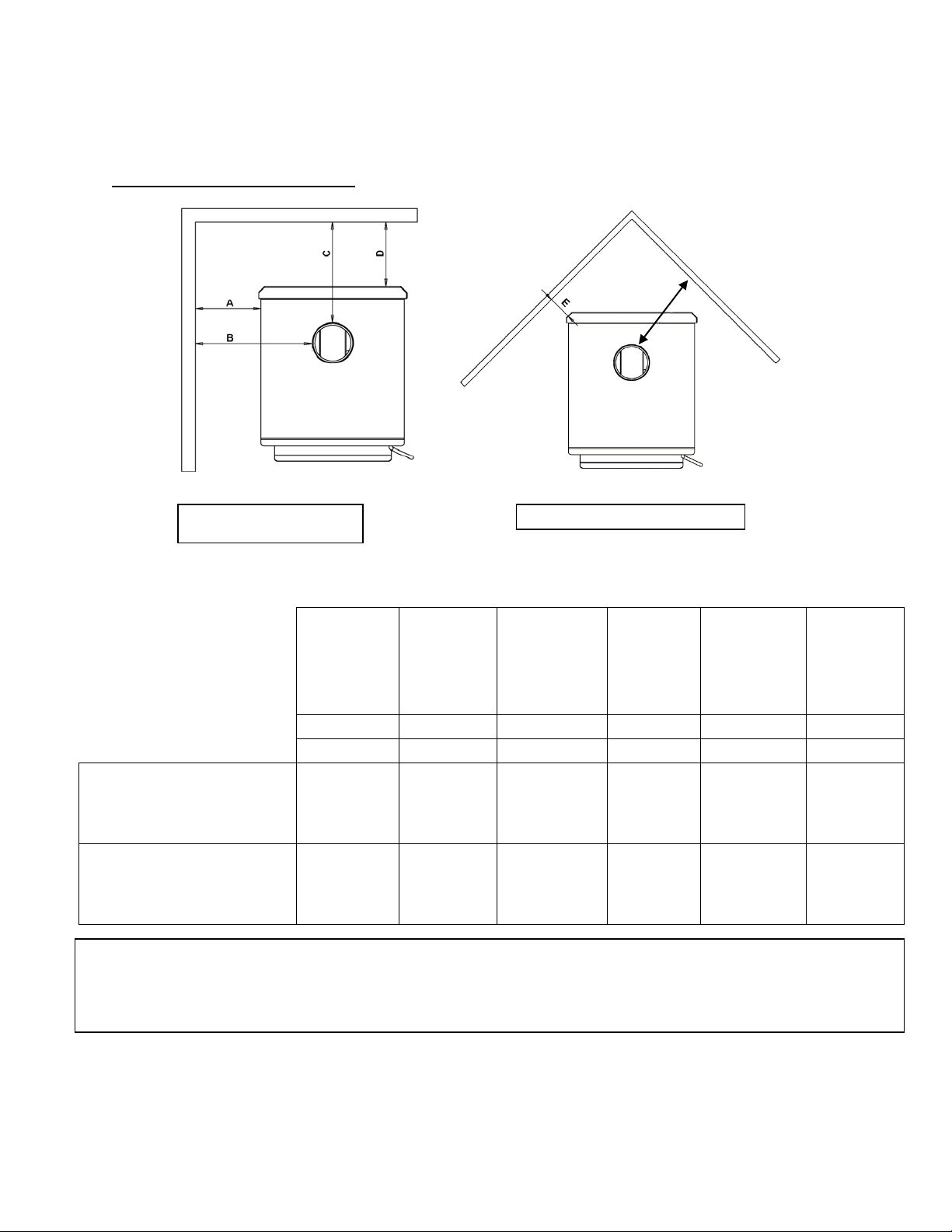

Venting Introduction

INSTALLATION

Venting Guidelines

This wood stove operates on a

natural draft system, in which the chimney

system pulls air through the stove. This unit

must be installed in accordance with the

following detailed descriptions of venting

techniques; not installing the stove in

accordance with the details listed here can

result in poor stove performance, property

damage, bodily injury or death. Avoid

make-shift compromises when installing the

venting system. Englander is not

responsible for any damage incurred

due to a poor or unsafe installation.

Be certain that all aspects of the

venting system are installed to the venting

manufacturer’s instructions, particularly the

required clearances to combustibles. Also,

be certain to use an attic radiation shield to

prevent insulation from contacting a

chimney which passes through an attic.

The chimney system is the “engine”

which drives a wood stove, so it is

imperative for proper unit function that the

venting system be installed exactly as

described in the following section.

If questions arise pertaining to the

safe installation of the stove, our Technical

Support line (877 356-6663) is available.

Contact your local code official to be certain

your installation meets local and national

fire codes, and if you’re uncertain about

how to safely install the stove, we strongly

recommend contacting a local NFI certified

installer to perform the installation.

•

ALWAYS install vent pipe in strict

adherence to the instructions and

clearances included with your

venting system.

