Eno Scientific Well Watch 700 User manual

Eno Scientific Well Watch 700 Page 1

Eno Scientific

PO Box 1586

Hillsborough, NC 27278

USA

www.enoscientific.com

910-778-2660

Copyright Notice

Copyright © 2017 Eno Scientific, Hillsborough, NC 27278, USA.

All rights reserved.

Part number: 700-901

Eno Scientific Well Watch 700 Page 2

WELL WATCH 700

USER MANUAL

TABLE OF CONTENTS

PRODUCT OVERVIEW...................................................................................4

QUICK START GUIDE....................................................................................5

CAUTIONS........................................................................................................7

BACKGROUND – HOW IT WORKS..............................................................9

INSTALLATION.............................................................................................11

SET UP.............................................................................................................14

LOGGING........................................................................................................23

USB COMMUNICATIONS............................................................................24

ANALOG OUTPUT.........................................................................................25

RS232 COMMUNICATIONS.........................................................................26

REMOTE SERIAL OPERATION OVER RS232...........................................27

INTERPRETATION OF SERIAL DATA.......................................................29

MODBUS COMMUNICATIONS...................................................................30

MAINTENANCE.............................................................................................35

FREQUENTLY ASKED QUESTIONS..........................................................36

Appendix A: UPDATE RATES......................................................................38

Appendix B: BAUD RATES..........................................................................39

SPECIFICATIONS..........................................................................................43

ADDITIONAL NOTES...................................................................................44

WARRANTY AND SERVICE........................................................................45

Eno Scientific Well Watch 700 Page 3

PRODUCT OVERVIEW

The Well Watch 700 is a simple to use self-contained acoustic ranging instrument

designed specifically to find the distance through a closed pipe (well casing or

sounding tube as small as 1/2”) from one closed end to the to the other. The Well

Watch works by sending a low frequency sound pulse into the pipe, then measuring

the time it takes for the echo to return from the opposite end, which could be a plug or

water surface. The distance is calculated using the sound speed and the time. The low

frequency sound can follow the pipe around corners and in any direction up/down or

horizontally. It can be used to measure any closed pipe, straight or crooked with a

constant diameter.

The Well Watch 700 consists of a model 710 control unit and a model 730 smart probe

which are which are interconnected by a 4 conductor cable. The 710 controller

contains the driver electronics, processor, data logger, display, and keypad, while the

smart probe contains a second processor, drive electronics, speaker, a microphone

and a threaded spout to connect to the test pipe.

When the unit powers, it immediately begins sending sound pulses into the well and

attempts to characterize the well. After a few seconds, the depth is calculated and

output for the user. Data can be output in a variety of formats through the several

outputs provided. The controller requires 12-36 vdc external power. The probe is

powered by the controller through the 4 conductor interconnect cable.

Eno Scientific Well Watch 700 Page 4

QUICK START GUIDE

The Well Watch is nearly ready to go right out of the box. Follow the few steps below to

find the depth to water. If depth to the water is all you are interested in, then this is all

you need to read. To learn about the more advanced features continue reading the

operation section of this manual.

1.

Mount Probe to Well. Connect the threaded end of the probe to a well

access port. A reducing bushing down to as little as 1/2” can be used if

necessary, however it is better to use as big as possible up to 2”. The probe

is heavy and may require additional support if connected to the well with a

small or flexible tube. The well casing must be closed for the Well Watch to

perform correctly. (See Setup in the manual if this is an issue.)

2.

Mount Controller. Mount the controller in a protected area. It is not weather

proof. It can be mounted using the screw flange or to a DIN rail.

3.

Connect the Controller to the Probe. It is recommended that 1/2” flexible

liquid tight conduit be used between the probe and controller area to prevent

damage and moisture intrusion. However, a moisture tight strain relief may

also be used. Connect the four conductor cable between the probe and 4

probe terminals on the controller matching pin for pin.

4.

Connect Power to the controller. Connect the power source to the Ext Pwr

terminal and adjacent GND terminal. The unit requires 12 to 36 VDC at a

peak load of 150 ma.

5.

Turn meter on. Apply power to turn the meter on. You should see the

display show the product name and hear a popping sound coming from the

probe.

