ENN Solar Energy EST-110 User manual

新奥光伏能源有限公司

ENN Solar Energy Co. Ltd

EST Series 电池板安装手册

EST SERIES SOLAR MODULE

ISTALLATION MANUAL

Revision Change ECO # Originator/Approver Date

A Wang Xiqiao/Tang Qing 06/11/2009

B Wang Xiqiao/Tang Qing 22/03/2010

C Wang Xiqiao/Tang Qing 24/05/2010

D Section 4.6&7 Guo Rui/Tang Qing 31/03/2011

河北省廊坊市经济技术开发区华祥路 106 邮编:065001

No.106 Huaxiang Road, E&T Development Zone,Langfang 065001 P.R.China

1. OBJECTIVE

The purpose of this procedure is to provide installation instructions for EST SERIES thin film solar

module for field installation.

2. SCOPE

This procedure establishes the key installation requirements to mount EST SERIES thin film solar

modules in the field which includes, but is not excluded to, roof tops, solar farms, and commercial

buildings.

3. RESPONSIBILITY

ENN Solar Energy Co. Ltd. shall maintain the engineering change control of this product.

End installer of the thin film Photovoltaic (PV) modules is responsible for the design and

integrity of the mounting structure of the modules. The PV module manufacturer is responsible

for the design and structural integrity of the PV modules. Installation of the PV modules must be

performed by appropriately trained and equipped installers.

Supplier is responsible for maintaining and supporting the bill of materials on the Supplier database.

4. INSTALLATION

4.1. Unpacking and handling

The site and personnel must obtain the proper handling and transport equipment to install the PV

modules.

4.2. Personnel

Only trained personnel are to handle, transport, and install the PV modules. Immediate exposures

to sunlight instantly energize the modules and pose a shock risk.

4.3. Safety

It is the responsibility of the supplier to provide adequate safety to its employees while

performing the procedures.

Under normal conditions, a photovoltaic module may experience conditions that produce more

current and/or voltage than reported at Standard Test Conditions. Accordingly, the values of Isc

and Voc marked this module should be multiplied by the following factors: The multiplying

factors at conditions of an irradiance of 125 mW/cm^2, AM 1.5 spectrum is 1.19, and at a cell

temperature of minus 10 deg C for Voc is 0.895 and at plus 75 deg C for Isc is 1.05.

河北省廊坊市经济技术开发区华祥路 106 邮编:065001

No.106 Huaxiang Road, E&T Development Zone,Langfang 065001 P.R.China

Refer to Section 690.8 of the National Electrical Code for an additional multiplying factor of 125

percent (80 percent derating) which may be applicable

Artificially concentrated sunlight shall not be directed on the module or panel.

4.4. Tools/Materials

EST series Solar Module

0021-51814 RAIL CLAMP 30 DEG (if end installer has not specified their own clamp)

Ilsco GBL-4DB (Tin Coated)

Sheet Metal Screws #10 x ½” with zinc plating

M5 Star Washer

M5 Lock Washer Stainless Ste

M5 Washer Stainless Steel

M5 x .8 x 16mm Socket Head Screw Stainless Steel

M5 Nut

Socket Sets

Wrenches

4.5. Installing the modules

4.5.1. Materials of the mounting structure must be compatible with the PV module rails as to

not allow galvanic corrosion to either member (PV rail or mounting structure). The PV

rails are made of galvanized steel.

4.5.2. PV modules are not to be installed around or near open flames, flammable gases or

vapors, constant wetting/moisture (fountains), salt air conditions, or other corrosive

chemicals/vapors.

4.5.3. Orientation and tilt of the modules are responsibilities of the end installer.

4.5.4. Sunlight exposure is the responsibility of the end installer. Care should be taken to place

the modules in areas without overshadowing or significant shade.

4.5.5 For roof mounting, the module must be mounted over a fire resistant roof covering rated

for the application.

4.5.6 The modules should be mounted with the junction box connectors facing down to

minimize the ingress of water.

河北省廊坊市经济技术开发区华祥路 106 邮编:065001

No.106 Huaxiang Road, E&T Development Zone,Langfang 065001 P.R.China

4.6. Mounting

4.6.1. PV modules are to be mounted in a minimum of two different locations per rail, as

shown in the diagrams below.

4.6.2. The mounting structure must be capable of supporting the weight of the PV modules and

snow loading (if applicable to the site). It should also be able to withstand seismic

loading in the corresponding applicable seismic areas.

These modules have been evaluated by Underwriters Laboratories Inc for a maximum

positive or negative design loading of 33 lbs/ft2.

