

• Check that the connections are tight.

• The power pack should only be connected to 230V and

checked by authorized technical personnel.

• Check on the display whether a

triangle appears in the lower right

corner, as shown in the illustration.

• Screw the cable gland tight by hand.

• Close the cover of the calculator housing and protect

against unauthorized opening using the delivered

Optional:

For the dual-purpose heat/

cooling meter version, sepa-

rate pulse outputs for heating

energy and cooling energy

are available.

Engelmann

The heat meter specialists

®

Engelmann Sensor GmbH, Rudolf-Diesel-Straße 24-28 , 69168 Wiesloch-Baiertal, Germany

Phone.: +49 (0)6222-9800-217 , Fax: +49 (0)6222-9800-50, E-Mail: [email protected], www.engelmann.de

Article-No. 1080700010 - 2011-04-01 Page 7

11 Calculator Operation

The

SENSOSTAR®2C

calculator has a liquid crystal display with 8 digits and special characters. The values that can be shown

are divided into three display loops.

All data is retrieved using the Engelmann pushbutton next to the display.

To scan all the information in a loop, simply press the pushbutton briefly. To change to the next loop press the pushbutton longer.

Keep the pushbutton pressed until you reach the desired information loop. As soon as the desired loop appears, let go of the push-

button. After one minute of non-use of the pushbutton, the display automatically returns to the main loop.

1. Level / Main Loop

1) Total heat energy / total cooling energy

–standard display-

(alternating display without pressing the

button heat/cooling meters)

2) Segment test, all segments triggered

simul-taneously.

3) Total heat energy / cooling energy at last

billing date alternating with that date. 1)

Flow volume, tariff values, or the values of the

individual pulse counters can be shown if this

has been set.

4) Total volume in m3

5) Current power in kW

6) Current flow in m3/h

7) Current date

8) Error message (alternating binary and

hexadecimal display)

9) Selectable customer-set calculator no.

(secondary address); factory setting is the

serial no.

10)Tariff register1: Values alternating with

tariff register and criteria. 2) 3)

11)Tariff register 2: Values alternating with

tariff register and criteria. 2) 3)

12) Momentary reading of the pulse counter1

alternating with the pulse value.2) 3)

13) Momentary reading of the pulse counter 2

alternating with the pulse value.2) 3)

2. Level / Technician’s Loop

1) Current forward flow temperature in C°

2) Current return flow temperature in C°

3) Temperature difference in C°

4) Days since first verification of calculator

5) Pulse value of calculator

6) M-bus address (primary address)

7) Serial number

8) Software / firmware version

9) return flow or forward flow

Temperature sensor type and mounting

position

10) Set billing date

11), 13), 15) Maximum power value

alternating with date and time of

occurrence.

12), 14), 16) Maximum flow value alternating with

date and time of occurrence.

1) Previous billing date alternating with its values.

Alternatively, the total volume, tariff values, or values of

individual instruments connected to the optional pulse inputs

can be displayed, if so set. 1)

2-16) 15 Monthly values: Dates alternating with their values.

Alternatively, the total volume, tariff values, or the values of

individual pulse counters can be displayed, if so set. 1)

3. Level / Statistics Loop

1) Up to the end of the month the consumption and billing date for that month will be shown as 0.

2) Can be set using the software “Engelmann®Monitor”. A dedicated meter password is necessary. Password available from manufacturer.

3) Note: For invoicing, the total heat energy must be used.

Engelmann Sensor GmbH, Rudolf-Diesel-Straße 24-28 , 69168 Wiesloch-Baiertal, Germany

Phone.: +49 (0)6222-9800-217 , Fax: +49 (0)6222-9800-50, E-Mail: [email protected], www.engelmann.de

Article-No. 1080700010 - 2011-04-01

Engelmann

The heat meter specialists

®

Page 8

12 Calculator Settings

12.1 Pulse inputs 1+2

The optional pulse inputs 1+2 for external meters can be set using

the configuration software Engelmann®Monitor. The settings are the

input pulse value and the units in which the external meter counts.