6.

Measure well. After the unit characterizes the well, the measured depth will

Eno Scientific Well Watch 700 Page 5

be displayed on the screen. If the measured distance is not as expected,

then proceed to the next step to change the initial settings.

7.

Change initial settings. Press the SET button once to enter the settings

mode. Press the UP or DOWN button to scroll through the available settings.

To change a setting, press ENTER to start the number flashing, press the UP

or DOWN button to change as desired, then press ENTER to enter the new

setting and stop the flashing. Press the UP or DOWN button to continue to

scroll through the other available settings. Press DISP at any time to return to

read the measured depth. For best depth results, the Range Min, Range

Max, and the Well Temperature should all be set.

8. Read

other information. While reading the depth display, press the UP or DOWN

buttons to read other information.

We encourage you to read the frequently asked questions section. They really are

frequently asked. Also, visit our website www.enoscientific.com for the latest manual

and installation tips.

Eno Scientific Well Watch 700 Page 6

CAUTIONS

The Well Watch 710 Controller is not water proof!

The controller is designed to be housed in a weather proof shelter. A gasketed

enclosure or well shelter are desired.

Sudden application of well pressure may damage the probe!

The 730 Probe was designed to be used on wells under pressure up to 100 psi.

However, when first connecting the probe to pressure, allow pressure to build slowly (1

psi/second) would be desirable.

External power cannot exceed 36 volts DC!

When supplying external power to the Well Watch, care must be taken to insure that

voltage spikes or induced transients are not conducted into the unit. Over voltage and

surge protectors and proper grounding should be used if this is a possibility.

Use surge suppressors and grounding on signal lines!

When connecting the Well Watch to remote equipment through the RS232 port or

analog outputs, care is required to prevent ground loops, lightning induced transients

etc from reaching the Well Watch. Over voltage and surge protectors and proper

grounding should be used if this is a possibility.

FCC Warning Statement.

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS

SUBJECT TO THE FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY NOT

CAUSE HARMFUL INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANY

INTERFERENCE RECEIVED, INCLUDING INTERFERENCE THAT MAY CAUSE

UNDESIRED OPERATION.

NOTE: THE GRANTEE IS NOT RESPONSIBLE FOR ANY CHANGES OR

MODIFICATIONS NOT EXPRESSLY APPROVED BY THE PARTY RESPONSIBLE

FOR COMPLIANCE. SUCH MODIFICATIONS COULD VOID THE USER’S

AUTHORITY TO OPERATE THE EQUIPMENT.

Eno Scientific Well Watch 700 Page 7

Industry Canada.

This device complies with Industry Canada license-exempt RSS standard(s). Operation

is subject to the following two conditions: (1) this device may not cause interference,

and (2) this device must accept any interference, including interference that may cause

undesired operation of the device.

Le pre !sent appareil est conforme aux CNR d'Industrie Canada applicables aux

appareils radio exempts de licence. L'exploitation est autorise !e aux deux conditions

suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de

l'appareil doit accepter tout brouillage radioe !lectrique subi, me "me si le brouillage est

susceptible d'en compromettre le fonctionnement.

Under Industry Canada regulations, this radio transmitter may only operate using an

antenna of a type and maximum (or lesser) gain approved for the transmitter by

Industry Canada. To reduce potential radio interference to other users, the antenna

type and its gain should be so chosen that the equivalent isotropically radiated power

(e.i.r.p.) is not more than that necessary for successful communication.

Conforme !ment a # la re !glementation d'Industrie Canada, le pre !sent e !metteur radio

peut fonctionner avec une antenne d'un type et d'un gain maximal (ou infe !rieur)

approuve ! pour l'e !metteur par Industrie Canada. Dans le but de re !duire les risques

de brouillage radioe !lectrique a # l'intention des autres utilisateurs, il faut choisir le type

d'antenne et son gain de sorte que la puissance isotrope rayonne !e quivalente (p.i.r.e.)

ne de !passepas l'intensite ! ne !cessaire a # l'e !tablissement d'une communication

satisfaisante.