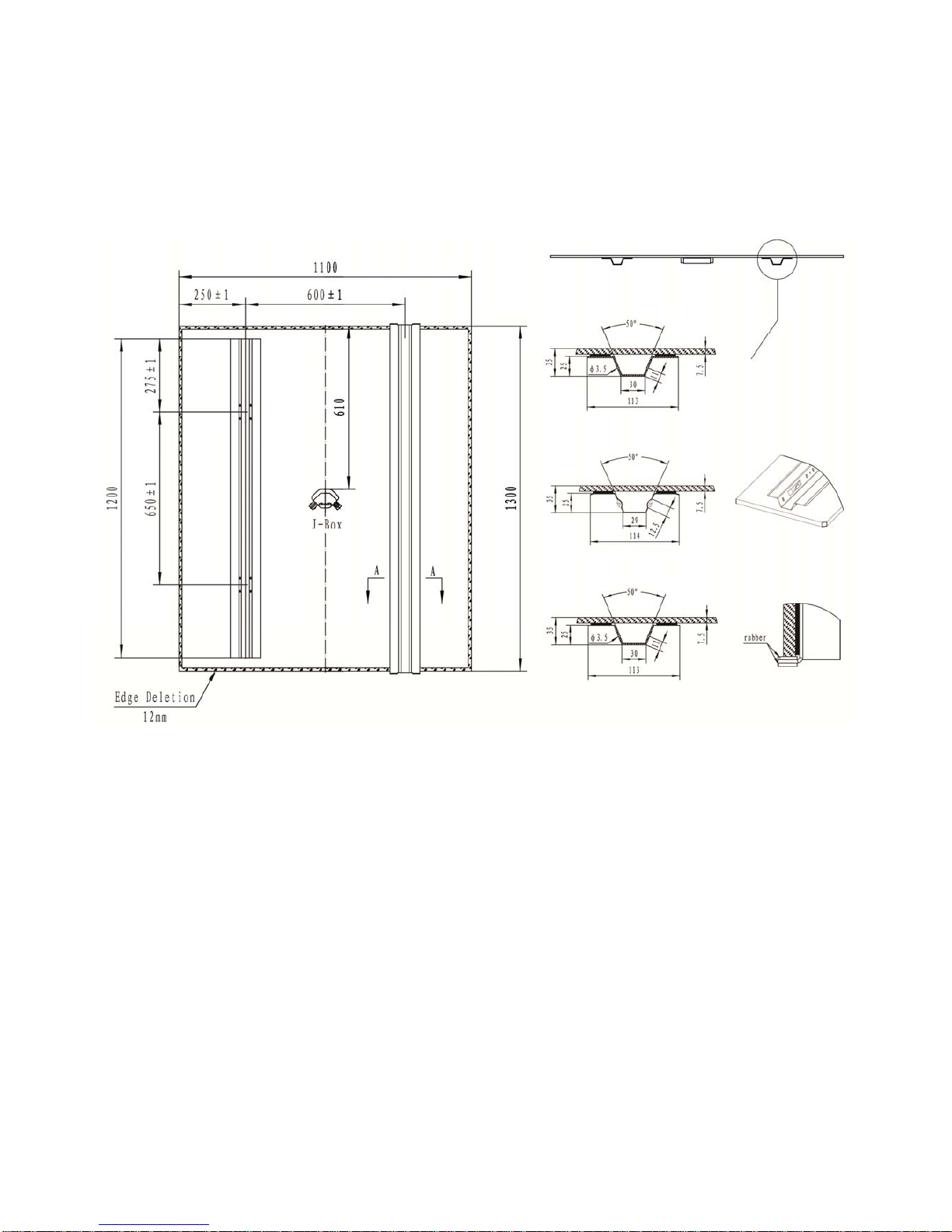

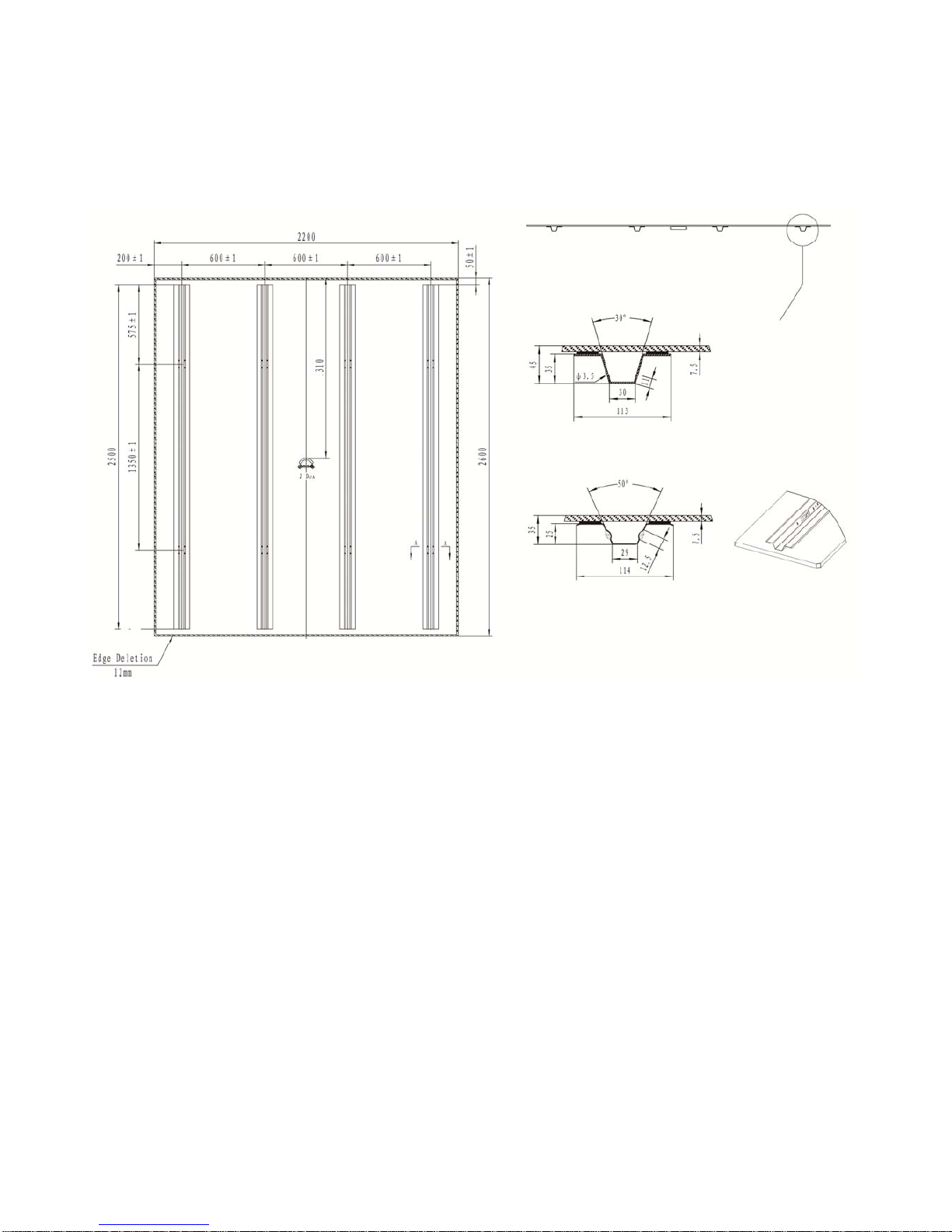

4.6.3. Key Dimensions

4.6.3.1. The key dimensions are shown in Figure 1, and Figure 2 for a structural

engineer to design an infrastructure. Note all dimensions are in millimeter

unless otherwise specified.

河北省廊坊市经济技术开发区华祥路 106 邮编:065001

No.106 Huaxiang Road, E&T Development Zone,Langfang 065001 P.R.China

Figure 1 – 1.3 X 1.1 m Module

Boned rail s

y

stems

Back View#

#Shadow areas are schematic drawing of boned rail system.

ENN Solar Energy provides various boned rail systems upon customs’ request.

1#

2#

3#

1#

2# 3#

Side View

河北省廊坊市经济技术开发区华祥路 106 邮编:065001

No.106 Huaxiang Road, E&T Development Zone,Langfang 065001 P.R.China

Figure 2 – 2.6 X 2.2 m Module

4.6.4. Mounting Position

4.6.4.1. The Bracket is mounted to the rail with #10 sheet metal screws as shown in

Figures 1-2 The bracket has a U-shape design to hold a structure with a width

of 50.8mm. The structure holes (diameter 10mm) are designed for two bolts;

size M8 x 1.25 x 65mm, to fasten the brackets to a structure.

4.6.4.2. The modules have been evaluated by UL for mounting using the brackets

provided at the mounting locations in the rails.

Side ViewBack View #

#Shadow areas are schematic drawing of boned rail system.

ENN Solar Energy provides various boned rail systems upon customs’ request.

Boned rail s

y

stems

1#

2#

河北省廊坊市经济技术开发区华祥路 106 邮编:065001

No.106 Huaxiang Road, E&T Development Zone,Langfang 065001 P.R.China

4.7. Wiring

4.7.1. Warnings

4.7.1.1. If, during self assembly, parts and tools other than those stated by MC are used

or if the preparation and assembly instructions described here are disregarded

then neither safety nor compliance with the technical data can be guaranteed

4.7.1.2. For protection against electric shock, PV connectors must be isolated from the

power supply while being assembled or disassembled.

4.7.1.3. The end product must provide protection from electric shock.

4.7.1.4. The integral output connector should only be used where they will not interrupt

current. Unplugging under load: PV plug connections must not be unplugged

while under load. They can be placed in a no load state by switching off the

DC/AC converter or breaking the AC circuit interrupter. Plugging and

unplugging while under voltage is permitted.

4.7.1.5. It is unadvisable to use non-tinned cables of type H07RN-F, since with oxidized

copper wires the contact resistances of the crimp connection may exceed the

permitted limits.

4.7.1.6. Disconnected connectors should be protected from dirt and water with sealing

caps.

4.7.1.7. Plugged parts are watertight IP67. They can not be used permanently under

water. Do not lay PV connectors on the roof surface.