For invoicing, the meter readings of the instruments connected to

the pulse inputs must be included in the calculation

12.2 Pulse output for energy (OUT1-Energy)

A pulse is sent via the pulse output for energy when the last digit

of the energy display is increased. The pulse value is automatically

determined by the last place of the energy display.

The pulse units are identical to the units of the energy display:

Example 1: Display 12345678 kWh => pulse value for energy pulse

output = 1 kWh / pulse

Example 2: Display 12345,678 MWh => pulse value for energy

pulse output = 0.001 MWh / pulse

Example 3: Display 1234567,8 GJ => pulse value for energy pulse

output = 0.1 GJ / pulse

12.3 Pulse output for volume (OUT2-Volume)

A pulse is sent via the pulse output for volume, when the second-

to-last digit of the volume display is increased.

The pulse value is automatically determined by the second-to-

last place of the volume display. The pulse units are identical to

the units of the volume display.

Example 1: Display 12345,678 m3=> pulse value for volume

pulse output = 0.01 m3/ pulse

Example 2: Display 12345678 l => pulse value for volume pulse

output = 10 l / pulse

Display examples Description of example in tariff register 1

(either the energy or the time can be measured)

0 Not defined (at delivery).

1 The energy (0.683 MWh) in the time period from 18.00 (6 pm) to

6.00 am (the time can be set in 10-min. steps) is being measured.

2 The energy (0.683 MWh) above a power of ≥2.000 kW

3 The energy (0.683 MWh) up to a power ≤2.000 kW

4 The energy (0.683 MWh) above a flow of ≥0.600 m3/h

5 The energy (0.683 MWh) up to a flow ≤0.600 m3/h

6 The time (11 h) above a temperature in the

forward flow of ≥65.00 oC (in steps of 0.01 oC)

7 The time (11 h) up to a temperature in the

forward flow ≤65.00 oC (in steps of 0.01 oC)

8 The time (11 h) above a temperature in the

return flow ≥36.00 oC (in steps of 0.01 oC)

9 The time (11 h) up to a temperatur in the

return flow ≤36.00 oC (in steps of 0.01 oC)

10 The energy (0.683 MWh) above a

temperature difference of ≥10.00 oC (in steps of 0.01 K)

11 The time (11 h) up to a temperature difference

of ≤10,00 oC (in steps of 0,01 K)

12.4 Tariff registers

There are 2 tariff registers, which add up the energy or time, depending on certain criteria. The registers can be individually set using the

Engelmann®Monitor software and can be read via the display or using the read-out software.

Engelmann

The heat meter specialists

®

Engelmann Sensor GmbH, Rudolf-Diesel-Straße 24-28 , 69168 Wiesloch-Baiertal, Germany

Phone.: +49 (0)6222-9800-217 , Fax: +49 (0)6222-9800-50, E-Mail: [email protected], www.engelmann.de

Article-No. 1080700010 - 2011-04-01 Page 9

13 Interfaces and Options

13.1 Optical (infrared) interface

In order to be able to communicate with a

SENSOSTAR®2C

ins-

trument, an optocoupler must be connected to the USB or serial

interface of the PC. The optocoupler (USB or serial interface) and

the Engelmann®Monitor software are available as options.

The optical (infrared) interface is activated by pressing the

Engelmann pushbutton.

If within 60 seconds neither a valid telegram is received now the

pushbutton pressed again, then the interface is deactivated.

13.2 M-bus interface

An M-bus interface is also available as a built-in option for the

SENSOSTAR®2C

(must be stated when ordering). An inst-

rument with an M-bus interface is supplied with power via the

M-bus network (no galvanic separation). The number of read-outs

via the M-bus interface per instrument per day is unlimited.

The valid standards for the M-bus protocol are EN13757-2 and

13757-3 and the M-bus recommendation (Version 4.8 from Nov.

1997) with the standard IEC 870 part 1,2 and 4.

Notes on installation:

• Each end instrument is only protected against high voltage

up to the maximal allowed bus voltage (±50V). Additional

protective measures must be provided by the level converter.

• The installation of an instrument in an M-bus network may

only be carried out by authorized, qualified technical

personnel.