Eno Scientific Well Watch 700 Page 8

BACKGROUND – HOW IT WORKS

The Well Watch 700 works by pushing an air pressure wave or low frequency sound

wave into the well. For this reason, it is important that the probe be connected to a

closed end of the pipe to prevent the air pressure from just escaping the open end.

After the Well Watch sends its sound pulse, it listens for the pulse to return. Since

sound travels at a predictable rate, the Well Watch can calculate where in the well the

pulse was reflected by timing the returning pulse.

The pressure wave generated by the probe will continue to travel into the well until

something disturbs it. Every imperfection in the well will disturb the wave, and every

time it is disturbed, some of the wave changes direction and is reflected back to the

Well Watch leaving the main wave a little weaker. A complete obstruction like the

surface of the water, reflects the entire remaining wave. Most common obstructions like

wires and tubes and pipe couplings do not reflect enough of the wave to cause a

Eno Scientific Well Watch 700 Page 9

problem, provided that the remaining part of the main wave is relatively big enough to

be obviously the one of interest.

Some imperfections like a change in casing diameter can cause a significant part of the

wave to be reflected. Where the water may be very far away and its reflected pulse

very weak, the reflection from the imperfection could be the largest wave returning to

the Well Watch. In this case, the Well Watch would lock in on the erroneous reflection

and tell you that the water was at the end of the casing. The Well Watch therefore

offers settings to limit the range in which it will look for reflections. If for example the

casing in your well ended at 40 feet and the water was around 80 feet, then the

minimum range could be set to 60 feet so that the Well Watch would ignore any

reflection from the casing.

The sound wave traveling through the well also loses energy as it travels, more as the

surface of the well casing gets rough or porous. To compensate for this, the Well

Watch increases its gain with time to listen for fainter signals. This can cause problems

if the Well Watch listens for too long. The gain will get so high that the pump noise or

even noise from outside the well will outweigh the desired pulse. Therefore, the

maximum range setting is available to tell the Well Watch how long to listen. If for

example the pump is mounted at 200 feet, then there is no reason to set any more than

250 ft as a maximum range.

The strength of the sound pulse generated by the probe depends on how much space

it needs to fill. A 12” pipe is 4 times larger than a 6” pipe in volume and therefore the

pulse will be 4 times smaller. A weaker pulse becomes more susceptible to pump noise

and loss with depth. While the Well Watch is being used in wells up to 30”, many of

these installations do not get reliable results with running pumps etc. These wells

usually require a sounding tube installed in the well which reaches into the water and

provides a tight connection to the probe at the top. A 3/4” or 1” tube is adequate.

Something to keep in mind, especially for shallow wells, is that the sound wave

bounces off the top and bottom of the well. So it is possible for the pulse to bounce

back and forth many times. In a well where the water level is at 6 feet, the Well Watch

would hear a reflection at 6 feet, then again at 12 feet, then 18 etc, until the pulse gets

weak enough to ignore. In this example, you would be able to see the multiple

reflections by increasing the min range. When set to 9ft, the depth would read 12.

When set to 14ft, it would read 18 etc. In this case, it may be helpful to leave a small

leak at the probe to help dissipate the pulse.

Eno Scientific Well Watch 700 Page 10

INSTALLATION

1.

Mount Probe to Well. Connect the threaded end of the probe to a well

access port. A reducing bushing down to as little as 1/2” can be used if

necessary, however it is better to use as big as possible up to 2”. The well

watch pushes air pressure waves

into the well. It is therefore

important that the connection to

the well and top of the well be

closed to air to prevent the air

pressure from escaping and for the

Well Watch to perform correctly. It

is best to install the probe mostly

vertical with the wire connection

toward the lower side to prevent

any water leakage past a poor

seal. Also keep in mind that the

probe is heavy and may require

additional support if connected to

the well with a small or flexible

tube.

2.

Mount Controller. Mount the

controller in a protected area.

It is not weather proof and will

suffer damage if exposed to

the elements. It can be

mounted in any orientation

using the screw flange or to a

DIN rail where access to the

keypad and visibility of the

display can be achieved.

Eno Scientific Well Watch 700 Page 11

3.

Connect the Controller to the Probe. Four wires are required to connect

the probe to the controller. Any gauge wire from #18 to #28 can be used. A 4

conductor direct bury cable is usually adequate, or if conduit is used ethernet

wire is sufficient. 1/2” flexible liquid tight conduit is recommended between

the probe and controller area to prevent damage and moisture intrusion.