4.7.2. Tools

4.7.2.1. Crimping tool.

4.7.2.2. PV-MS Open-end spanner

4.7.2.3. PV-PST Test Plug

4.7.3. Connectors without cables

4.7.3.1 Connectors

Use only UL recognized connectors which include catalogue numbers PV-KST4

and PV-KBT4 followed by 2.5 or 6, followed by “I” or “II” followed by UR or

additional suffixes. See table below for acceptable cable diameters that can be use

with each connector.

河北省廊坊市经济技术开发区华祥路 106 邮编:065001

No.106 Huaxiang Road, E&T Development Zone,Langfang 065001 P.R.China

Series (TYLZ) Wire types Wire size (AWG) Number of

strands

Outer Cable

Diameter Range

PV-KST4/2.5I-UR USE or USE-2 8-12 N/A 3.0 – 6.0 mm

PV-KBT4/2.5I-UR USE or USE-2 8-12 N/A 3.0 – 6.0 mm

PV-KST4/2.5II-UR USE or USE-2 8-12 N/A 5.5 – 9.0 mm

PV-KBT4/2.5II-UR USE or USE-2 8-12 N/A 5.5 – 9.0 mm

PV-KST4/6I-UR USE or USE-2 8-12 N/A 3.0 – 6.0 mm

PV-KBT4/6I-UR USE or USE-2 8-12 N/A 3.0 – 6.0 mm

PV-KST4/6II-UR USE or USE-2 8-14 N/A 5.5 – 9.0 mm

PV-KBT4/6II-UR USE or USE-2 8-14 N/A 5.5 – 9.0 mm

Series (ZKLA) Wire types Wire size (AWG) Number of wire

strands (Range)

Outer Cable

Diameter (Range)

