Eno Scientific 128-2025 User manual

FLOW METER

USER MANUAL

www.enoscientific.com

STATIC WATER LEVEL MEASUREMENT

Eno Scientific

1606 Faucette Mill Rd

Hills orough, NC 27278

USA

www.enoscientific.com

919-778-2660

Copyright Notice

Copyright © 2010 Eno Scientific, Hills orough, NC 27278, USA.

All rights reserved.

Part num er: 128-2025

FLOW METER

USER MANUAL

TABLE OF CONTENTS

PRODUCT OVERVIEW.................................................................................................. 4

FLOW SENSOR OPERATING RANGE..........................................................................5

FLOW SENSOR INSTALLATION: MECHANICAL.......................................................... 6

FLOW SENSOR INSTALLATION: ELECTRICAL........................................................... 7

USING FLOW METER WITH THE WELL SOUNDER....................................................8

USING FLOW METER WITH OTHER EQUIPMENT..................................................... 9

SPECIFICATIONS........................................................................................................ 10

WARRANTY AND SERVICE........................................................................................ 11

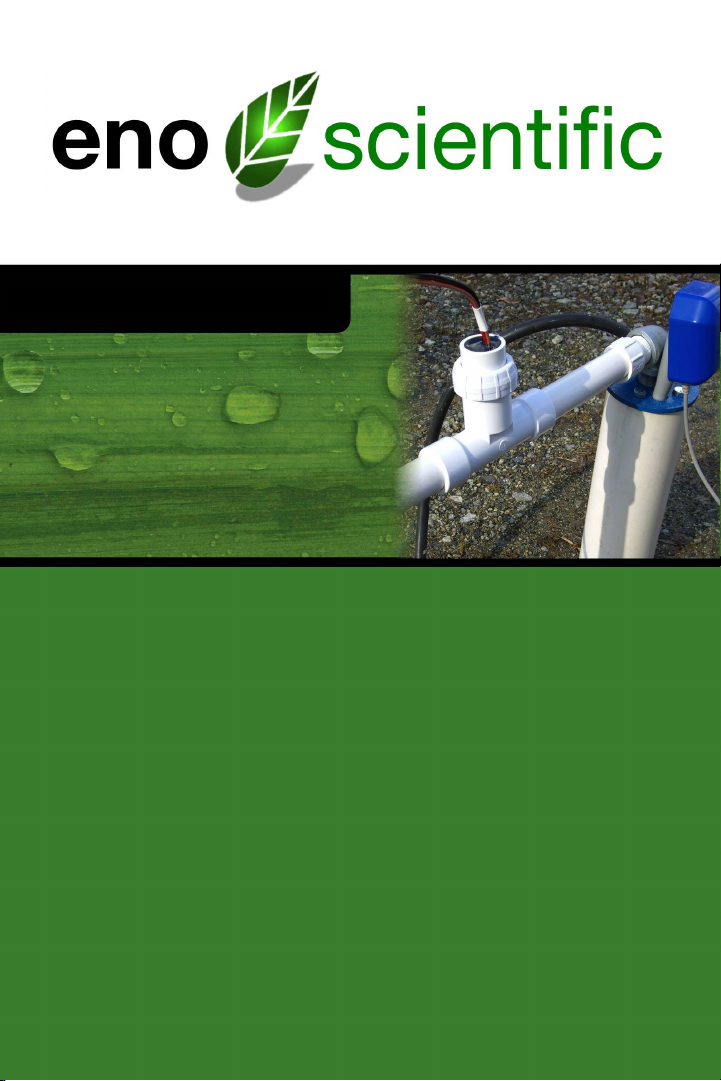

PRODUCT OVERVIEW

The Eno Scientific paddle wheel flow meters measure water flow y converting the

rotation of the internal paddle wheel into a num er of electrical pulses proportional to

the amount of water passing through. The flow meter is a modular unit resem ling a

pipe tee with PVC slip type pipe connections on the run and a socket on the ranch to

mount the sensor unit. The housings are made of PVC with sockets for schedule 40

PVC pipe connections in a variety of sizes. The sensor unit contains the paddle wheel

and electronics, and easily mounts to any of the housing sizes with a simple hand-

tightened ring nut. The PVC housings are designed to permanently install at the test

site to provide a socket for the flow sensor. The sensor can e connected while testing

is under way, then can then e removed and replaced with a cap for future testing.

The output from the sensor unit can e plugged into an Eno Scientific Well Sounder for

data collection and readout. It is designed to use very little power to conserve attery

life.

Additional housings, caps and other accessories are availa le from your local

distri utor or on our we site at www.enoscientific.com.

Eno Scientific Well Sounder 2010 / 2010 PRO Page 4

FLOW SENSOR OPERATING RANGE

Eno Scientific flow sensors use a rotating impeller to sense the water moving through a

closed pipe. As the water moves, it drags the paddles with it, producing a digital pulse

as each paddle passes the sensor. Note that the pipe must e full for the impeller to

accurately reflect flow. The ta le elow shows the flow rate range for each sensor size.