However, a moisture tight strain relief with the direct bury cable may also be

used. Connect the four conductor cable between the probe and 4 probe

terminals on the controller matching pin for pin.

4.

Connect Power to the controller. Connect the power source to the Ext Pwr

terminal and adjacent GND terminal. The unit requires 12 to 36 VDC at a

peak load of 150 ma. GND on the controller refers to the signal ground and

power supply negative, not earth ground.

5.

Connect Outputs from the controller. The controller offers several options

for data and control outputs.

There are two independently programmable relay outputs which have a UL

rating for 30 VDC, 2 A (resistive), or 110 VDC, 0.3 A (resistive) , or 125 VAC,

0.5 A (resistive). These outputs can be used for a remote alarm or control

signal to a pump controller. The outputs are not sufficient to run a pump or

possibly a contactor directly.

Eno Scientific Well Watch 700 Page 12

There are 3 available serial output options of which one can be software

selected at a time. RS232, RS485 Modbus, and SDI-12.

RS232 – 3 wires are required to connect the RS232 port to another device

such as a PC with a 9 pin D connector. The TX terminal on the well watch

connects to pin 2 of the D connector, RX to pin 3, and GND to pin 5.

RS485 - 3 wires are required to connect the RS485 port to a Modbus bus.

The A line, the B line, and the shield to the GND terminal.

SDI-12 - 2 wires are required to connect the SDI-12 port to an SDI-12 bus,

the SDI-12 line, and the shield to the GND terminal.

There are 2 analog outputs, 0-5V and 4-20mA. These outputs are available

concurrently and are independently programmable. The 0-5V output can

source up to 15mA and requires and requires one wire for the output as well

as a ground wire or common ground with the destination device.

The 4-20mA output acts as a throttle valve for an applied voltage and is

isolated so that the device power can be used to power the current loop. In

this case a jumper from the ext pwr terminal to 4-20mA+ will power the loop,

and 4-20mA- will act as a source for output current to the target device. This

also requires either a ground wire or common ground with the target device.

Eno Scientific Well Watch 700 Page 13

Last is the input for a pulsed flow meter. This input requires a signal wire and

a ground wire. The input is designed to accept an input from a flow meter

that provides either a switch closure or a TTL level pulse.

6.

Turn meter on. Apply power to turn the meter on. You should see the

display show the product name and hear a popping sound coming from the

probe. The Well Watch is now ready to run.

SET UP

POWER ON: Apply power to start the Well Watch. The probe will pulsate and the

LCD screen will display a product information screen for a few seconds then go to the

default DISPLAY mode screen. The depth is displayed on the top line once the unit

adjusts to the well and calculates a stable reading. While the unit adjusts to the well the

display will read “DEPTH SEARCHING.”

Eno Scientific Well Watch 700 Page 14

Note: If error conditions exist, line two of the display will be replaced by an alternating

error message. See the ERROR CODES section for details.

The Well Watch has two different operating modes, DISPLAY mode and SET modes.

The DISPLAY modes are accessed by pressing the DISP button, then the UP and

DOWN keys cycle through the available display options. The SET modes are accessed

by pressing the SET button, then the UP and DOWN keys cycle through the available

setting options. When a parameter is shown, pressing the ENT key causes it to flash,

during which time the UP and DOWN keys change the parameter. Press ENT again or

BACK to stop the flashing and return to scrolling through the setting options.

*The DISP key will always return the display to the first display option and the SET key

will always return to the first setting option.

**If left on a set screen, the system will return to the first display screen automatically

after 30 seconds of inactivity.

DISPLAY MODES: There are several DISPLAY options as follow:

1 – DEFAULT display screen which shows current water level with the

time/date on the second line. Once the signal is locked and stable, the depth is

displayed in the units selected. Occasionally a spurious depth reading will be

calculated due to random noise in the well. Software in the Well Watch identifies the

anomaly and holds the last good data through a few bad data points while a good

depth is obtained. An asterisk is displayed before the depth while holding. If a stable

depth is not found in several tries, the depth is replaced with “searching” until one can

be found. If there are any error conditions, such as when the probe is not on the well,

or when the external power supply is low, an error message will alternately be

displayed on the second line.