PV-KST4/6II-UR PV Wire 12 7 - 52 6.05 - 7.0 mm

PV-KBT4/6II-UR PV Wire 12 7 - 52 6.05 - 7.0 mm

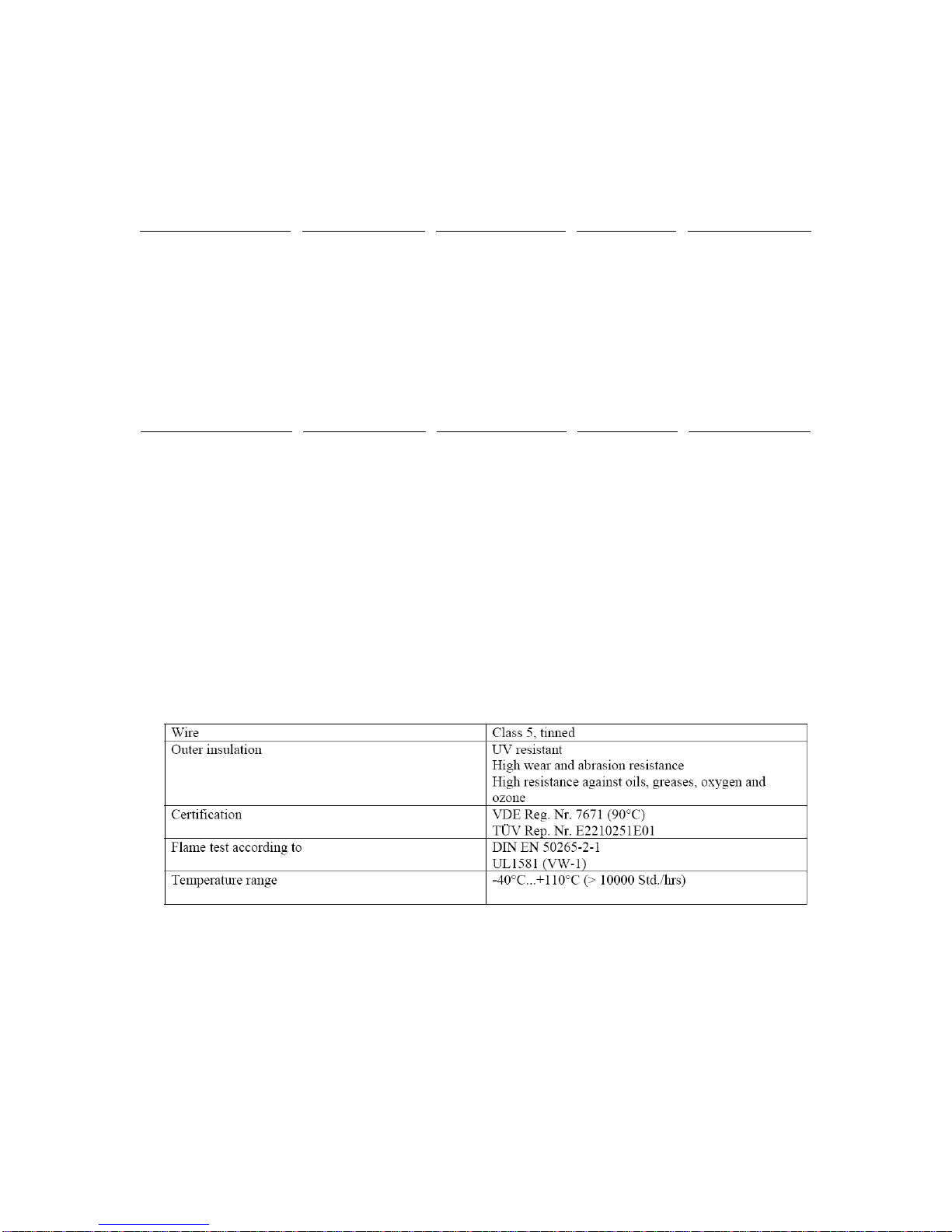

4.7.3.2 Cable Preparation (Reference: Multi-Contact MA231 Assembly Instructions).

4.7.3.2.1. Use appropriate size and type of UL recognized cable for the connector

(14, 12, or 10 AWG with a 90˚C temperature rating, marked sunlight

resistant).

4.7.3.2.2. See table below for additional information important: Cables with class

2, 5 or 6 construction can be connected. It is advantageous to use tinned

conductors. It is unadvisable to use non-tinned cables of type H07RN-F,

since with oxidized copper wires the contact resistances of the crimp

connection may exceed the permitted limits.

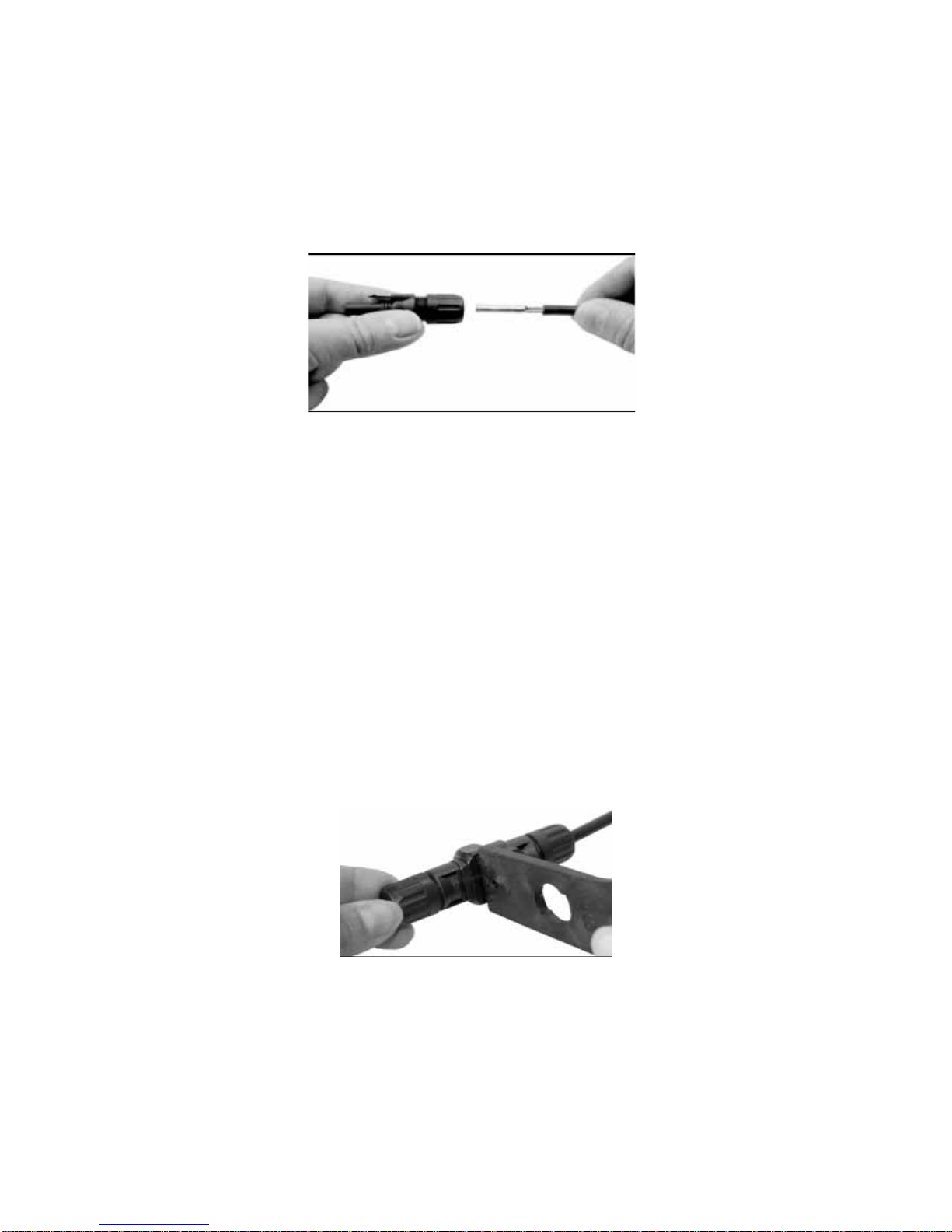

4.7.3.2.2 Strip cable insulation. L = 6-7.5 mm. Take care not to cut individual

strands. Recommended tool: Stripping pliers PV-AZM, Order No.