• Attention must be paid to ensure that the cable lengths and

cable cross-sections in the bus network are appropriate for

the baud rate of the end instrument (2400 baud).

• Recommended cable type:

Telephone cable J-Y(ST) Y2 x 2 x 0.8 mm²

SENSOSTAR®2C

instruments with the M-bus option can be

addressed primarily or secondarily.

Both addresses can be set via the optical interface using the

Engelmann®Monitor software. They can also be set using the

display.

The primary address is the M-bus address displayed in the 2nd

level (technician’s loop) in menu item 6) ‘M-bus address (primary

address)’.

The secondary address is the customer identification no. and can

be selected under menu item 9) ‘Selectable customer-set

calculator no.’ ‚ in the first level (the main loop).

If a customer no. has not been identified, the serial no. is

displayed. This is the factory setting.

13.3 Settings of the Datalogger

The datalogger is an optional additional function for meters and

calculators which must be specified in the original order (instru-

ments cannot be retrofitted).

The Engelmann datalogger makes it possible to record consump-

tion data and the individual meter values in the internal storage

module in freely selectable time intervals. The recorded data can

be stored in various data formats, for example for analysis of

peak values in order to optimize cost-effective supply of heat.

The datalogger can be read out either via the optical interface or

via M-bus, so that the data can be used for individual analysis.

The Engelmann datalogger is a ring buffer. The current values

are always stored; this means that when the memory is full, the

oldest values are written over by each new piece of data.

The storage capacity is up to 10,589 values.

The software “Engelmann Datalogger“ reads out only one meter

at a time, which is addressed using the set primary address.

If only one meter is at hand, the address 254 can be used.

The following parameters can be individually set for recording,

singly or jointly, using the software “Engelmann Datalogger“:

• time (is always stored)

• heat energy

• cooling energy

• volume

• power

• flow

• forward flow temperature

• return flow temperature

• temperature difference

The meters values can be measured at the following freely

selectable time intervals:

• 1 minute

• 10 minutes

• 15 minutes

• 30 minutes

• 60 minutes

• 3 hours

• 6 hours

• 12 hours

• 24 hours

Depending on the configuration, the datalogger can store

between 2117 and 10,589 sets of data.

Note:

All previous stored values are lost (deleted) upon

reparameterization!

Engelmann Sensor GmbH, Rudolf-Diesel-Straße 24-28 , 69168 Wiesloch-Baiertal, Germany

Phone.: +49 (0)6222-9800-217 , Fax: +49 (0)6222-9800-50, E-Mail: [email protected], www.engelmann.de

Article-No. 1080700010 - 2011-04-01

Engelmann

The heat meter specialists

®

Page 10

14 Technical Data

Calculator

Ambient temperature °C 5 ... 55

Temperature range °C 1 ... 150 °C (optional 1 ... 180 °C)

Temperature difference

heat K

3 K... 100 K

(3 ... 130 for temperature meas-

urement range 1 °C - 180 °C)

Temperature difference

cooling K -3 K... -50 K

Calculation of heat from K ∆Θ> 0.05

Calculation of cooling from K ∆Θ< -0.05

Dual-purpose heat/

cooling meter K∆ΘHC< -0.5

Resolution temperature °C 0,01

Measurement cycle 30 seconds

(with external power supply 4 sec.)

Power supply

stan-

dard

3,6 V lithium

(6+1 years)

optional 3V power pack

supply via M-bus

Pulse values stan-

dard see type identification

Pulse length min. pulse length 25 ms

min. pulse interval 25 ms

Display LCD 8 digits + special characters

Units

stan-

dard MWh

optional kWh, GJ

Interfaces

stan-

dard infrared

optional

M-Bus

2 potential-free contact outputs for

volume and energy

or

2 additional pulse inputs

(max. length of cable 10 m)

2 potential-free contact outputs for

heat- and cooling energy (dual-

purpose meters) or

2 additional pulse inputs

Data storage E2PROM / daily

Maximal value storage 3 each for flow and power

Billing dates annual billing date selectable

(from dd.mm. to dd.mm.)