2 – Flow Meter display screen if the flow meter is enabled, shows the current

flow rate with the totalized flow on the second line. Pressing ENT while on this screen

will reset the flow total to 0.

3 – WIW display screen which shows the total reserve of water in the well

with the rate of change on the second line. The WIW (water-in-well) is calculated using

the set well diameter and the set depth of well. These settings are only used for this

calculation. If the well depth is set to the level of the pump, the WIW number will be the

number of usable gallons (liters) of water in the well.

4 – TIME AND DATA display screen which shows the system time and date.

Pressing ENT while on this screen allows the time and date to be set. Each time ENT

Eno Scientific Well Watch 700 Page 15

is pressed, the next number will flash, showing which number is to be changed. Press

BACK or DISP any time to return to normal operation.

SET MODES: Press the SET button at any time to select the first SET option then

UP or DOWN to show the available settings. While viewing a SET screen, press the

ENT key to select the value for change and cause it to flash. While the value flashes,

press the UP or DOWN button to change the value. Rapid scrolling is activated by

holding the up or down button for about a second. Scrolling gets faster and faster while

the button is held down. The button can be released briefly then repressed to resume

change at the high speed. If the button is released, the scroll rate will be decreased at

the same rate that it increased. When the value is as desired, press the ENT or BACK

button to allow scrolling to the other settings or press the DISP button to return to

normal operation. The new settings are saved automatically as they are changed so

there is no need to press ENTER.

There are several setting options as follow:

CONTROLLER PRODUCT INFO – displays the controller product type, configuration

and the software version number. The unit serial number is displayed by pressing the

ENT button. Press ENT or BACK to return to scroll settings.

PROBE PRODUCT INFO – displays the probe product type, configuration and the

software version number. The unit serial number is displayed by pressing the ENT

button. These numbers will all be zero if the controller is not communicating with the

probe. Press ENT or BACK to return to scroll settings.

UNIT ID – sets a user selectable ID number in the range 0-255 to identify the source of

logged data. The default is 0.

PROBE ENABLE – if advance scheduling is enabled allows the user to disable the

probe and use for example, the flow meter only. The default is ENABLED.

UPDATE RATE – selects the time interval for sounding by the probe. Setting to 0

causes continuous sounding. The default is 0.

Eno Scientific Well Watch 700 Page 16

REFERENCE LEVEL – THIS IS IMPORTANT! All depth measurements by the Well

Watch will be displayed with reference to this reference level. Positive numbers are

higher than the reference level into the sky, and negative numbers are below the

reference level into the earth. The default reference level is 0, meaning that all reported

depths are from the Well Watch. It is common to set the reference level to the level of

the pump (for example -550ft), so that numbers will be positive feet (meters) above the

pump. When this number is changed all other settings and readouts will be changed

accordingly.

Eno Scientific Well Watch 700 Page 17

LEVEL MAX – sets the highest level ( with respect to the reference level) at which the

Well Watch will start looking for the surface of the water. This is used where there may

be a known defect in the well such as a step down in bore diameter. This kind of defect

will reflect some of the pulse which could compete with the desired reflection from the

water surface. If for example this transition occurred at 42 feet, then set the range min

to 50 feet or more to ignore this erroneous reflection.

LEVEL MIN– sets the lowest level (with respect to the reference level) at which the

Well Watch will continue to look for the surface of the water. A shorter range means

more frequent pulses and faster updates. A longer range gives less frequent updates

and increases the possibility of collection spurious noise. This should be set just

beyond the lowest level expected.