32.6027

4.7.3.3 Crimping

4.7.3.3.1 Crimp the contact onto the wire using the appropriate tool and procedure.

河北省廊坊市经济技术开发区华祥路 106 邮编:065001

No.106 Huaxiang Road, E&T Development Zone,Langfang 065001 P.R.China

4.7.3.3.2 Push the crimped contact into the socket receptacle/plug insulator until

it engages. Pull lightly on the lead to check that the metal part has

engaged.

Figure 5 – Contact insertion.

4.7.3.4 Assembly Control

4.7.3.4.1 Insert the test pin with the corresponding side into the socket or plug to

the end position. If the contact is correctly assembled, the white marking

on the test pin must be still visible. (Figure 4)

4.7.3.4.2 Screw on the cable gland, hand-tight, with the tools PV-MS.

4.7.3.4.3 The tightening torque must be adapted to the solar cables used in each

specific case. Typical values lie in a range between 2,5Nm to 3Nm

4.7.4. Plugging

4.7.4.1 Mount the plug connection until it engages. Check correct engagement by

pulling on the coupling.

4.7.5. Unplugging

4.7.5.1. The plug connection can only be unlocked with the tool PV-MS (Figure 5)

Figure 6 – Unplugging using PV-MS tool.

4.7.6. Array Wiring

4.7.6.1. Series

河北省廊坊市经济技术开发区华祥路 106 邮编:065001

No.106 Huaxiang Road, E&T Development Zone,Langfang 065001 P.R.China

To wire modules in series use an interconnect cable assemblies that has a female

connector on one end and a male connector on the other. The modules can be

connected together in a chain forming a series connected circuit. (See Figure 7).

The maximum current of fuse for the connected circuit can be found in the

section 7.

Figure 7 – Series connection

4.7.6.2. Parallel

To wire the modules in parallel it is necessary to connect the module leads using

a method that meets national and local electrical codes and to us UL listed

hardware

Each module (or series string of modules so connected) shall be provided with

the maximum series fuse as specified in Section 7.