•

DO NOT CONNECT THIS UNIT TO A

CHIMNEY FLUE SERVING ANOTHER

APPLIANCE.

•

DO NOT install a flue pipe damper

or any other restrictive device in the

exhaust venting system of this unit.

•

USE an approved wall thimble when

passing and a ceiling support/fire

stop when passing through a ceiling.

•

INSTALL three sheet metal screws at

every chimney connector joint.

•

AVOID excessive horizontal runs and

elbows, as both will reduce the draft

of the venting system and will result

in poor stove performance.

•

INSPECT your venting system often,

to be certain it is clear of creosote,

fly-ash and other restrictions.

•

CLEAN the venting system as

detailed in the maintenance section

of this manual.

•

ADHERE to the 10-3-2 rule regarding

chimney terminations.

•

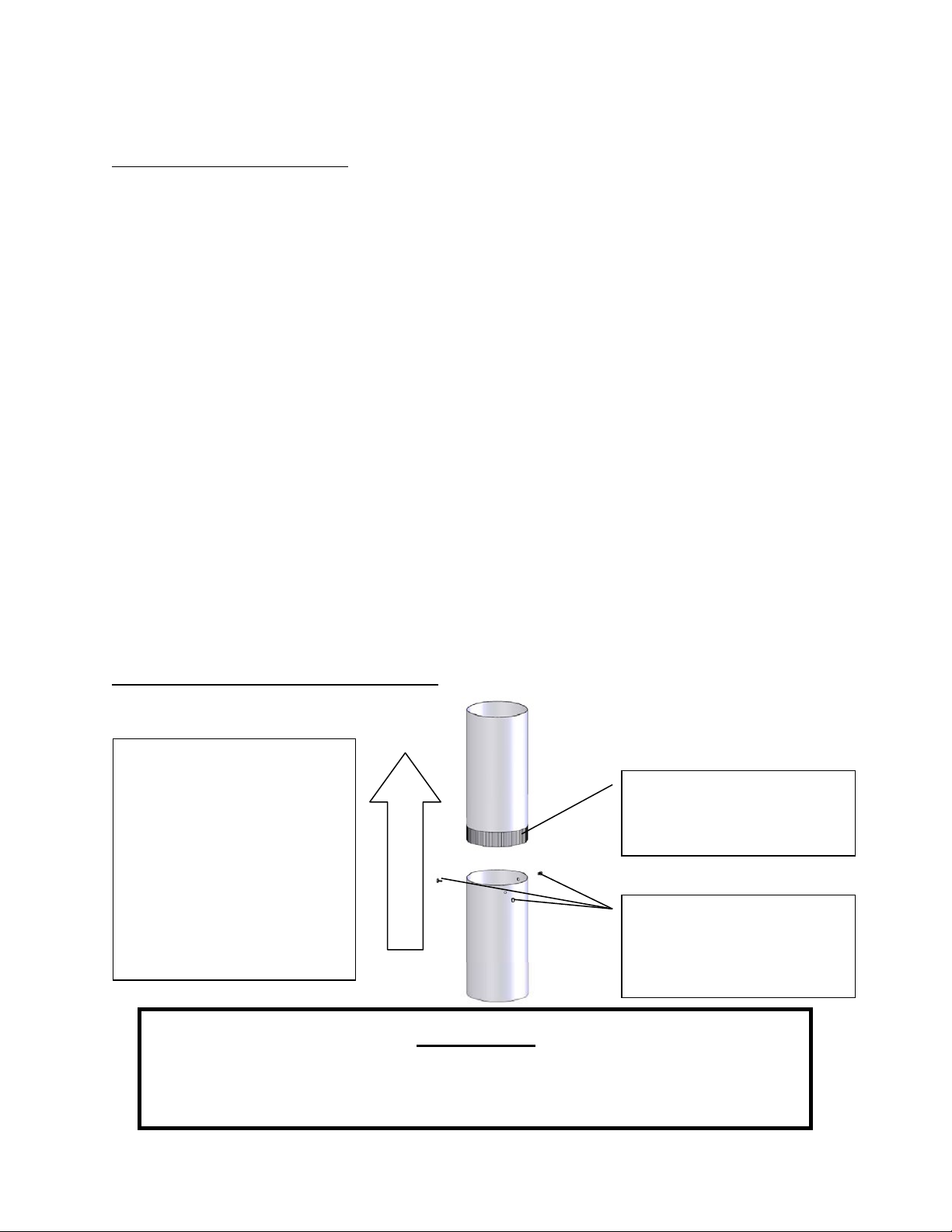

INSTALL single wall chimney

connector with the male end down

to prevent creosote leakage. Follow

double wall chimney connector

manufacturer’s instructions

regarding proper pipe installation.

WARNING: Venting system surfaces get HOT, and can cause burns if

touched. Noncombustible shielding or guards may be required.

Where passage through a wall or partition of combustible construction is desired, the

installation shall conform with CAN/CSA-B365.