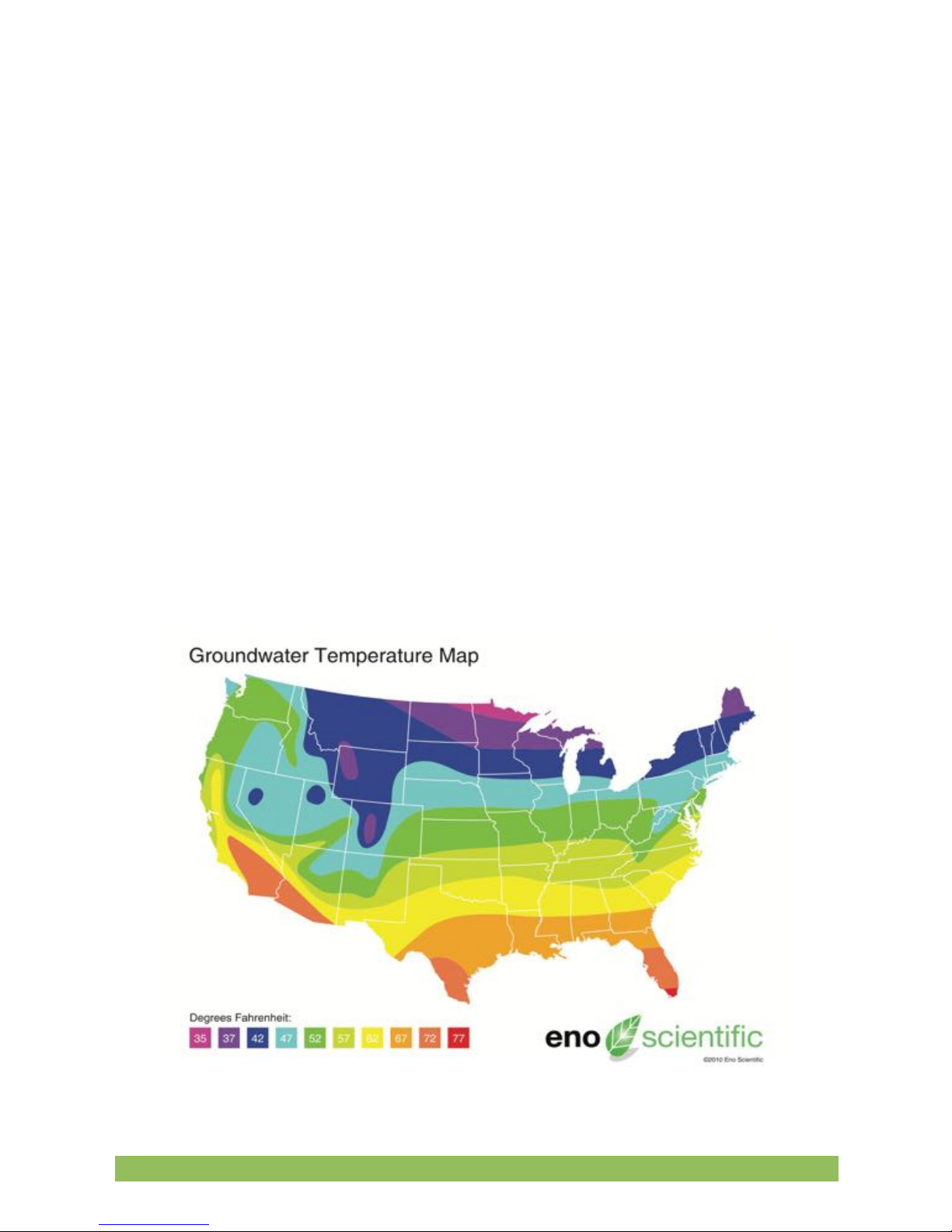

WELL TEMP – sets the average air temperature in the well. If you do not know the well

temperature, reference the Water Temperature chart below. It is also usually very close

to the water temperature. This temperature is used to calculate the sound speed and in

turn, the distance. The distance error is fairly small for variations in temperature, about

1% (1 ft per 100 ft) for a 10 ºF (5.6 ºC) temperature error.

Eno Scientific Well Watch 700 Page 18

METHANE – sets the concentration of methane mixed with the air in the well. Sound

travels through methane much faster than through air. The concentration set here is

used to calculate the sound speed and correct for this error. The Well Watch does not

measure methane but can be used to estimate the concentration if a reference

measurement is taken using another method like a tape, then changing the methane

so that the two methods match.

SOUND TUBE – sets the diameter of a tube used to carry the sound pulse to the

water. Small diameter (less than 2”) tend to reduce the sound speed. At 1/2” diameter it

is approximately 2% less, which results in approximately 2' per 100'. This setting

corrects for this error.