河北省廊坊市经济技术开发区华祥路 106 邮编:065001

No.106 Huaxiang Road, E&T Development Zone,Langfang 065001 P.R.China

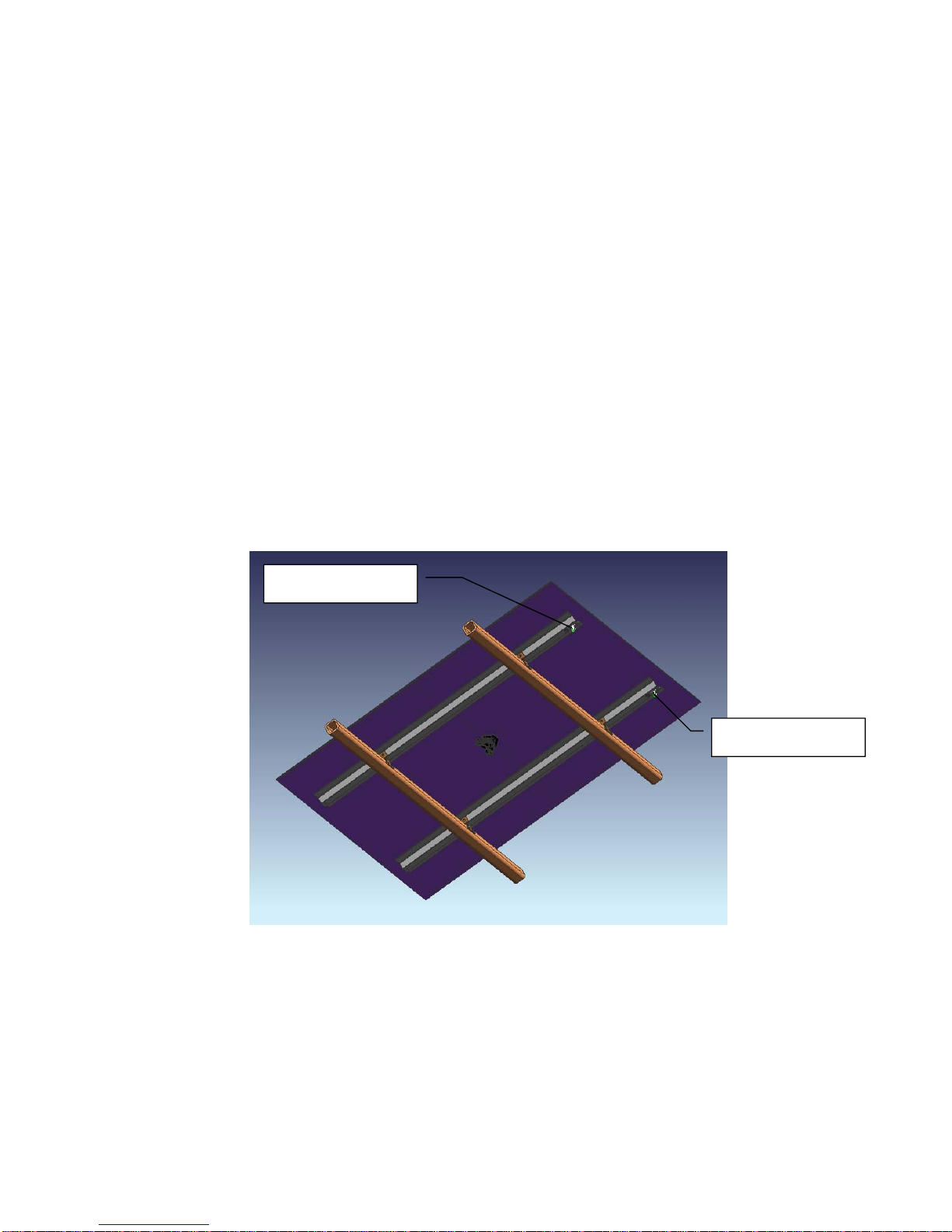

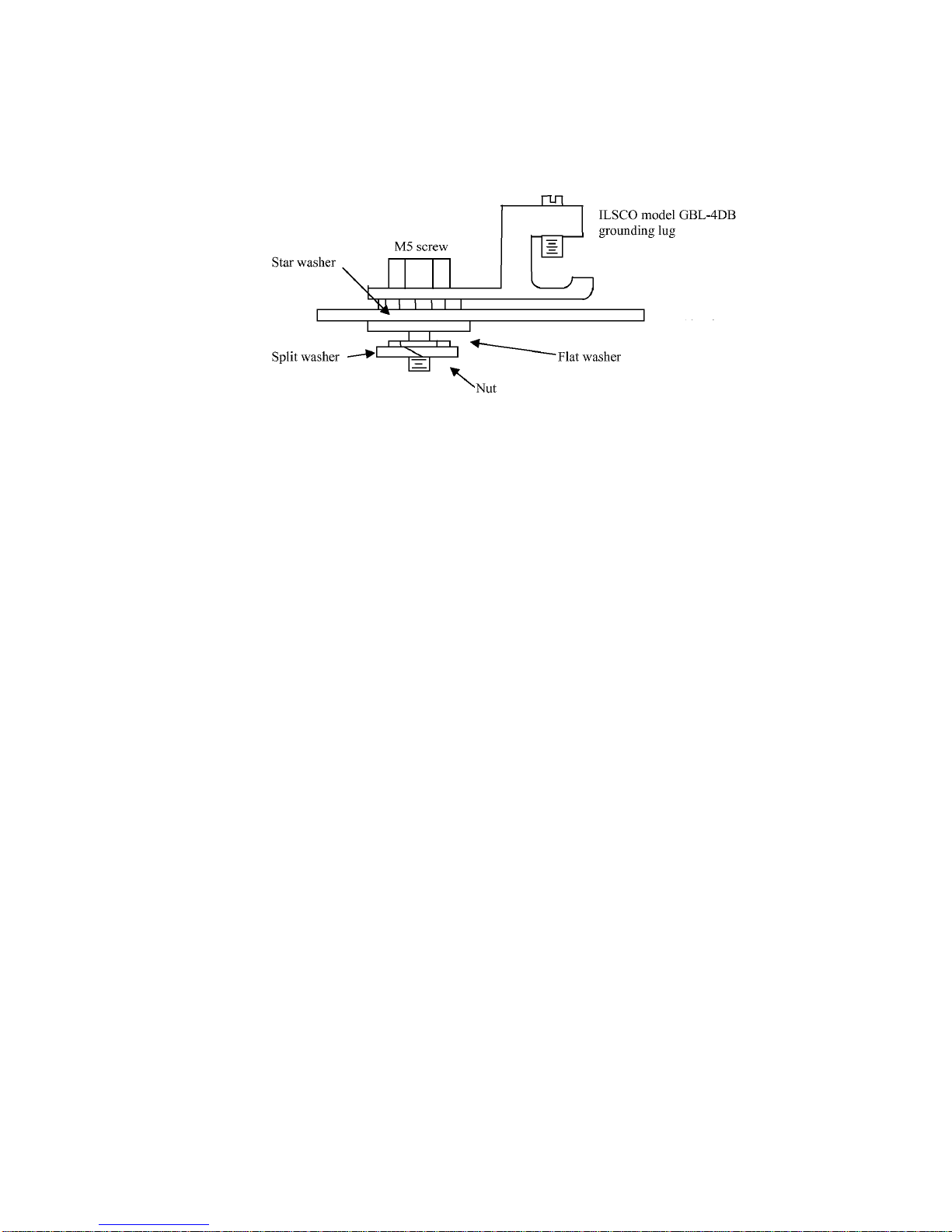

4.7.7. Grounding

Attach a ground conductor to two grounding bushing lug mounted at the designated location

shown in Figure 8 (An Ilsco GBL-4DB is shown in the Figure). Use an Ilsco GBL-4DB