Monthly values 24 monthly values readable

Protection class housing IP65

EMC class E1

Mechanical environment class M1

Pulse input device microcontroller CMOS input class IB as per

EN1434-2:2007

Dimensions length x width x height

198 mm x 123.7 mm x 45.8 mm

Weight approx. 250 g

Requirements for the temperature sensor pair

Platinum precision resistor Pt500; separately approved type

as per EN 60751

Length of connecting

cables (unshielded)

3 m in 2-wire technique

10 m in 4-wire technique

Installation

direct

in temperature pocket as per

EN1434

In the case of non-permanently attached temperature sensors

the temperature sensors that are later connected must meet the

following requirements:

Application Requirements for separate tem-

perature sensors

Heat meter EU (MID) identification on the tempera-

ture sensors

Cooling meter National approval as a temperature

sensor for cooling meters *)

Dual-purpose heat

and cooling meter

EU (MID) identification and

separate national approval as a

temperature sensor for cooling meters *)

*) Requirements in countries other than Germany may be different.

All classes refer to the currently valid legal requirements for heat

meters (see Declaration of Conformity).

15 Application of Configuration Software

Engelmann®Monitor

Available separately (including instructions).

Engelmann

The heat meter specialists

®

Engelmann Sensor GmbH, Rudolf-Diesel-Straße 24-28 , 69168 Wiesloch-Baiertal, Germany

Phone.: +49 (0)6222-9800-217 , Fax: +49 (0)6222-9800-50, E-Mail: [email protected], www.engelmann.de

Article-No. 1080700010 - 2011-04-01 Page 11

17 Disposal

This instrument contains a lithium battery.

This battery may not be opened by force, come into contact with

water, short-circuited, or subjected to temperatures over 80°C.

Dead batteries, and electronic instruments or components which are

no longer needed are hazardous waste and must be disposed of at

designated collection points.

Return shipment of the lithium batteries must be carried out approp-

riately.

19 Contact

Engelmann Sensor GmbH

Rudolf-Diesel-Straße 24-28

D-69168 Wiesloch-Baiertal

Germany

Phone: +49 (0)6222-98000-217

Fax: +49 (0)6222-9800-50

www.engelmann.de

E-Mail: [email protected]

Subject to technical change!

16 Error Codes

When the instrument detects an error, the error

symbol and number are displayed.

The error can also be displayed in binary form by selecting the

menu item 8) ‘error display’ in the first level / main loop.

There are seven possible causes of error, and they can appear in

combination with each other, depending on the situation.

At delivery, the display shows ‘ERR 03’ until temperature sensors

have been attached. This message disappears as soon as tempe-

rature sensors have been connected and the first measurement is

carried out (every 30 seconds for standard instruments).

Example: sensors switched

Error

Error code

Binary display

LCD

Check sum fault

E2PROM fault

Reset

Reference sensor fault

Return flow senso fault

Sensors switched

Forward flow sen. fault

Error

display

hexadeci-

mal (LCD)

When an error occurs, with the exception of the ‚reset’ and

‚sensors switched’ error, the instrument must be exchanged and

sent to the manufacturer for examination.

Recognition of switched temperature sensors is only activated

for meters which are purely heat meters or cooling meters.

Recognition of switched sensors is not possible for dual-purpose

heat / cooling meters.

18 MID Declaration of Conformity

For the product described in this document we confirm, as the

manufacturer, that it meets the fundamental requirements according

to the

• Council Directive 2004/22/EC of 31 March 2004 on the appro-

ximation of the laws of the member states relating to measure-

ment instruments, in particular those in annex MI-004, as well as

• the requirements relating to emissions in the European Council

Directive on EMC 2004/108/EC, and the requirements according

to the Council Low Voltage Directive 2006/95/EC.

The complete signed declaration can be found at

www.engelmann.de.

Using the binary display, it is easy to identify an error:

1 at 1st position: check sum fault

1 at 2nd position: E2PROM fault

1 at 3rd position: instrument has been reset

1 at 4th position: sensors switched

1 at 5th position: reference temp. sensor fault

1 at 6th position: return flow temp. sensor fault/not connected

1 at last position: forward flow temp. sensor fault/not connected