WELL DIAMETER – sets the diameter of the well casing. This setting is used

exclusively to calculate the amount of water in the well. It does not effect the

measurement.

WELL DEPTH – sets the depth of the well. This setting is used exclusively to calculate

the amount of water in the well. It does not effect the measurement. This is usually set

to the level of the pump so that the WIW display indicates the amount of useable water

in the well.

FLOW METER – enables the flow meter functions in software if the flow meter input is

being used. Press ENT to enable the flow meter. Press enter again to set the scale

factor for the flow meter in gal/pulse (liters/pulse). Press ENT again or BACK to return

to setting scroll mode.

LOGGING – enables the logging features of the Well Watch. When logging is enabled,

The Well Watch schedules the next periodic log point to align with the system clock so

all log periods will result with a point on the hour. When the next scheduled time

arrives, a message is displayed on the error line and remains until valid data is

recorded. Logged data is stored in the SD memory card and is appended to a data file

named WSLOGxxx.txt, where xxx is the 3 digit well ID set earlier.

**LOG RATE – sets the time interval in minutes between logged data points. This

setting is available if logging is ENABLED. Every measurement is recorded if it is set to

zero.

Eno Scientific Well Watch 700 Page 19

SERIAL COMM – selects the type of serial communications to be used. Even though

there are 3 sets of serial communications terminals on the controller, only one can be

used at a time. Press ENT to select RS232, RS485 Modbus, SDI-12 or none.

RS232 DATA – enables the transmission of current data over the RS232 connection.

This feature is used when the Well Watch is used with a remote readout or data

transmission system such as SCADA or a PC. Press the ENT to change the setting,

then UP or DOWN button to select: Off, Continuous, Depth only. When set to

Continuous, a data line for every measurement is sent over the serial port

automatically. Transmitted data includes all measured data, as well as the error code.

When Depth Only is selected, only the depth is included in the data. Select Off to

disable automatic data transmission, but retain the ability to program the unit remotely

or request data. (See the section on serial communication for details)

RS232 UPDATE – if advanced scheduling is enabled allows reporting of serial data to

be scheduled independently of the system update time.

RS232 SETUP – if RS232 is selected, sets the serial port parameters. The default is

19,200 baud, 8 data bits, 1 stop bit, and no parity. Press ENT to cycle through the

various parameters. Then ENT again or BACK to return to settings scroll mode.

RS485 MODBUS DATA – if RS485 is selected, sets MODBUS parameters for

transmission of data over the RS485 connection. Two modes are available: RTU

(default) or ASCII.

RS485 SETUP – if RS485 is selected, sets the serial port parameters for RS485

communications. The default is 9,600 baud, 8 data bits, 1 stop bit, and no parity. Press

ENT to cycle through the various parameters. Then ENT again or BACK to return to

settings scroll mode.

MODBUS ADDRESS – if RS485 is selected, sets the MODBUS address. This is the

address which will identify the Well Watch on the Modbus bus, which can be any

unused address on the bus from 1 to 247.

ANALOG DEPTH @0V – sets the range for both the 0-5V and the 4-20mA analog

outputs. This setting sets the depth with respect to the reference level at which the

outputs will be 0V and 4mA.

Eno Scientific Well Watch 700 Page 20

This manual suits for next models

2

Table of contents

Other Eno Scientific Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Powerfix Profi

Powerfix Profi 278296 Operation and safety notes

Test Equipment Depot

Test Equipment Depot GVT-427B user manual

Fieldpiece

Fieldpiece ACH Operator's manual

FLYSURFER

FLYSURFER VIRON3 user manual

GMW

GMW TG uni 1 operating manual

Downeaster

Downeaster Wind & Weather Medallion Series instruction manual

Hanna Instruments

Hanna Instruments HI96725C instruction manual

Nokeval

Nokeval KMR260 quick guide

HOKUYO AUTOMATIC

HOKUYO AUTOMATIC UBG-05LN instruction manual

Fluke

Fluke 96000 Series Operator's manual

Test Products International

Test Products International SP565 user manual

General Sleep

General Sleep Zmachine Insight+ DT-200 Service manual