(Tin Plated) , and M5 stainless steel hardware (screw, lock washer, star washer, flat washer

and nut) as shown in Figure 9. The assembly must be torque to 6.1 Nm. The copper

conductor must be attached to the ground lug using the stainless steel set screw provided by

the lug manufacturer. The electrical wiring of the ground circuit should be such that the

negative leg of the array circuit shall have the same voltage as earth ground, and when

performing a DC voltage measurement between the positive leg of array circuit and earth

ground the meter shall read a positive DC voltage, or when performing a DC voltage

measurement between the negative leg of array circuit and earth ground the meter shall read

zero volts DC voltage. Please refer to NEC Article 690 on grounding PV arrays for specific

requirements.

Figure 8 – Ground Bushing Lug Locations

Ground Bushing Lug

Ground Bushing Lug

河北省廊坊市经济技术开发区华祥路 106 邮编:065001

No.106 Huaxiang Road, E&T Development Zone,Langfang 065001 P.R.China

Figure 9 – Ground Bushing Lug Installation

5. REFERENCES

5.1. Acronyms/Definitions

PV – Photovoltaic

TF – Thin Film

5.2. Documents

Not Applicable

6. METHODS

Not Applicable

河北省廊坊市经济技术开发区华祥路 106 邮编:065001

No.106 Huaxiang Road, E&T Development Zone,Langfang 065001 P.R.China

7. ELECTRICAL RATINGS

Stabilized ratings (Displayed on label):

Model

Open

Circuit

Voltage

at STC,

(V dc)+

Rated

Voltage

at STC,

(V dc)+

Maximum

System

Voltage,

(V dc)+

Rated

Current

at STC,

(A dc)+

Short

Circuit

Current

at STC,

(A dc)+

Rated

Maximum

Power at

STC,

(Watts)+

Maximum

Series

Fuse,

(A)

EST-110

1.3 X 1.1 m 139 100

UL 600

IEC 1000 1.10 1.40 110 3

EST-115

1.3 X 1.1 m 140 103

UL 600

IEC 1000 1.12 1.41 115 3

EST-120

1.3 X 1.1 m 141 105

UL 600

IEC 1000 1.14 1.42 120 3

EST-125

1.3 X 1.1 m 142 108

UL 600

IEC 1000 1.16 1.43 125 3

EST-130

1.3 X 1.1 m 143 111

UL 600

IEC 1000 1.18 1.44 130 3

EST-135

1.3 X 1.1 m 146 113

UL 600

IEC 1000 1.20 1.46 135 3

EST-440

2.6 X 2.2 m 280 200

UL 600

IEC 1000 2.20 2.80 440 5

EST-460

2.6 X 2.2 m 282 206

UL 600

IEC 1000 2.24 2.82 460 5

EST-480

2.6 X 2.2 m 284 210

UL 600

IEC 1000 2.28 2.84 480 5

EST-500

2.6 X 2.2 m 286 216

UL 600

IEC 1000 2.32 2.86 500 5

EST-520

2.6 X 2.2 m 288 222

UL 600

IEC 1000 2.36 2.88 520 5

EST-540

2.6 X 2.2 m 292 226

UL 600

IEC 1000 2.39 2.92 540 5

Note: A. During initial 6 weeks of operation,the module has higher electrical output than the rated output . The

Pmax may be higher by 15% and the Impp may be higher by 10%.

B. The electrical ratings recorded in the Electrical Rating Label are stabilized values.

河北省廊坊市经济技术开发区华祥路 106 邮编:065001

No.106 Huaxiang Road, E&T Development Zone,Langfang 065001 P.R.China

8. ATTACHMENTS

Not Applicable

河北省廊坊市经济技术开发区华祥路 106 邮编:065001

No.106 Huaxiang Road, E&T Development Zone,Langfang 065001 P.R.China

THIS PAGE INTENTIONALLY LEFT BLANK.

This manual suits for next models

11

Table of contents

Popular Solar Panel manuals by other brands

Chicago Electric

Chicago Electric 66369 Installation and service instructions

Klein Tools

Klein Tools 29251 instruction manual

Solarbayer

Solarbayer NANOSOL 135 Product information

Renogy

Renogy 100W Solar Suitcase manual

Xantrex

Xantrex 783-0100-01 owner's guide

Autarco

Autarco TBJ Series Installation and operation manual

Wasserstein

Wasserstein Solar Panel For Blink XT and Blink XT 2 Cam user manual

Yingli Solar

Yingli Solar YL265P-29b Installation and user manual

Sygonix

Sygonix SY-VRU214-2 operating instructions

Solar Technology International

Solar Technology International PV Logic Flexi user manual

Kyocera

Kyocera KD 200-60 F brochure

Sharp

Sharp NS-F128G6 manual