The pressure drop through the sensor at maximum flow rates are included for

reference.

Eno Scientific Well Sounder 2010 / 2010 PRO Page 5

Water flowing too slow or too fast will not e measured accurately. Eno Scientific flow

sensors measure flow over a range from 0.25 fps to 15 fps. It is important that the flow

size e selected ased on the flow rate to e measured and not the pipe size.The most

common mistake in selecting a flow sensor is to oversize the unit and not e a le to

measure low flow. The flow sensor will operate at significantly higher velocities than

commonly used for sizing pipe. Note: a 2” flow sensor has an operating range high

enough for use with 3 or 4 inch diameter pipelines running at lower velocities. If the

system flow rate falls elow the minimum shown in these ta les, use a smaller

diameter flow sensor installed in a “meter run”- a section of pipe containing 10

diameters of straight pipe ahead of the sensor and 5 diameters of straight pipe after the

sensor, as shown elow.

FLOW SENSOR INSTALLATION: MECHANICAL

Always install a flow sensor in a straight section of pipe where there is a minimum of 10

diameters upstream (ahead) and a minimum of 5 diameters downstream ( ehind) of

the flow sensor. Pipe ends, other fittings, valves, pipe enlargements or reductions or

anything else that would cause a flow distur ance should not e present in this length

of pipe.

The flow meter may e installed in any orientation, horizontal or vertical. It is important,

however, that the pipe e full of water without u les or de ris. With this in mind, in a

vertical pipe, upflow is prefera le to downflow. Orient the sensor so that it is easily

removea le for service or replacement with a cap.

If the flow sensor is installed elow grade, provide access to the sensor y installing a

valve ox or meter pit over it. In underground installations, sensor tees are usually

installed with the insert located in the 12:00 o’clock or straight up position to make

removal easier. Be sure to leave an adequate loop of wire to allow the sensor insert to

e removed for service while still remaining attached.

Eno Scientific Well Sounder 2010 / 2010 PRO Page 6

The PVC pipe sockets are intended to e solvent welded to the PVC pipe using

standard solvent welding techniques. Threaded connectors or unions may e welded to

the tee for a remova le installation. Disassem le the flow sensor efore joining the tee

to the piping system. Remove the flow sensor from the housing y loosening the

retaining nut y turning it counter-clockwise then pulling the sensor housing straight

out. Caution: do not pull b the wires!

After installation of the tee, make sure the pipe is clean and free of any de ris. Then re-

install the sensor into the tee. Align the ridge on the sensor housing with the groove in

the sensor socket, then carefully slide the sensor all the way into the socket. Slide the

retaining nut over the sensor housing and hand tighten. Do not use a sealant or teflon

tape on the threads.

FLOW SENSOR INSTALLATION: ELECTRICAL

The flow sensor comes in two configurations:

1 – with a plugged ca le for simple attachment to other Eno Scientific devices such as

the Well Sounder. Installation is simple. Plug the ca le into the compati le connector

on the Well Sounder. Where the connector is occupied y another device such as the

pro e, a splitter is availa le to provide sockets for oth devices. An extension ca le is

availa le if the flowmeter is to e mounted more than 6 feet from the Well Sounder

connection point.

2 – with 3 separate wire leeds for connection to a well sounder or other devices. The

three leeds must e connected as follow:

Black - signal and power ground

Red - power 5 – 12 VDC

Brown - signal

Caution: improper connection ma damage or destro the sensor.

Attachment to a Well Sounder with this configuration requires a reakout adapter which

provides a plugged connection to the Well Sounder on one end and terminals on the

other end for the connection of the sensor leeds.

Eno Scientific Well Sounder 2010 / 2010 PRO Page 7

If the sensor is to e mounted more than 4 feet from the connection point, the leeds

can e spliced and extended using wire as small as #28 AWG up to 300 feet. On runs

of more than 20 feet, it is recommended that shielded ca le e used and that the shield

e tied to a good earth ground. Otherwise lightning induced transients may damage the

sensor or other equipment.

USING FLOW METER WITH THE WELL SOUNDER

Once the flow meter is attached to the Well Sounder, ena le the flow meter y pressing

the SET utton several times until the Flow Meter ena le screen is displayed. Press

the UP utton until Ena led is displayed. The flow meter functions in the Well Sounder

are now turned on.

Press the SET utton once more to show the auto cali ration screen. To perform an

automatic cali ration, press the UP utton to start. Turn on the pump or open a valve to

pump 5 gallons into a ucket. As the ucket reaches the 5 gallon mark, press the

DOWN utton on the keypad. Cali ration is complete and has compensated for any

irregularities of the installation.

There may e situations where an auto-cali ration is not possi le. In this case, when

on the auto cali ration screen, press the ENTER utton to show the scale factor

screen. Use the UP or DOWN uttons to enter the scale factor for the installed flow

meter. When the correct scale factor shows on the display, the cali ration is complete

and the DISP utton may e pressed to resume operation mode on the Well Sounder.

Scale factors are as follow for the three housing sizes:

1” .0057

1.5” .0121

2” .0209

Once the display mode is active, press the DOWN utton to the new flow meter

information screens, Flow, Flow rate and Recov rate.

Flow - displays the total water through the flow meter in gallons or liters if in metric

mode. The total can e reset y pressing the ENTER utton while viewing on the

display.

Eno Scientific Well Sounder 2010 / 2010 PRO Page 8

Flow Rate – displays the rate at which water is flowing through the flow meter in

gallons per minute (liters/minute). The flow rate displays a running average of the flow

per time. The flow rate may appear to not e very responsive as a result. An instant

reading can e o tained y pressing the ENTER utton while viewing the flow rate.

This clears the running average and starts over.

Recov Rate – displays the instantaneous recovery rate of the well. This is the net

difference etween the change in the level of the well and the water eing pumped

from the well. This value is also filtered with a running average which can e reset y

pressing the ENTER utton as a ove.

USING FLOW METER WITH OTHER EQUIPMENT

The flow meter can e used with data loggers which can count pulses and accept a

TTL level signal or a switch to ground signal. The data can e configured as a totalizer

tracking the total water pumped or as a frequency counter tracking the instantaneous

flow rate. The cali ration constants are different.

As a flow totalizer, the scale factors convert each pulse to a volume of water in gallons

as follow:

1” .0057

1.5” .0121

2” .0209

Keep in mind that the total water volume will only e accurate if the flow rate is greater

than the minimum flow rate for the flow meter used.

As a frequency counter, the scale factors convert pulses per second to gallons per

minute and include an offset

Size K Offset

1” .322 0.20

1.5” .650 0.75

2” 1.192 0.94

The offset increases the accuracy in the operating range of the flow meter ut also will

yield a net flow when the flow rate is elow the minimum or zero. Used to calculate

total water pumped, this technique is not appropriate.

Eno Scientific Well Sounder 2010 / 2010 PRO Page 9

SPECIFICATIONS

Materials:

Housings – Type 1 PVC

Rotor – HDPE

O-ring – Buna N

Axle – Tungsten Car ide

Plumbing:

Pipe size – Schedule 40 PVC

Pressure - 240PSI

Ph sical:

Pipe size – Schedule 40 PVC

Test Pressure – 240 PSI

Temperature: 32 – 140 F (0 – 60 C)

Dimensions:

1” 5.75 x 4.5 x 2.4”

1.5” 6.25 x 5.25 x 2.4”

2” 7.11 x 5.75 x 3”

Clearance for sensor removal: 3.5”

Electrical:

Power: 5 – 24V @ 500 uA max

Output signal: Pull-to-ground (+V – 0V)

Pulse width: ~5mS

Frequency: .3 – 200 Hz

Eno Scientific Well Sounder 2010 / 2010 PRO Page 10

WARRANTY AND SERVICE

Eno Scientific warrants to the user that all products manufactured y Eno Scientific, will

e free from defects in workmanship and materials for 1 year from the date of

shipment.

Eno Scientific warrants to repair or replace any such defective equipment or part

(determined to our satisfaction to have a defect in workmanship or original material)

upon receipt and inspection of such defective equipment to Eno Scientific with all

shipping pre paid y the user.

In no event shall Eno Scientific e lia le for any direct, indirect or consequential

damages, a use, acts of third parties (rental equipment), environmental conditions or

other expenses which may arise in connection with such defective equipment. This

warranty shall not apply to damage of equipment caused y incorrect installation,

usage, lightning, storage, alteration or inadequate care.

This warranty does not apply to parts, assem lies or devices not manufactured y Eno

Scientific which are covered y other manufacturers’ warranties. There are no

warranties except as specifically provided in writing herein.

Contact Eno Scientific with any warranty or service questions.

For additional information, please visit our we site at www.enoscientific.com.

Eno Scientific Well Sounder 2010 / 2010 PRO Page 11

Eno Scientific Well Sounder 2010 / 2010 PRO Page 12

Table of contents

Other Eno Scientific Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

PCE Instruments

PCE Instruments KREBS PCE-RVI 5 manual

LEYBOLD

LEYBOLD 332 101 instruction sheet

Niigata seiki

Niigata seiki D-HL Series user manual

PCE Health and Fitness

PCE Health and Fitness PCE-CP Series user manual

Kobold

Kobold Heinrichs TSK Installation and operating instructions

Dostmann Electronic

Dostmann Electronic P300 Series Operating lnstructions